Professional Documents

Culture Documents

Centrifugal Pump Troubleshooting Guide: Symptoms Symptoms Symptoms Symptoms

Centrifugal Pump Troubleshooting Guide: Symptoms Symptoms Symptoms Symptoms

Uploaded by

thongpvgas0 ratings0% found this document useful (0 votes)

21 views2 pagesOriginal Title

56631726 Troubguide Centrifugal Pump

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

21 views2 pagesCentrifugal Pump Troubleshooting Guide: Symptoms Symptoms Symptoms Symptoms

Centrifugal Pump Troubleshooting Guide: Symptoms Symptoms Symptoms Symptoms

Uploaded by

thongpvgasCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 2

Centrifugal Pump Troubleshooting Guide

Possible Causes # A B C D E F G H # Possible Remedies

Strainer Partially

Clogged

7 3 7

* Inspect And Clean

Pump Impeller

Clogged

8 8 8 5 8

* Check For Damage

And Clean

Suction And/Or

Discharge Valve(s)

Closed

9 9 9

* Shut Down And Open

Valves

Viscosity Too High 10 7 5 4 10

* Heat Up Liquid To

Reduce Viscosity

* I ncrease Size Of

Discharge Piping To

Reduce Pressure Loss

* Use Larger Driver Or

Change Type Of Pump

* Slow Pump Down

Specific Gravity Too

High

11 2 11

* Check Design Specific

Gravity

Total System Head

Lower Than Design

Head Of Pump

12 4 11 3 12

* Increase System

Resistance To Obtain

Design Flow

* Check Design

Parameters Such As

Impeller Size, Etc.

Total System Head

Higher Than Design

Head Of Pump

13 6 5 4 10 2 13

* Decrease System

Resistance To Obtain

Design Flow

* Check Design

Parameters Such As

Impeller Size, Etc.

Unsuitable Pumps In

Parallel Operation

14 7 6 6 14

* Check Design

Parameters

Improper Mechanical

Seal

15 1 15

* Check Mechanical

Seal Selection Strategy

Possible Causes # A B C D E F G H # Possible Remedies

D Insufficient Disch. Pressure .

Symptoms

Table 4-6 (cont.)

Symptoms

Short Mech. Seal Life F

Short Bearing Life E

H

Y

D

R

A

U

L

I

C

S

Y

S

T

E

M

Power Demand Excessive H

Vibration & Noise G

A No Liquid Delivery .

C Intermittent Operation .

B Insufficient Capacity .

Possible Causes # A B C D E F G H # Possible Remedies

Pump I s Cavitating

(Symptom For Liquid

Vaporizing I n Suction

System) -Horizontal

Pumps

1 2 1 1 9 1 1

* Check NPSHa/ NPSHr

Margin

* I f Pump I s Above

Liquid Level, Raise

Liquid Level Closer To

Pump

* If Liquid Is Above

Pump, I ncrease Liquid

Level Elevation

I nsufficient

I mmersion Of Suction

Pipe Or Bell

(VertTurbinePump)

2 1 1 1 1 2

* Lower Suction Pipe

Or Raise Sump Level

* I ncrease System

Resistance

Pump Not Primed 3 1 2 3

* Fill Pump And Suction

Piping

Complete With Liquid

* Eliminate High Points

I n Suction

* Remove All Non-

Condensibles (Air From

Pump, Piping and

Valves)

* Eliminate High Points

I n Suction Piping

* Check For Faulty Foot

Valve Or Check Valve

Non-Condensibles I n

Liquid

4 2 3 1 4

* Check For Gas/Air

I ngress Through Suction

System/Piping

* I nstall Gas Separation

Chamber

Supply Tank Empty 5 3 5 * Refill Supply Tank

Obstructions I n Lines

Or Pump Housing

6 9 7 7 6

* I nspect And Clear

Possible Causes # A B C D E F G H # Possible Remedies

Vibration & Noise G

A No Liquid Delivery .

S

U

C

T

I

O

N

P

R

O

B

L

E

M

S

H

Y

D

R

A

U

L

I

C

S

Y

S

T

E

M

Table 4-6

Troubleshooting Guide -- Centrifugal Process Pumps

Power Demand Excessive H

Short Bearing Life E D I nsufficient Disch. Pressure .

C I ntermittent Operation .

Symptoms

B I nsufficient Capacity .

Symptoms

Short Mech. Seal Life F

Centrifugal Pump Troubleshooting Guide

This material was reproduced from Practical Machinery Management for Process Plants:

Machinery Failure Analysis and Troubleshooting by Heinz P. Bloch and Fred K. Geitner by

permission of the publisher Butterworth Heinemann of 225 Wildwood Avenue, Woburn MA

01801 (www.bh.com). 10% Discount on copies of this book will be offered with this sheet.

1-800-767-6700

Possible Causes # A B C D E F G H # Possible Remedies

Speed Too High 16 1 16

* Check Motor Voltage -

Slow Down Driver

Speed Too Low 17 4 4 2 17

* Consult Driver

Troubleshooting Guide

Wrong Direction Of

Rotation

18 5 3 6 18

* Check Rotation With

Arrow On Casing -

Reverse Polarity On

Motor

Impeller Installed

Backward (Double

Suction Imp.)

19 10 12 19

* Inspect

Misalignment 20 1 2 4 7 20

* Check Angular And

Parallel Alignment

Between Pump And

Driver

Casing Distorted

From Excessive Pipe

Strain

21 2 3 5 21

* Check For

Misalignment

* Check Pump For

Wear Between Casing

And Rotating Elements

* Analyze Piping Loads

Inadequate Grouting

Of Base

22 6 22

* Check Grouting And

Regrout If Required

Bent Shaft 23 3 4 7 8 23

* Check Deflection

(Should Not Exceed

0.002"). Replace Shaft

And Bearings If

Necessary

Internal Wear 24 8 9 24

* Check Impeller

Clearances

Possible Causes # A B C D E F G H # Possible Remedies

Table 4-6 (cont.)

B Insufficient Capacity .

A No Liquid Delivery .

M

E

C

H

A

N

I

C

A

L

S

Y

S

T

E

M

Symptoms Symptoms

Short Mech. Seal Life F

Vibration & Noise G

D Insufficient Disch. Pressure . Short Bearing Life E

C Intermittent Operation .

Power Demand Excessive H

Possible Causes # A B C D E F G H # Possible Remedies

Mechanical Defects

Worn, Rusted,

Defective Bearings

25 5 8 10 25

* Inspect Parts For

Defects - Repair Or

Replace. Use Bearing

Failure Analysis Guide

* Check Lubrication

Procedures

Unbalance - Driver 26 5 7 9 26

* Run Driver

Disconnected From

Pump Unit - Perform

Vibration Analysis

Unbalance - Pump 27 4 6 3 27

* Investigate Natural

Frequency

Motor Troubles 28 6 8 10 11 28

* Consult Motor

Troubleshooting Guide

Possible Causes # A B C D E F G H # Possible Remedies

Table 4-6 (cont.)

M

E

C

H

A

N

I

C

A

L

S

Y

S

T

E

M

A No Liquid Delivery .

B Insufficient Capacity .

C Intermittent Operation .

D Insufficient Disch. Pressure .

Symptoms Symptoms

Power Demand Excessive H

Vibration & Noise G

Short Mech. Seal Life F

Short Bearing Life E

You might also like

- User Guide ENGDocument29 pagesUser Guide ENGcarlosorizaba100% (1)

- Mark 3 ASME Pumps PDFDocument94 pagesMark 3 ASME Pumps PDFInf IngNo ratings yet

- Vaneless DiffuserDocument8 pagesVaneless Diffuseramir_karimiNo ratings yet

- Pump KnowledgeDocument17 pagesPump Knowledgesmupy_122100% (1)

- Stan Shiels on centrifugal pumps: Collected articles from 'World Pumps' magazineFrom EverandStan Shiels on centrifugal pumps: Collected articles from 'World Pumps' magazineRating: 5 out of 5 stars5/5 (1)

- Pump Troubleshooting: Problem Probable Cause SolutionDocument2 pagesPump Troubleshooting: Problem Probable Cause SolutionKarim MamdouhNo ratings yet

- Schroedahl ArvDocument19 pagesSchroedahl ArvfadzilharmanNo ratings yet

- Durco Mark 3 Brochure PDFDocument36 pagesDurco Mark 3 Brochure PDFVic Van PeborghNo ratings yet

- S. No. Problem Potential Causes SolutionsDocument6 pagesS. No. Problem Potential Causes SolutionsSyed Abdullah FaizNo ratings yet

- Pumping Control Methods and Their Impact On System EfficiencyDocument16 pagesPumping Control Methods and Their Impact On System EfficiencyWahidHamedNo ratings yet

- Mechanical Seal ClassificationsDocument1 pageMechanical Seal ClassificationsAkshayGuptaNo ratings yet

- EthanolDocument8 pagesEthanolapi-3699282No ratings yet

- Vertical PumpsDocument27 pagesVertical PumpsmersiumNo ratings yet

- Centrifugal Pump - Troubleshooting MatrixDocument1 pageCentrifugal Pump - Troubleshooting MatrixSuresha Pd100% (1)

- Pump Bearing HousingDocument9 pagesPump Bearing Housingapi-372195253No ratings yet

- Microproject Report HPCDocument7 pagesMicroproject Report HPCkadamnavadeep5863No ratings yet

- Mechanical Seal TrainingDocument42 pagesMechanical Seal Traininglopes_anderson5078No ratings yet

- Influence of Impeller Suction Specific Speed On Vibration LCCDocument32 pagesInfluence of Impeller Suction Specific Speed On Vibration LCCjuan villarroelNo ratings yet

- Pitfalls of Pump PipingDocument3 pagesPitfalls of Pump PipingChris PeramunugamaNo ratings yet

- Listings of Texas A&M Pump Users Symposiums Proceedings From 1984 To 2013Document116 pagesListings of Texas A&M Pump Users Symposiums Proceedings From 1984 To 2013jehodgsonNo ratings yet

- Compressors Course-Chapter 8Document3 pagesCompressors Course-Chapter 8vela vanNo ratings yet

- Kirloskar Ebara Pumps Limited: A Presentation byDocument11 pagesKirloskar Ebara Pumps Limited: A Presentation bypsshnkr100% (1)

- Centrifugal PumpsDocument24 pagesCentrifugal PumpsHari Babu DharmavarapuNo ratings yet

- Pumps CentrifugalDocument44 pagesPumps CentrifugalEhab Abowarda100% (1)

- Pump Motor TripDocument4 pagesPump Motor TripKamal UddinNo ratings yet

- Centrifugal Pump Axial ThrustDocument4 pagesCentrifugal Pump Axial Thrustfawmer61100% (1)

- Vertical Turbine PumpsDocument6 pagesVertical Turbine PumpsadehriyaNo ratings yet

- Anti Friction Bearings For PumpsDocument165 pagesAnti Friction Bearings For PumpsJaime BerryNo ratings yet

- Centrifugal Pump Books PDFDocument1 pageCentrifugal Pump Books PDFyusufNo ratings yet

- Troubleshooting Centrifugal Pumps July04!28!34Document7 pagesTroubleshooting Centrifugal Pumps July04!28!34ho-faNo ratings yet

- 01 Chemical ProcessDocument333 pages01 Chemical ProcessDavid ValladaresNo ratings yet

- Persatuan Insinyur Indonesia (PII) Badan Koordinasi Mesin (BKM)Document19 pagesPersatuan Insinyur Indonesia (PII) Badan Koordinasi Mesin (BKM)HaryadiNo ratings yet

- Short Course 4 - Selecting The Right Pump For The ApplicationDocument62 pagesShort Course 4 - Selecting The Right Pump For The ApplicationFayez Al-ahmadiNo ratings yet

- Effects of Impeller Design and Surface RoughnessDocument36 pagesEffects of Impeller Design and Surface RoughnessHayderAlSamawiNo ratings yet

- Root Cause Analysis: HPDGA 1000 KW Centrifugal Pump High Vibration ResolvedDocument8 pagesRoot Cause Analysis: HPDGA 1000 KW Centrifugal Pump High Vibration ResolvedAbdulrahman AlkhowaiterNo ratings yet

- A Study On Failure of Mechanical PumpDocument34 pagesA Study On Failure of Mechanical PumpAzif Ali MoothantevileyilNo ratings yet

- SEALDocument6 pagesSEALkishorsinghNo ratings yet

- Sundyne Pumps & Compressors Training Course: THREE DAYS (Theoretical and Practical)Document3 pagesSundyne Pumps & Compressors Training Course: THREE DAYS (Theoretical and Practical)önder KarakayaNo ratings yet

- Pump MagazineDocument116 pagesPump Magazinerajiv_ramachandran100% (3)

- P 10 500 Ea4 PDFDocument36 pagesP 10 500 Ea4 PDFDanielNo ratings yet

- 08-Sundyne Presentation - Fs Installation1Document15 pages08-Sundyne Presentation - Fs Installation1joseellargo100% (1)

- Submersible Pumps Brochure en Aug20Document10 pagesSubmersible Pumps Brochure en Aug20Karina MedinaNo ratings yet

- 3-Day Gen Open 112003 1a (Compatibility Mode)Document84 pages3-Day Gen Open 112003 1a (Compatibility Mode)api-3703348100% (1)

- Centrifugal Pump Health Check Up 1691257011Document35 pagesCentrifugal Pump Health Check Up 1691257011Luis MarshNo ratings yet

- Submersible Propeller Pump Type ABS VUPXDocument8 pagesSubmersible Propeller Pump Type ABS VUPXAgus SalmanNo ratings yet

- Using Variable Speed Drives VSDs in Pump Applications 1700774456Document36 pagesUsing Variable Speed Drives VSDs in Pump Applications 1700774456hamedNo ratings yet

- KSB Sewabloc Sewatec CharakterystykiDocument112 pagesKSB Sewabloc Sewatec Charakterystykilouis etienneNo ratings yet

- Instructions On Installation, Operation and Maintenanace For Sam Turbo Pump TypeDocument30 pagesInstructions On Installation, Operation and Maintenanace For Sam Turbo Pump TypeSai RamNo ratings yet

- 10 Ways To Murder A PUMPDocument10 pages10 Ways To Murder A PUMPBaqirMuhammadNo ratings yet

- Flowserve Reg PumpDocument66 pagesFlowserve Reg Pumpshaad_ksi100% (1)

- RUHRPUMPEN Pump - VTP - B - EN PDFDocument8 pagesRUHRPUMPEN Pump - VTP - B - EN PDFhenryNo ratings yet

- Best Practice in Process Pump Maintenance & ReliabilityDocument18 pagesBest Practice in Process Pump Maintenance & Reliabilityvijayabaskaran PalanisamyNo ratings yet

- Improving Reliability and Efficiency of Centrifugal PumpsDocument4 pagesImproving Reliability and Efficiency of Centrifugal PumpsHatem ShawkiNo ratings yet

- Operation & Maintenance ManualDocument22 pagesOperation & Maintenance ManualAnivaryaPumpsNo ratings yet

- SideWinder 40 60 80 CHMCL PMP BrchreDocument4 pagesSideWinder 40 60 80 CHMCL PMP BrchreSH McNo ratings yet

- Preventive Maintenance Introduction: For Centrifugal Pump SystemsDocument13 pagesPreventive Maintenance Introduction: For Centrifugal Pump SystemsZaenal AripinNo ratings yet

- Maintenance Schedule Trailer PumpsDocument8 pagesMaintenance Schedule Trailer PumpsGhabriNo ratings yet

- 3 Pumpenwechsel 2006 GBDocument5 pages3 Pumpenwechsel 2006 GBAndrei 26No ratings yet

- Troubleshooting The Divider Block SystemDocument3 pagesTroubleshooting The Divider Block SystemMarcus MorganNo ratings yet

- Preventive Maintenance of Hydraulic Pumps and Motors: Induction/Refresher Drilling Training Programme Foreman (Drilling)Document25 pagesPreventive Maintenance of Hydraulic Pumps and Motors: Induction/Refresher Drilling Training Programme Foreman (Drilling)mukesh ojhaNo ratings yet

- Vigon SDS US EnglishDocument14 pagesVigon SDS US EnglishFahad MaqsoodNo ratings yet

- M. Waseem (Instrumentation Technician)Document2 pagesM. Waseem (Instrumentation Technician)Fahad MaqsoodNo ratings yet

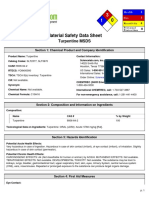

- 2075 Turpentine Oil Rectified SDSDocument5 pages2075 Turpentine Oil Rectified SDSFahad MaqsoodNo ratings yet

- Affinity DiagramDocument1 pageAffinity DiagramFahad MaqsoodNo ratings yet

- Msds PDFDocument6 pagesMsds PDFFahad Maqsood100% (1)

- White Spirit - SPECSDocument1 pageWhite Spirit - SPECSFahad MaqsoodNo ratings yet

- 2.4 Attachments - Risk Assessment and Method StatementDocument10 pages2.4 Attachments - Risk Assessment and Method StatementFahad MaqsoodNo ratings yet

- IGC 2 Element 8Document74 pagesIGC 2 Element 8Fahad Maqsood100% (4)

- Base Oil SN 600:: Property Kinematic Viscosity at 100 °C AstmDocument1 pageBase Oil SN 600:: Property Kinematic Viscosity at 100 °C AstmFahad MaqsoodNo ratings yet

- Chemsical IndustrieDocument8 pagesChemsical IndustrieFahad MaqsoodNo ratings yet

- IOSH Managing Safely: Special Fee Discount OfferDocument1 pageIOSH Managing Safely: Special Fee Discount OfferFahad MaqsoodNo ratings yet

- Controller TYpesDocument10 pagesController TYpesFahad MaqsoodNo ratings yet

- Analytical Ability TipsDocument9 pagesAnalytical Ability TipsFahad MaqsoodNo ratings yet

- Viberation and Noise in Centrifugal PumpsDocument12 pagesViberation and Noise in Centrifugal PumpsFahad MaqsoodNo ratings yet

- Effluent Traetment Plant SopDocument45 pagesEffluent Traetment Plant SopFahad Maqsood100% (2)

- Compressor Settleout Pressure Temperature EstimationDocument3 pagesCompressor Settleout Pressure Temperature EstimationFahad Maqsood100% (1)

- Pentane: Cautionary Response InformationDocument2 pagesPentane: Cautionary Response InformationFahad MaqsoodNo ratings yet

- Pump Lose Suction After Some TimeDocument12 pagesPump Lose Suction After Some TimeFahad MaqsoodNo ratings yet