Professional Documents

Culture Documents

Geology 229 Engineering Geology: Elementary Soil Mechanics (Cont. 2) (West, Ch. 7)

Geology 229 Engineering Geology: Elementary Soil Mechanics (Cont. 2) (West, Ch. 7)

Uploaded by

RodneyXerriOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Geology 229 Engineering Geology: Elementary Soil Mechanics (Cont. 2) (West, Ch. 7)

Geology 229 Engineering Geology: Elementary Soil Mechanics (Cont. 2) (West, Ch. 7)

Uploaded by

RodneyXerriCopyright:

Available Formats

Geology 229

Engineering Geology

Lecture 12

Elementary Soil Mechanics (cont. 2)

(West, Ch. 7)

Outline of this Lecture

1. Compaction/Consolidation

Soil densification include compaction and

consolidation.

Densification compaction + consolidation

Compaction is one kind of densification that is

realized by rearrangement of soil particles without

outflow of water. It is realized by application of

mechanic energy. It does not involve fluid flow, but

with moisture changing.

Consolidation is another kind of densification with

fluid flow away. Consolidation is primarily for clayey

soils. Water is squeezed out from its pores under

load.

The engineering purpose of compaction is to increase

the materials density.

1. Compaction effort,

2. soil type and gradation,

3. moisture content, and

4. dry density

are the 4 control factors to the extent of compaction.

Increase

permeability and

decrease

compressibility

West, Figure 7.11 Plasticity Chart

Lower compressibility

Higher compressibility

Standard Proctor Test

Compaction Effort is calculated with

the following parameters

Mold volume = 1/30 cubic foot

Compact in 3 layers

25 blows/layer

5.5 lb hammer

12" drop

hammer

cylindrical

container

Dry of optimum

wet of optimum

Total or wet density :

t

w s

t

t

V

M M

V

M +

= =

Solid density

s

dry density

d

s

s

s

V

M

=

s d s t

t

s

d

V V

V

M

< > = Q ,

Also we have

w

and w that so

w

V M

M M

V

M

V

M

V

M M

V

M

d d d

d

t s

s w

t

w

t

t

t

w t

t

s

d

+

= = +

= = =

= =

1

The purpose of conducting the Proctor

test is for finding out the optimal water

content and guide the compaction

project in the field.

Practically, you know the water content

w, you measure the wet density , and

then calculate the dry density. Sure you

can also bake the sample and directly

measure the dry density

d

.

Zero-air-void density:

At certain water content, what is the density

called if there is no air in the voids

s

w s

wG

G

v a z

+

=

1

) . . (

w

(zav)

s w w s w w w w w w

s w s s w s w

w s s s s s s s s

s

wG wG M V or V M

V by wG M w M then M M w

G V V M then V M

V

= = = =

= = = =

= = =

=

/ / ,

1 , , /

, /

1

s

s w

s

s w

t

t

dry

wG

G

wG w

G w

w V

M

w +

=

+ +

+

=

+

=

+

=

1 ) 1 )( 1 (

) 1 (

) 1 ( 1

Zero-air-void density:

At certain water content, what is the density

called if there is no air in the voids

s

w s

wG

G

v a z

+

=

1

) . . (

It is clear that in the above equation, specific gravity of the solid and the

water density are constant, the zero-air-void density is inversely

proportional to water content w. For a given soil and water content the

best possible compaction is represented by the zero-air-voids curve. The

actual compaction curve will always be below. For dry soils the unit

weight increases as water is added to the soil because the water

lubricates the particles making compaction easier. As more water is

added and the water content is larger than the optimum value, the void

spaces become filled with water so further compaction is not possible

because water is a kind like incompressible fluid. This is illustrated by the

shape of the zero-air-voids curve which decreases as water content

increases.

w

(zav)

Now we can make another description of

compaction in the engineering sense:

Compaction is for making the optimum density

as close as the zero-air-void as possible

Also we can conclude that more compaction

effort make the optimum density closed to

(zav) by the fact of the 2 linear lines have

different slopes.

Compaction curves for different soils with the same compact effort

(West, Figure 7.19); fine grain soil needs more water to reach optimum

and coarse grain soil needs less water to reach optimum.

In contrast to compaction, consolidation is the

reduction in volume of clayey soil under

external loading as water drained out from

pores.

e

water

solid

Vv=Vw=e

0

Vs=1

water

solid

0

0

0 0

1

,

1 e

e

H H then

e

e

H

H

+

=

+

Apparently, consolidation is the reason for

surface subsidence in areas of groundwater or

other crustal fluid over-draw.

Compaction Equipment

A. Types of Action

* Ramming

* Vibration

* Static Rollers

B. Ramming

Rammers have a low frequency (800

blows/minute), and a higher stroke (1.5" to

3.5height). As the machine operates the

ramming action breaks down the soil,

pushes the particles closer together, and

forces air out of the voids.

C. Vibration

Vibratory machines are distinguished by

their high frequency (2,000 to 6,000

blows/minute) and a low amplitude. The

vibratory action sets the soil particles in

motion, which rearranges them into a

denser packing.

Types of Rollers

1. Smooth Wheel Rollers or Smooth Drum Rollers are suitable for thin layers,

and for finishing operations.

2. Pneumatic Rubber-Tired Rollers have a series of rubber tires side-by-side

instead of a smooth drum. Compaction is achieved by a combination of

weight and kneading action.

3. Sheepsfoot Rollers are drums with a large number of "sheepsfoot"

projections. They are most effective in compacting clayey soils. The initial

pass in the field compacts the lower portion of the lift, with subsequent

passes compacting the middle and upper portions. The roller is said to "walk

out" as the soil is compacted and the feet do not penetrate as deeply as the

initial pass.

4. Vibratory Rollers work well in compacting granular soils. Vibratory action can

be used with smooth drum, rubber tired, or sheepsfoot rollers.

Field Compaction

A. Relative Compaction

Relative compaction is a way of comparing

compaction on the construction site with the

laboratory compaction results. It is defined as:

B. Water Content

In the field it has been found that soils compact better at water contents on

the dry side of the optimum water content.

C. Determination of Dry Unit Weight in the Field

Two methods in common use today to determine units weights and water

contents in the field are:

the Sand Cone Method, ASTM D-1556

the nuclear and non-nuclear density meters.

Field Compaction (cont.)

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5814)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (845)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Standard Fuel Consumption (Model)Document11 pagesStandard Fuel Consumption (Model)Sreekanth Sattiraju88% (48)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Mine Haul Road ManualDocument136 pagesMine Haul Road Manualfbtura100% (11)

- AASHTO GeoTechnical Design of PileDocument6 pagesAASHTO GeoTechnical Design of PileTee Bun PinNo ratings yet

- Tandem Vibratory Rollers: CB44B, CB54BDocument24 pagesTandem Vibratory Rollers: CB44B, CB54Brizki afynNo ratings yet

- Generic ProgrammingDocument90 pagesGeneric ProgrammingMostafa NouhNo ratings yet

- How Are Cracked Sections Analyzed in SAFE?Document2 pagesHow Are Cracked Sections Analyzed in SAFE?Mostafa NouhNo ratings yet

- Nonlinear Frame Finite Elements in OpenSeesDocument40 pagesNonlinear Frame Finite Elements in OpenSeesMostafa NouhNo ratings yet

- 3 Moments EquationDocument20 pages3 Moments EquationMostafa Nouh100% (2)

- Consolidation TestDocument10 pagesConsolidation TestMostafa NouhNo ratings yet

- Bearing Capacity of Pile: Sheet1Document2 pagesBearing Capacity of Pile: Sheet1Mostafa NouhNo ratings yet

- Hydrogen Engine - GeneralDocument35 pagesHydrogen Engine - GeneralMohamed EL SheikhNo ratings yet

- Finite Element Analysis of Deep Beams On Nonlinear Elastic FoundationsDocument30 pagesFinite Element Analysis of Deep Beams On Nonlinear Elastic FoundationsMostafa NouhNo ratings yet

- Buckling Secant Notes - Chapter6Document18 pagesBuckling Secant Notes - Chapter6vx800bikeNo ratings yet

- Autodesk - Free AutoLISP CourseDocument43 pagesAutodesk - Free AutoLISP CourseIván Men100% (1)

- Soil Laboratory Manual-DasDocument165 pagesSoil Laboratory Manual-Dassavsengineering93% (15)

- Siphon SpillwayDocument16 pagesSiphon SpillwayMostafa Nouh100% (1)

- Siphon SpillwayDocument16 pagesSiphon SpillwayMostafa Nouh100% (1)

- Cieewre08 09spl i&IIDocument5 pagesCieewre08 09spl i&IIMostafa NouhNo ratings yet

- Quality Control & Quality Assurance in National HighwaysDocument76 pagesQuality Control & Quality Assurance in National HighwaystauheedrameezNo ratings yet

- Basement Excavation: Excavation Is An Activity Where Man-Made Cut, Cavity, Trench, or Depression Are FormedDocument12 pagesBasement Excavation: Excavation Is An Activity Where Man-Made Cut, Cavity, Trench, or Depression Are FormedSHELAR GAURINo ratings yet

- Two Laning of Pasighat-Mariyang-Yingkiong Road From KM 0.00 To KM 19.887 in The State of Arunachal PradeshDocument21 pagesTwo Laning of Pasighat-Mariyang-Yingkiong Road From KM 0.00 To KM 19.887 in The State of Arunachal Pradeshمهدي المقدمNo ratings yet

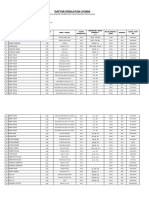

- Daftar AlatDocument2 pagesDaftar AlatRobby DarwisNo ratings yet

- Contruction Materials and EquipmentDocument31 pagesContruction Materials and EquipmentKristian RocaforNo ratings yet

- Chapter 6 - Road Construction MachineryDocument21 pagesChapter 6 - Road Construction MachineryAfricana Royal100% (1)

- Venkats Master DATA2008 09new1Document185 pagesVenkats Master DATA2008 09new1V Venkata Narayana67% (3)

- Materials and Equipment Management: Course No-Ncp 24/25 Assignment - 3Document15 pagesMaterials and Equipment Management: Course No-Ncp 24/25 Assignment - 3kangnaelaNo ratings yet

- Bomrg: Product Guide Heavy EquipmentDocument92 pagesBomrg: Product Guide Heavy Equipmentvatasa100% (1)

- ACI 309.5R-00 Compaction of Roller-Compacted Concrete PDFDocument15 pagesACI 309.5R-00 Compaction of Roller-Compacted Concrete PDFpatriciovernal100% (1)

- Lime Stabilisation ManualDocument42 pagesLime Stabilisation ManualMiguel RochaNo ratings yet

- What Is ThisDocument125 pagesWhat Is ThisMAC BROOKENo ratings yet

- Compaction and PavingDocument87 pagesCompaction and PavingRaphael Ruiz RamosNo ratings yet

- Hire ChargesDocument15 pagesHire ChargesRama Krishna ChaitanyaNo ratings yet

- Building Schedule of Rates Volume - IIIDocument1,055 pagesBuilding Schedule of Rates Volume - IIIA M100% (1)

- Top 120 Question Highway EngineeringDocument23 pagesTop 120 Question Highway Engineeringakash pandey100% (1)

- Hume Pipe Culvert Within Sump No - 2Document21 pagesHume Pipe Culvert Within Sump No - 2MD Maruf HussainNo ratings yet

- Hoisting Equipments - Construction & Building Materials Questions and Answers - SanfoundryDocument3 pagesHoisting Equipments - Construction & Building Materials Questions and Answers - SanfoundrySumedha SawniNo ratings yet

- Compactio N: R.Ravindranath, M.E (Geo. Tech)Document30 pagesCompactio N: R.Ravindranath, M.E (Geo. Tech)Ankur ChoudharyNo ratings yet

- Tools and Equipments Type Rate Per Day CalculationDocument5 pagesTools and Equipments Type Rate Per Day CalculationCherryl Chrissie JamesNo ratings yet

- Sistemas Hidrostáticos para Rodillos VibratoriosDocument12 pagesSistemas Hidrostáticos para Rodillos VibratoriosJheins GupeNo ratings yet

- Sumitomo Aspalt FinisherDocument24 pagesSumitomo Aspalt Finisherarfa ujiantoNo ratings yet

- Ingersoll Rand Roller SD70F BrochureDocument2 pagesIngersoll Rand Roller SD70F BrochureEd Calhe100% (2)

- RollersDocument15 pagesRollersRohith ChNo ratings yet

- Heavy Construction Equipment Needed For Dam ConstructionDocument5 pagesHeavy Construction Equipment Needed For Dam ConstructionEng-Mukhtaar Catoosh100% (1)

- NH Sor 2018 - 19Document50 pagesNH Sor 2018 - 19Monjit GogoiNo ratings yet

- Road Works PDFDocument13 pagesRoad Works PDFSasidhar ReddyNo ratings yet