Professional Documents

Culture Documents

Surface Exploration Drilling Checklist

Uploaded by

Zulfiqar HyderOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Surface Exploration Drilling Checklist

Uploaded by

Zulfiqar HyderCopyright:

Available Formats

Surface exploration drilling checklist

Guidance Note

August 2010

Background

In surface exploration drilling, a number of holes are drilled

in the ground to retrieve samples from varied depths. This

often presents potential hazards due to the variety of drill

rigs and auxiliary equipment used in diffcult or rugged

areas, and new or changing conditions.

As an employer, you must have an OHS plan and ensure

workers onsite are aware of it. In this plan, you must identify

all hazards and implement adequate control measures to

eliminate or reduce the risks to safety.

The main hazards in surface exploration drilling are associated

with four critical areas:

1. Access to drill site.

2. Establishing drill site.

3. Drill rig work area including:

work place ergonomics

exposure (dust and aerosol or noise)

working at heights

objects falling from heights

fre hazards

overhead or underground infrastructure and services

hazards (eg pipelines).

4. Equipment:

high pressure systems (such as hydraulic pressure or

compressed air)

worn or fatigued parts

malfunction of operational safety systems

operator error

handling of objects.

These four areas are addressed in part 1 of the checklist.

Part 2 focuses on additional OHS considerations and part 3

is a prompt for your Safety Management System.

Using the checklist

Use the checklist as a starting point to ensure health and

safety is being maintained and controls are regularly

reviewed at your work site.

Complete parts 1 and 2 of the checklist. Part 3 has been

included as a prompt for your safety management system.

If you answer NO anywhere on the checklist, this means

action must be taken to make your workplace safer and you

should seek advice from a suitably qualifed person.

GUI0112/01/08.10

This checklist has been developed for employers such as mining and exploration licence holders and drilling

contractors to help identify and eliminate common safety issues associated with surface exploration drilling.

Note: This guidance material has been prepared using the best information

available to the Victorian WorkCover Authority and should be used for general

use only. Any information about legislative obligations or responsibilities

included in this material is only applicable to the circumstances described in

the material. You should always check the legislation referred to in this

material and make your own judgement about what action you may need to

take to ensure you have complied with the law. Accordingly, the Victorian

WorkCover Authority cannot be held responsible and extends no warranties

as to the suitability of the information for your specifc circumstances; or

actions taken by third parties as a result of information contained in the

guidance material.

Further information

Contact the WorkSafe Victoria Advisory Service on

1800 136 089 or go to worksafe.vic.gov.au

Related WorkSafe publications

Guidance Note, Occupational health and safety in surface

exploration

Guidance Note, First aid in the workplace

Guidance Note, Workplace amenities and work environment

Other publications

Queensland Resources Council, 2004, Minerals

exploration safety (Guidance Note)

Checklist overleaf

2

Guidance Note Safety in surface exploration drilling checklist

Part 1. The four critical areas

1. Access to drill site Yes/No Action

Are the access roads/tracks to the drill site well formed: steepness and width?

Are roads suitable for the vehicles and machines in use?

Is access to the drill site on an exploration or mining licence clearly marked?

Is edge protection in place where required?

2. The drill site Yes/No Action

Is the drill site safe from natural hazards (eg falling rocks, trees or branches,

vertical openings, sheer drops)?

Have overhead powerlines or underground services been identifed?

Does the drill site allow:

clear access

good visibility (no blind spots)

suitable working space

parking area

escape routes in case of emergency?

Are deep ponds fenced or equipped to prevent people falling into them?

Is the drill site free of litter and slips, trips and falls hazards?

Is the drill site level and stable?

3. Drill rig work area Yes/No Action

3.1 Set up

Are the drill rig jacks on a suitable foundation?

If jacks can be locked in position, are they secure?

3.2 Access

Is the ground around the drill rig free from litter and slips, trips and falls hazards?

Are walkways clear?

Are ladders used according to the Australian Standard AS 1567 1992?

3.3 Inspection and maintenance

Are there specifcation/service manuals on site covering the rig and additional

equipment?

Are there records relating to pre-start checks including third party inspections?

Is there a system for recording/reporting mechanical faults?

Are gauges, warnings, emergency stop buttons and controls on the drillers

console labelled (eg clean, legible and operational)?

3.4 Mast and lifting

Is the rig mast in good condition (eg no bends, twists, cracked welds or supports)?

Are mast pivot points and locking pins secured and in good condition?

Are all bolts tightened and in place (not loose or missing)?

Are pull-down/pull-back chains or cables in good condition?

Checklist for safety in surface exploration drilling.

If you answer no to anything in the checklist, you should develop a safety action plan using the template at the end of the

checklist. This may also be used to update your OHS plan.

3

Guidance Note Safety in surface exploration drilling checklist

Are hoisting cables, wire lines and slings free from knots, kinks, whiskers or

broken wires?

Is all lifting gear (eg chain, swivels, shackles, wire rope and slings) tagged or

stamped with safe working load?

Are winch drums and sheaves in good condition (free from signs of excessive

wear, visible damage or cracks)?

Do wire ropes conform to the original manufacturers specifcations?

Are hoist limits regularly checked and tested?

3.5 Drill rod handling

Does the site layout reduce the need to handle, move or carry drill rods?

Do drill rod handling procedures assist to prevent injury and include:

pre-drilling/collaring activity

production

pack up

jammed drill rods?

Is there a drill rod handling carousel and procedure for loading the carousel?

Are drill rod break-out tools and equipment in good condition?

Have drill rod break-out tools been checked for wear?

Are the drill rods stored securely?

4. Equipment Yes/No Action

4.1 Pressure

If pressure relief valves are ftted, is there a testing procedure?

Are hydraulic hoses inspected for leaks, cuts and torn outer casing?

Is any double braid wire showing?

Are all high pressure hoses in good condition and free from sharp edges?

Are high pressure hoses equipped with whip checks or fogger chains?

Are manifolds, exhaust pipes, turbo-chargers and muffers in good condition

and adequately guarded or heat shielded?

4.2 Electrical

Is a residual-current device ftted to generators and regularly tested?

Are electric cables and tools in good condition and ftted with current test tag?

Are electrical cables safely positioned (not a tripping hazard) and protected

from damage?

Are the drill rig night lights and electrical fttings waterproof, clean and adequate?

4.3 Dangerous parts

Is suitable guarding in place for hot surfaces and rotating, moving and

electrical parts?

Is the area free from potentially dangerous objects (eg falling objects,

whipping ropes or gas bottles)?

Does the drill rig have an automatic cut-off device to the operators position/seat?

If there are any potentially explosive gases around, are potential ignition

sources guarded and checked?

4

Guidance Note Safety in surface exploration drilling checklist

Part 2. Additional OHS considerations

People and amenities Yes/No Action

Are all site personnel aware of and working free from entanglement hazards

(eg loose/ragged clothing, loose bootlaces, jackets with draw strings, long hair

and loose jewellery)?

Is personal protective equipment used and suitable for purpose?

Are precautions against extreme weather conditions (eg UV exposure or cold)

taken?

If a heating system is in use, are there procedures in place to prevent and

protect from any additional hazards posed such as fre, electrics, burning?

Are the crib room, toilet or washing facilities adequate?

Emergency Yes/No Action

Is there an emergency plan?

Does it cover vehicle incidents, communication for assistance including numbers/

authorities, extraction of personnel, bush fres and notifcation?

Are these facilities adequate and up to date:

frst aid

back up communication

transport

fuel/chemicals storage

fre extinguishers

fre break?

Do operators hold current frst aid certifcates?

Are operators trained in fre prevention and fre fghting?

Site procedures Yes/No Action

Are drill rig operators aware of procedures for:

camping (if applicable)

checking ftness for work (fatigue, heat, drugs and alcohol)

manual handling

fre prevention and fghting

working at heights

noise and dust

use of vehicles

use of portable tools

use of dangerous goods and hazardous substances

use of heaters and electricity including emergency shutdown?

Are processes in place to ensure drill rig operators comply with the above

procedures or requirements?

Part 3. Safety Management System (SMS)

Is a licence holder SMS kept on site and does the licence

holder SMS cover:

training

management of contractors

hazard and risk management

maintenance

management of change

communication and consultation

inspection, auditing and verifcation

continuous improvement

emergency management?

5

Guidance Note Safety in surface exploration drilling checklist

S

a

f

e

t

y

a

c

t

i

o

n

p

l

a

n

U

s

e

t

h

i

s

p

l

a

n

t

o

e

l

i

m

i

n

a

t

e

o

r

c

o

n

t

r

o

l

h

a

z

a

r

d

s

i

d

e

n

t

i

f

e

d

i

n

t

h

e

c

h

e

c

k

l

i

s

t

.

S

a

f

e

t

y

i

s

s

u

e

o

r

h

a

z

a

r

d

A

c

t

i

o

n

r

e

q

u

i

r

e

d

P

e

r

s

o

n

r

e

s

p

o

n

s

i

b

l

e

D

a

t

e

o

f

a

c

t

i

o

n

t

o

b

e

c

o

m

p

l

e

t

e

d

R

e

v

i

e

w

d

a

t

e

a

n

d

c

o

m

m

e

n

t

H

i

g

h

p

r

i

o

r

i

t

y

M

e

d

i

u

m

p

r

i

o

r

i

t

y

L

o

w

p

r

i

o

r

i

t

y

Y

o

u

c

a

n

d

o

w

n

l

o

a

d

t

h

i

s

p

a

g

e

f

r

o

m

w

o

r

k

s

a

f

e

.

v

i

c

.

g

o

v

.

a

u

.

P

u

t

i

t

o

n

y

o

u

r

n

o

t

i

c

e

b

o

a

r

d

a

n

d

d

i

s

c

u

s

s

i

t

w

i

t

h

y

o

u

r

w

o

r

k

e

r

s

.

You might also like

- Al-Khalij 3X450 MW Power Plant Project Job Safety Analysis WorksheetDocument3 pagesAl-Khalij 3X450 MW Power Plant Project Job Safety Analysis WorksheetMustafa hse JafferNo ratings yet

- JSA - 003 - Tripod Rig Erection, Operation and DismantlingDocument2 pagesJSA - 003 - Tripod Rig Erection, Operation and DismantlingAbhijit JanaNo ratings yet

- Job Safety Analysis for Workover OperationsDocument5 pagesJob Safety Analysis for Workover OperationsAshok SureshNo ratings yet

- Hira - CivilDocument20 pagesHira - Civilmurthy100% (1)

- The Silent KillerDocument26 pagesThe Silent KillerMohed LipanNo ratings yet

- Working at Height Rescue Plan: WHS-FM-008Document2 pagesWorking at Height Rescue Plan: WHS-FM-008Purwo PrihartonoNo ratings yet

- Ocp BatchingDocument1 pageOcp BatchingAarya Mishra TiwariNo ratings yet

- Confind Space RCDocument11 pagesConfind Space RCIrfan ashrafNo ratings yet

- Dismantling of Concrete Pump TowerDocument1 pageDismantling of Concrete Pump TowerChandruNo ratings yet

- HSE Emergency Response ChecklistDocument4 pagesHSE Emergency Response ChecklistMargaretta WijayantiNo ratings yet

- Rigging Safety TipsDocument2 pagesRigging Safety Tipspruncu.alianmNo ratings yet

- DevicorebbtDocument1 pageDevicorebbtDaviss Pauca Morón100% (1)

- Pera JackhammerDocument7 pagesPera Jackhammerjumansyahamid1988No ratings yet

- SOP Module Unloading & StorageDocument1 pageSOP Module Unloading & StorageRahul SahaNo ratings yet

- Surface Blasting Safety Procedures ManualDocument21 pagesSurface Blasting Safety Procedures ManualRajanbabu100% (1)

- Plywood Material Safety Data Sheet For MR Plywood PDFDocument4 pagesPlywood Material Safety Data Sheet For MR Plywood PDFNirvana NircisNo ratings yet

- Confined Space PermitDocument1 pageConfined Space PermitNethiyaaRajendranNo ratings yet

- JSA-009a Drilling and Mon Well Construction-Sonic - 2Document4 pagesJSA-009a Drilling and Mon Well Construction-Sonic - 2sudarmanNo ratings yet

- Grand Toolbox (Monthly)Document3 pagesGrand Toolbox (Monthly)Suresh Praba PNo ratings yet

- CHECKLIST FOR LIFTING PLANDocument1 pageCHECKLIST FOR LIFTING PLANAndrianoNo ratings yet

- Confined Space SapDocument2 pagesConfined Space SapfairusNo ratings yet

- JSA of Charging UnitDocument3 pagesJSA of Charging UnitMuhammad AliNo ratings yet

- Job Hazard Analysis Worksheet: Page 1 of 2Document2 pagesJob Hazard Analysis Worksheet: Page 1 of 2Lourdes Marianne MenesesNo ratings yet

- JSA CT Cement (Example)Document2 pagesJSA CT Cement (Example)aneshseNo ratings yet

- SWMS Bored PilingDocument17 pagesSWMS Bored PilingnaraNo ratings yet

- JHA For Work PermitDocument1 pageJHA For Work PermitShahid RazaNo ratings yet

- Confined Spaces CardsDocument1 pageConfined Spaces CardsJafar KhanNo ratings yet

- Ramapo College Vehicle Fueling SOPDocument1 pageRamapo College Vehicle Fueling SOPAnees EkNo ratings yet

- Job Hazard Analysis Template SampleDocument2 pagesJob Hazard Analysis Template SampleJohn KurongNo ratings yet

- GENCHI INDIA PVT.LTD JOB HAZARDS ANALYSISDocument2 pagesGENCHI INDIA PVT.LTD JOB HAZARDS ANALYSISsakthi venkatNo ratings yet

- High Risk Job Safety Analysis: Contractor ArgonneDocument13 pagesHigh Risk Job Safety Analysis: Contractor ArgonneVwoke OyibogareNo ratings yet

- Risk Assess T-23 - Hilti Cartridge Tool OperationDocument2 pagesRisk Assess T-23 - Hilti Cartridge Tool OperationMAB Ali100% (1)

- Unloading of EWPs From ContainersDocument10 pagesUnloading of EWPs From ContainersPirashanth SathananthanNo ratings yet

- Chemical Handling ChecklistDocument12 pagesChemical Handling ChecklistEric TNo ratings yet

- JSA-Confined Space Activity - 05Document4 pagesJSA-Confined Space Activity - 05babjihanumanthuNo ratings yet

- Safety Inspection ChecklistDocument6 pagesSafety Inspection ChecklistVel MuruganNo ratings yet

- JHA (Excavation of IPS Rev. B)Document4 pagesJHA (Excavation of IPS Rev. B)Armando AballeNo ratings yet

- Environmental, Health and Safety Risks AnalysisDocument2 pagesEnvironmental, Health and Safety Risks AnalysisKrishna Patil100% (1)

- Working at Height PresentationDocument11 pagesWorking at Height PresentationAbdul Hameed OmarNo ratings yet

- Scaffold Pre Use Daily Inspection ChecklistDocument2 pagesScaffold Pre Use Daily Inspection ChecklistmaramNo ratings yet

- Halliburton: Job Safety AnalysisDocument2 pagesHalliburton: Job Safety Analysisaneshse100% (1)

- Occupational Hazards Water Treatment ProcessesDocument14 pagesOccupational Hazards Water Treatment ProcessesMohamed Salem100% (1)

- HSE Incident Lesson Learnt Eye Injury Charging Lifeboat Air BottlesDocument1 pageHSE Incident Lesson Learnt Eye Injury Charging Lifeboat Air BottlesKyaw MinNo ratings yet

- Jsa Fan Coil Unites MaintenanceDocument5 pagesJsa Fan Coil Unites MaintenanceASLAM MULANINo ratings yet

- Water Tank Cleaning TRADocument5 pagesWater Tank Cleaning TRAyehia sayedNo ratings yet

- Hand - Protection Safety TrainingDocument2 pagesHand - Protection Safety TrainingEmmaprinceNo ratings yet

- Schedule For Inspection Nov 19Document1 pageSchedule For Inspection Nov 19Siddharth RanaNo ratings yet

- Drilling Process PDFDocument2 pagesDrilling Process PDFmool rajNo ratings yet

- Risk Assessment-KioskDocument3 pagesRisk Assessment-Kioskmubeen hassanNo ratings yet

- Asian Paints - Prem Gloss EnamelDocument1 pageAsian Paints - Prem Gloss EnamelwilliumstNo ratings yet

- Excavation Safety Dos and DontsDocument4 pagesExcavation Safety Dos and DontsVidya SagarNo ratings yet

- Dr. Nirali Patel Pediatric Emergency MedicineDocument31 pagesDr. Nirali Patel Pediatric Emergency Medicinemarsan12No ratings yet

- Over Head Guards-Are There Broken Welds, Missing: Bolts, or Damaged Areas?Document1 pageOver Head Guards-Are There Broken Welds, Missing: Bolts, or Damaged Areas?Mithlesh SinghNo ratings yet

- Confined Space Entry Safety AnalysisDocument2 pagesConfined Space Entry Safety AnalysisDheeraj Kapoor /QOGIL/QuippoworldNo ratings yet

- Jha Rig Up Hwu Equipment & Surface Line N-U and N-D BopDocument7 pagesJha Rig Up Hwu Equipment & Surface Line N-U and N-D BopHSE PULAI A100% (1)

- SDS - Fenomastic Enamel Semigloss - English (Uk) - DubaiDocument5 pagesSDS - Fenomastic Enamel Semigloss - English (Uk) - DubaiBalasubramanian AnanthNo ratings yet

- Copy (2) of JSA For Welding, Cutting and Grinding (Alam Engineering)Document5 pagesCopy (2) of JSA For Welding, Cutting and Grinding (Alam Engineering)Viron BaxhiaNo ratings yet

- Guidance Checklist WebDocument5 pagesGuidance Checklist WebmeidiansyahNo ratings yet

- Air Winch Operation Hand Placement: Haz-IDDocument1 pageAir Winch Operation Hand Placement: Haz-IDZulfiqar HyderNo ratings yet

- Haz-ID: Pipe Spinner Hand PlacementDocument1 pageHaz-ID: Pipe Spinner Hand PlacementZulfiqar HyderNo ratings yet

- Haz-ID: Pulling Drill Pipe Up The V-DoorDocument1 pageHaz-ID: Pulling Drill Pipe Up The V-DoorZulfiqar HyderNo ratings yet

- NGC1 Flash Cards 2Document14 pagesNGC1 Flash Cards 2Kevin Josh BonalesNo ratings yet

- Rig Tong Feet Placement: Haz-IDDocument1 pageRig Tong Feet Placement: Haz-IDZulfiqar HyderNo ratings yet

- Haz-ID: Hand Placement When Using Rig TongsDocument1 pageHaz-ID: Hand Placement When Using Rig TongsZulfiqar HyderNo ratings yet

- Manrider Winch Line Spooling: Haz-IDDocument1 pageManrider Winch Line Spooling: Haz-IDZulfiqar HyderNo ratings yet

- Manrider Winch Line Spooling: Haz-IDDocument1 pageManrider Winch Line Spooling: Haz-IDZulfiqar HyderNo ratings yet

- Rig Floor Using D.C Slips: Haz-IDDocument1 pageRig Floor Using D.C Slips: Haz-IDZulfiqar HyderNo ratings yet

- Running Spiral Haz-ID Title 01-01-01-ODEDocument1 pageRunning Spiral Haz-ID Title 01-01-01-ODEZulfiqar HyderNo ratings yet

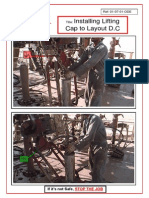

- Installing Lifting Cap To Layout D.C: Haz-IDDocument1 pageInstalling Lifting Cap To Layout D.C: Haz-IDZulfiqar HyderNo ratings yet

- Pulling Back and Guiding Elevators: Haz-IDDocument1 pagePulling Back and Guiding Elevators: Haz-IDZulfiqar HyderNo ratings yet

- Pulling Back and Guiding Elevators: Haz-IDDocument1 pagePulling Back and Guiding Elevators: Haz-IDZulfiqar HyderNo ratings yet

- Rig Floor 5Document1 pageRig Floor 5Zulfiqar HyderNo ratings yet

- Pulling Drill Pipe Slips: Haz-IDDocument1 pagePulling Drill Pipe Slips: Haz-IDZulfiqar HyderNo ratings yet

- Haz-ID: Drill Floor Stabbing H.W.PDocument1 pageHaz-ID: Drill Floor Stabbing H.W.PZulfiqar HyderNo ratings yet

- Haz-ID: Using Pipe Spinner To Make Up H.W.PDocument1 pageHaz-ID: Using Pipe Spinner To Make Up H.W.PZulfiqar HyderNo ratings yet

- 13.04 Drilling OverviewDocument2 pages13.04 Drilling OverviewZulfiqar HyderNo ratings yet

- 5 Steps Risk AssessmentDocument1 page5 Steps Risk AssessmentJayson V Caranto RNNo ratings yet

- ExcavationDocument18 pagesExcavationlmavullathilNo ratings yet

- Exercise # 2: Pete 203: Drilling EngineeringDocument3 pagesExercise # 2: Pete 203: Drilling EngineeringZulfiqar HyderNo ratings yet

- Fire HazardsDocument2 pagesFire HazardsZulfiqar HyderNo ratings yet

- Surface Exploration Drilling ChecklistDocument5 pagesSurface Exploration Drilling ChecklistZulfiqar HyderNo ratings yet

- Health and Safety at Work SlidesDocument195 pagesHealth and Safety at Work SlidesZulfiqar Hyder100% (2)

- H2S in The OilfieldDocument7 pagesH2S in The OilfieldSum LMNo ratings yet

- Fire HazardsDocument2 pagesFire HazardsZulfiqar HyderNo ratings yet

- Rig Check - 2011-204cDocument74 pagesRig Check - 2011-204cDesi Vivi Janna PakpahanNo ratings yet

- Drill EngineeringDocument0 pagesDrill EngineeringZulfiqar HyderNo ratings yet