Professional Documents

Culture Documents

Linx td001 - en P PDF

Uploaded by

Soufi BadrOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Linx td001 - en P PDF

Uploaded by

Soufi BadrCopyright:

Available Formats

RS

Linx

is a complete communication server providing

plant floor device connectivity for a wide variety

of Rockwell Software applications such as RSLogix 5,

RSLogix 500, RSLogix 5000, RSView32, and RSSql. In addition,

several open interfaces are provided for third-party HMI,

data collection and analysis packages or custom client

application software.

RSLinx is an OPC

- compliant data server supporting the OPC

Data Access 2.05 specifications. OPC is the standard for plant

floor communications between data servers and client

applications. RSLinx provides an OPC custom interface for

C/C++clients and an OPC Automation interface for VB/VBA

clients. RSLinx also supports multiple DDE formats

(AdvanceDDE, XL_TBL, CF_TXT) for clients such as Microsoft

Excel. RSLinx supports the integration of plant floor devices to

supply chain and business decision software applications using

products like RSSql. RSLinx can support multiple software

applications simultaneously communicating to devices on many

different networks.

FromAnywhere to Anywhere

You can virtually communicate from anywhere to anywhere

using RSLinx. The product provides a user-friendly graphical

interface for navigating through your network hierarchy. This

includes routing over the office Ethernet network through a

ControlLogix Gateway to get to your control networks and

devices on the plant floor. Select a device and right mouse click

to access a variety of integrated configuration and monitoring

tools such as configuration for the 1756-DHRIO module, Ladder

Viewer for PLC-5

, SLC, or MicroLogix

family processors, or a

Data Monitor for viewing data out of any ControlLogix, PLC-5,

SLC-5, or MicroLogix family controllers. A complete set of

communication drivers is provided for your networking needs

from older legacy Allen-Bradley networks supported by remote

routing through 1785-KA, 1785-KA5, 5130-KA, and 5820-EI to the

newer more capable ControlLogix Gateways. Communication

hardware such as PCMCIA, serial port, or PC-based network

card is supported.

The table below lists the supported device/networks:

Ethernet to PLC-5 / SLC-5 / 5820-EI / 1756-ENB

Ethernet/IP CIP Protocol

1784-KTX(D) / PKTX(D) / PCMK / KT / KT2 to DH+

1784-KTX(D) / PKTX(D) / PCMK to DH-485

1784-KTCX to ControlNet

1784-PCC to ControlNet

1784-PCIC(S) to ControlNet

1784-PCD / PCIDS to DeviceNet

(Windows NT

)

RS-232 Serial (DF1) to 1770-KF2 / 1785-KE to DH+

RS-232 Serial (DF1) to 1770-KF3 / 1747-KE / 1747-PIC

to DH-485

Te chnical Data

RSLinx

RS-232 Serial (DF1) to PLC-5, SLC-5, MicroLogix, PanelView

RS-232 Serial (DF1) to 1770-KFC to ControlNet

RS-232 Serial (DF1) to 1770-KFD to DeviceNet

RS-232 Serial (DF1) to ControlLogix

DF1 Polling Master (RS-232 serial)

DF1 Slave (RS-232 Serial)

SoftLogix 5

Controller

SoftLogix 5800 Controller

Remote Devices via RSLinx Gateway

RSWho

RSWho is the network browse interface providing a single

window to view all configured network drivers. The multi-pane

window allows navigation through network hierarchy in the left

pane while displaying device icons along with their status in

the right pane. A device that appears with a red X through it

indicates a communication status error, such as loss of power

to a device or disconnected communication cable. Select a

device, right-click, and a context-sensitive menu is displayed to

perform such actions as Configure New DDE/OPC topic or

displaying diagnostic information. This component has been

integrated into many of the Rockwell Software products to

provide a consistent, easy to use, graphical interface for device

selection.

Data Table Monitor

You can use RSLinx to view data values in a PLC-5, SLC-5,

MicroLogix, CompactLogix, FlexLogix or ControlLogix

processors. For a PLC-5 / SLC-5 / MicroLogix device, select a

data table file to view from a list of available data table files in

the controller. For a ControlLogix processor, view tag

information in a hierarchical list as the tags are defined in the

target device. Multiple data monitor windows can be displayed

at the same time providing an effective trouble-shooting tool.

Data Monitor functionality is only available with RSLinx

Professional and Gateway.

2

Ladder Viewer

RSLinx includes an extremely valuable Ladder Viewer for

PLC-5, SLC-5, or MicroLogix controller. Based on the RSLogix

family of programming software, it allows viewing of the ladder

code including symbols, address descriptions and rung

comments for an effective and complete diagnostic tool when

used on your HMI or data collection station on the production

floor. To view a ladder program, simply right-click on a

processor and select "View Ladder Code" from the context

menu. The control program is uploaded from the device and

displayed on the screen. If the matching offline program file

exists on the PC, then all associated comments and symbols

are also displayed. The Ladder Viewer has the capability to

select different program files to view. Use this capability in

conjunction with the ability to display multiple viewing windows

for effective trouble-shooting. Ladder Viewer functionality is

only available with RSLinx Professional and Gateway.

Remote Gateway Connectivity

RSLinx Gateway extends communications throughout the

enterprise. RSLinx clients such as RSLogix 5/500/5000 can

connect over Ethernet through an RSLinx Gateway and

seamlessly go online to a PLC-5, SLC-5, MicroLogix, or

ControlLogix processor residing on a control network

accessible by the gateway machine. Another key usage of

RSLinx Gateway is to optimize communications between

multiple OPC clients and plant floor devices. The benefit of

using RSLinx Gateway is that overlapping data requests from

multiple clients are consolidated into one request to the

controller thus reducing the overall network traffic and burden

on the target controller. From a cost perspective, you no longer

need a copy of RSLinx running on each client machine.

Open Interfaces

RSLinx provides connectivity for client applications using OPC

or DDE. OPC is the preferred

interface for data acquisition

applications because it is the

standard for factory

communications.

OLE for Process Control (OPC) OPC is based on Microsofts OLE

technology and is defined and managed by the OPC

Foundation, a coalition of industrial/manufacturing companies

of which Rockwell Software is a prominent member. The

charter of this group is to provide an industry-standard

exchange mechanism optimized for performance. RSLinx is an

OPC Data Access 2.05 compliant server providing an OPC

custom interface for C/C++client applications and an OPC

Automation interface for VB/VBA client applications. The

added benefit provided from RSLinx is its ability to provide

several DDE formats in addition to OPC and its DDE/OPC

diagnostic information.

RSLinx also supports multiple DDE formats (AdvanceDDE,

XL_Table, CF_Text) for client connectivity. These interfaces are

3

provided mainly for applications developed prior to the

incorporation of OPC in RSLinx and are still the primary

mechanism for creating DDE Hot Links in Excel.

Data Collection Modes

In RSLinx, you create a DDE/OPC Topic as a named alias to a

targeted device. This alias name is used when requesting data

in a client application through the OPC or DDE interfaces. Each

topic has parameters to specify poll rate, communication

timeout, and the data collection mode (Polled or Unsolicited). In

polled mode, RSLinx does all of the work, so it is easy to make

changes and control the communications. Polled mode does

however, add to the CPU usage on the PC since RSLinx is

constantly polling and increases the communication traffic

volume compared to unsolicited mode.

In Unsolicited mode, data is sent to RSLinx by a message

instruction in the processor. RSLinx waits for a packet from the

processor instead of polling. The advantage of this mode is that

communication traffic is typically reduced due to the controller

determining how often to send the data. Unsolicited mode is a

good method of transferring large amounts of data that

changes infrequently like when a product or batch completes

and the record data needs to be transferred to the client. The

disadvantage is that unsolicited mode requires ladder

programming to gather and send the data.

CustomApplications through SDK (Software

Development Kit)

RSLinx SDK is the Software Development Kit used for

creating custom applications utilizing the open interfaces built

into RSLinx. It contains development files, sample programs,

online documentation, and a copy of RSLinx OEM; everything

needed to create custom applications to communicate with

devices connected to RSLinx. RSLinx provides a migration

patch forward for existing INTERCHANGE Software

applications.In most cases, an INTERCHANGE software

application can be ported to RSLinx directly with minimal

changes.

Operational Tools

RSLinx includes a Backup/Restore utility accessible from the

Start menu. This tool saves configured drivers, topics, and

configuration settings. This allows you to restore your

application in case of a hardware failure or even deploy the

configuration to another PC.

An EDS Hardware Installation tool is provided for registering a

new Electronic Data Sheet (EDS). Electronic Data Sheets are

used by RSLinx to determine what to display in RSWho and to

resolve device properties.

An OPC Test Client is included with RSLinx for the purpose of

testing OPC communications. This simple tool allows you to test

and validate OPC data communications through RSLinx as an

HMI or data-based client would interact.

Diagnostic Tools

RSLinx includes a wealth of diagnostic information to assist you

in analyzing your system. Whether its troubleshooting a

communication problem or analyzing network throughput,

RSLinx provides the information you need. Diagnostics fall into

three major categories: Networks, Station, and OPC/ DDE.

Networks Diagnostic counters track server information such

as messages sent, messages received, messages

acknowledged, communication errors, and timeouts.

4

Performance counters give throughput in terms of

packets/second.

Station Diagnostic counters indicate information for a

selected station such as messages sent and received,

message retries, and packet errors.

OPC/DDE Multiple dialogs for DDE clients, OPC Groups,

Optimized Packets, and OPC/ DDE server connections display

diagnostic information specific to the category. A

Communication event log displays information specific to an

OPC/DDE transaction. You can configure RSLinx to save

communication events automatically at a specified interval

thus providing better diagnostic information when trouble-

shooting communication problems.

Selecting the Right Package

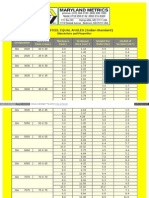

RSLinx is available in multiple packages to meet the demand for a variety of cost and functionality requirements. The following table

contains specific information on features supported in each package.

5

FEATURES LITE SINGLE NODE OEM SDK PROFESSIONAL GATEWAY

Communication Drivers X X X X X X

Integrated ControlLogix Gateway Configuration Tool X X X X X X

Driver and Station Diagnostics X X X X X X

Device Properties X X X X X X

Data Monitor X X

Ladder Viewer X X

DDE Support (CF_Text, XL_Table, AdvanceDDE) X* X X X X

Runtime support for local OPC Client Connection X* X X X X

Runtime support for custom C API application X X X X

OPC Automation Interface Documentation, Samples X

Remote OPC Client capability X

Remote Gateway Client Connection X

*Can only communicate with one device.

RSLinx Single Nodeincludes the required functionality to

supply communications services for all Rockwell Software

products. OPC and DDE interfaces are supported, but to only

one device. It does not support applications developed for the

RSLinx C Application Programming Interface (API) or direct

drivers in HMI applications.

RSLinx Single Node is used for the following:

Data acquisition using OPC or DDE to only one device. This

includes clients such as RSView32, Microsoft Office

, Visual

Basic

, and Web pages.

Ladder logic programming using RSLogix products.

Network and device configuration and diagnostics using

RSNetWorx

Configuring 1756-ENET, 1756-ENB, 1756-DHRIO, and 1757-

SRM modules.

Browsing networks and getting device information such as

firmware revision

Supports client applications using OPC (custom or

automation) or DDE (AdvanceDDE, XL_TBL, and CF_TXT).

RSLinx OEM includes the required functionality to supply

communications services for all Rockwell Software products.

OPC and DDE clients are supported for any number of devices.

It also supports applications developed for the RSLinx C

Application Programming Interface (API). RSLinx OEM Versions

2.30 or later support DDE formats XL_TBL and CF_TXT

in addition to AdvanceDDE.

RSLinx OEM is used for the following:

Data acquisition using OPC or DDE to any number of devices.

This includes clients such as RSView32, RSSql, Microsoft

Office, Visual Basic, and Web pages.

Ladder logic programming using RSLogix products.

Network and device configuration and diagnostics using

RSNetWorx

Configuring 1756-ENET, 1756-ENB, 1756-DHRIO, and 1757-

SRM modules.

Browsing networks and getting device information such as

firmware revision

Supports client applications using OPC (custom or

automation), DDE (AdvanceDDE, XL_TBL, and CF_TXT), or

custom applications developed for the RSLinx C API.

RSLinx Professional includes the required functionality to

supply communications services for all Rockwell Software

products. OPC and DDE clients are supported for any number of

devices. It also supports applications developed for the

RSLinx C Application Programming Interface (API). Additionally,

RSLinx Professional contains a data monitor for PLC, SLC,

MicroLogix and ControlLogix-based controllers and a ladder

logic viewer for PLC and SLC based controllers. RSLinx

Professional is great for maintenance and diagnostics. Access

your data and ladder logic within RSLinx!

RSLinx Professional is used for the following:

Monitoring PLC, SLC, MicroLogix, or ControlLogix data table

value directly from RSLinx.

Monitoring ladder logic of PLC, SLC, or MicroLogix family

processors directly from RSLinx.

Data acquisition using OPC or DDE to any number of devices.

This includes clients such as RSView32, RSSql, Microsoft

Office, Visual Basic, and Web pages running on the same PC.

Ladder Logic programming using RSLogix products.

Network and device configuration and diagnostics using

RSNetWorx.

Configuring 1756-ENET, 1756-ENB, 1756-DHRIO, and 1757-

SRM modules.

Supports client applications using OPC (custom or

automation), DDE (AdvanceDDE, XL_TBL, and CF_TXT), or

custom applications developed for the RSLinx C API.

6

RSLinx Gateway extends RSLinx-based communications

throughout the enterprise by connecting clients over TCP/IP

networks. Programming and configuration products such as

RSLogix and RSNetWorx use a local RSLinx connection via

RSLinx Gateway to communicate to plant floor networks and

devices. Remote HMI applications such as RSView32 can use

remote OPC to communicate through RSLinx Gateway for data

collection. This allows you to have multiple distributed

computers performing data collection through an RSLinx

Gateway to automatically optimize all OPC communications on

the subnets connected to the processors.

In addition to the capabilities provided in the RSLinx

Professional version, RSLinx Gateway offers remote

connectivity to:

Multiple RSView32 clients accessing data through one

RSLinx Gateway (remote OPC).

Remote PC running RSLogix connecting to a plant network

over a modem for online program changes.

Remote Microsoft Office applications displaying plant floor

data such as Excel.

A web page displaying plant floor data when the web server

and RSLinx are on separate computers.

Supports client applications using local or remote OPC

(custom or automation)

Local DDE (AdvanceDDE, XL_TBL, and CF_TXT), or custom

applications developed for the RSLinx C API.

RSLinx Software Development Kit (SDK)includes

documentation and technical support for developing OPC or C-

API clients to RSLinx. OPC clients are developed for data

acquisition, while C-API clients are typically used for device

configuration. A copy of RSLinx OEM is also supplied with

RSLinx SDK.

When developing OPC clients to RSLinx, you can use the OPC

automation interface for developing a VB/VBA client

application or the OPC custom interface for developing a C/C++

client application.

RSLinx SDK is used to:

Develop a VB/VBA client using the OPC Automation

Interface. With SDK you get documentation on how to use

Automation Interface, development support, and samples.

Develop a C/C++client using the OPC Custom interface.

Develop a client using RSLinx C-API by providing access to

libraries and documentation.

Build solutions using RSLinx, which makes it a great

resource for OEMs.

Supports direct programming to RSLinx OEM, RSLinx

Professional, and RSLinx Gateway.

Supports OPC programming to RSLinx Single Node, RSLinx

OEM, RSLinx Professional, and RSLinx Gateway

Web Based Answer Station

RSLinx Answer Station has been added to the RSLinx "Help"

menu. This site is a handy resource to the most up-to-date

information about RSLinx products and their use. You can reach

this site directly at

http://www.software.rockwell.com/assistance/rslinx/.

Catalog Numbers

RSLinx Lite This item is only available with other

appropriate products

9355-WABSNENE RSLinx Single Node

9355-WABOEMENE RSLinx OEM

9355-WABENE RSLinx Professional

9355-WABGWENE RSLinx Gateway

9355-WABCENE RSLinx SDK

Updates are also available by calling Technical Services

7

Technical Specifications

Pentium

100 MHz processor (faster processors will improve

performance)

32 MB of RAM minimum (64 MB or more recommended)

35 MB of available hard disk space (or more based on

specific application requirements)

16-color SVGA display with 800 x 600 or greater resolution

Windows-compatible pointing device

RSLinx can be used on any of the following Microsoft

operating systems:

Windows XP, Windows 2000 (Workstation, Advanced Server),

Windows NT SP3 or later (Workstation or Server), Windows

ME, or Windows 98.

RSLinx supports Windows 2000 Terminal Services and Citrix

2002 Rockwell Software Inc. All rights reserved. Printed in the United States of America. RSLinx, RSLogix, RSLogix 5, RSLogix 500, RSLogix 5000, RSView32, RSSql, AdvanceDDE, RSLinx Gateway,

RSWho, RSLinx SDK, INTERCHANGE, RSLinx OEM, RSNetWorx, and the Rockwell Software logo are trademarks of Rockwell Software Inc. PanelView, SoftLogix, ControlLogix, SLC and SLC-5 are

trademarks, and PLC, PLC-5, and MicroLogix are registered trademarks of Rockwell Automation. OPC is a registered trademark of the OPC Foundation. Microsoft, Windows, Visual Basic, Windows

NT, and Windows 95/98/2000/ME are registered trademarks of the Microsoft Corporation. ControlNet is a trademark of ControlNet International, Ltd., DeviceNet is a trademark of Open DeviceNet

Vendors Association, Inc. Pentiumis a registered trademark of Intel Corporation. All other trademarks are the property of their respective holders and are hereby acknowledged.

Doc ID LINX-TD001C-EN-P

Ro ckwe ll So ftware

For more information on the latest pricing or a demonstration of any

Rockwell Software package, please contact your local Rockwell Automation

sales office or Allen-Bradley distributor. For the very latest on Rockwell

Software products, visit our website at:

www.software.rockwell.com

You might also like

- RSLogix 5000 and RSLogix 500Document90 pagesRSLogix 5000 and RSLogix 500sayedmh100% (9)

- Computer Security NotesDocument28 pagesComputer Security NotesDr. Sandeep SaxenaNo ratings yet

- A Comparison of PACs To PLCsDocument3 pagesA Comparison of PACs To PLCskouki982hotmailcomNo ratings yet

- 9 Software Hmi PLC Opc Server AutomationDocument42 pages9 Software Hmi PLC Opc Server AutomationEngr Nayyer Nayyab MalikNo ratings yet

- Connecting To Allen-BradleyDocument16 pagesConnecting To Allen-Bradleycjutp86No ratings yet

- Controlnet ABDocument48 pagesControlnet ABCamilo A. InfanteNo ratings yet

- Humanities Data in RDocument218 pagesHumanities Data in REdwin Wang100% (1)

- Control The Future Today With Allen-Bradley's SLC 500™ Processors: Small Controllers For Big ApplicationsDocument6 pagesControl The Future Today With Allen-Bradley's SLC 500™ Processors: Small Controllers For Big Applicationsrahul_jagdev883914No ratings yet

- KEPServerEX FeaturesDocument28 pagesKEPServerEX FeaturesobinnabenedictNo ratings yet

- FactoryLink 7 2 Technical Overview Rev2Document30 pagesFactoryLink 7 2 Technical Overview Rev2sershp100% (1)

- OPC Is A Software Interface StandardDocument6 pagesOPC Is A Software Interface Standarditsurturn000No ratings yet

- Engineering Note. Connectivity To Allen-Bradley Controllers: by Eduardo BallinaDocument16 pagesEngineering Note. Connectivity To Allen-Bradley Controllers: by Eduardo BallinaJavier MiramontesNo ratings yet

- hc900 OpcserverDocument12 pageshc900 Opcservermanu2020No ratings yet

- Openenterprise: New Capability of Integrating Dcs and Scada Client / Server ArchitectureDocument20 pagesOpenenterprise: New Capability of Integrating Dcs and Scada Client / Server Architectureilie_vlassaNo ratings yet

- Figur 1: OPC Can Be Used To Conveniently Access S7, S5 and Other ControllersDocument6 pagesFigur 1: OPC Can Be Used To Conveniently Access S7, S5 and Other ControllersSaid AsseffaNo ratings yet

- Introduction To OPC - National InstrumentsDocument3 pagesIntroduction To OPC - National InstrumentsefasaravananNo ratings yet

- ChstutDocument2 pagesChstutDinesh Rukman RanarajaNo ratings yet

- Standardized Access To Process DataDocument4 pagesStandardized Access To Process Datasina20795No ratings yet

- Bu34p2a00 01eDocument7 pagesBu34p2a00 01eAlex AlvesNo ratings yet

- Communication For Process ControlDocument9 pagesCommunication For Process ControlVan QuynhNo ratings yet

- OPC Server SoftwareDocument8 pagesOPC Server SoftwaregauravNo ratings yet

- CX Lite Opc en Int01Document8 pagesCX Lite Opc en Int01fdfdfdfrtmNo ratings yet

- Integration Techniques of The Embedded Distributed Systems Using Programming Environments and Industrial Standard Communication ProtocolsDocument12 pagesIntegration Techniques of The Embedded Distributed Systems Using Programming Environments and Industrial Standard Communication ProtocolsSabine CrihanNo ratings yet

- SCADA Data Gateway Fact SheetDocument3 pagesSCADA Data Gateway Fact SheetAswanth Kumar KurellaNo ratings yet

- MatrikonOPC Server For SCADA UCS DatasheetDocument2 pagesMatrikonOPC Server For SCADA UCS DatasheetDonald Santana BautistaNo ratings yet

- HC900 Hybrid Controller: Kepware OPC Server For HC900 - Product NoteDocument12 pagesHC900 Hybrid Controller: Kepware OPC Server For HC900 - Product NoteTÀi VÕNo ratings yet

- Modbus Source Code LibrariesDocument4 pagesModbus Source Code LibrariesSocaciu VioricaNo ratings yet

- FactoryTalk GatewayDocument4 pagesFactoryTalk GatewayĐăngDũng100% (1)

- Automation Software Concept v2.6Document8 pagesAutomation Software Concept v2.6Iz MaxxNo ratings yet

- SCADA Data Gateway Fact SheetDocument3 pagesSCADA Data Gateway Fact Sheetjulio.dayanNo ratings yet

- Copy of PLC EXPERIMENT 6Document10 pagesCopy of PLC EXPERIMENT 6Anonymous DtXw1wNo ratings yet

- MVI69 MCM DatasheetDocument3 pagesMVI69 MCM DatasheetdroncanciomNo ratings yet

- 60 Series: Weight-Based Indicators & ControllersDocument6 pages60 Series: Weight-Based Indicators & ControllersDavid RodriguezNo ratings yet

- Architect OPC HartDocument3 pagesArchitect OPC HartAlex GonzalezNo ratings yet

- Power Generation Portal ABBDocument20 pagesPower Generation Portal ABBCristian TilinschiNo ratings yet

- Controllogix: Selection GuideDocument92 pagesControllogix: Selection GuideneoflashNo ratings yet

- Active Directory Replication Over FirewallsDocument22 pagesActive Directory Replication Over FirewallsServerGeeksNo ratings yet

- Tech Note 671 - Optimizing IO Performance in System PlatformDocument13 pagesTech Note 671 - Optimizing IO Performance in System PlatformsimbamikeNo ratings yet

- TX Factorylink BrochureDocument8 pagesTX Factorylink Brochurefrankp_147No ratings yet

- SAP Basis - Basic ReferenceDocument10 pagesSAP Basis - Basic Referencesai_balaji_8No ratings yet

- PAC Versus PLC: Measurement & ControlDocument1 pagePAC Versus PLC: Measurement & ControlEngr Nayyer Nayyab MalikNo ratings yet

- Inside: Delphi InformantDocument38 pagesInside: Delphi InformantjivasumanaNo ratings yet

- Serial To Parallel in Vhdl......Document18 pagesSerial To Parallel in Vhdl......Saurabh SasteNo ratings yet

- Delphi Informant Magazine Vol 6 No 8Document61 pagesDelphi Informant Magazine Vol 6 No 8sharkfinmikeNo ratings yet

- 1785 System OverviewDocument56 pages1785 System Overviewblade_king_3No ratings yet

- Dde ModbusDocument45 pagesDde ModbusJavier Alejandro QuingaNo ratings yet

- Kepserverex: Opc Server Software - Maximize The Promise of OpcDocument50 pagesKepserverex: Opc Server Software - Maximize The Promise of OpcsukasnoNo ratings yet

- OPC e PROFIBUS PDFDocument2 pagesOPC e PROFIBUS PDFChrixShines JornalNo ratings yet

- Introduction To OPC - National InstrumentsDocument3 pagesIntroduction To OPC - National InstrumentskarthikNo ratings yet

- Iasimp Qr010 en PDocument10 pagesIasimp Qr010 en PviorelducaNo ratings yet

- Adwin Flexray Data Acquisition SystemDocument2 pagesAdwin Flexray Data Acquisition SystemStewart ThompsonNo ratings yet

- RSView 32Document5 pagesRSView 32Josephus Ravanera100% (1)

- EOScada BrochureDocument4 pagesEOScada BrochuredanilonavNo ratings yet

- May 2000, Volume 6, Number 5: On The CoverDocument36 pagesMay 2000, Volume 6, Number 5: On The CoverjivasumanaNo ratings yet

- Introduction And: Figure 1-1. Control Panel BoardDocument41 pagesIntroduction And: Figure 1-1. Control Panel BoardRasoul SadeghiNo ratings yet

- OPC Overview: OPC (OLE For Process Control)Document3 pagesOPC Overview: OPC (OLE For Process Control)sifuszNo ratings yet

- Brochure Introduction To VTScada in The North East United StatesDocument5 pagesBrochure Introduction To VTScada in The North East United StatesTrihedralEngineeringNo ratings yet

- PLC: Programmable Logic Controller – Arktika.: EXPERIMENTAL PRODUCT BASED ON CPLD.From EverandPLC: Programmable Logic Controller – Arktika.: EXPERIMENTAL PRODUCT BASED ON CPLD.No ratings yet

- Citrix XenDesktop Implementation: A Practical Guide for IT ProfessionalsFrom EverandCitrix XenDesktop Implementation: A Practical Guide for IT ProfessionalsNo ratings yet

- Rslinx Classic Setup: Reporting From Rslinx Classic Defining A Dde/Opc TopicDocument2 pagesRslinx Classic Setup: Reporting From Rslinx Classic Defining A Dde/Opc TopicBhamidipati PremNo ratings yet

- Sl. No Description Make Qty: Annexure-2 List of Approved Make 160 KW Star Delta StarterDocument1 pageSl. No Description Make Qty: Annexure-2 List of Approved Make 160 KW Star Delta StarterBhamidipati PremNo ratings yet

- The Travancore Cochin Chemicals LTD.: EnquiryDocument2 pagesThe Travancore Cochin Chemicals LTD.: EnquiryBhamidipati PremNo ratings yet

- Nava Graha Stotram TeluguDocument2 pagesNava Graha Stotram TeluguBhamidipati PremNo ratings yet

- Esquema Schematic Dell - Inspiron n4030 WISTRON DJ1 Capella UMA 10212-1 48.4EK19.011Document90 pagesEsquema Schematic Dell - Inspiron n4030 WISTRON DJ1 Capella UMA 10212-1 48.4EK19.011Leandro PereiroNo ratings yet

- SAGE Pipeline DesignDocument5 pagesSAGE Pipeline DesignSanjivaniNo ratings yet

- LIN Basics and Implementation of The MCC LIN Stack Library On 8-Bit PIC MicrocontrollersDocument28 pagesLIN Basics and Implementation of The MCC LIN Stack Library On 8-Bit PIC MicrocontrollersNik NameNo ratings yet

- CT9 PDFDocument4 pagesCT9 PDFDevendra ShakyawarNo ratings yet

- CE3155 Introduction To ETABS (Multi-Storey)Document42 pagesCE3155 Introduction To ETABS (Multi-Storey)Imran SaikatNo ratings yet

- Question: Why Are Collisions Not Very Important in Modern Networks? WHDocument1 pageQuestion: Why Are Collisions Not Very Important in Modern Networks? WHAdrian Villanueva DatoNo ratings yet

- Blood-Bank-Management-Ssystem For Medicare Hospital in Nawina System Requerment SpecificationDocument31 pagesBlood-Bank-Management-Ssystem For Medicare Hospital in Nawina System Requerment SpecificationMohamed MusharrafNo ratings yet

- Accenture Vertical Integration POV Vertical 20Document21 pagesAccenture Vertical Integration POV Vertical 20Way DevNo ratings yet

- Chapter 4 - Queue 2019Document25 pagesChapter 4 - Queue 2019amirul hakimNo ratings yet

- Submitted in Partial Fulfillment of The Requirements For Award of The Degree ofDocument49 pagesSubmitted in Partial Fulfillment of The Requirements For Award of The Degree ofudit kosuruNo ratings yet

- B1+ UNIT 3 Life Skills Video WorksheetDocument1 pageB1+ UNIT 3 Life Skills Video WorksheetOlga100% (1)

- Choudhury2014 PDFDocument29 pagesChoudhury2014 PDFmaleeha mushtaqNo ratings yet

- Contextual Report (2023006)Document24 pagesContextual Report (2023006)Tech FiFtyNo ratings yet

- Customer Relationship ManagementDocument22 pagesCustomer Relationship ManagementAffan PrinceNo ratings yet

- Cs614 Assignment 02 BY AR Lucky TeamDocument3 pagesCs614 Assignment 02 BY AR Lucky TeamSadaqat BaigNo ratings yet

- AdvCiv ManualDocument622 pagesAdvCiv Manualjlaczko2002No ratings yet

- MIS605 Systems Analysis and DesignDocument5 pagesMIS605 Systems Analysis and DesignAbhilasha Dahiya100% (1)

- Rolled Steel Equal Angles (Indian Standard)Document4 pagesRolled Steel Equal Angles (Indian Standard)sandeepricky3dNo ratings yet

- Seqrite Data Loss Prevention DLP DatasheetDocument7 pagesSeqrite Data Loss Prevention DLP DatasheetAniel NathanialNo ratings yet

- Unit3 CryptographyDocument87 pagesUnit3 CryptographyRαndσm thíngsNo ratings yet

- Gaurav - ETHERNET CABLE - COLORCODE STANDARDS - Ethernet Cable Color CodeDocument6 pagesGaurav - ETHERNET CABLE - COLORCODE STANDARDS - Ethernet Cable Color CodeDejan VujanicNo ratings yet

- Anixter Data Center Solutions Brochure enDocument8 pagesAnixter Data Center Solutions Brochure enchristian kurniawanNo ratings yet

- 2d PlatformerDocument25 pages2d PlatformerNamithaNo ratings yet

- EdittedDocument11 pagesEdittedAkash DograNo ratings yet

- Ancel-X7: 2. Software DownloadingDocument2 pagesAncel-X7: 2. Software DownloadingOsmir MonteiroNo ratings yet

- CCNA 1 v6 Chapter 3Document8 pagesCCNA 1 v6 Chapter 3Webber JonxNo ratings yet

- ESI Online Help FileDocument44 pagesESI Online Help FileP.k. Venugopalan0% (1)

- PE NWC203c Made by MyselfDocument6 pagesPE NWC203c Made by MyselfNguyen Minh Tuan (K16HL)No ratings yet