Professional Documents

Culture Documents

Inspección de Grilletes-Asme b30.26

Inspección de Grilletes-Asme b30.26

Uploaded by

CLIFFORDPACopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Inspección de Grilletes-Asme b30.26

Inspección de Grilletes-Asme b30.26

Uploaded by

CLIFFORDPACopyright:

Available Formats

CMCO:Rigging Training

1

Copyright

2010

RIGGING HARDWARE

ASME B30.26

Addresses detachable lifting hardware for lifting purposes

Shackles

Adjustable Hardware (Turnbuckles, Eye nuts, Swivel Hoist Rings

and Eyebolts

Compression Hardware (Wire Rope Clips and Wedge Sockets)

Rings, Links and Swivels

Rigging Blocks

Rigging Hardware

Shac k l es

CMCO:Rigging Training

2

Copyright

2010

Screw pin shackles continued

MOUSE TAIL SHACKLE IF IT REMAINS IN

PLACE FOR ANY EXTENDED PERIOD OF TIME.

THIS WILL PREVENT PIN FROM BACKING OUT

How tight does the pin need to be?

The pin must be tightened hand tight or until pin

head is fully seated against the body of the shackle.

It may be necessary to tighten an additional 1/8 turn

to ensure proper engagement . . Do not back the

pin off the body of the shackle.

Screw pin anchor style

Screw Pin Anchor/Chain Shackles allow quick

and easy removal of the screw pin and can be

useful in applications where the shackle is

frequently removed, but not so much in

applications where the pin is subject to torque

or twisting or cyclically loaded.

Round pin chain Anchor style

Allow easy removal of pin by removing cotter pin and

perform well where pin is subject to torque or twisting,

but not so much in applications where pin is subject to

an axial load. Do not use for Rigging! !

Bolt & Nut Cotter Anchor style

Provide the most secure pin arrangement and

will resist axial loading and torsional loading, but

should only be used in applications where

shackle is infrequently or never removed.

Rigging Hardware

Shac k l es

CMCO:Rigging Training

3

Copyright

2010

SHACKLES

One of the safest and easiest ways to attach

to a load. They provide a positive attachment

for slings, hoists or cranes to connect to load.

DO NOT EXCEED 120

0

INCLUDED ANGLE

WHEN USING

MULTIPLE SLING LEGS

120

0

MAXIMUM

90

0

LOAD

V

E

R

T

I

C

A

L

(

I

N

L

I

N

E

)

L

O

A

D

BOLT NUT COTTER

TYPE SHACKLE

45

0

LOAD

DO NOT SIDE LOAD ROUND PIN SHACKLES

ANGLE OF SIDE LOAD

0

0

VERTICAL OR IN LINE 100% WLL

45

0

70% WLL

90

0

50% WLL

SYMMETRICAL LOADING

Shackles symmetrically loaded with two

legs at maximum angle of 120

0

can be

used to full working load limit.

CAUTION: Round pin anchor shackles

and round pin chain shackles that only

use cotter pins for retainers must not be

used for overhead lifting. The retainers

are not designed to withstand the load

applied on them in a rigging application.

Rigging Hardware

Shac k l es

CMCO:Rigging Training

4

Copyright

2010

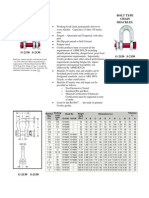

The bow diameter is how a

shackle is specified and marked.

The WLL of shackles diameters to not

match up with working load limits of

chain diameters. You need to look at

the WLL of the shackle if you are

matching them up with an equal WLL

chain size.

SAME DIAMETER SHACKLES CAN HAVE

DIFFERENT RATINGS

Rigging Hardware

Shac k l es

CMCO:Rigging Training

5

Copyright

2010

Shackle Body Markings: ASME B30.26

name or trademark of manufacturer

rated load

size (diameter of body)

Below are markings you will find on a 1 dia. Shackle:

M M

MIDLAND FORGE TRADEMARK MIDLAND FORGE TRADEMARK

Carbon

Super Carbon

Alloy

ALWAYS USE MARKING ON SHACKLE BODY TO IDENTIFY W.L.L.

DO NOT USE DIAMETER TO DETERMINE W.L.L.

SHACKLES CAN BE MADE FROM

CARBON

SUPER CARBON

ALLOY

ALL HAVE DIFFERENT W.L.L. LIMITS

REQUIRED SHACKLE MARKINGS

Rigging Hardware

Shac k l es

CMCO:Rigging Training

6

Copyright

2010

REQUI RED SHACKLE MARKI NGS

SHACKLE PIN IDENTIFICATION: ASME B30.26

END OF SCREW PIN END OF ROUND PIN END OF HEX HEAD

name or trademark of manufacturer

grade, material type or load rating

NOTE:

ALL CM SHACKLES, REGARDLESS

OF TYPE, HAVE HIGH STRENGTH

PINS. (Alloy quenched and tempered)

The pin or bolt of the shackle is what is embossed with HS

The body is not marked HS

This meets the requirements of Federal Specification RRC-271D

MANUFACTURE

TRACE CODE

HS High Strength

Rigging Hardware

Shac k l es

CMCO:Rigging Training

7

Copyright

2010

ASME B30.26

DISCARD SHACKLES IF:

Any parts worn more than 10% of original

dimensions

Bent, twisted, distorted, stretched, elongated,

cracked, or broken load bearing components.

Excessive pitting or corrosion, nicks or gouges

Indication of heat damage

Missing or illegible manufactures name or

trademark or rated load identification

Body spread

Makeshift or sub standard pins not supplied by

original manufacturer.

Any field modification is evident

.

.

WEAR AREA

PIN

DISTORTION

AND WEAR

SPREAD

PIN FULLY

SEATED

Rigging Hardware

Shac k l es

You might also like

- Rigging and Slinging Training Course (2)Document187 pagesRigging and Slinging Training Course (2)nbih mrou100% (1)

- Gunnebo Lifting Shackle Catalogue 2010Document16 pagesGunnebo Lifting Shackle Catalogue 2010ofitec787No ratings yet

- Crosby ShacklesDocument12 pagesCrosby Shacklesj_herndzNo ratings yet

- G-2130 / S-2130 Bolt Type Anchor ShacklesDocument1 pageG-2130 / S-2130 Bolt Type Anchor Shacklesramy abazaNo ratings yet

- Crosby Catalog 2008 - Page 76 To 88Document13 pagesCrosby Catalog 2008 - Page 76 To 88Prejit RadhakrishnaNo ratings yet

- Crosby Shackle Cotter Pin GuideDocument2 pagesCrosby Shackle Cotter Pin Guidesdb15840% (5)

- S G209 CrosbyDocument1 pageS G209 CrosbyJS168No ratings yet

- LEEA Correspondence Courses: Assignment 1.9Document3 pagesLEEA Correspondence Courses: Assignment 1.9Primelift Safety Resources LimitedNo ratings yet

- Industrial Safety of Lifting ProcedureDocument83 pagesIndustrial Safety of Lifting Proceduresaravanan_c1No ratings yet

- Whip ChecksDocument2 pagesWhip ChecksherlandscNo ratings yet

- BVM Corporation Maintenance Manual: 4-1/2 - 14" Casing Spider / ElevatorDocument40 pagesBVM Corporation Maintenance Manual: 4-1/2 - 14" Casing Spider / ElevatorAnang SakraniNo ratings yet

- February 2013 Wire Rope ExchangeDocument84 pagesFebruary 2013 Wire Rope ExchangeWire Rope ExchangeNo ratings yet

- McKissick - 431 Super Champion Snatch Block W Shackle Specs Lengkap Dengan PerhitungannyaDocument9 pagesMcKissick - 431 Super Champion Snatch Block W Shackle Specs Lengkap Dengan PerhitungannyaChusnadiNo ratings yet

- Crosby ShacklesDocument6 pagesCrosby Shacklessabah8800No ratings yet

- Crosby G-2130 Shackle Data Sheet PDFDocument1 pageCrosby G-2130 Shackle Data Sheet PDFdavidandrewleggNo ratings yet

- Spider Elevator B+V Forum CatalogDocument40 pagesSpider Elevator B+V Forum CatalogIRWIN_DSOUZA100% (1)

- Drill Pipe - 114477340Document7 pagesDrill Pipe - 114477340Rüstəm Emrah QədirovNo ratings yet

- API CatalogueDocument20 pagesAPI CatalogueMadirley Pimenta100% (1)

- Safe Lifting PracticesDocument69 pagesSafe Lifting Practicesvikas verma100% (1)

- Wearlimitgauge PDFDocument1 pageWearlimitgauge PDFAbrar HussainNo ratings yet

- Safety Alert: Driller Inattention Results in Dropped BlocksDocument1 pageSafety Alert: Driller Inattention Results in Dropped Blockscase013No ratings yet

- Safety Alert: From The International Association of Drilling ContractorsDocument1 pageSafety Alert: From The International Association of Drilling ContractorsJohnHynesNo ratings yet

- Catalog BVE BVS 500 Air Operated ElevatorSpiderDocument62 pagesCatalog BVE BVS 500 Air Operated ElevatorSpideryelmustafaaliNo ratings yet

- BVM Corporation Maintenance Manual: Series "S" ElevatorDocument11 pagesBVM Corporation Maintenance Manual: Series "S" ElevatorAnang SakraniNo ratings yet

- Crosby ShackleDocument1 pageCrosby ShacklevrandyNo ratings yet

- Ipss Handbook PDFDocument45 pagesIpss Handbook PDFSarbendu Paul100% (1)

- Safety Alert: Tong Incident Results in A FatalityDocument1 pageSafety Alert: Tong Incident Results in A FatalityVimal SinghNo ratings yet

- Rig Equipment Inspection FloatingDocument4 pagesRig Equipment Inspection FloatingSiva100% (1)

- API 8 Round 23Document4 pagesAPI 8 Round 23walid ben khedherNo ratings yet

- Rigger Training Stages 1 and 2 Valid From 4th of May 2015Document57 pagesRigger Training Stages 1 and 2 Valid From 4th of May 2015aymenmoatazNo ratings yet

- Rutong DH 吊环使用说明书(ZY)2013 links - 1Document3 pagesRutong DH 吊环使用说明书(ZY)2013 links - 1QAMAR ALI KHANNo ratings yet

- ABS-Lifting Appliances Guide E-May17 PDFDocument232 pagesABS-Lifting Appliances Guide E-May17 PDFLeonardo Lannes VieiraNo ratings yet

- Ingersollrand Ajuste IndustrialDocument40 pagesIngersollrand Ajuste Industrialarturolachira176100% (1)

- Safe Rigging PresentationDocument46 pagesSafe Rigging PresentationSachin SahooNo ratings yet

- Wire Rope ConstructionsDocument34 pagesWire Rope ConstructionsrustamriyadiNo ratings yet

- Tubular Running Services ItemisedDocument10 pagesTubular Running Services ItemisedNoel JenningsNo ratings yet

- F4a 2020 LEEA Assessments - Information For Members Students Nov 2019Document4 pagesF4a 2020 LEEA Assessments - Information For Members Students Nov 2019VishnuNo ratings yet

- Wire GuideDocument28 pagesWire GuideRuben Bartolome GarciaNo ratings yet

- Drill String ComponentsDocument8 pagesDrill String ComponentsMUHAMMED FUADNo ratings yet

- 801 I.1.3 Man Rider Winch Product Maintenance InformationDocument14 pages801 I.1.3 Man Rider Winch Product Maintenance InformationPedro SanchezNo ratings yet

- BPcraneLifting North Sea Rules OffshoreDocument56 pagesBPcraneLifting North Sea Rules Offshorebwadsager75% (4)

- Gunnebo 2000Document36 pagesGunnebo 2000Ed CalheNo ratings yet

- Shear Force For SBRDocument14 pagesShear Force For SBRnjava1978No ratings yet

- Krulex Services Limited: InternationalDocument5 pagesKrulex Services Limited: InternationalikponmwonsaNo ratings yet

- 9094 01 HVG Catalogus - TAB - 8 Lifting Rigging Gears PDFDocument267 pages9094 01 HVG Catalogus - TAB - 8 Lifting Rigging Gears PDFZiaul HaqueNo ratings yet

- Data Sheet Brake MalacateDocument10 pagesData Sheet Brake MalacateAnonymous ciu3QEjuS100% (1)

- Rig Catalog PDF FreeDocument52 pagesRig Catalog PDF FreeIsrael VenancioNo ratings yet

- 2004 Oil CountryDocument26 pages2004 Oil CountryYina Useche100% (1)

- Shackle Marking Information PDFDocument7 pagesShackle Marking Information PDFparkerworkerNo ratings yet

- Toggle ClampsDocument84 pagesToggle ClampsSamik Mukherjee0% (1)

- Devices For Distribution Lines - ENDocument8 pagesDevices For Distribution Lines - ENHukic77No ratings yet

- Beams Spreader PDFDocument4 pagesBeams Spreader PDFravikumarangNo ratings yet

- Elevator Ropes IPHDocument8 pagesElevator Ropes IPHAbhishek SahaNo ratings yet

- MAZZ-Alloy Chain Slings Type Terms GuideDocument6 pagesMAZZ-Alloy Chain Slings Type Terms GuideGustavo ArancibiaNo ratings yet

- Belting Correia de BorrachaDocument54 pagesBelting Correia de BorrachaFilype NascimentoNo ratings yet

- (CarrLane) Fullproductcatalogpdf-2017Document701 pages(CarrLane) Fullproductcatalogpdf-2017Diogo_23No ratings yet

- Wire Rope Hoist Wire Rope Hoist: Lift & Connect SafelyDocument20 pagesWire Rope Hoist Wire Rope Hoist: Lift & Connect SafelyFiroz PawaskarNo ratings yet

- Strutfast Steelwork Connections LRDocument7 pagesStrutfast Steelwork Connections LRzimtonyNo ratings yet

- General Information: Toggle-Action PrinciplesDocument1 pageGeneral Information: Toggle-Action PrinciplescontrolorNo ratings yet

- Module 2 - CouplingsDocument18 pagesModule 2 - CouplingsthandonksNo ratings yet

- Logiqids Sample Paper KG FinalDocument15 pagesLogiqids Sample Paper KG FinalJuber Farediwala82% (17)

- BarleyDocument18 pagesBarleyPrince KambojNo ratings yet

- History of ArtsDocument122 pagesHistory of ArtsSherian AndradeNo ratings yet

- Submission Fighting and The Rules of Ancient Greek WrestlingDocument35 pagesSubmission Fighting and The Rules of Ancient Greek WrestlingIgnacioPérezBurgaréNo ratings yet

- Unit 3 - Fem CST Element Notes-1Document14 pagesUnit 3 - Fem CST Element Notes-1catchmesugan7No ratings yet

- Chapter 13-pDocument9 pagesChapter 13-paravindkbNo ratings yet

- Functions in C - HackerRankDocument1 pageFunctions in C - HackerRankTeenie Weenie TitansNo ratings yet

- Arduino DAQ SystemDocument34 pagesArduino DAQ SystemVesa RäisänenNo ratings yet

- Reviewer in ItDocument4 pagesReviewer in ItAnne Thea AtienzaNo ratings yet

- S4H - 1614 Implementing SAP S4HANA Cloud Private EditionDocument12 pagesS4H - 1614 Implementing SAP S4HANA Cloud Private EditionYasai MoyashiNo ratings yet

- Pune Metro EIA ReportDocument357 pagesPune Metro EIA ReportSumeet Hulugade100% (1)

- A Mobile-Based Departmental Examination Scheduler For New Era University StudentsDocument7 pagesA Mobile-Based Departmental Examination Scheduler For New Era University StudentsarnaldyNo ratings yet

- Are There Any Legal Implications To Be Aware of As A Result of This Selection DecisionDocument2 pagesAre There Any Legal Implications To Be Aware of As A Result of This Selection DecisionVikram Kumar100% (1)

- Class 2 - Parts of Speech PDFDocument10 pagesClass 2 - Parts of Speech PDFmahesh kumarNo ratings yet

- Pet SemataryDocument7 pagesPet Semataryapi-721737905No ratings yet

- Brazing Procedure Specification (BPS) : JOINTS (QB-408)Document1 pageBrazing Procedure Specification (BPS) : JOINTS (QB-408)Bernard PenuliarNo ratings yet

- Model Exam 1Document25 pagesModel Exam 1rahelsewunet0r37203510No ratings yet

- The Financial Expert: One Word Questions and AnswersDocument3 pagesThe Financial Expert: One Word Questions and AnswersSadaHasiruNo ratings yet

- RIGHT TO BAIL Case DoctrinesDocument37 pagesRIGHT TO BAIL Case DoctrinesEileen MañiboNo ratings yet

- En DECKING Installation Guide DeckingDocument15 pagesEn DECKING Installation Guide DeckingMinh LinhTinhNo ratings yet

- Critical Growth StagesDocument3 pagesCritical Growth StagesSunil DhankharNo ratings yet

- IJICRDocument6 pagesIJICRrkkoiriNo ratings yet

- Operating Manual MSF220V (VU) : - PTC-resistor RelayDocument8 pagesOperating Manual MSF220V (VU) : - PTC-resistor RelayMarko Maky ZivkovicNo ratings yet

- Management Assignment (14 Principles0Document9 pagesManagement Assignment (14 Principles0Deepak Rajoriya100% (1)

- Find The Ratio of The Smaller To Larger of The Two Consecutive Even Numbers Whose Sum Is 26Document10 pagesFind The Ratio of The Smaller To Larger of The Two Consecutive Even Numbers Whose Sum Is 26Anonymous EvbW4o1U7No ratings yet

- Transformer Schneider 1600 KVADocument1 pageTransformer Schneider 1600 KVALe HuyNo ratings yet

- Stage2412 DMX Manual-EnDocument36 pagesStage2412 DMX Manual-Enisasro1458No ratings yet

- Jose Rizal Group 2Document25 pagesJose Rizal Group 2Blee TecsonNo ratings yet

- Letter of Rec For Griselda Zaragoza-OrtizDocument1 pageLetter of Rec For Griselda Zaragoza-Ortizapi-403578442No ratings yet

- Asco E398a005Document2 pagesAsco E398a005ersanjeeb_456No ratings yet