Professional Documents

Culture Documents

Viscosity Information

Viscosity Information

Uploaded by

kilean_lucas0 ratings0% found this document useful (0 votes)

18 views1 pageViscosity of various substances.

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentViscosity of various substances.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

18 views1 pageViscosity Information

Viscosity Information

Uploaded by

kilean_lucasViscosity of various substances.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

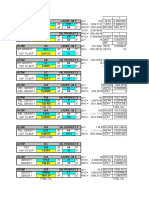

Viscosity Information

CPS Temp Fluid CPS Temp Fluid

1 65 F water 1600 17.400 60 F SAE 70 motor oil

2 60 F turpentine 2000 75 F barbecue sauce

3 40 F milk 2200 70 F pancake batter

3 68 F kerosene 2250 62 F chocolate syrup

8 70 F gasoline 2400 70 F water based paint

11 60 F # 2 fuel oil 2600 40 F tomato sauce

14 60 F # 2 diesel 3000 65.000 65 F glue

18 60 F beer 3800 70 F lard

20 40 F cream 4000 60 F newspaper ink

40 65 F vegetable oil 5000 160 F titanium dioxide

50 70 F sugar syrup (sucrose) 60 Brix 5000 75 F salad dressing

68 100 F raw honey 5000 70 F shampoo

75 70 F liquid wax 5000 65 F hand lotion

88 - 206 60 F SAE 10 motor oil 5000 65 F epoxy resin

94 60 F sesame oil 5000 38 F OJ concentrate

103 60 F peanut oil 5000 62 F neoprene latex

110 60 F coconut oil 5000 40.000 70 F mayo

125 330 60 F SAE 20 motor oil 6000 70 F sweetened condensed milk

180 65 F tomato juice 10.000 70 F butter

200 - 540 60 F SAE 30 motor oil 10.000 40 F yogart

319 - 970 60 F SAE 40 motor oil 10.000 60 F icing

320 60 F varnish 15.000 60 F corn syrup 41 be

435 68 F maple syrup 15.000 45 F sour cream

540 2000 60 F SAE 50 motor oil 18.000 35.000 100 F corn syrup 44 be

648 - 800 69 F 100% glycerine 20.000 60 F baby food

720 18.000 60 F molasses 20.000 60 F printers ink

750 65 F latex paint 36.000 80 F hot fudge

800 80 F HFCS high fructose corn syrup 40.000 100 F blackstrap molasses

1000 80 F horse radish sauce 50.000 65 F ketchup

1000 70 F spaghetti sauce 64.000 65 F petroleum jelly

1000 - 3000 60 F SAE 60 motor oil 65.000 65 F PVA resin

1210 70 F sugar syrup (sucrose) 74 Brix 100.000 120 F cream cheese

1500 70.000 85 F mustard 250.000 65 F peanut butter

1500 100 F honey

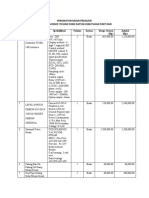

Tomato Paste: 26% & 37% cold break & 31% hot break has been pumped using Flux #F560GS3A50/21 tubeset & F 458-1 motor

Consideration of pumps for viscous liquid applications requires a thorough discussion of

the viscous nature of the liquid and piping system. The viscous characteristics of the

liquid --- Newtonian, Thixotropic, Dilatant, Colloidal or Rheopectic should be established

when providing viscosity data. Most all calculations for pressure drops and pipeline

losses for viscous liquids are in laminar flow patterns.

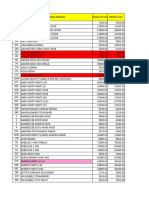

CONVERSION FACTORS

Centistokes =

_Centipoises__

Specific Gravity

SSU* = Centistokes x 4.55

Degrees Engler* = Centistokes x 0.132

Seconds Redwood 1* = Centistokes x 4.05

*Where Centistokes are greater than 50

You might also like

- Benoît Mandelbrot: Fractal Geometry of NatureDocument2 pagesBenoît Mandelbrot: Fractal Geometry of NatureindrabudhiNo ratings yet

- Feature Guide: XG (S) - PON (XG-PON and XGS-PON)Document48 pagesFeature Guide: XG (S) - PON (XG-PON and XGS-PON)mosesNo ratings yet

- List of Fluid and ViscoityDocument7 pagesList of Fluid and Viscoityburhanuddin bhavnagarwalaNo ratings yet

- ASTM TablesDocument29 pagesASTM TablesStemo100% (1)

- MSDS - Dipsol L-800 (Na HSO3) (Plating) PDFDocument6 pagesMSDS - Dipsol L-800 (Na HSO3) (Plating) PDFEbit FristaNo ratings yet

- Viscosity Values From Cole-ParmerDocument1 pageViscosity Values From Cole-Parmergalaxy grandNo ratings yet

- Viscosity Guide ChartDocument2 pagesViscosity Guide ChartDeepikaNo ratings yet

- Viscosity Guide ChartDocument2 pagesViscosity Guide Chartedlyn91No ratings yet

- Rice Pudding Viscosity CHRTDocument1 pageRice Pudding Viscosity CHRTspartha_beNo ratings yet

- Viscosity: Viscosity Comparison Chart Material Viscosity (Centipoise)Document1 pageViscosity: Viscosity Comparison Chart Material Viscosity (Centipoise)Saepul RochmanNo ratings yet

- Motorna Ulja Pakovanje Pakovanje Jed. Mere V.P. Cena Cena (KOM)Document4 pagesMotorna Ulja Pakovanje Pakovanje Jed. Mere V.P. Cena Cena (KOM)Zoran Bogićević RakunNo ratings yet

- Harga Barang BaruDocument5 pagesHarga Barang BaruAgung Bagus SanjayaNo ratings yet

- Master List SparepartDocument10 pagesMaster List SparepartHanif SayyidNo ratings yet

- Lista de Stock Da Loja NicuadalaDocument3 pagesLista de Stock Da Loja NicuadalaferminojosecumbaneNo ratings yet

- Sales Sheet For FebDocument10 pagesSales Sheet For FebAnimie ForeverNo ratings yet

- Lubricantes Recomendados SD105Document3 pagesLubricantes Recomendados SD105Vale DudaNo ratings yet

- Nissan SXDocument1 pageNissan SXmarino246No ratings yet

- Desmet Ballestra GroupDocument25 pagesDesmet Ballestra GroupDesa MadukaraNo ratings yet

- Inventory ReportDocument158 pagesInventory ReportAdèity TVNo ratings yet

- Closong Stock 1 To 5 NovDocument5 pagesClosong Stock 1 To 5 Novpavan kumarNo ratings yet

- Harga Jual PrintDocument127 pagesHarga Jual PrintShabillNo ratings yet

- Inventory Kitchen March31Document238 pagesInventory Kitchen March31cynthiaNo ratings yet

- Closing Stock Nov 1 To 12Document4 pagesClosing Stock Nov 1 To 12pavan kumarNo ratings yet

- PRODUITS Longrich PDFDocument1 pagePRODUITS Longrich PDFMohamed Fouad Bissiriou50% (4)

- Closing Stock 1 To 31 OctDocument5 pagesClosing Stock 1 To 31 Octpavan kumarNo ratings yet

- Ilog Maria Order SeptemberDocument4 pagesIlog Maria Order Septembersales officeNo ratings yet

- Metal or Alloy Kg/cu.mDocument17 pagesMetal or Alloy Kg/cu.mElixir CabsNo ratings yet

- Daftar Harga PelumasDocument12 pagesDaftar Harga Pelumas07071201730% (1)

- ZAKOLÉDocument7 pagesZAKOLÉMelissa OteroNo ratings yet

- Survei Harga Kompetitor JULI 2020-1Document6 pagesSurvei Harga Kompetitor JULI 2020-1Achmad TurmuziNo ratings yet

- S3 Audi A3 - Vehicle Model Code 8P PDFDocument3 pagesS3 Audi A3 - Vehicle Model Code 8P PDFAlexNo ratings yet

- Red Line Synthetic 10W 60 Technical DatasheetDocument2 pagesRed Line Synthetic 10W 60 Technical DatasheetMario FliesserNo ratings yet

- Guideline SOS Sampling LoaderDocument1 pageGuideline SOS Sampling LoaderMuhammad fikhri Al AyubiNo ratings yet

- Said Jan Summary PaymentDocument1 pageSaid Jan Summary Paymentapi-3726455100% (1)

- BHL Recommended Maximum Labour Chart: GeneralDocument6 pagesBHL Recommended Maximum Labour Chart: GeneralMd. Ripon AliNo ratings yet

- Operational Mu-X 4x4Document1 pageOperational Mu-X 4x4Anindito W WicaksonoNo ratings yet

- Reference Guide: Everyday Consumable Goods in Relation To General Product Viscosity in Centipoise (CPS)Document1 pageReference Guide: Everyday Consumable Goods in Relation To General Product Viscosity in Centipoise (CPS)Engg DesignNo ratings yet

- Pump Sizing Calculation (Photo)Document25 pagesPump Sizing Calculation (Photo)anto3harrish3fdoNo ratings yet

- The Inventory Characteristics of The Refined Oils AreDocument2 pagesThe Inventory Characteristics of The Refined Oils AreA MNo ratings yet

- Untitled SpreadsheetDocument4 pagesUntitled SpreadsheetAsifa NoorNo ratings yet

- Laboratory Work BookDocument8 pagesLaboratory Work BookgadaubacNo ratings yet

- Perawatan Mesin Produksi Upt. Riau Science Techno Park Daftar Kebutuhan Part DanDocument2 pagesPerawatan Mesin Produksi Upt. Riau Science Techno Park Daftar Kebutuhan Part Danrozita izanNo ratings yet

- Steam TableDocument14 pagesSteam TableFata AmalNo ratings yet

- Viscosity TablesDocument4 pagesViscosity TablesAshwin ShettyNo ratings yet

- Industrial Gearbox Oils: Parthan EpDocument20 pagesIndustrial Gearbox Oils: Parthan EpChetan PrajapatiNo ratings yet

- G10 G11 G9 CanvasDocument1 pageG10 G11 G9 CanvasJair AyalaNo ratings yet

- Rate List 2019Document11 pagesRate List 2019tiks88No ratings yet

- Additional MilkDocument5 pagesAdditional MilkRestu FauzanNo ratings yet

- Lister Type Slow Speed Diesel Engine Custom Builts Engine Order FormDocument1 pageLister Type Slow Speed Diesel Engine Custom Builts Engine Order FormhamadaeidNo ratings yet

- Pump CalculationDocument8 pagesPump CalculationankitNo ratings yet

- Special LubsDocument2 pagesSpecial LubsidealparrotNo ratings yet

- Beverage ListDocument2 pagesBeverage ListBijoy DasNo ratings yet

- Parthan Ep: Industrial Gearbox OilsDocument1 pageParthan Ep: Industrial Gearbox OilsHesham MahdyNo ratings yet

- Recipe Hot and SpicyDocument4 pagesRecipe Hot and Spicyrezaakum13No ratings yet

- Equipment & Machinery Equipment Unit Price Total Cost (RS.) (RS.)Document13 pagesEquipment & Machinery Equipment Unit Price Total Cost (RS.) (RS.)Hamid NasirNo ratings yet

- Akb Lubricants Price List W.E.F. 15th May, 2022Document2 pagesAkb Lubricants Price List W.E.F. 15th May, 2022Lalremruata SingsonNo ratings yet

- Scale Price ListDocument17 pagesScale Price ListdrsamaratefNo ratings yet

- Lista de Precios Lubricantes ROSHFRANS 2018.12Document2 pagesLista de Precios Lubricantes ROSHFRANS 2018.12Anonymous eJwbx9WnNo ratings yet

- Suhu Terhadap Berat Bahan BakarDocument5 pagesSuhu Terhadap Berat Bahan BakarIlham Dwi ShaputraNo ratings yet

- PRECIOS PRODUCCION Vibalca 2020 (Boleta y Factura)Document7 pagesPRECIOS PRODUCCION Vibalca 2020 (Boleta y Factura)KEVIN MEJIANo ratings yet

- PPC All Solved Open Book PapersDocument366 pagesPPC All Solved Open Book PapersGrd GrdNo ratings yet

- Cutting Tools: Your Partner For Clever ToolingDocument9 pagesCutting Tools: Your Partner For Clever ToolingPalade LucianNo ratings yet

- Adani BessDocument45 pagesAdani Bessdan_geplNo ratings yet

- Underground Cable Fault Locating Using The Arc Reflection Method - Mike Scott, Product Manager, Megger - Electric Energy OnlineDocument3 pagesUnderground Cable Fault Locating Using The Arc Reflection Method - Mike Scott, Product Manager, Megger - Electric Energy OnlinelavudyakrishnaNo ratings yet

- Emulsion Micro Emulsion and Nano Emulsion: A ReviewDocument9 pagesEmulsion Micro Emulsion and Nano Emulsion: A ReviewHajrah SuhardiNo ratings yet

- Useful Vocabulary For Writing Emails in EnglishDocument16 pagesUseful Vocabulary For Writing Emails in EnglishchioknippNo ratings yet

- The Importance of A Physiotherapist in Management of Sport TeamDocument32 pagesThe Importance of A Physiotherapist in Management of Sport TeamJanet EmmaNo ratings yet

- IT - (X) - Practice Question Paper FinalDocument4 pagesIT - (X) - Practice Question Paper Finalarchitthakur1508No ratings yet

- Friday File 2023.03.10 PDFDocument11 pagesFriday File 2023.03.10 PDFAlycia MarkNo ratings yet

- Argumentative Facial RecognitionDocument6 pagesArgumentative Facial Recognitionfigueroajoshua0129No ratings yet

- Biema G61i (Schematic)Document4 pagesBiema G61i (Schematic)osman saraçNo ratings yet

- Relative and Absolute DatingDocument37 pagesRelative and Absolute DatingDIGNA ENCANTONo ratings yet

- FIAC5112 WorkbookDocument138 pagesFIAC5112 WorkbookarronyeagarNo ratings yet

- GeoTECH Free User ManuelDocument60 pagesGeoTECH Free User Manuelayaz5555No ratings yet

- Floating Point Representation: Major: All Engineering Majors Authors: Autar Kaw, Matthew EmmonsDocument21 pagesFloating Point Representation: Major: All Engineering Majors Authors: Autar Kaw, Matthew EmmonsHarris AnchesNo ratings yet

- H&M QC Inspection Manual: ContentDocument9 pagesH&M QC Inspection Manual: ContentMark Arvel Pe Singson100% (2)

- MCPHS Drug Information QuestionDocument5 pagesMCPHS Drug Information QuestionG TeenaNo ratings yet

- Machinery Listings: KnittingDocument55 pagesMachinery Listings: KnittingDARK TRICKS & FUN0% (1)

- HSIR14 Professional EthicsDocument7 pagesHSIR14 Professional EthicsAjeeth BNo ratings yet

- User Guide Server Flex X240Document902 pagesUser Guide Server Flex X240Bruri S WahyudiNo ratings yet

- Nodel Analysis MTE120Document15 pagesNodel Analysis MTE120Wee Khang100% (1)

- 07 03 06 08 8.the Steady Magnetic FieldDocument42 pages07 03 06 08 8.the Steady Magnetic FieldM. Ahmad IjazNo ratings yet

- User Manual of HikCentral Control ClientDocument68 pagesUser Manual of HikCentral Control ClientLord oklain IcarusdeepNo ratings yet

- P6F Course ObjectivesDocument4 pagesP6F Course ObjectivesJung ChanwooNo ratings yet

- Ding Dong BellDocument2 pagesDing Dong BellelectatulNo ratings yet

- Critical Dimension of Inclusive ClassroomsDocument3 pagesCritical Dimension of Inclusive ClassroomsYuri Pamaran100% (1)

- Introduction To Marketing Submitted To: Mr. Midhat Nadeem Submitted On 29 August 2021 Submitted By: Ayesha AyubDocument4 pagesIntroduction To Marketing Submitted To: Mr. Midhat Nadeem Submitted On 29 August 2021 Submitted By: Ayesha AyubAyesha Ayub AwanNo ratings yet