Professional Documents

Culture Documents

SRU

SRU

Uploaded by

ian84Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

SRU

SRU

Uploaded by

ian84Copyright:

Available Formats

PARTS & SERVICE INCINERATORS FLARES BURNERS

zeeco.com

COMBUSTION AND ENVIRONMENTAL SOLUTIONS.

PURE AND SIMPLE.

Zeeco Corporate Headquarters

22151 East 91st Street

Broken Arrow, Oklahoma 74014 USA

Phone: +1.918.258.8551 Fax: +1.918.251.5519

E-mail: sales@zeeco.com

FLARES BURNERS THERMAL OXIDIZERS PARTS & SERVICE

Ultra-Low NO

x

Technology

ZEECO tail gas incinerators can provide

Ultra-Low NO

x

performance via the use of Zeecos

patented Free-Jet burner technology. ZEECO Free-

Jet burner technology uses the jet momentum of

the fuel gas injection system to entrain relatively

inert tail gases in a manner that significantly

lowers core flame temperatures, resulting in

dramatically reduced thermal NO

x

production.

Independent third party tests prove Zeecos ultra-

Low NO

x

incineration technology provides as

low as 5 ppm(vd) NO

x

performance under actual

field conditions.

CFD

The chemical and hydrocarbon industries

employ Computational Fluid Dynamics (CFD)

modeling tools to aid in equipment design. Zeeco

combines CFD technology with our extensive

experience in the design, fabrication, and operation

of combustion equipment in order to ensure

optimal performance.

Trust Zeeco with Your Sulfur

Recovery Equipment

Zeeco has provided combustion and

environmental solutions around the world for

more than 30 years. Let us put our experience to

work for you. Call us today for more information

on Zeecos full line of combustion products and

replacement parts.

ZEECO pilot burners are fully tested to ensure reliable long term

operation in severe service.

ZEECO GLSF Ultra-Low NOx

Free-Jet Burner

COMBUSTION AND ENVIRONMENTAL SOLUTIONS.

PURE AND SIMPLE.

Natural draft SRU tail gas incinerator.

SULFUR RECOVERY UNIT

Combustion Equipment

COMBUSTION AND ENVIRONMENTAL SOLUTIONS.

PURE AND SIMPLE.

ZEECO CORPORATE HEADQUARTERS

ZEECO HOUSTON

ZEECO EUROPE

ZEECO INDIA

ZEECO ASIA

ZEECO JAPAN/

APPLICOT

ZEECO MIDDLE EAST

REGISTERED

ISO 9001: 2008

CERTIFIED

ASME

CERTIFIED

ASME

CERTIFIED

NBBI

CERTIFICATIONS APPLY TO ZEECO HEADQUARTERS.

ZEECO CHINA

ZEECO BRAZIL

ZEECO CANADA

ZEECO ITALY

ZEECO AUSTRALIA

2011 COPYRIGHT ZEECO, INC. ALL RIGHTS RESERVED

ZEECO office, affiliate, sales, representative, or third party representive/licensee offices.

ZEECO

is a registered trademark of Zeeco, Inc. in the U.S.

ZEECO CONNECTICUT

ZEECO RUSSIA

SULFUR RECOVERY UNIT

Combustion Equipment

Custom Designed SRU Equipment

The Sulfur Recovery Unit (SRU) is often referred to as

the Claus Process. This process recovers elemental sulfur

from petroleum and natural gas refining processes and

reduces the hazardous sulfur emissions to limits permitted

by national and local air quality requirements. Zeeco

supplies all of the combustion equipment used in the Claus

process, including high intensity style burners, reaction

furnaces, inline heaters/reducing gas generators, tail gas

incinerators, and waste heat boilers.

World-Class Engineering & Reliability

Zeeco is a world leader in the development of

combustion solutions for the refining, petrochemical,

petrochemical, chemical and power generation industries.

Our staff members have extensive experience in design,

fabrication, and operation of Sulfur Recovery Unit (SRU)

Combustion Equipment.

Zeeco has a proven track record of producing the

worlds largest and most advanced combustion equipment

for the sulfur recovery process. Our combustion

equipment is always custom engineered to meet our

clients specific needs, whatever the situation requires.

Equipment reliability is essential for profitable plant

operations. For this reason, Zeeco chooses quality

components and materials for all of our products in

order to maximize service life and eliminate unnecessary

shutdowns.

Worlds largest SRU tail gas incinerator. One of nine similar incineration

systems supplied by Zeeco.

High Capacity Low NO

x

SRU

Thermal Oxidizer Burners

Typical Claus

Sulfur Recovery

Process

SRU reaction furnace with firetube waste heat boiler.

Tail Gas Incinerators

The tail gas resulting from the upstream Claus unit contains sulfur-

bearing compounds that must be incinerated in order to oxidize

the various compounds to sulfur dioxide and sulfur trioxide. The

incineration process typically occurs between 1200-1600

O

F (650-

870

O

C) in the presence of excess oxygen with a residence time

between 0.7 and 2.0 seconds. The relatively inert tail gas must be

carefully mixed with the flue gas products to achieve satisfactory

oxidation of the sulfur-containing compounds without destabilizing the

burner flame.

Incinerator Waste Heat Recovery

Due to the large amount of heat generated by the thermal oxidizer,

many Zeeco systems incorporate waste heat recovery equipment to

further reduce operating costs by generating steam and/or heating oil

that is used for other plant operations.

High Intensity Style Burners

Zeecos high intensity style burners achieve rapid combustion in

very small volumes in a wide range of conditions. This allows the

burner to operate under reducing (oxygen-deficient) environments

without smoke, soot, or oxygen slippage that otherwise could

damage downstream catalytic reactors.

Zeeco employs proprietary spin vanes to create a vor tex

recirculation zone upstream of the burner discharge. Hot flue gas

is recirculated into the burner mixing zone to create a highly stable

flame front.

Reaction Furnaces

The reaction furnace is the most important component of the SRU,

initiating the conversion of H

2

S and other sulfur-bearing compounds

to elemental sulfur. The overall reaction furnace dimensions are often

specified by the process licensor. In the absence of licensor input, Zeeco

can design the reaction furnace to meet your desired processing needs.

Reaction Furnace Waste Heat Boilers

A firetube waste heat boiler is typically located directly downstream

of the reaction furnace. This waste heat boiler generates waste heat

steam while cooling the reaction furnace effluent. The inlet tube sheet

of the reaction furnace waste heat boiler is typically refractory lined

with ceramic ferrules located on the inlet of each tube to prevent

damage to the tube sheet and the tube sheet welds.

In-line Heaters

In-line, direct-fired heaters are usually designed to raise the temperature

of the sulfur-containing process gas to the required inlet temperature of

the catalytic reactor. Because the heater is located just upstream of the

catalytic equipment, it is essential that it produces soot-free products

without any oxygen slippage to the downstream catalytic reactor. Zeeco

installs the burner in a refractory lined combustion chamber and hot

combustion gases are mixed with the process gas to reach the reactor

inlet temperature.

PARTS & SERVICE INCINERATORS FLARES BURNERS

zeeco.com

COMBUSTION AND ENVIRONMENTAL SOLUTIONS.

PURE AND SIMPLE.

Zeeco Corporate Headquarters

22151 East 91st Street

Broken Arrow, Oklahoma 74014 USA

Phone: +1.918.258.8551 Fax: +1.918.251.5519

E-mail: sales@zeeco.com

FLARES BURNERS THERMAL OXIDIZERS PARTS & SERVICE

Ultra-Low NO

x

Technology

ZEECO tail gas incinerators can provide

Ultra-Low NO

x

performance via the use of Zeecos

patented Free-Jet burner technology. ZEECO Free-

Jet burner technology uses the jet momentum of

the fuel gas injection system to entrain relatively

inert tail gases in a manner that significantly

lowers core flame temperatures, resulting in

dramatically reduced thermal NO

x

production.

Independent third party tests prove Zeecos ultra-

Low NO

x

incineration technology provides as

low as 5 ppm(vd) NO

x

performance under actual

field conditions.

CFD

The chemical and hydrocarbon industries

employ Computational Fluid Dynamics (CFD)

modeling tools to aid in equipment design. Zeeco

combines CFD technology with our extensive

experience in the design, fabrication, and operation

of combustion equipment in order to ensure

optimal performance.

Trust Zeeco with Your Sulfur

Recovery Equipment

Zeeco has provided combustion and

environmental solutions around the world for

more than 30 years. Let us put our experience to

work for you. Call us today for more information

on Zeecos full line of combustion products and

replacement parts.

ZEECO pilot burners are fully tested to ensure reliable long term

operation in severe service.

ZEECO GLSF Ultra-Low NO

x

Free-Jet Burner

COMBUSTION AND ENVIRONMENTAL SOLUTIONS.

PURE AND SIMPLE.

Natural draft SRU tail gas incinerator.

SULFUR RECOVERY UNIT

Combustion Equipment

COMBUSTION AND ENVIRONMENTAL SOLUTIONS.

PURE AND SIMPLE.

ZEECO CORPORATE HEADQUARTERS

ZEECO HOUSTON

ZEECO EUROPE

ZEECO INDIA

ZEECO ASIA

ZEECO JAPAN/

APPLICOT

ZEECO MIDDLE EAST

REGISTERED

ISO 9001: 2008

CERTIFIED

ASME

CERTIFIED

ASME

CERTIFIED

NBBI

CERTIFICATIONS APPLY TO ZEECO HEADQUARTERS.

ZEECO CHINA

ZEECO BRAZIL

ZEECO CANADA

ZEECO ITALY

ZEECO AUSTRALIA

2011 COPYRIGHT ZEECO, INC. ALL RIGHTS RESERVED

ZEECO office, affiliate, sales, representative, or third party representive/licensee offices.

ZEECO

is a registered trademark of Zeeco, Inc. in the U.S.

ZEECO CONNECTICUT

ZEECO RUSSIA

SULFUR RECOVERY UNIT

Combustion Equipment

Custom Designed SRU Equipment

The Sulfur Recovery Unit (SRU) is often referred to as

the Claus Process. This process recovers elemental sulfur

from petroleum and natural gas refining processes and

reduces the hazardous sulfur emissions to limits permitted

by national and local air quality requirements. Zeeco

supplies all of the combustion equipment used in the Claus

process, including high intensity style burners, reaction

furnaces, inline heaters/reducing gas generators, tail gas

incinerators, and waste heat boilers.

World-Class Engineering & Reliability

Zeeco is a world leader in the development of

combustion solutions for the refining, petrochemical,

petrochemical, chemical and power generation industries.

Our staff members have extensive experience in design,

fabrication, and operation of Sulfur Recovery Unit (SRU)

Combustion Equipment.

Zeeco has a proven track record of producing the

worlds largest and most advanced combustion equipment

for the sulfur recovery process. Our combustion

equipment is always custom engineered to meet our

clients specific needs, whatever the situation requires.

Equipment reliability is essential for profitable plant

operations. For this reason, Zeeco chooses quality

components and materials for all of our products in

order to maximize service life and eliminate unnecessary

shutdowns.

Worlds largest SRU tail gas incinerator. One of nine similar incineration

systems supplied by Zeeco.

High Capacity Low NOx SRU

Thermal Oxidizer Burners

Typical Claus

Sulfur Recovery

Process

SRU reaction furnace with firetube waste heat boiler.

Tail Gas Incinerators

The tail gas resulting from the upstream Claus unit contains sulfur-

bearing compounds that must be incinerated in order to oxidize

the various compounds to sulfur dioxide and sulfur trioxide. The

incineration process typically occurs between 1200-1600

O

F (650-

870

O

C) in the presence of excess oxygen with a residence time

between 0.7 and 2.0 seconds. The relatively inert tail gas must be

carefully mixed with the flue gas products to achieve satisfactory

oxidation of the sulfur-containing compounds without destabilizing the

burner flame.

Incinerator Waste Heat Recovery

Due to the large amount of heat generated by the thermal oxidizer,

many Zeeco systems incorporate waste heat recovery equipment to

further reduce operating costs by generating steam and/or heating oil

that is used for other plant operations.

High Intensity Style Burners

Zeecos high intensity style burners achieve rapid combustion in

very small volumes in a wide range of conditions. This allows the

burner to operate under reducing (oxygen-deficient) environments

without smoke, soot, or oxygen slippage that otherwise could

damage downstream catalytic reactors.

Zeeco employs proprietary spin vanes to create a vor tex

recirculation zone upstream of the burner discharge. Hot flue gas

is recirculated into the burner mixing zone to create a highly stable

flame front.

Reaction Furnaces

The reaction furnace is the most important component of the SRU,

initiating the conversion of H

2

S and other sulfur-bearing compounds

to elemental sulfur. The overall reaction furnace dimensions are often

specified by the process licensor. In the absence of licensor input, Zeeco

can design the reaction furnace to meet your desired processing needs.

Reaction Furnace Waste Heat Boilers

A firetube waste heat boiler is typically located directly downstream

of the reaction furnace. This waste heat boiler generates waste heat

steam while cooling the reaction furnace effluent. The inlet tube sheet

of the reaction furnace waste heat boiler is typically refractory lined

with ceramic ferrules located on the inlet of each tube to prevent

damage to the tube sheet and the tube sheet welds.

In-line Heaters

In-line, direct-fired heaters are usually designed to raise the temperature

of the sulfur-containing process gas to the required inlet temperature of

the catalytic reactor. Because the heater is located just upstream of the

catalytic equipment, it is essential that it produces soot-free products

without any oxygen slippage to the downstream catalytic reactor. Zeeco

installs the burner in a refractory lined combustion chamber and hot

combustion gases are mixed with the process gas to reach the reactor

inlet temperature.

PARTS & SERVICE INCINERATORS FLARES BURNERS

zeeco.com

COMBUSTION AND ENVIRONMENTAL SOLUTIONS.

PURE AND SIMPLE.

Zeeco Corporate Headquarters

22151 East 91st Street

Broken Arrow, Oklahoma 74014 USA

Phone: +1.918.258.8551 Fax: +1.918.251.5519

E-mail: sales@zeeco.com

FLARES BURNERS THERMAL OXIDIZERS PARTS & SERVICE

Ultra-Low NO

x

Technology

ZEECO tail gas incinerators can provide

Ultra-Low NO

x

performance via the use of Zeecos

patented Free-Jet burner technology. ZEECO Free-

Jet burner technology uses the jet momentum of

the fuel gas injection system to entrain relatively

inert tail gases in a manner that significantly

lowers core flame temperatures, resulting in

dramatically reduced thermal NO

x

production.

Independent third party tests prove Zeecos ultra-

Low NO

x

incineration technology provides as

low as 5 ppm(vd) NO

x

performance under actual

field conditions.

CFD

The chemical and hydrocarbon industries

employ Computational Fluid Dynamics (CFD)

modeling tools to aid in equipment design. Zeeco

combines CFD technology with our extensive

experience in the design, fabrication, and operation

of combustion equipment in order to ensure

optimal performance.

Trust Zeeco with Your Sulfur

Recovery Equipment

Zeeco has provided combustion and

environmental solutions around the world for

more than 30 years. Let us put our experience to

work for you. Call us today for more information

on Zeecos full line of combustion products and

replacement parts.

ZEECO pilot burners are fully tested to ensure reliable long term

operation in severe service.

ZEECO GLSF Ultra-Low NO

x

Free-Jet Burner

COMBUSTION AND ENVIRONMENTAL SOLUTIONS.

PURE AND SIMPLE.

Natural draft SRU tail gas incinerator.

SULFUR RECOVERY UNIT

Combustion Equipment

COMBUSTION AND ENVIRONMENTAL SOLUTIONS.

PURE AND SIMPLE.

ZEECO CORPORATE HEADQUARTERS

ZEECO HOUSTON

ZEECO EUROPE

ZEECO INDIA

ZEECO ASIA

ZEECO JAPAN/

APPLICOT

ZEECO MIDDLE EAST

REGISTERED

ISO 9001: 2008

CERTIFIED

ASME

CERTIFIED

ASME

CERTIFIED

NBBI

CERTIFICATIONS APPLY TO ZEECO HEADQUARTERS.

ZEECO CHINA

ZEECO BRAZIL

ZEECO CANADA

ZEECO ITALY

ZEECO AUSTRALIA

2011 COPYRIGHT ZEECO, INC. ALL RIGHTS RESERVED

ZEECO office, affiliate, sales, representative, or third party representive/licensee offices.

ZEECO

is a registered trademark of Zeeco, Inc. in the U.S.

ZEECO CONNECTICUT

ZEECO RUSSIA

You might also like

- Proespektif of PlantDocument8 pagesProespektif of Plantrudy_423522658No ratings yet

- Acid Regeneration TechnologyDocument5 pagesAcid Regeneration TechnologyNadia WhiteNo ratings yet

- The Institute of Energy's Second International Conference on COMBUSTION & EMISSIONS CONTROL: Proceedings of The Institute of Energy Conference Held in London, UK, on 4-5 December 1995From EverandThe Institute of Energy's Second International Conference on COMBUSTION & EMISSIONS CONTROL: Proceedings of The Institute of Energy Conference Held in London, UK, on 4-5 December 1995Rating: 5 out of 5 stars5/5 (1)

- 2012 Erp Practice Exam 1Document44 pages2012 Erp Practice Exam 1shashinmishra4222No ratings yet

- Oil and Gas - A Reporter's HandbookDocument58 pagesOil and Gas - A Reporter's HandbookAfrican Centre for Media Excellence100% (1)

- IoclDocument59 pagesIoclRenu KaushikNo ratings yet

- Nigerias Refining Revolution PDFDocument16 pagesNigerias Refining Revolution PDFWillieNo ratings yet

- SRU Brochure ZEECODocument5 pagesSRU Brochure ZEECOmomemmNo ratings yet

- Low NOx Burners Folder. LRDocument6 pagesLow NOx Burners Folder. LRLTE002No ratings yet

- Sulphuric Acid PlantsDocument16 pagesSulphuric Acid PlantsSekar.SNo ratings yet

- Callidus-Honeywell Thermal Brochure 13Document8 pagesCallidus-Honeywell Thermal Brochure 13nay denNo ratings yet

- Rotary KilnsDocument3 pagesRotary KilnsReginaldojoaquimNo ratings yet

- Snox Pet Coke BoilersDocument14 pagesSnox Pet Coke BoilersФранческо ЛеньямеNo ratings yet

- Flue Gas DesulphurizationDocument12 pagesFlue Gas DesulphurizationFernanda Garrido SotoNo ratings yet

- Flue Gas CleaningDocument6 pagesFlue Gas CleaningmasilamaniNo ratings yet

- 12Document16 pages12Anonymous kBjvdERRQNo ratings yet

- Wartsila O GS Flare Gas Recovery SystemDocument2 pagesWartsila O GS Flare Gas Recovery SystemthaisonnguyenhoangNo ratings yet

- Gasification: (Turnw2E™ Gasification Enhanced Gasification Performance)Document2 pagesGasification: (Turnw2E™ Gasification Enhanced Gasification Performance)Arini Rizal100% (1)

- Conocophillips S Zorb Diesel Process: Ed Sughrue and John S. ParsonsDocument6 pagesConocophillips S Zorb Diesel Process: Ed Sughrue and John S. ParsonsBharavi K SNo ratings yet

- Ultralow NOx BurnersDocument3 pagesUltralow NOx Burnersdatalogger123456100% (2)

- Delivering Excellence in Combustion and Process HeatingDocument11 pagesDelivering Excellence in Combustion and Process HeatingsajjadyasinNo ratings yet

- Topsoe Wet Gas Sulphuric Acid (WSA) TechnologyDocument8 pagesTopsoe Wet Gas Sulphuric Acid (WSA) Technologytsaleh100% (1)

- Biomass To Energy General PresentationDocument29 pagesBiomass To Energy General PresentationveenaNo ratings yet

- Chapter 5 - Microturbine Fuels and EmissionsDocument4 pagesChapter 5 - Microturbine Fuels and EmissionsGarip GerçeklerNo ratings yet

- Gastech2015 - WSA Case StudyDocument1 pageGastech2015 - WSA Case StudyIlham HakimNo ratings yet

- Pet CokeDocument2 pagesPet Cokepinku_thakkarNo ratings yet

- Industrial Energy Efficiency Project Training Module: Fuels & CombustionDocument32 pagesIndustrial Energy Efficiency Project Training Module: Fuels & CombustionNaveen ShettyNo ratings yet

- Coking and Thermal ProcessDocument26 pagesCoking and Thermal Processkuldeep100% (3)

- Industrial Watertube BrochureDocument12 pagesIndustrial Watertube Brochuregonzaracing84No ratings yet

- Enclosed Ground FlareDocument4 pagesEnclosed Ground FlareAamerMAhmadNo ratings yet

- Thermal OxidisersDocument6 pagesThermal OxidisersMohammed AlShammasiNo ratings yet

- Brochure Biomass & WTE BoilersDocument2 pagesBrochure Biomass & WTE BoilersjmayorNo ratings yet

- Boilers For Plant Waste-RajavelDocument21 pagesBoilers For Plant Waste-RajavelSathish PaulNo ratings yet

- Environmental Control Systems DESOX and DENOXDocument20 pagesEnvironmental Control Systems DESOX and DENOXPetros IosifidisNo ratings yet

- 2012 Burner Range: Leaders in Combustion TechnologyDocument5 pages2012 Burner Range: Leaders in Combustion TechnologyBbaPbaNo ratings yet

- John Zink - Flare Downstream RefDocument20 pagesJohn Zink - Flare Downstream RefJose Bijoy0% (1)

- Vacuum Heat Treatment For Epitaxy Susceptor Cleaning Furnace Type COVDocument4 pagesVacuum Heat Treatment For Epitaxy Susceptor Cleaning Furnace Type COVDgek LondonNo ratings yet

- Sonic BURNDocument2 pagesSonic BURNjaviermartinmariaNo ratings yet

- Chemical 20 26 20hydrocarbon 20processing 20PDF, Templateid Default, Property DataDocument34 pagesChemical 20 26 20hydrocarbon 20processing 20PDF, Templateid Default, Property Datagems_gce074325No ratings yet

- AFRC 2011 NextGenLoNOx Boiler PaperDocument16 pagesAFRC 2011 NextGenLoNOx Boiler Paperjacquesstrappe06No ratings yet

- Technical Brochure On Flare SystemsDocument20 pagesTechnical Brochure On Flare SystemsN P SrinivasaraoNo ratings yet

- AP Anode Technology v3Document4 pagesAP Anode Technology v3Anup DalalNo ratings yet

- Multi-Point Ground FlareDocument3 pagesMulti-Point Ground FlareOctavio BetanzosNo ratings yet

- Denox DesoxDocument20 pagesDenox DesoxArzu AkarNo ratings yet

- Brochure-02 GGH 06Document2 pagesBrochure-02 GGH 06Harsh AgarwalNo ratings yet

- Heat Treatment Processes in The Ceramics Industry: Edition 09.09 GBDocument8 pagesHeat Treatment Processes in The Ceramics Industry: Edition 09.09 GBKosphy Arden100% (1)

- Boiler Quotation d8Document31 pagesBoiler Quotation d8Rahul Patil100% (4)

- Producer GAS: Complied by Ashish DarjiDocument18 pagesProducer GAS: Complied by Ashish DarjiNimesh PatelNo ratings yet

- CO2 Stack Gas Recovery SystemsDocument4 pagesCO2 Stack Gas Recovery SystemsRodrigo Lagos EscobarNo ratings yet

- Modular Hydrogen Plants: Hydro-ChemDocument12 pagesModular Hydrogen Plants: Hydro-ChemFahryPurnamaNo ratings yet

- Costos de Inversión IGCCDocument16 pagesCostos de Inversión IGCCFrancisco José Lara TeuberNo ratings yet

- Thermal Ox PDFDocument8 pagesThermal Ox PDFHeri SetyantoNo ratings yet

- Tar Removal AbstractDocument1 pageTar Removal AbstractMasagus Sapta RyandaNo ratings yet

- What You Require To Know About NOx Reduction.20130104.123704Document2 pagesWhat You Require To Know About NOx Reduction.20130104.123704anon_931869105No ratings yet

- Monograph Aluminium Scrap Recycling Oscar Iribarren 1630810457Document9 pagesMonograph Aluminium Scrap Recycling Oscar Iribarren 1630810457yacanthiuNo ratings yet

- Stork Low NOx 2007 LRDocument6 pagesStork Low NOx 2007 LRhoangviet20006No ratings yet

- 3.2.1.4.1-1 Trapped Vortex CombustionDocument9 pages3.2.1.4.1-1 Trapped Vortex Combustiontesfaye awelNo ratings yet

- TopsoeDocument5 pagesTopsoelaiping_lumNo ratings yet

- Atmospheric Distillation UnitDocument5 pagesAtmospheric Distillation UnitMukund KsNo ratings yet

- Heat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsFrom EverandHeat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsRating: 5 out of 5 stars5/5 (1)

- Clean Ironmaking and Steelmaking Processes: Efficient Technologies for Greenhouse Emissions AbatementFrom EverandClean Ironmaking and Steelmaking Processes: Efficient Technologies for Greenhouse Emissions AbatementNo ratings yet

- Carbon Capture Technologies for Gas-Turbine-Based Power PlantsFrom EverandCarbon Capture Technologies for Gas-Turbine-Based Power PlantsNo ratings yet

- Liquid Fuels: The Commonwealth and International Library of Science, Technology, Engineering and Liberal Studies: Metallurgy DivisionFrom EverandLiquid Fuels: The Commonwealth and International Library of Science, Technology, Engineering and Liberal Studies: Metallurgy DivisionRating: 4.5 out of 5 stars4.5/5 (2)

- Carbon Monoxide Fact Book and Indoor Evaluation ChecklistFrom EverandCarbon Monoxide Fact Book and Indoor Evaluation ChecklistRating: 3 out of 5 stars3/5 (1)

- Prequalification HecDocument37 pagesPrequalification HecSaad SarfarazNo ratings yet

- Objective: Sales OfficerDocument1 pageObjective: Sales OfficerSaad SarfarazNo ratings yet

- Abdul Hameed: ObjectiveDocument1 pageAbdul Hameed: ObjectiveSaad SarfarazNo ratings yet

- 1365 PDFDocument221 pages1365 PDFSaad SarfarazNo ratings yet

- Industrial Visit Report: Id No: Branch: Report OnDocument11 pagesIndustrial Visit Report: Id No: Branch: Report OnAshutosh ChauhanNo ratings yet

- Cortec GenBrochDocument28 pagesCortec GenBrochpoojaverma21021991No ratings yet

- Crude Assay - Lecture NotesDocument18 pagesCrude Assay - Lecture Notessam joseph100% (1)

- Refinery Configuration (With Figures)Document9 pagesRefinery Configuration (With Figures)phantanthanhNo ratings yet

- Termiiiomii - Delayed Coker Unit (Dcu)Document15 pagesTermiiiomii - Delayed Coker Unit (Dcu)Arnab Guha MallikNo ratings yet

- GDN-178 (Moc) PDFDocument19 pagesGDN-178 (Moc) PDFmkkamaraj0% (1)

- Codes and Standards Related To Piping: What Are Rigid Struts?Document1 pageCodes and Standards Related To Piping: What Are Rigid Struts?tibor121774_66173108No ratings yet

- Hi Oil Gas BrochureDocument14 pagesHi Oil Gas BrochureCamilo PeraltaNo ratings yet

- Stress Analysis of Piping Systems and Pipelines-Harvard UniversityDocument542 pagesStress Analysis of Piping Systems and Pipelines-Harvard UniversityRjeb mohamed100% (2)

- Altivar Process EngDocument80 pagesAltivar Process EngRully Himawan NstNo ratings yet

- Smart Technology For Aging Infrastructure: E G: Focused On Plant ProfitabilityDocument6 pagesSmart Technology For Aging Infrastructure: E G: Focused On Plant ProfitabilityGerardo RiveraNo ratings yet

- 08 - Relief System Adequacy - A Step Towards SAFER Operations - Deepak - IngeneroDocument40 pages08 - Relief System Adequacy - A Step Towards SAFER Operations - Deepak - IngeneroCalNo ratings yet

- Crude Oil Distillation and Petrochemicals: Chemical TechnologyDocument41 pagesCrude Oil Distillation and Petrochemicals: Chemical TechnologyMansi SinghNo ratings yet

- Caustic SCC Paper 080, (ACA, Corrosion Control 007, 2007 Sydney, Australia)Document8 pagesCaustic SCC Paper 080, (ACA, Corrosion Control 007, 2007 Sydney, Australia)APINo ratings yet

- Clean Fuel Project (CFP), Thaioil Public Company Limited: Objective and Project Information Project LocationDocument1 pageClean Fuel Project (CFP), Thaioil Public Company Limited: Objective and Project Information Project LocationPaolo VisentinNo ratings yet

- Winners Power Gardens Refinery BPLANDocument18 pagesWinners Power Gardens Refinery BPLANOwunari Adaye-OrugbaniNo ratings yet

- Booz & Co Iraq Energy Strategy ReportDocument174 pagesBooz & Co Iraq Energy Strategy ReportferitbinzetNo ratings yet

- Refinery Operator 1585971914Document3 pagesRefinery Operator 1585971914arun kukuNo ratings yet

- Bleaching Processes PDFDocument12 pagesBleaching Processes PDFWahaniNo ratings yet

- Report On Industrial Training at Eastern Refinery LimitedDocument109 pagesReport On Industrial Training at Eastern Refinery LimitedTouhid Islam67% (3)

- Process OperatorDocument2 pagesProcess Operatorapi-78201706No ratings yet

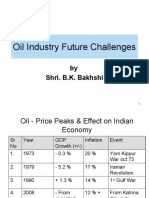

- Oil Industry Future Challenges: by Shri. B.K. BakhshiDocument21 pagesOil Industry Future Challenges: by Shri. B.K. BakhshiGirish1412No ratings yet

- Curriculum Vitae MustafaDocument7 pagesCurriculum Vitae Mustafaazrulazlan89No ratings yet

- Chevron RichmondDocument4 pagesChevron RichmondAZDOLMANNo ratings yet

- Case Study: Financial Management of PTT After PrivatizationDocument4 pagesCase Study: Financial Management of PTT After PrivatizationGrand OverallNo ratings yet

- Safety Circles Among EmployeesDocument4 pagesSafety Circles Among EmployeesDeepu RavikumarNo ratings yet