Professional Documents

Culture Documents

Equipment Certification Guide For Hazardous Areas

Equipment Certification Guide For Hazardous Areas

Uploaded by

limresOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Equipment Certification Guide For Hazardous Areas

Equipment Certification Guide For Hazardous Areas

Uploaded by

limresCopyright:

Available Formats

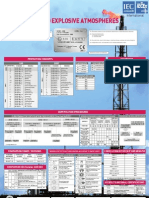

Explosion Protection Concepts

Type of

Protection

Code Basic concept of

protection

Class

Typical

Division / Zone

Applicable

Standard

Protection of Electrical Equipment for Gases and Vapours Class I

Flameproof AEx d Class 1 Zone 1, 2 ISA 600791

Explosion proof XP Class 1 Division 1 UL1203

Enclosed Break AEx nC

Contain the

explosion

Class 1 Zone 2 ISA 6007915

Increased Safety AEx e Class 1 Zone 1, 2 ISA 600797

Non Sparking AEx nA Class 1 Zone 2 ISA 6007915

Non Incendive NI

No arcs, sparks or

hot surfaces

Class 1 Division 2 ISA 12.12.01 / FM3611

Sand Filled AEx q Quench the flame Class 1 Zone 1, 2 ISA 600795

AEx ia Class 1 Zone 0, 1, 2

AEx ib Class 1 Zone 1, 2

ISA 6007911

Intrinsic Safety

IS Class 1 Division 1 UL913 / FM3610

Limited Energy AEx nC

Limit circuit

energy and hot

surfaces

Class 1 Zone 2 ISA 6007915

AEx m Class 1 Zone 1, 2

AEx ma Class 1 Zone 0, 1, 2 Encapsulation

AEx mb Class 1 Zone 1, 2

ISA 6007918

Oil Filled AEx o Class 1 Zone 1, 2 ISA 600796

Type X Class 1 Division 1

Type Y Class 1 Division 1

Type Z Class 1 Division 2

NFPA 496 / FM3620

AEx px Class 1 Zone 1

AEx px Class 1 Zone 1

Pressurised

AEx px Class 1 Zone 2

ISA 600792

Restricted

Breathing

AEx nR

Exclude fuel

Class 1 Zone 2 ISA 6007915

Protection of Electrical Equipment for Combustible Dust Class II & III

Dust Ignition

Proof

DIP Class II Division 1 & 2 UL1203

Dust Protected NI Class II Division 2 ISA 12.12.01 / FM3611

Protection by

Enclosure

AEx tD Class II Zone 2

ISA 6007931

AEx maD

Exclude

combustible dust

Zone 20, 21, 22

Encapsulation

AEx mbD Zone 21, 22

ISA 6124118

AEx iaD Zone 20, 21, 22

AEX ibD Zone 21, 22

ISA 6124111

IS Class II Division 1

Intrinsic Safety

IS

Limit circuit

energy and hot

surfaces

Class III Division 1

UL 913 / FM3610

Explosion Protection Concepts

Type of Protection Symbol

Basic Concept of

Protection

Typical

Zone(s)

Gas

Group

IEC/EN

Standard

Typical

IEC EPL

Protection of Electrical Equipment for Gases and Vapours G

Flameproof d 1,2 600791 Gb

Enclosed Break nC

Contain the

explosion 2

II

6007915 Gc

Increased Safety e 1, 2 600797 Gb

Non Sparking nA

No arcs, sparks or

hotsurfaces.

Enclosure IP54 2

II

6007915 Gc

ia 0, 1, 2 Ga

ib 1, 2 Gb Intrinsic Safety

ic

limit circuit energy

and hot surfaces

2

II 6007911

Gc

ma 0, 1, 2 Ga

mb 1, 2 Gb Encapsulation

mc 2

6007918

Gc

Sealed/Hermetic Sealing nC 2 Gc

Restricted Breathing nR 2

6007915

Gc

Oil Filled o 1, 2 600796 Gb

px 1, 2 Gb

py 1, 2 Gb Pressurised

pz

Exclude fuel

2

II

600792

Gc

Sand Filled q Quench the flame 1, 2 II 600795 Gb

OP sh 0, 1, 2 Ga

Op is 0, 1, 2 Ga Optical Radiation

Op pr

Inherently safe

1, 2

II 6007928

Gb

Protection of Electrical Equipment for Combustible Dusts D

ta 20, 21, 22 Da

tb 21, 22 Db Enclosure

tc

Exclude dusts by

use of enclosure

21, 22

III 6007931

Dc

iaD 20, 21, 22 Da

ibD 21, 22 Db Intrinsic Safety

icD

Use of enclosure

and energy

limitation 21, 22

III 6124111

Dc

ma 20, 21, 22 Da

mb 21, 22 Db Encapsulation

mc

Exclude dust

21, 22

6007918

Dc

General requirements Covers application and testing related to above protection methods

Equipment Certification Guide for Hazardous Areas

Typical ATEX and IEC Ex Equipment Marking

Ex II 2 G Ex e IIC T4 Gb

S

p

e

c

ific

m

a

r

k

in

g

fo

r

e

x

p

lo

s

io

n

p

r

o

t

e

c

t

io

n

*

E

q

u

ip

m

e

n

t

G

ro

u

p

*

E

q

u

ip

m

e

n

t

C

a

t

e

g

o

r

y

*

E

n

v

ir

o

n

m

e

n

t

*

E

x

p

lo

s

io

n

P

r

o

t

e

c

t

io

n

T

y

p

e

o

f

P

r

o

t

e

c

t

io

n

G

a

s

G

r

o

u

p

T

e

m

p

e

r

a

t

u

r

e

C

la

s

s

E

q

u

ip

m

e

n

t

P

ro

t

e

c

t

io

n

L

e

v

e

l

For ATEX certified equipment, the CE mark should be shown, along with the relevant Notified Body number, where applicable.

*Required for ATEX only

Ingress Protection Ratings (EN60529/IEC529)

First Numeral

Protection from Solid Bodies

Second Numeral

Protection from Liquids

Third Numeral*

Protection from Impact

0 No special protection 0 No special protection 0 No special protection

1

Large foreign bodies, diam.

>50mm

1

Water dripping/falling

vertically

1

Protected against 0.225J

impact

2

Mediumsized foreign

bodies, diam. >12mm

2

Water dripping/falling at an

angle (up to 15 degrees from

the vertical)

2

Protected against 0.375J

impact

3

Small foreign bodies, diam.

>2.5mm

3

Spray water (any direction up

to 60 degrees from the

vertical)

3 Protected against 0.5J impact

4

Granular foreign bodies,

diam. >1mm

4

Spray/splashing water from all

directions, (limited ingress

permitted)

4 Protected against 2.0J impact

5

Dust protected; dust

deposits are permitted, but

their volume must not affect

the function of the unit.

5

Lowpressure water jets from

all directions, (limited ingress

permitted)

5 Protected against 6.0J impact

6 Complete protection 6

High pressure jets from all

directions

6

Protected against 20.0J

impact

7

Temporary immersion, 1m for

30 minutes

8

Permanent Immersion or

defined pressure**

* Third numeral impact is optional and need not be shown.

** Second numeral 8 is defined as submersion at a depth and length of time to be agreed between manufacturer and user

Typical NEC Equipment Marking

Class 1 Division 1

Group

A,B,C

T3

P

e

r

m

it

t

e

d

C

la

s

s

P

e

r

m

it

t

e

d

D

iv

is

io

n

G

a

s

G

r

o

u

p

T

e

m

p

e

r

a

t

u

r

e

C

la

s

s

NEC 500

Class 1 Zone 1 AEx d IIC T3

P

e

r

m

it

t

e

d

C

la

s

s

P

e

r

m

it

t

e

d

Z

o

n

e

A

m

e

r

ic

a

n

S

t

a

n

d

a

r

d

P

r

o

t

e

c

t

io

n

C

o

n

c

e

p

t

G

a

s

G

r

o

u

p

T

e

m

p

e

r

a

t

u

r

e

C

la

s

s

NEC 505

NEMA Enclosure Type Ratings

Type Area of Use Description

1 Indoor General Purpose

2 Indoor Drip Proof Protection against falling water and dirt

3

Indoor/Outdoor Dust & Rain Tight Protection against windblown dust, rain, and sleet &

damage from formation of ice

3R

Outdoor Rain Proof & Ice/Sleet Proof protection against falling rain & damage from

formation of ice

3S

Outdoor Dust Tight, Rain Tight, & Ice/Sleet Proof Protection against sleet and

damage from formation of ice

4 Indoors/Outdoors Water Tight & Dust Tight

4X

Indoors/Outdoors Water Tight, Dust Tight, & Corrosion Resistant Protection from corrosion,

hose directed water and damage from formation of ice

5

Indoor Dust Tight & Drip Tight protection against dust, fibres, falling dirt, and

dripping noncorrosive liquids

6

Indoors/Outdoors Temporary Submersion protection against falling dirt, dust, fibres, hose

directed water and temporary submersion in water.

6P

Indoors/Outdoors Prolonged Submersion protection against falling dirt, dust, fibres, hose

directed water and prolonged submersion in water.

12

Indoor Dust Tight & Drip Tight protection against dust, fibres, falling dirt, and

dripping noncorrosive liquids (enclosure without knockouts)

12K

Indoor Dust Tight & Drip Tight protection against dust, fibres, falling dirt, and

dripping noncorrosive liquids (enclosure with knockouts)

13

Indoor Dust Tight & Oil Tight protection against dust, spraying of water, oil, and

noncorrosive coolant.

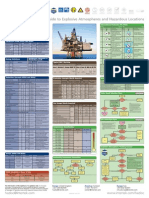

North America ATEX and IEC Ex Comparison

Comparison of IP and NEMA Enclosure Ratings

Enclosure

Type

IP23 IP30 IP32 IP55 IP64 IP65 IP66 IP67

1

2

3

4

4X

6

12

13

This comparison is for guidance only. It is the responsibility of the user to ensure the

enclosure rating is suitable for the given application.

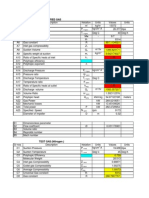

Temperature Classification

Max Surface

Temperature

ATEX/IEC* NEC 505 NEC 500

Max Surface

Temperature

450C T1 T1 T1 450C

300C T2 T2 T2 300C

T2A 280 C

T2B 260 C

T2C 230 C

T2D 215 C

200C T3 T3 T3 200C

T3A 180 C

T3B 165 C

T3C 160 C

135C T4 T4 T4 135C

T4A 120 C

100C T5 T5 T5 100C

85 T6 T6 T6 85

*For ATEX/IEC applications applies to Group II gases only. Group 1 applications have different classifications

Abtech is a leading manufacturer of enclosures, electrical

connection products, lighting and associated equipment.

Our product range consists of;

Hazardous Area enclosures and junction boxes

manufactured from stainless and mild Steel, GRP and

diecast aluminium.

High voltage junction boxes up to 35kV.

Cable glands and adaptors.

The Ablux range of hazardous area lighting.

Contact us for further details

www.abtech.eu

sales@abtech.eu

Zone 2

Zone 1

Zone 0

Zone 0

CENELEC Classification EN 6007910

IEC Classification IEC 60 07910

ATEX Classification ATEX Directive 94/9/EC

US Classification ANSI/INFPA70 NEC Article 505

Division 2

Division 1

Division 1

Division 1

US Classification ANSI/INFPA70 NEC Article 500

Classification of Zones and Divisions

Type of Area NEC ATEX and IEC Definition

Continuous

hazard Division 1

Zone 0 / Zone 20

explosive

atmosphere is

continually

present

Intermittent

hazard Division 1

Zone 1 / Zone 21

explosive

atmosphere is

likely to occur in

normal operation

Hazard under

abnormal

conditions

Division 2

Zone 2 / Zone 22

explosive

atmosphere is

unlikely to occur

but if it does, will

exist only for a

short period

Equipment intended for use in zone 1 areas cannot be used in Division 1 areas as this

covers zone 0 rated areas also.

About Abtech

Gas/Atmosphere Groups IEC Ex and ATEX

Group Environment Typical Location Typical Gas/Substance

I Underground Mining Underground Methane (Firedamp)

IIA Acetone, Methane, propane

IIB Ethylene, Hydrogen Sulphide

IIC

Gases

And

Vapours Above Ground

Hydrogen, Acetylene, Carbon Disulphide

IIIA Combustible fibres & flyings

IIIB Combustible dusts non conductive

IIIC

Combustible

Dusts

Above Ground

Combustible dusts conductive

Equipment Categories/Levels of Protection ATEX & IEC Ex

Equipment

Category ATEX

94/9/EC

Category

Equipment Protection

Level

Zone of Use

1G Ga Suitable for use in Zone 0, 1, 2

Category 1

1D Da Suitable for use in Zone 20, 21, 22

2G Gb Suitable for use in Zone 1, 2

Category 2

2D Db Suitable for use in Zone 21, 22

3G Gc Suitable for use in Zone 2

Category 3

3D Dc Suitable for use in Zone 22

Worldwide Agents

Located in the following countries;

Belgium

Denmark

Finland

France

Italy

Russia

Sweden

Oman

Qatar

Saudi Arabia

Asia

Abtech S.E Asia Pte Ltd

7 International Business Park

#0408

TechQuest Building

Singapore

609919

Tel: +65 656 79020

Fax: +65 656 70446

Email: sales@abtechasia.com

Abtech Korea

Astar Apt #1012801

DongRae Gu

OnChen Dong, Busan

South Korea

Tel: +82 708807 2137

Fax: +82 51553 2137

Email: sales@abtechkorea.com

North America

A.B Controls & Technology Inc.

1813 Rotary Drive

Humble

Texas

USA

TX77338

Tel: +001 281 5483424

Fax: +001 281 5483624

Email: sales@abtechinc.net

Abtech Limited

Sanderson Street

Lower Don Valley

Sheffield,

South Yorkshire

S9 2UA

United Kingdom

Tel: +44 (0) 114 244 2424

Fax: +44 (0) 114 243 4312

Email: sales@abtech.eu

Abtech Scotland

46 Telford Road

Lenziemill

Cumbernauld

G67 2AX

Abtech GmBH

Dnner Kirchweg 11

32257, Bnde, Germany

Tel: +49 (0) 522 375016

Fax: +49 (0) 522 375019

Email: sales@abtech.de

Abtech Nederland BV

Glasblazerstraat 1 2984 BL Ridderkerk,

Nederland

Tel: +31 (0) 180 428417

Fax: +31 (0) 180 431668

Email: sales@abtech.nl

Europe

Approvals

ABTHX 2011

Worldwide Sales and Service Network

UAE

Australia

China

Hong Kong

Indonesia

Malaysia

Taiwan

Thailand

Vietnam

ABTHX2011

Equipment Categories/Levels of Protection ATEX & IEC Ex

Equipment

Category ATEX

94/9/EC

Category

Equipment Protection

Level

Zone of Use

1G Ga Suitable for use in Zone 0, 1, 2

Category 1

1D Da Suitable for use in Zone 20, 21, 22

2G Gb Suitable for use in Zone 1, 2

Category 2

2D Db Suitable for use in Zone 21, 22

3G Gc Suitable for use in Zone 2

Category 3

3D Dc Suitable for use in Zone 22

You might also like

- Comprehensive List of CausesDocument1 pageComprehensive List of Causessocrates1958240550% (2)

- Research 7 Activity Sheet Quarter 1 - MELC 8 Week 7: Communicating The Result of ObservationDocument8 pagesResearch 7 Activity Sheet Quarter 1 - MELC 8 Week 7: Communicating The Result of ObservationClifford Jay Lachica100% (4)

- Hazardous Area Table IEC & NEC (NEMA) Cooper Crouse Hinds PDFDocument1 pageHazardous Area Table IEC & NEC (NEMA) Cooper Crouse Hinds PDFAgustinus Made Theo Dwijaya100% (4)

- Electrical Certificate TemplateDocument8 pagesElectrical Certificate TemplateMoh HouariNo ratings yet

- iUPS101: XXXX Ii 2 G Ex D (E) Iib T6 GBDocument1 pageiUPS101: XXXX Ii 2 G Ex D (E) Iib T6 GBAdemola Olajide TejumolaNo ratings yet

- Bartec Hazardous Class PosterDocument1 pageBartec Hazardous Class PosterDen Andri Nchu100% (2)

- Surge Protection Devices SpecificationsDocument6 pagesSurge Protection Devices SpecificationsAnonymous XS9jAhY1pENo ratings yet

- Astrology Chart Key PDFDocument1 pageAstrology Chart Key PDFganapathi_gNo ratings yet

- At ExDocument2 pagesAt ExMoustafa Ibrahim YehyaNo ratings yet

- Lcie Bureau Veritas Atex Poster PDFDocument1 pageLcie Bureau Veritas Atex Poster PDFAncaOniscuNo ratings yet

- iPRODUCT100: Ii 2 GD Ex D Iic T6 GB Ex TD Iiic T100°C DB I M2 Ex D I MBDocument1 pageiPRODUCT100: Ii 2 GD Ex D Iic T6 GB Ex TD Iiic T100°C DB I M2 Ex D I MBmlutfimaNo ratings yet

- ABB - 1SFA898111R7000 pstx170 600 70 Softstarter - Datasheet PDFDocument3 pagesABB - 1SFA898111R7000 pstx170 600 70 Softstarter - Datasheet PDFandri putrantoNo ratings yet

- Appendix A Environmental Identification (ENVID) SummaryDocument14 pagesAppendix A Environmental Identification (ENVID) SummaryJag KhadseNo ratings yet

- Presentation o Surge Protection DevicesDocument50 pagesPresentation o Surge Protection DevicesramprakashpatelNo ratings yet

- SDS Nytro LyraDocument2 pagesSDS Nytro LyraUmair Maqbool100% (1)

- Transformer Aircel PDFDocument2 pagesTransformer Aircel PDFMuthukumar SivaramanNo ratings yet

- Transformer Protection RET650: Commissioning ManualDocument96 pagesTransformer Protection RET650: Commissioning Manualhaichau199No ratings yet

- Enclosure Form of SegregationDocument18 pagesEnclosure Form of Segregationkkn1234No ratings yet

- Rasmi LED Lighting Company. LED Light, Indoor, Outdoor, Underwater LED LightDocument30 pagesRasmi LED Lighting Company. LED Light, Indoor, Outdoor, Underwater LED LightRasmi Lighting & Energy India Pvt. Ltd100% (1)

- H LV Switch Gear Functions and SelectionDocument28 pagesH LV Switch Gear Functions and SelectionRavindar ArumugamNo ratings yet

- Pipe Heat Tracing Calculation: A.1. Piping InformationDocument21 pagesPipe Heat Tracing Calculation: A.1. Piping InformationflyzalNo ratings yet

- The Purification of BiogasDocument23 pagesThe Purification of BiogasHamed HpNo ratings yet

- Test Gas CalculationDocument4 pagesTest Gas CalculationadammzjinNo ratings yet

- Micrologic 6Document12 pagesMicrologic 6Karin Aca OviNo ratings yet

- Circuit Breaker CalculationDocument4 pagesCircuit Breaker CalculationparameshvkrNo ratings yet

- Aa 02 Short-Circuit Iec StandardDocument58 pagesAa 02 Short-Circuit Iec StandardSupriyanto SuhonoNo ratings yet

- Wind Energy PresentationDocument77 pagesWind Energy PresentationPranjul GargNo ratings yet

- IP RatingsDocument1 pageIP RatingsTANGEDCOENGGNo ratings yet

- ASU Process & Energy OptimizationDocument24 pagesASU Process & Energy OptimizationSambaru Prasad0% (1)

- Transformer Regulation - Losses (As Per TC Name Plate) (1.1.19)Document4 pagesTransformer Regulation - Losses (As Per TC Name Plate) (1.1.19)jiguparmar1516No ratings yet

- Rittal - Enclosure Heat Dissipation ManualDocument74 pagesRittal - Enclosure Heat Dissipation ManualExequiel RieterNo ratings yet

- DCS Grounding - LinkedInDocument8 pagesDCS Grounding - LinkedInmaryam100% (1)

- Electrical Load Classification and TypesDocument13 pagesElectrical Load Classification and Typesapi-312620075100% (1)

- 03HYUNDAI Intelligent Preventative Diagnostic System (HiPDS)Document12 pages03HYUNDAI Intelligent Preventative Diagnostic System (HiPDS)juliancansenNo ratings yet

- General Specifications For Soft StarterDocument7 pagesGeneral Specifications For Soft StarterIsmael AhmedNo ratings yet

- Amp DS 40 005 A4Document9 pagesAmp DS 40 005 A4sugeng wahyudiNo ratings yet

- Eeha Arcia White Paper Ver 1.1 Jan16Document66 pagesEeha Arcia White Paper Ver 1.1 Jan16Sin Quee CheNo ratings yet

- En 50288Document3 pagesEn 50288rose chenNo ratings yet

- Basics of Built-In Motor Protection For BeginnersDocument8 pagesBasics of Built-In Motor Protection For BeginnersrodinooNo ratings yet

- Section 9Document43 pagesSection 9Yahya AsiriNo ratings yet

- Micom P220 Motor Protection RelayDocument16 pagesMicom P220 Motor Protection RelayAONLANo ratings yet

- Vol2-4.8 11 KV SwitchgearDocument7 pagesVol2-4.8 11 KV SwitchgearNazakat HussainNo ratings yet

- SS - (535 - 550) - 72MTF SunovaDocument2 pagesSS - (535 - 550) - 72MTF SunovaPaulo Henrique SantosNo ratings yet

- Chemical Dosing I/o ListDocument3 pagesChemical Dosing I/o Listpriyo_a_sNo ratings yet

- End-Suction Fire Pumpset Diesel Engine Driven: LBSD SeriesDocument6 pagesEnd-Suction Fire Pumpset Diesel Engine Driven: LBSD SeriesMuhammad MustafaNo ratings yet

- techNOTE - Coding Principles of Beacons and Indicators PDFDocument1 pagetechNOTE - Coding Principles of Beacons and Indicators PDFŽarko MočnikNo ratings yet

- Development of PLC Based Monitoring and Control of Pressure in Biogas Power Plant DigesterDocument7 pagesDevelopment of PLC Based Monitoring and Control of Pressure in Biogas Power Plant DigesterKentner Chavez CorreaNo ratings yet

- LCS PanelDocument8 pagesLCS PanelRana NishithNo ratings yet

- Low Current System PDFDocument3 pagesLow Current System PDFPurevee PureveeNo ratings yet

- How To Select A Variable Frequency DriveDocument2 pagesHow To Select A Variable Frequency Drivehasbi fadli100% (1)

- 7SJ66 IEC 61850 MappingDocument144 pages7SJ66 IEC 61850 Mappingsougata mukherjee100% (1)

- Iec60079 18 2009Document35 pagesIec60079 18 2009Victor Castellanos AlegriaNo ratings yet

- Vacuum Stations: Vacplus Compact Vacplus VerticalDocument5 pagesVacuum Stations: Vacplus Compact Vacplus VerticalElena GrecuNo ratings yet

- 85 RDGJ 478 GDocument10 pages85 RDGJ 478 GGanda PrajaNo ratings yet

- VArticle - Thermal Design of APFC PanelsDocument4 pagesVArticle - Thermal Design of APFC PanelsChandru RangarajNo ratings yet

- Adr241a Do 01 810Document17 pagesAdr241a Do 01 810Vishwanath TodurkarNo ratings yet

- Electrical Equipment in Hazardous AreasDocument8 pagesElectrical Equipment in Hazardous AreasMehulkumar PatelNo ratings yet

- NFC 17102 - Lightning Protection - Protection of Structures and Open Areas Against Lightning Using Early Streamer Emission Air TerminalsDocument58 pagesNFC 17102 - Lightning Protection - Protection of Structures and Open Areas Against Lightning Using Early Streamer Emission Air TerminalsLEONARDONo ratings yet

- Abtech Hazardous Area Poster WebDocument1 pageAbtech Hazardous Area Poster Webmanohar_033100% (1)

- Ingress SafetyDocument1 pageIngress Safetyjohn_tigerNo ratings yet

- Intertek Poster A1 (HazLoc - Guide) - 0Document1 pageIntertek Poster A1 (HazLoc - Guide) - 0Antonio FilipeNo ratings yet

- ExtronicsWallchart 160708Document1 pageExtronicsWallchart 160708Shyam VarunNo ratings yet

- MTL Flamable FactsDocument1 pageMTL Flamable FactsAdeDCNo ratings yet

- Chinese Lesson1Document8 pagesChinese Lesson1Balan PalaniappanNo ratings yet

- RERL Fact Sheet 2a Capacity FactorDocument4 pagesRERL Fact Sheet 2a Capacity FactorAbdullah KaymakcıNo ratings yet

- International Review of Wind Policies and RecommendationsDocument43 pagesInternational Review of Wind Policies and RecommendationsbluesbankyNo ratings yet

- Wind Energy - The Case of DenmarkDocument39 pagesWind Energy - The Case of DenmarkletvineyardersdecideNo ratings yet

- Wind Energy Development in The Caribbean: Raymond M. WrightDocument6 pagesWind Energy Development in The Caribbean: Raymond M. WrightSaravana KumarNo ratings yet

- Wind Power:: 20 Myths Blown AwayDocument12 pagesWind Power:: 20 Myths Blown AwayBalan PalaniappanNo ratings yet

- Active Load Control Techniques For Wind Turbines: Sandia ReportDocument132 pagesActive Load Control Techniques For Wind Turbines: Sandia ReportBalan PalaniappanNo ratings yet

- 0035 PDFDocument8 pages0035 PDFBalan PalaniappanNo ratings yet

- Wind FactsDocument16 pagesWind Factsbiotech_vidhyaNo ratings yet

- Wind Energy Benefits: Wind and Water Power ProgramDocument2 pagesWind Energy Benefits: Wind and Water Power ProgramBalan PalaniappanNo ratings yet

- Wpa Factsheet Series PDFDocument2 pagesWpa Factsheet Series PDFBalan PalaniappanNo ratings yet

- Wind Power PDFDocument3 pagesWind Power PDFBalan PalaniappanNo ratings yet

- Hughes Windpower PDFDocument44 pagesHughes Windpower PDFBalan Palaniappan100% (1)

- Pure Power Full Report PDFDocument78 pagesPure Power Full Report PDFBalan PalaniappanNo ratings yet

- Common Concerns About Wind Power: Centre For Sustainable Energy, May 2011Document40 pagesCommon Concerns About Wind Power: Centre For Sustainable Energy, May 2011Balan PalaniappanNo ratings yet

- SatWindPot2012 PDFDocument14 pagesSatWindPot2012 PDFBalan PalaniappanNo ratings yet

- A Case Study of Engineering Ethics: Lesson Learned From Building Collapse Disaster Toward Malaysian EngineersDocument11 pagesA Case Study of Engineering Ethics: Lesson Learned From Building Collapse Disaster Toward Malaysian EngineerspavynashNo ratings yet

- Typical Heat Treatment Defects of GearsDocument8 pagesTypical Heat Treatment Defects of GearsRamon BrownNo ratings yet

- Transport Policy: Lakshya Kumar, Apurva Jindal, Nagendra R. VelagaDocument10 pagesTransport Policy: Lakshya Kumar, Apurva Jindal, Nagendra R. VelagaPrantikNo ratings yet

- Marine CatalogueDocument43 pagesMarine Cataloguefarhan_82No ratings yet

- 10) What Is A Flame DetectorDocument4 pages10) What Is A Flame Detectorsujiv_sujiv1278No ratings yet

- Arc Fuse 3b1e 4b1eDocument3 pagesArc Fuse 3b1e 4b1ej25he4df5No ratings yet

- International Journal of Fatigue: SciencedirectDocument12 pagesInternational Journal of Fatigue: SciencedirectKurra SrikanthNo ratings yet

- CIV407 Earthquake Engineering 17413::gaurav Sharma 3.0 0.0 0.0 3.0 Courses With Numerical and Conceptual FocusDocument10 pagesCIV407 Earthquake Engineering 17413::gaurav Sharma 3.0 0.0 0.0 3.0 Courses With Numerical and Conceptual FocusSuresh KhangembamNo ratings yet

- Timetable Route BMTDocument9 pagesTimetable Route BMTAimi SyafiqahNo ratings yet

- Harvard Applied Mathematics 205 Homework 1Document6 pagesHarvard Applied Mathematics 205 Homework 1J100% (2)

- IEEE STD 81.2-1991Document7 pagesIEEE STD 81.2-1991JesúsNo ratings yet

- 2 MapElementsDocument34 pages2 MapElementspoonnapha.wNo ratings yet

- Problem Solving PerformanceDocument3 pagesProblem Solving PerformanceNoreen Deanne RagasNo ratings yet

- Cigre SC B4Document4 pagesCigre SC B4Jose ValdiviesoNo ratings yet

- Abu Azfar: Curriculum VitalDocument4 pagesAbu Azfar: Curriculum VitalBrueNo ratings yet

- Design: IdeasDocument5 pagesDesign: Ideasdcastrelos2000No ratings yet

- BigJoe S22Document162 pagesBigJoe S22martinNo ratings yet

- De-Mystifying Semiotics: Some Key Questions Answered: Rachel LawesDocument9 pagesDe-Mystifying Semiotics: Some Key Questions Answered: Rachel LawesminglessisNo ratings yet

- Distributed Generation: Benefits & Issues: Johan Driesen K.U.Leuven - Esat/Electa WWW - Esat.kuleuven - Be/electaDocument26 pagesDistributed Generation: Benefits & Issues: Johan Driesen K.U.Leuven - Esat/Electa WWW - Esat.kuleuven - Be/electaahmedNo ratings yet

- Competitiveness of Garment Technology As A CourseDocument11 pagesCompetitiveness of Garment Technology As A CourseMargie Ballesteros ManzanoNo ratings yet

- The Proper Way To Ohm A Single Phase Compressor PDFDocument3 pagesThe Proper Way To Ohm A Single Phase Compressor PDFslipargolokNo ratings yet

- Feminist EpistemologyDocument6 pagesFeminist EpistemologyZikra MehjabinNo ratings yet

- Companies DatabaseDocument15 pagesCompanies DatabaseSanthsoh KumarNo ratings yet

- Corporate Innovation Basic & Intrapreneur: For AmoebaDocument4 pagesCorporate Innovation Basic & Intrapreneur: For AmoebaHammamMuhammadIrfantoroNo ratings yet

- Summary of The Invisible ManDocument3 pagesSummary of The Invisible ManMahmood FayyazNo ratings yet

- PowerLogic PM1000 METSEPM1200Document2 pagesPowerLogic PM1000 METSEPM1200Dicky FirmansyahNo ratings yet

- CAE English Test 7Document12 pagesCAE English Test 7Nga Nguyen VuNo ratings yet