Professional Documents

Culture Documents

Spetospir SWZ PTFE 4,8mm Revision 1 (2012!05!24)

Spetospir SWZ PTFE 4,8mm Revision 1 (2012!05!24)

Uploaded by

Dieter BuysseCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Spetospir SWZ PTFE 4,8mm Revision 1 (2012!05!24)

Spetospir SWZ PTFE 4,8mm Revision 1 (2012!05!24)

Uploaded by

Dieter BuysseCopyright:

Available Formats

Company Address

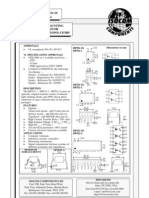

C.S.U.T. SPETECH Sp. z o.o., ul. Szyprow 17, 43-382 Bielsko-Biala, Poland

Gasket Type

Spetospir SWZ PTFE

Sealing element dimensions [mm]

72 x 56 x 4,8

Remark

all tests were done with a load rate of 0.5 MPa/s

Minimum stress to seal Qmin/L (at assembly), QSmin/L (after off-loading) for p = 40 bar

L [mg/(s*m)]

QSmin/L [MPa]

Qmin/L [MPa]

QA= 20 MPa

QA= 40 MPa

QA= 60 MPa

QA= 80 MPa

QA= 100 MPa

QA= 120 MPa

QA= 140 MPa

QA= 160 MPa

10-0

10

10

10

10

10

10

10

10-1

10

10

10

10

10

10

10

10-2

10

10

10

10

10

10

10

10-3

15

10

10

10

10

11

11

10-4

39

14

10

12

16

16

10-5

57

43

19

21

25

10-6

95

79

79

10-7

10-8

Leakage - ambient temperature / inner pressure = 40 bar

1E+0

loading curve

unloading curve

Qmin/Qsmin

1E1

leakrate[mg/(s*m)]

1E2

1E3

1E4

1E5

1E6

1E7

0

20

40

60

Note: the content of darkened cells was not determined respectively is unnecessary

80

100

gasketstress[MPa]

Rev - No: 1

120

140

Creation date of this sheet:

160

180

24.05.2012

page 1 of 2

Center of Sealing Technologies, Brgerkamp 3, 48565 Steinfurt, Germany

Company Address

C.S.U.T. SPETECH Sp. z o.o., ul. Szyprow 17, 43-382 Bielsko-Biala, Poland

Gasket Type

Spetospir SWZ PTFE

Sealing element dimensions [mm]

72 x 56 x 4,8

Remark

all tests were done with a load rate of 0.5 MPa/s

Relaxation ratio PQR for stiffness C = 500 kN/mm

Gasket stress [MPa]

ambient temperature

temperature 1 [100 C]

temperature 2 [250 C]

Stress level 1 [50 MPa]

0,94

0,95

1,00

Stress level 2 [150 MPa]

0,94

0,85

0,81

PQR at QSmax

0,95 at 200 MPa

0,84 at 200 MPa

0,83 at 200 MPa

Maximal applicable gasket stress QSmax

QSmax [MPa]

QSmax [MPa] temperature 1

QSmax [MPa] temperature 2

ambient temperature

[100 C]

[250 C]

200

200

200

Sekant unloading modulus of the gasket EG [MPa] and gasket thickness eG [mm]

ambient temperature

Gasket stress [MPa]

EG [MPa]

eG [mm]

20

1459

30

40

temperature 1 [100 C]

EG [MPa]

eG [mm]

4,494

1571

2414

4,441

3448

4,405

50

4368

60

temperature 2 [250 C]

EG [MPa]

eG [mm]

4,476

881

4,526

2674

4,445

1655

4,504

3568

4,416

2276

4,470

4,376

4397

4,391

2772

4,434

5070

4,349

4944

4,369

3148

4,390

80

5795

4,301

5473

4,322

3396

4,259

100

5999

4,248

5555

4,255

3581

4,124

120

5612

4,110

5250

3,996

3650

3,921

140

5389

3,915

5001

3,723

3865

3,742

160

5546

3,710

5426

3,585

4178

3,599

180

5975

3,559

5914

3,478

4674

3,511

200

6544

3,452

6404

3,386

5249

3,450

0

1

4,959

4,918

4,972

Gasket thickness eG

5,1

ambient temperature

100[C]

250[C]

4,9

gasketthikness[mm]

4,7

4,5

4,3

4,1

3,9

3,7

3,5

3,3

0

20

40

60

80

Note: the content of darkened cells was not determined respectively is unnecessary

100

gasketstress[MPa]

120

Rev - No: 1

140

160

Creation date of this sheet:

180

200

24.05.2012

page 2 of 2

Center of Sealing Technologies, Brgerkamp 3, 48565 Steinfurt, Germany

You might also like

- James Walker Metaflex SGIR - SPG Revision 0 (2009!05!11)Document1 pageJames Walker Metaflex SGIR - SPG Revision 0 (2009!05!11)Dieter BuysseNo ratings yet

- APM4305KDocument10 pagesAPM4305KvannadioNo ratings yet

- Micropower, Rail-to-Rail Input and Output Operational Amplifiers OP196/OP296/OP496Document16 pagesMicropower, Rail-to-Rail Input and Output Operational Amplifiers OP196/OP296/OP496Ram NiwasNo ratings yet

- PM4018MUDocument11 pagesPM4018MUaldo_suviNo ratings yet

- Apm2558nu 2Document10 pagesApm2558nu 2minhchatnguyenNo ratings yet

- Installation Manual: Switzerland (Head Office) New ZealandDocument20 pagesInstallation Manual: Switzerland (Head Office) New ZealandTelapia MaachNo ratings yet

- SUPERtwin 2015Document2 pagesSUPERtwin 2015RaulFernandoMurilloSilvaNo ratings yet

- Upvc Pipe FittingDocument38 pagesUpvc Pipe FittingRiyas UdheenNo ratings yet

- Mc78Lxxa / Lm78Lxxa 3-Terminal 0.1 A Positive Voltage RegulatorDocument13 pagesMc78Lxxa / Lm78Lxxa 3-Terminal 0.1 A Positive Voltage RegulatorleolayonerNo ratings yet

- N-Channel JFET General Purpose AmplifierDocument1 pageN-Channel JFET General Purpose AmplifierDaniela Cardenas LuboNo ratings yet

- Cimberio 3790 Automatic Balancing Valve2Document3 pagesCimberio 3790 Automatic Balancing Valve2Quynh NguyenNo ratings yet

- Leser Certificate For Global ApplicationDocument2 pagesLeser Certificate For Global ApplicationThiago Souza da SilvaNo ratings yet

- Polypac Special SealsDocument30 pagesPolypac Special SealsMarko AleksicNo ratings yet

- Octal 3-State Noninverting Transparent Latch: SL74HC573Document5 pagesOctal 3-State Noninverting Transparent Latch: SL74HC573Prayu GarnurmNo ratings yet

- Leser Certificate For Global ApplicationDocument2 pagesLeser Certificate For Global ApplicationThiago Souza da SilvaNo ratings yet

- Apm 2030Document10 pagesApm 2030jnuñez_59No ratings yet

- 2N4393 TransistorDocument2 pages2N4393 TransistorJuan Carlos Arellano BeltránNo ratings yet

- Buzzer LPB4333SDocument4 pagesBuzzer LPB4333SAlex GribbinNo ratings yet

- ASME SA234 - 2013 WPB: ASTM A234 - I 3e 1 WPB: ASME 816.9-2012 / ASME 816.25-2012 BS EN 10204 3. 1-2004Document1 pageASME SA234 - 2013 WPB: ASTM A234 - I 3e 1 WPB: ASME 816.9-2012 / ASME 816.25-2012 BS EN 10204 3. 1-2004Omar Bautista Díaz100% (1)

- Venta: Two-Way Pressure Balanced Valve PN 16 (232 Psi)Document5 pagesVenta: Two-Way Pressure Balanced Valve PN 16 (232 Psi)DedeKurniawanNo ratings yet

- SW2213 Ab TDSDocument4 pagesSW2213 Ab TDSمحمد عبدالرحيمNo ratings yet

- MC14516B Binary Up/Down Counter: Marking DiagramsDocument11 pagesMC14516B Binary Up/Down Counter: Marking DiagramsSreejita MajumderNo ratings yet

- SSC W FemaleDocument3 pagesSSC W FemaleshyhuNo ratings yet

- Characteristic TestDocument1 pageCharacteristic TestLam NguyenNo ratings yet

- Igbt ChryslerDocument8 pagesIgbt ChryslerFer NandoNo ratings yet

- Go STC4606Document8 pagesGo STC4606briatmaNo ratings yet

- Series: Chip Type, Extra Low ImpedanceDocument13 pagesSeries: Chip Type, Extra Low ImpedanceselocaNo ratings yet

- CV Calculation Sheet - 5 NovDocument11 pagesCV Calculation Sheet - 5 NovAmarnath YadavNo ratings yet

- OPA128Document11 pagesOPA128अमरेश झाNo ratings yet

- APM2556NUDocument11 pagesAPM2556NULullaby summerNo ratings yet

- ProductGuide913120 en Grey 2014.LRDocument32 pagesProductGuide913120 en Grey 2014.LRmevisuNo ratings yet

- Difet: OPA627 OPA637Document23 pagesDifet: OPA627 OPA637Sachin Ten100% (1)

- CRV Foot Valve Catalogue PDFDocument2 pagesCRV Foot Valve Catalogue PDFsathishNo ratings yet

- CTJ 10 10 3004 BK PX FSDocument14 pagesCTJ 10 10 3004 BK PX FSwebmaster5813No ratings yet

- THHN THWN 2 Unscreened CableDocument3 pagesTHHN THWN 2 Unscreened CableСергей КозловNo ratings yet

- Danfoss Kps SwitchesDocument13 pagesDanfoss Kps Switchescheng207No ratings yet

- STK404-120N-E: 1ch class-AB Audio Power IC 120WDocument11 pagesSTK404-120N-E: 1ch class-AB Audio Power IC 120WgapjgNo ratings yet

- MDFO UK LowDocument17 pagesMDFO UK Lowmsn86No ratings yet

- SM4833NSK PDFDocument10 pagesSM4833NSK PDFsike1977100% (1)

- B 804 AbffaDocument10 pagesB 804 Abffaev4540064No ratings yet

- Ne5534 PDFDocument7 pagesNe5534 PDFJhelson CondeNo ratings yet

- RC Unit, Class X2, Metallized Paper With Integrated Resistor - 0.047 - 0.47 F, 22 - 470, 250 VAC, +85 °CDocument2 pagesRC Unit, Class X2, Metallized Paper With Integrated Resistor - 0.047 - 0.47 F, 22 - 470, 250 VAC, +85 °CantonioNo ratings yet

- P521Document3 pagesP521ge_bdNo ratings yet

- Transformer Presentation VftoDocument28 pagesTransformer Presentation VftoAlberto Tupac YupanquiNo ratings yet

- FR4Document2 pagesFR4Luis MárquezNo ratings yet

- Sensors & Input Devices: SpecificationsDocument4 pagesSensors & Input Devices: SpecificationsHussein AkilNo ratings yet

- 8 Bit Shift Register With Output Latches (3 State) : Order CodesDocument16 pages8 Bit Shift Register With Output Latches (3 State) : Order CodesQuyet Pham DangNo ratings yet

- Norseman Nordic Void Technical & Submittal Information December 2014Document22 pagesNorseman Nordic Void Technical & Submittal Information December 2014Rajdip GhoshNo ratings yet

- Heavy Duty Gas Filled Capacitors - 1Document4 pagesHeavy Duty Gas Filled Capacitors - 14usangeetNo ratings yet

- Pilot Run Report 0702Document23 pagesPilot Run Report 0702Greg MackeyNo ratings yet

- Series 008PCQT Specification SheetDocument2 pagesSeries 008PCQT Specification SheetWattsNo ratings yet

- AMP02Document12 pagesAMP02ivan bragaNo ratings yet

- STP100-101 DatasheetDocument4 pagesSTP100-101 DatasheetNATHANNo ratings yet

- Regulador de Tension 78T05Document7 pagesRegulador de Tension 78T05William Yesid Rodriguez MuñozNo ratings yet

- Sizing Cable MotorDocument65 pagesSizing Cable MotorDoly DamanikNo ratings yet

- Data SheetDocument10 pagesData SheetAnonymous phg4RBNo ratings yet

- Anpec Electronics Corporation Apm4115pu E9dfa47844Document11 pagesAnpec Electronics Corporation Apm4115pu E9dfa47844Flaviano Costa SilvaNo ratings yet