Professional Documents

Culture Documents

MMA Electrodes for Welding Stainless Steels AISI 321 and AISI 347

Uploaded by

Gogo P0 ratings0% found this document useful (0 votes)

14 views1 pageSupranox RS 347 is a semi-basic MMA electrode suitable for welding stabilized austenitic stainless steels AISI 321 and AISI 347. It provides excellent weldability with a spatter free arc and self-releasing slag, resulting in a very smooth bead appearance. The weld metal has excellent mechanical properties at high temperatures. The electrode comes in various diameters and lengths and provides an efficiency of 100%.

Original Description:

112

Original Title

121

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentSupranox RS 347 is a semi-basic MMA electrode suitable for welding stabilized austenitic stainless steels AISI 321 and AISI 347. It provides excellent weldability with a spatter free arc and self-releasing slag, resulting in a very smooth bead appearance. The weld metal has excellent mechanical properties at high temperatures. The electrode comes in various diameters and lengths and provides an efficiency of 100%.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

14 views1 pageMMA Electrodes for Welding Stainless Steels AISI 321 and AISI 347

Uploaded by

Gogo PSupranox RS 347 is a semi-basic MMA electrode suitable for welding stabilized austenitic stainless steels AISI 321 and AISI 347. It provides excellent weldability with a spatter free arc and self-releasing slag, resulting in a very smooth bead appearance. The weld metal has excellent mechanical properties at high temperatures. The electrode comes in various diameters and lengths and provides an efficiency of 100%.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

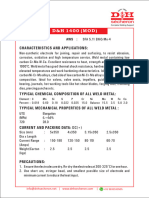

SUPRANOX RS 347

Keep dry and avoid condensation.

Re-drying not generally required.

If necessary: 350-370 C for 1 hour, 3 times max.

AWS A5.4: E 347-16

EN 1600: E 19 9Nb R 12

GOST 10052-75: 08X20H10 2 similar

AC; DC+

2,0 30-60 11,1 6,6 300

2,5 50-80 18,7 11,2 300

3,2 60-120 35,0 21,0 350

4,0 100-140 52,5 31,5 350

5,0 130-180 82,6 49,5 350

Packaging data

Classification

Weld metal weight

per electrode (g)

Diameter

(mm)

Current

(A)

Electrode

average weight (g)

MMA Electrodes

All-weld metal Mechanical Properties

As Welded 550 350 30 48 -

Impact Energy

ISO - V (J)

Heat Treatment

Tensile

Strength

N/mm

2

Yield

Strength

N/mm

2

Elongation

A5 (%)

20C

Hardness

1.4541 (X6CrNiTi18-10); 1.4301 (X4CrNi18-10); 1.4550 (X6CrNiNb18-10);

AISI 347 - 321

Length

(mm)

Current condition and welding position Storage and redrying

PA PB PC PF PE

Analysis of all-weld metal (Typical values in %)

C Ferrite

0.05 5-10 0.80 0.60 0.025 0.020 19 10 - 0.50 - -

Mn Si P S Cr Ni Mo Nb Cu N

Stainless and Heat resistant steels

Materials

Semi-basic MMA electrode suitable for welding stabilized austenitic stainless steels AISI 321 and AISI 347. The Nb+Ta in

the weld metal is due to the Ti sublimation at the liquidus temperature of the weld pool. The weld metal mechanical

properties are excellent at high temperatures. Excellent weldability with a spatter free arc, self-releasing slag results in a

very smooth bead appearance. Efficiency 100%. Packed in Gaspack system.

MMI

TV

Approvals Grades

see Appendix, Classification Society Approvals, for details pag. 521

121

You might also like

- L1 - 12937 - en - Thermanit 25 22 H - Marathon 104 - ENDocument1 pageL1 - 12937 - en - Thermanit 25 22 H - Marathon 104 - ENkamals55No ratings yet

- Supranox Rs 309L: MMA Electrodes Stainless and Heat Resistant SteelsDocument1 pageSupranox Rs 309L: MMA Electrodes Stainless and Heat Resistant SteelsbrunizzaNo ratings yet

- Basinox 318: MMA Electrodes Stainless and Heat Resistant SteelsDocument1 pageBasinox 318: MMA Electrodes Stainless and Heat Resistant SteelsbrunizzaNo ratings yet

- Thermanit Chromo 9V SMAW enDocument1 pageThermanit Chromo 9V SMAW ensoft4gsmNo ratings yet

- SMAW high-alloy electrode applicationsDocument1 pageSMAW high-alloy electrode applications2003vinayNo ratings yet

- Fox - FFDocument1 pageFox - FFGustavo NietoNo ratings yet

- Böhler CN 13/4-Mc Hi: Classifi CationsDocument1 pageBöhler CN 13/4-Mc Hi: Classifi CationsBranko FerenčakNo ratings yet

- E8018 B8Document1 pageE8018 B8Issac GeorgeNo ratings yet

- 347 Stainless Steel: 1.4541 1.4543/1.4561/1.4550 1.4552 (Cast)Document4 pages347 Stainless Steel: 1.4541 1.4543/1.4561/1.4550 1.4552 (Cast)Prem NautiyalNo ratings yet

- 1.smaw All PDFDocument76 pages1.smaw All PDFkaviatchennaiNo ratings yet

- Thermanit NiMo 100 low-alloyed stick electrodeDocument1 pageThermanit NiMo 100 low-alloyed stick electrodebrayanNo ratings yet

- Avesta 2205 AC DCDocument1 pageAvesta 2205 AC DCpipedown456No ratings yet

- Thermanit 308 Mo 1SE3A00G 3407112 ENDocument1 pageThermanit 308 Mo 1SE3A00G 3407112 ENbrayanNo ratings yet

- Bohler Fox DMV 83 KB - SmawDocument1 pageBohler Fox DMV 83 KB - Smawsoft4gsmNo ratings yet

- KST 309LDocument1 pageKST 309LTharman SupramaniamNo ratings yet

- Fincord DB: MMA Electrodes C-MN and Low-Alloy SteelsDocument1 pageFincord DB: MMA Electrodes C-MN and Low-Alloy SteelsbrunizzaNo ratings yet

- Wire Thermanit CSiDocument1 pageWire Thermanit CSiviphemantNo ratings yet

- TOOLCORD MMA Electrodes for HardfacingDocument1 pageTOOLCORD MMA Electrodes for HardfacingbrunizzaNo ratings yet

- DH 1400modDocument1 pageDH 1400modGopiNathNo ratings yet

- A-23 WB36 Rev 03 15NiCuMoNb5 MicrostructureDocument4 pagesA-23 WB36 Rev 03 15NiCuMoNb5 Microstructuremavis16No ratings yet

- CF10MC (1.4571)Document3 pagesCF10MC (1.4571)Gilcimar Cavalcante GilcimarNo ratings yet

- Nickel-base filler metals GTAW rodsDocument1 pageNickel-base filler metals GTAW rodsc131508No ratings yet

- B Bã-Hler Nibas 70 20-Fd Fcaw 02Document1 pageB Bã-Hler Nibas 70 20-Fd Fcaw 02kamals55No ratings yet

- Boehler CM2-UPDocument1 pageBoehler CM2-UPdiahNo ratings yet

- Metrode Cryogenic ER316 B-38Document5 pagesMetrode Cryogenic ER316 B-38Claudia MmsNo ratings yet

- Böhler Fox CM 2 KB: Classifi CationsDocument1 pageBöhler Fox CM 2 KB: Classifi CationsBranko FerenčakNo ratings yet

- Inertfil 308lsi: MIG-MAG Wires Stainless and Heat Resistant SteelsDocument1 pageInertfil 308lsi: MIG-MAG Wires Stainless and Heat Resistant SteelsEdison CheongNo ratings yet

- DH 1232NSDocument1 pageDH 1232NSGopiNathNo ratings yet

- T Thermanit Nicro 82 Gtaw 01 01 enDocument2 pagesT Thermanit Nicro 82 Gtaw 01 01 enKathir VelNo ratings yet

- Ok 347 AutrodDocument2 pagesOk 347 Autrodjoao guilhermeNo ratings yet

- Steel Clasification and WeldabilityDocument32 pagesSteel Clasification and Weldabilitycentaury2013No ratings yet

- Consumables To Match Cast & Wrought Alloy 800: Astm Bs en & DinDocument3 pagesConsumables To Match Cast & Wrought Alloy 800: Astm Bs en & Dinankitniranjan1390No ratings yet

- Description:: AWS A5.4 E308-16 JIS Z3221 ES308-16 EN 1600 E 19 9 R 1 2 Covered Electrodes For Stainless SteelDocument1 pageDescription:: AWS A5.4 E308-16 JIS Z3221 ES308-16 EN 1600 E 19 9 R 1 2 Covered Electrodes For Stainless Steel13421301508No ratings yet

- L1 34264 en T Thermanit MTS 3 Se en v2Document1 pageL1 34264 en T Thermanit MTS 3 Se en v2Enrique MurgiaNo ratings yet

- CHG 55B2Document1 pageCHG 55B2Nhien ManNo ratings yet

- Metrode Cryogenic 308lcf B-37Document5 pagesMetrode Cryogenic 308lcf B-37Claudia MmsNo ratings yet

- GMAW Solid Wire for High Temperature Steel WeldingDocument1 pageGMAW Solid Wire for High Temperature Steel Weldingदिनेश कुशवाहाNo ratings yet

- Advanced Welding TechnologyDocument60 pagesAdvanced Welding TechnologySwati AgarwalNo ratings yet

- Thermanit Nicro 82: TIG Rods, Nickel-AlloyDocument2 pagesThermanit Nicro 82: TIG Rods, Nickel-AlloyMaximiliano Ezequiel LopezNo ratings yet

- Thermanit X Stick Electrode for Stainless Steel WeldingDocument2 pagesThermanit X Stick Electrode for Stainless Steel WeldingMadhusudan YeoleNo ratings yet

- Section 2 - Nichia Welding ConsumableDocument9 pagesSection 2 - Nichia Welding ConsumableLodyNo ratings yet

- With The Knowledge of Now Error-Free in The Future-1Document5 pagesWith The Knowledge of Now Error-Free in The Future-1apNo ratings yet

- AUTROD 316LSiDocument2 pagesAUTROD 316LSijoao guilhermeNo ratings yet

- L1 34410 en Avesta 309 AC DC 2SE6A22E 3383012 ENDocument1 pageL1 34410 en Avesta 309 AC DC 2SE6A22E 3383012 ENkamals55No ratings yet

- Electrodes Hilchrome 308rDocument1 pageElectrodes Hilchrome 308rManu NistorNo ratings yet

- Tencord KB (E 42 4 Z B 42 h5)Document1 pageTencord KB (E 42 4 Z B 42 h5)brunizzaNo ratings yet

- مكونات نقط اللحام شامل بنط اللحامDocument2 pagesمكونات نقط اللحام شامل بنط اللحامdaha333No ratings yet

- S-23804-Eng - 22 12 HTDocument2 pagesS-23804-Eng - 22 12 HTbiliboi5No ratings yet

- CERTILAS EN Edition2023 316Document1 pageCERTILAS EN Edition2023 316Alireza KhodabandehNo ratings yet

- 1564 Fox Ev 85 ElettrodoDocument1 page1564 Fox Ev 85 ElettrodoAminNo ratings yet

- Fox CN 23-12-ADocument1 pageFox CN 23-12-AVIRPOPNo ratings yet

- 1 4501 Super Duplex TubesDocument3 pages1 4501 Super Duplex TubesAlma JakirovićNo ratings yet

- Mild Steel 490mpa High Tensile Strength SteelDocument38 pagesMild Steel 490mpa High Tensile Strength SteelCarlos PadillaNo ratings yet

- Citorail OerlikonDocument1 pageCitorail OerlikonGiancarlo BlandinoNo ratings yet

- Metrode E2209 (B-60) ElectrodeDocument6 pagesMetrode E2209 (B-60) ElectrodeClaudia MmsNo ratings yet

- Metrode ER110S-G FillerDocument6 pagesMetrode ER110S-G FillerBernie SimcsNo ratings yet

- Thermanit 22/09 Solid Wire For Joining Duplex Stainless SteelsDocument1 pageThermanit 22/09 Solid Wire For Joining Duplex Stainless SteelsbrayanNo ratings yet

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- Setup AquariumDocument2 pagesSetup AquariumGogo PNo ratings yet

- IAPLC 2008 Results Aquascaping ContestDocument40 pagesIAPLC 2008 Results Aquascaping ContestGogo P100% (2)

- Goldfish: Starting Out WithDocument16 pagesGoldfish: Starting Out WithGogo PNo ratings yet

- Mission Concepts and TimelinesDocument8 pagesMission Concepts and TimelinesGogo PNo ratings yet

- CDocument1 pageCGogo PNo ratings yet

- CDocument1 pageCGogo PNo ratings yet

- CDocument1 pageCGogo PNo ratings yet

- CDocument1 pageCGogo PNo ratings yet

- CDocument1 pageCGogo PNo ratings yet

- CDocument1 pageCGogo PNo ratings yet

- CDocument1 pageCGogo PNo ratings yet

- NCycleDocument2 pagesNCycleGogo PNo ratings yet

- 100+ Types of Goldfish: Learn About Ordinary & Fancy VarietiesDocument11 pages100+ Types of Goldfish: Learn About Ordinary & Fancy VarietiesGogo PNo ratings yet

- CDocument1 pageCGogo PNo ratings yet

- CDocument1 pageCGogo PNo ratings yet

- Aquarium Fish Compatibility ChartDocument1 pageAquarium Fish Compatibility ChartGogo PNo ratings yet

- Popis Zoo Shopova ZGDocument10 pagesPopis Zoo Shopova ZGGogo PNo ratings yet

- CDocument1 pageCGogo PNo ratings yet

- Optimum GoldfishDocument5 pagesOptimum GoldfishGogo PNo ratings yet

- Tropical Fish A Beginners Guide by William BergDocument86 pagesTropical Fish A Beginners Guide by William Bergdrluci2005100% (1)

- Fizika 1 Reklama 2011Document1,030 pagesFizika 1 Reklama 2011Gogo PNo ratings yet

- Goldfish: Carassius AuratusDocument2 pagesGoldfish: Carassius AuratusGogo PNo ratings yet

- Goldfish VarietiesDocument5 pagesGoldfish VarietiesGogo PNo ratings yet

- Basic Aquarium GuideDocument23 pagesBasic Aquarium GuidesecretpakNo ratings yet

- Elezović - Linearna AlgebraDocument104 pagesElezović - Linearna AlgebraGogo P100% (1)

- Optimum GoldfishDocument5 pagesOptimum GoldfishGogo PNo ratings yet

- Goldfish Care SheetDocument1 pageGoldfish Care SheetGogo PNo ratings yet

- Aquarium Water Chemistry For Goldfish - AspxDocument2 pagesAquarium Water Chemistry For Goldfish - AspxGogo PNo ratings yet

- Mig Welding HandbookDocument20 pagesMig Welding HandbookMomentumm100% (5)

- Fizika 1 Reklama 2011Document1,030 pagesFizika 1 Reklama 2011Gogo PNo ratings yet