Professional Documents

Culture Documents

ABS Megane

ABS Megane

Uploaded by

Violeta VioCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

ABS Megane

ABS Megane

Uploaded by

Violeta VioCopyright:

Available Formats

XA0X

C

The repair methods given by the manufacturer in this document are based

on the technical specifications current when it was prepared.

The methods may be modified as a result of changes by the manufacturer

in the production of the various component units and accessories from

which his vehicles are constructed".

All copyrights reserved by Renault.

Copying or translating, in part or in full, of this document or use of the

service part reference numbering system is forbidden without the prior

written authority of RENAULT.

77 11 197 913 JANUARY 1998 Edition Anglaise

Renault 1998

N.T. 2916A

Basic manual : M.R. 312

BOSCH ABS 5.3

Contents

38-1

38-13

38-14

38-16

38-31

38-32

38-33

38-35

Page

Bosch ABS

Fault finding - Introduction

Fault finding - XR25 fiche

Fault finding - Interpretation of

XR25 bargraphs

Fault finding - Checking conformity

Fault finding - Aid

Fault finding - Customer complaints

Fault finding - Fault charts

ELECTRONICALLY CONTROLLED

HYDRAULIC SYSTEM

38

ELECTRONICALLY CONTROLLED HYDRAULIC SYSTEM

BOSCH ABS

38

This vehicle is equipped with BOSCH ABS 5.3 of the four channel additional type ; the conventional braking

equipment and the ABS equipment are separate.

SPECIAL FEATURES

The system comprises four speed sensors. Each hydraulic braking channel has a sensor at each wheel. The

front wheels are therefore separately regulated. On the other hand, the rear wheels are simultaneously

regulated and in the same way according to the low selection principle known as "select low" (the first wheel

which tends to lock, causes immediate regulation on the complete axle assembly ).

On this vehicle, the braking compensator is suppressed (on versions equipped with ABS) and its role is

ensured by a special programme in the ABS assembly computer, called REF (Electronic Braking Distributor).

IMPORTANT :when the ABS fuse is removed, if a road test is carried out, be careful not to brake sharply as

the REF function is no longer activated (front and rear pressure is identical), so there is a risk that the vehicle

will spin.

38-1

ELECTRONICALLY CONTROLLED HYDRAULIC SYSTEM

BOSCH ABS

38

DI3801

PRESENTATION OF THE HYDRAULIC REGULATION UNIT

A Front left wheel

B Front right wheel

C Master cylinder inlet

D Rear right wheel

E Rear left wheel

38-2

ELECTRONICALLY CONTROLLED HYDRAULIC SYSTEM

BOSCH ABS

38

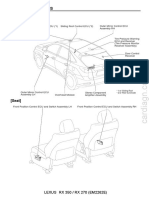

LOCATION OF COMPONENTS

PRH3801R

1 Hydraulic distributor

2 Wheel speed sensor

3 Toothed target

4 Brake lights switch

5 Nivocode warning light

6 ABS warning light

A Fitting of wheel drum

B Fitting of wheel disc

Hydraulic connections

Electrical connections

38-3

ELECTRONICALLY CONTROLLED HYDRAULIC SYSTEM

BOSCH ABS

38

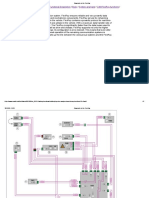

WIRING DIAGRAM

PRH14509

38-4

ELECTRONICALLY CONTROLLED HYDRAULIC SYSTEM

BOSCH ABS

38

WIRING DIAGRAM

PRH14683

38-5

ELECTRONICALLY CONTROLLED HYDRAULIC SYSTEM

BOSCH ABS

38

WIRING DIAGRAM KEY

150 Rear right hand wheel sensor

151 Rear left hand wheel sensor

152 Front right hand wheel sensor

153 Front left hand wheel sensor

160 Stop switch

225 Diagnostic socket

247 Instrument panel

645 Passenger compartment connection unit

721 ABS / hydraulic assembly / computer assembly

777 Power supply fuse board

R34 Engine/dashboard

R36 ABS/dashboard

R237 ABS engine / ABS under body

38-6

ELECTRONICALLY CONTROLLED HYDRAULIC SYSTEM

BOSCH ABS

38

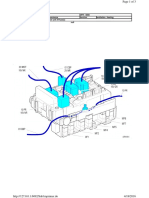

31 TRACK CONNECTOR

PRN3813

Track Description

1 Rear RH sensor earth

2 Not connected

3 Rear RH sensor information

4 Front RH sensor earth

5 Front RH sensor information

6 Front LH sensor earth

7 Front LH sensor information

8 Rear LH sensor earth

9 Rear LH sensor information

10 Not connected

11 Diagnostic line K

12 Diagnostic line L

13 Not connected

Allocation of connector tracks

Track Description

14 Stop lights switch information

15 + after ignition computer feed

16 Pump motor earth

17 + BAT (solenoid valves and pump motor)

18 + BAT (solenoid valves and pump motor)

19 Electronic earth

20 ABS fault warning light

21 NIVOCODE (REF) fault warning light

22 Not connected

25 Not connected

26 Front RH wheel speed output

27 Not connected

31 Not connected

A : Micro - spring earthing (terminal 19) pins 20 and 21 ( ABS and NIVOCODE warning lights) in case the

connector is disconnected.

38-7

ELECTRONICALLY CONTROLLED HYDRAULIC SYSTEM

BOSCH ABS

38

DIAGNOSTIC SOCKET

PRN3807R

4 Chassis earth

5 Electronic earth

7 Diagnostic line K

15 Diagnostic line L

16 + battery

38-8

ELECTRONICALLY CONTROLLED HYDRAULIC SYSTEM

BOSCH ABS

38

Pipe unions M 10 x 100 1.7

M 12 x 100 1.7

TIGHTENING TORQUES (in daN.m)

Place the vehicle on a lift.

REMOVAL

Disconnect the battery.

Fit a pedal press to limit the amount of brake fluid

which will run out.

Disconnect the connectors from the injection

computer and from the canister bleed solenoid

valve.

Remove the canister bleed solenoid valve (two

nuts) and the injection computer (two bolts).

14284S

Lift the vehicle and disconnect the ABS computer

connector by pulling the control collar.

14286S

Disconnect the four hydraulic assembly pipes,

mark their position for refitting.

14286-1S

38-9

ELECTRONICALLY CONTROLLED HYDRAULIC SYSTEM

BOSCH ABS

38

Lower the vehicle and disconnect the two hydrau-

lic assembly pipes.

14285R

Remove the hydraulic assembly by slackening the

two retaining nuts (1) (without removing them).

REFITTING

Refitting is the reverse of removal.

Bleed the braking circuit.

NOTE : the computer must not be removed.If it is

faulty, replace the complete hydraulic assembly.

38-10

ELECTRONICALLY CONTROLLED HYDRAULIC SYSTEM

BOSCH ABS

38

BLEEDING PROCEDURE

NOTE : the hydraulic assembly is pre-filled.

This bleeding procedure must be used when one of the following components has been removed:

- the hydraulic assembly,

- the master cylinder,

- the pipework (between the hydraulic assembly and the master cylinder).

NOTE : a braking circuit equipped with ABS must have no faults and must be operating correctly.If this is not

the case, overhaul the ABS circuit hydraulically and electrically.

1) Bleed the braking system conventionally using the pedal or a bleeding device.

NOTE : if, after a road test with ABS regulation, the pedal travel is not correct, bleed the hydraulic assem-

bly.

2) Bleeding the hydraulic assembly.

IMPORTANT : the bleeding order must be observed, beginning with the rear right brake, then rear left,

front left then front right.

a) Bleed the rear right brake by bleeding the hydraulic assembly secondary circuit using the XR25 :

- position the bleed container and the hose, open the brake bleed screw,

- pump the brake pedal (about 10 times),

- start the bleed command on the XR25 (refer to the section "Fault finding - Aid"),

- pump the brake pedal during the diagnostic bleed phase,

- at the end of the bleed cycle on the XR25, continue to pump the brake pedal and close the brake

bleed screw.

b) Carry out the procedure described in a) for the rear left, front left and front right brake.

c) Check the pedal travel and if it is not correct, restart the bleeding procedure.

IMPORTANT : ensure that there is sufficient brake fluid in the reservoir.

38-11

ELECTRONICALLY CONTROLLED HYDRAULIC SYSTEM

BOSCH ABS

38

CHECKING THE WHEEL SPEED SENSORS

Carry out:

a) a check of the resistance on the sensor connections (from the computer connector to the speed sensor

2 track connector),

b) a visual inspection of the teeth on the target : if they are faulty replace them,

c) a check of the air gap using a set of shims,

Front : 0.3 < X < 1.5 mm Rear : 0.2 < X < 1.4 mm

The air gap can only be checked on vehicles

equipped with rear disc brakes.

DI3860

d) a check of the sensor mounting.

38-12

ABS 53641.0

ELECTRONICALLY CONTROLLED HYDRAULIC SYSTEM

Fault finding - Introduction

38

BOSCH

ABS 5.3

CONDITIONS FOR APPLYING THE TESTS DEFINED IN THIS FAULT FINDING

The tests defined in this fault finding are only to be applied when the description of the fault dealt with

corresponds exactly to the display given on the XR25.

If a fault is dealt with due to a bargraph flashing, the conditions for confirming the actual presence of the

fault (and the need to apply fault finding) are given in the "Notes" box or at the start of the bargraph

interpretation procedure.

If a bargraph is only interpreted when it is permanently illuminated, applying the tests recommended in the

fault finding when the bargraph is flashing will not allow the reason why this fault was memorised to be

located. In this case, only the wiring of the faulty component should be checked (the fault is simply

memorised since it was not present at the time of the test).

NOTE : the ignition must have been switched on before the XR25 is used.

SPECIAL TOOLING REQUIRED FOR WORKING ON THE ABS SYSTEM

- XR25 test kit.

- Cassette XR25 n 17 minimum.

Reminders:

The connection between the engine compartment / passenger compartment is different on "right hand

drive" and Scnic versions in relation to "left hand drive" versions :

- left hand drive apart from the Scnic : R36 ABS / dashboard union.

- right hand drive and Scnic : R254 dashboard / scuttle panel + R255 ABS / scuttle panel union.

The right hand drive and Scnic have additional scuttle panel wiring, the R255 connection being identical to

the R36 on the left hand drive version.

When memorising an intermittent fault, the ABS warning light will illuminate the next time the vehicle is

used until the speed equals 7.5 mph (12 km/h). When the fault is memorised, a counter associated to the fault

is set to 40. This value is reduced by 1 every time the ignition is switched on if the fault is not present when the

vehicle speed exceeds 7.5 mph (12 km/h).

When the counter value equals 1, it remains at 1 and the fault is not erased.

38-13

ABS 53641.0

ELECTRONICALLY CONTROLLED HYDRAULIC SYSTEM

Fault finding - XR25 fiche

38

BOSCH

ABS 5.3

XR25 FICHE N 53 CASSETTE N 17

FI21753

38-14

ABS 53641.0

ELECTRONICALLY CONTROLLED HYDRAULIC SYSTEM

Fault finding - XR25 fiche

38

BOSCH

ABS 5.3

REPRESENTATION OF THE BARGRAPHS

- Faults (always on a coloured background) :

If illuminated, there is a fault on the product tested. The associated text

defines the fault.

This bargraph can be:

- Illuminated : fault present.

- Flashing : fault memorised.

- Extinguished : fault absent or not found.

- Status (always on a white background):

Bargraph always located at the top right.

If illuminated, there is a problem setting up the dialogue with the product computer.

If it remains extinguished:

- The code does not exist.

- There is a tool, computer or XR25/computer connection fault.

The representation of the following bargraphs gives their initial status:

Initial status: (ignition on, engine stopped, no operator action).

Undefined is illuminated when the function or condition specified on the fiche is

met

Extinguished

Illuminated extinguishes when the function or condition specified on the fiche

is no longer being met

Additional details:

Some bargraphs have a *. The command *.., when the bargraph is illuminated is used to display additional

information about the type of fault or status present.

or

38-15

ABS 53641.0

ELECTRONICALLY CONTROLLED HYDRAULIC SYSTEM

Fault finding - Interpretation of XR25 bargraphs

38

BOSCH

ABS 5.3

AFTER

REPAIR

Bargraph 1 RH extinguished

Code present

1

None.

NOTES

Fiche n 53

Ensure that the XR25 kit is not the cause of the fault by trying to communicate with a computer on

another vehicle. If the XR25 is not the cause and if dialogue cannot be established with another computer

on the same vehicle, it may be that a faulty computer is disrupting fault finding lines K and L. Disconnect

the computers in sequence to locate the faulty one.

Check the ISO interface is in position S8 and that you are using the latest version of the XR25 cassette and

the correct access code.

Check the battery voltage and carry out any necessary repairs to obtain a correct voltage (9.5 volts < U

battery < 17.5 volts).

Check the presence and condition of the ABS fuse on the passenger compartment fuse board (5A).

Check that the computer connector is correctly connected and check the condition of the connection.

Check the connection of the 14 track R36 ABS / dashboard (R254 + R255 on the Scnic and on right hand

drive vehicles) connection in the scuttle panel near the battery and check the condition of the

connection.

Check the ABS earths (tighten the two earth bolts above the ABS assembly).

Check that the computer feed is correct :

- earth on track 19 of the 31 track connector,

- + after ignition on track 15 of the 31 track connector.

Check that the diagnostic socket feed is correct:

- +before ignition on track 16,

- earth on track 5.

Check the continuity and the insulation of the diagnostic socket / ABS computer connection lines:

- between track 12 of the computer connector and track 15 of the diagnostic socket ,

- between track 11 of the computer connector and track 7 of the diagnostic socket .

If a dialogue is still not established after these various tests, replace the ABS computer.

When communication has been established, deal with any fault bargraphs which

may be illuminated.

38-16

ABS 53641.0

ELECTRONICALLY CONTROLLED HYDRAULIC SYSTEM

Fault finding - Interpretation of XR25 bargraphs

38

BOSCH

ABS 5.3

AFTER

REPAIR

After replacing the computer, carry out another test using the XR25.

Bargraph 1 LH illuminated

Feed / Computer

1

None.

NOTES

Fiche n 53

Erase the computer memory, exit fault finding (G13*) and switch off the ignition.

Test again with the XR25. If the "feed / computer" fault persists, replace the ABS computer.

Check the condition and the position of the ABS 60A fuse on the engine connection unit.

Ensure the continuity between the fuse and tracks 17 and 18 of the computer connector ( presence of

+before ignition on both tracks ). Check the condition of the battery terminals and that they are tight.

Check the wiring on the 31 track connector of the ABS computer.

Check the ABS earths (above the hydraulic assembly) and visually check all the ABS wiring.

38-17

ABS 53641.0

ELECTRONICALLY CONTROLLED HYDRAULIC SYSTEM

Fault finding - Interpretation of XR25 bargraphs

38

BOSCH

ABS 5.3

Erase the computer memory (GO**).

Carry out a road test then check using the XR25.

AFTER

REPAIR

Bargraph 2, 3, 4 or 5 RH or LH flashing

Solenoid valve circuit

Even when present at the time of the test, these faults will always be declared by

a flashing bargraph.

To confirm their presence and therefore the need to apply the fault finding

below, start command G20*. The fault is present if the bargraph illuminates

again permanently at the end of the command.

If bargraph 11 LH is also illuminated, deal with this bargraph 11 LH first.

NOTES

Fiche n 53 2 - 3 - 4 - 5

Check the ABS earths (tighten the two bolts above the ABS assembly).

Check the condition and position of the ABS 60A fuse in the engine connection unit.

Check the connection and condition of the wiring on the 31 track connector of the computer .

Erase the computer memory, exit fault finding (G13*) and switch off the ignition.

Switch on the ignition and test again with the XR25 using command G20*.

If the "solenoid valve circuit" fault reappears, replace the ABS computer.

38-18

ABS 53641.0

ELECTRONICALLY CONTROLLED HYDRAULIC SYSTEM

Fault finding - Interpretation of XR25 bargraphs

38

BOSCH

ABS 5.3

Erase the computer memory (GO**).

Carry out a road test then check using the XR25.

AFTER

REPAIR

Bargraph 6 LH illuminated

Front LH wheel sensor circuit

6

None.

NOTES

Fiche n 53

If all the checks are correct, reconnect the computer and the wheel speed sensor then erase the computer

memory.

Exit fault finding (G13*) and switch off the ignition.

Switch on the ignition again and replace the sensor if the fault reappears.

If the fault reappears after the sensor is replaced, replace the computer.

Check the connection and the condition of the sensor wiring.

If the connector is correct, check the resistance of the sensor on its connector. Replace the sensor if its

resistance is not around 1.1 KOhms.

If the resistance is correct, check and ensure the continuity of the connections between the sensor

connector and the computer connector:

- between one track of the sensor connector and track 7 of the computer connector,

- between the other track of the sensor connector and track 6 of the computer connector.

Also check the insulation between these connections.

Visually check the wiring of the sensor and check the quality of the wiring on the 31 track connector of

the computer.

38-19

ABS 53641.0

ELECTRONICALLY CONTROLLED HYDRAULIC SYSTEM

Fault finding - Interpretation of XR25 bargraphs

38

BOSCH

ABS 5.3

Erase the computer memory (GO**).

Carry out a road test then check using the XR25.

AFTER

REPAIR

Bargraph 6 RH illuminated

Front right hand wheel sensor circuit

6

None.

NOTES

Fiche n 53

If all the checks are correct, reconnect the computer and the wheel speed sensor then erase the computer

memory.

Exit fault finding (G13*) and switch off the ignition.

Switch on the ignition again and replace the sensor if the fault reappears.

If the fault reappears after the sensor has been replaced, replace the computer.

Check the connection and the condition of the sensor wiring.

If the connector is correct, check the resistance of the sensor on its connector.

Replace the sensor if its resistance is not around 1.1 KOhms.

If the resistance is correct, check and ensure the continuity of the connections between the sensor

connector and the computer connector:

- between one track of the sensor connector and track 4 of the computer connector,

- between the other track of the sensor connector and track 5 of the computer connector.

Also check the insulation between these connections.

Visually check the wiring of the sensor and check the quality of the wiring on the 31 track connector of

the computer.

38-20

ABS 53641.0

ELECTRONICALLY CONTROLLED HYDRAULIC SYSTEM

Fault finding - Interpretation of XR25 bargraphs

38

BOSCH

ABS 5.3

Erase the computer memory (GO**).

Carry out a road test then check using the XR25.

AFTER

REPAIR

Bargraph 7 LH illuminated

Rear LH wheel sensor circuit

7

None.

NOTES

Fiche n 53

If all the checks are correct, reconnect the computer and the wheel speed sensor then erase the computer

memory.

Exit fault finding (G13*) and switch off the ignition.

Switch on the ignition again and replace the sensor if the fault reappears.

If the fault reappears after the sensor has been replaced, replace the computer.

Check the connection and the condition of the sensor wiring.

Check the connections at the intermediate connector under the body (R237).

If the connector and the connection are correct, check the resistance of the sensor on its connector.

Replace the sensor if its resistance is not around 1.1 KOhms.

If the resistance is correct, check and ensure the continuity of the connections between the sensor

connector and the computer connector:

- between one track of the sensor connector and track 8 of the computer connector (via track B of the

connection under the body R237),

- between the other track of the sensor connector and track 9 of the computer connector (via track A of

the connection under the body R237).

Also check the insulation between these connections.

Visually check the wiring of the sensor and check the quality of the wiring on the 31 track connector of

the computer.

38-21

ABS 53641.0

ELECTRONICALLY CONTROLLED HYDRAULIC SYSTEM

Fault finding - Interpretation of XR25 bargraphs

38

BOSCH

ABS 5.3

Erase the computer memory (GO**).

Carry out a road test then check using the XR25.

AFTER

REPAIR

Bargraph 7 RH illuminated

Rear RH wheel sensor circuit

7

None.

NOTES

Fiche n 53

If all the checks are correct, reconnect the computer and the wheel speed sensor then erase the computer

memory.

Exit fault finding (G13*) and switch off the ignition.

Switch on the ignition again and replace the sensor if the fault reappears.

If the fault reappears after the sensor has been replaced, replace the computer.

Check the connection and the condition of the sensor wiring.

Check the connections at the intermediate connector under the body (R237).

If the connector and the connection are correct, check the resistance of the sensor on its connector.

Replace the sensor if its resistance is not around 1.1 KOhms.

If the resistance is correct, check and ensure the continuity of the connections between the sensor

connector and the computer connector:

- between one track of the sensor connector and track 1 of the computer connector (via track D of the

connection under the body R237),

- between the other track of the sensor connector and track 3 of the computer connector (via track C of

the connection under the body R237).

Also check the insulation between these connections.

Visually check the wiring of the sensor and check the quality of the wiring on the 31 track connector of

the computer.

38-22

ABS 53641.0

ELECTRONICALLY CONTROLLED HYDRAULIC SYSTEM

Fault finding - Interpretation of XR25 bargraphs

38

BOSCH

ABS 5.3

Erase the computer memory (GO**).

Carry out a road test then check using the XR25.

AFTER

REPAIR

Bargraph 8 RH or LH flashing

Front RH or front LH wheel sensor signal

Even if present at the time of the test, these faults will always be declared by BG8

LH or RH flashing.

To confirm their presence and therefore the need to apply the fault finding be-

low, carry out a road test . The fault is present if the bargraph illuminates perma-

nently during the test.

If bargraphs 6 and 8 LH are both illuminated, deal with bargraph 6 first.

If bargraphs 6 and 8 RH are both illuminated, deal with bargraph 6 first.

NOTES

Fiche n 53 8

Check the quality of the wheel speed sensor mounting (position and tightening torque).

Check the sensor / target air gap over one wheel revolution : 0.3 mm < air gap < 1.5 mm.

Check the conformity of the target (condition, number of teeth= 44).

Visually check the sensor wiring and check the quality of the wiring on the 31 track connector of the

computer.

If all the checks are correct, reconnect the computer and the wheel speed sensor then erase the computer

memory.

Exit fault finding (G13*) and carry out a road test . Replace the sensor if the fault reappears.

If the fault reappears after replacing the sensor, it may be caused by the faulty operation of a solenoid

valve. The solenoid valves must therefore be checked hydraulically with the XR25 using command G03* or

G04*(refer to section "Aid"). If ten locking/releasing cycles are not performed on one of the wheels, re-

place the hydraulic assembly.

If the hydraulic assembly is not faulty, replace the computer.

Check the connection and the condition of the sensor wiring.

If the connector is correct, check the resistance of the sensor on its connector.

Replace the sensor if its resistance is not around 1.1 KOhms.

38-23

ABS 53641.0

ELECTRONICALLY CONTROLLED HYDRAULIC SYSTEM

Fault finding - Interpretation of XR25 bargraphs

38

BOSCH

ABS 5.3

Erase the computer memory (GO**).

Carry out a road test then check using the XR25.

AFTER

REPAIR

Bargraph 9 RH or LH flashing

Rear RH or rear LH wheel sensor signal

Even if present at the time of the test, these faults will always be declared by BG9

LH or RH flashing.

To confirm their presence and therefore the need to apply the fault finding be-

low, carry out a road test. The fault is present if the bargraph illuminates perma-

nently during the test.

If bargraphs 7 and 9 LH are both illuminated, deal with bargraph 7 first.

If bargraphs 7 and 9 RH are both illuminated, deal with bargraph 7 first.

NOTES

Fiche n 53 9

Check the quality of the wheel speed sensor mounting (position and tightening torque).

Check the connection and the condition of the sensor wiring.

Check the connections at the intermediate connector under the body R237.

If the connector is correct, check the resistance of the sensor on its connector.

Replace the sensor if its resistance is not around 1.1 KOhms.

Visually check the sensor wiring and check the quality of the wiring on the 31 track connector of the

computer.

If all the checks are correct, reconnect the computer and the wheel speed sensor then erase the computer

memory. Exit fault finding (G13*) and carry out a road test.

If the fault reappears, check the conformity of the target :condition, number of teeth = 44.

Check the sensor / target air gap over one wheel revolution : 0.2 mm < air gap < 1.4 mm (if disc brakes).

If the fault reappears after the sensor has been replaced, it may be caused by a solenoid valve operating

fault. It is therefore necessary to check the solenoid valves hydraulically with the XR25 using command

G05* or G06* (refer to the section "Aid"). If ten locking/releasing cycles are not performed on one of the

wheels, replace the hydraulic assembly.

If the hydraulic assembly is not faulty, replace the computer.

If all the checks are correct, erase the computer memory, exit fault finding and carry out a road test.

Replace the sensor if the fault reappears .

38-24

ABS 53641.0

ELECTRONICALLY CONTROLLED HYDRAULIC SYSTEM

Fault finding - Interpretation of XR25 bargraphs

38

BOSCH

ABS 5.3

Erase the computer memory (GO**).

Carry out a road test then check using the XR25.

AFTER

REPAIR

Bargraph 10 RH illuminated or flashing

Pump motor circuit

XR25 aid: * 30 1.dEF : Permanent control or CO engine earth.

2.dEF : Motor not rotating.

10

If bargraph 10 RH is flashing, confirm the presence of the fault and therefore the

need to apply the fault finding below by starting command G20* on the XR25.

The fault is present if the bargraph reappears permanently illuminated at the end

of the command.

NOTES

Fiche n 53

If all the tests are correct, reconnect the computer then erase the memory using command G0**.

Exit fault finding (G13*) and carry out a road test.

Replace the computer if the fault reappears.

Check the ABS earths (tighten the two earth bolts above the hydraulic assembly).

Check / ensure the continuity between the ABS earth and track 16 of the computer connector.

Check that the 2 track connector of the pump motor is locked.

NOTES Replace the computer if the pump motor operates permanently.

Replace the hydraulic assembly (mechanical blockage of the pump...).

NOTES None.

1.dEF

2.dEF

38-25

ABS 53641.0

ELECTRONICALLY CONTROLLED HYDRAULIC SYSTEM

Fault finding - Interpretation of XR25 bargraphs

38

BOSCH

ABS 5.3

Erase the computer memory (GO**).

If the computer is replaced, test again using the XR25.

AFTER

REPAIR

Bargraph 11 LH illuminated

Solenoid valve feed fault

11

Fiche n 53

If all checks are correct, reconnect the computer then erase the fault memory using command G0**.

Exit fault finding (G13*) and carry out a road test. Replace the computer if the fault reappears.

Carry out the operations necessary to obtain a correct voltage between tracks 19 and 17/18 of the 31

track connector of the ABS computer (9.5 volts < correct voltage < 17.5 volts) :

- Check the tightness and condition of the battery terminals.

- Check the 60A fuse on the engine connection unit (white mounting).

- Ensure the continuity between the 60A fuse and tracks 17 and 18 of the computer connector.

- Check the ABS earths (tighten the two earth bolts above the hydraulic assembly).

- Check/ ensure the continuity between the ABS earth and track 19 of the computer connector.

None.

NOTES

38-26

ABS 53641.0

ELECTRONICALLY CONTROLLED HYDRAULIC SYSTEM

Fault finding - Interpretation of XR25 bargraphs

38

BOSCH

ABS 5.3

AFTER

REPAIR

Bargraph 12 LH illuminated or flashing

Brake light circuit

12

Fiche n 53

Operate the brake pedal whilst monitoring bargraphs 13 RH and LH.

Are the "pedal released" and "pedal pressed down" positions correctly recognised?

None.

NOTES

YES

Check the two stop light bulbs and the earth of the rear light units ( track 14

not earthed through the bulbs when the pedal is not pressed down).

NO

Apply the fault finding described in the interpretation of bargraphs 13 LH and

RH for cases "Bargraph 13 LH extinguished, brake pedal pressed down".

Erase the computer memory (GO**).

If the computer has been replaced, test again using the XR25.

38-27

ABS 53641.0

ELECTRONICALLY CONTROLLED HYDRAULIC SYSTEM

Fault finding - Interpretation of XR25 bargraphs

38

BOSCH

ABS 5.3

Erase the computer memory (GO**).

Test again using the XR25.

AFTER

REPAIR

Bargraph 12 RH flashing

Target of one of the wheels

12

Fiche n 53

Even if present at the time of the test, this fault will always be declared by a BG12

RH flashing.

To confirm its presence and therefore the need to apply the fault finding below,

carry out a road test. The fault is present if the bargraph illuminates permanently

during the test.

NOTES

Check the quality of the wheel speed sensor mounting (position and tightening torque).

Check the conformity of the targets :condition, number of teeth = 44.

38-28

ABS 53641.0

ELECTRONICALLY CONTROLLED HYDRAULIC SYSTEM

Fault finding - Interpretation of XR25 bargraphs

38

BOSCH

ABS 5.3

AFTER

REPAIR

13

Bargraph 13 LH extinguished, brake pedal pressed down on a vehicle equipped with a passenger

compartment connection unit (UC BIC)

Only apply the checks below if the bargraph illumination is not consistent with

the pedal position.

NOTES

Bargraph 13 RH and LH

Brake pedal Illuminated LH side if pedal pressed down.

Illuminated RH side if pedal not pressed down.

If the brake lights are operating :

- Ensure the continuity between track 19 of the P17 connector of the passenger compartment connec-

tion unit and track 14 of the ABS computer connector .

- Replace the passenger compartment connection unit if its internal continuity between tracks B4 of P14

and 19 of P17 is not ensured.

If the brake lights are not operating :

- Check the condition and adjustment of the stop switch and the 15A fuse of the brake lights (on the

passenger compartment connection unit). Replace it if necessary.

- Disconnect the brake light switch then check / ensure the presence of+ after ignition on track 1 of the

connector (continuity between this track 1 and track A1 of the P14 connector of the passenger

compartment connection unit).

- Check the operation of the brake light switch contact (closed contact between tracks 1 and 3).

- Check and ensure the continuity between track 3 of the brake light switch connector and track B4 of

the P14 connector of the passenger compartment connection unit.

- Replace the passenger compartment connection unit if the internal continuity between tracks B4 of

P14, B5 of P13 and 19 of P17 is not ensured.

- Also ensure the continuity between track 19 of the P17 connector of the passenger compartment

connection unit and track 10 of the ABS computer connector ( R36 ABS / dashboard intermediate

connection or R254 + R255 on the Scnic and on right hand drive vehicles).

Bargraph 13 LH extinguished brake pedal pressed down on vehicles equipped with a relay fuse unit (no

UC BIC)

If the brake lights are operating :

- Ensure the continuity between dashboard / rear LH connection R2 on track 3 and track 14 of the ABS

computer connector .

If the brake lights are not operating :

- Check the condition and adjustment of the brake light switch and the 15A brake light fuse (on the

passenger compartment fuse board). Replace it if necessary.

- Disconnect the brake light switch then check / ensure the presence of + after ignition on track 1 of the

connector.

- Check the operation of the brake light switch contact (closed contact between tracks 1 and 3).

- Check and ensure continuity between track 3 of the brake light switch connector and the dashboard /

Rear LH R2 connection on track 3.

Carry out a road test followed by a check with the XR25 kit.

38-29

ABS 53641.0

ELECTRONICALLY CONTROLLED HYDRAULIC SYSTEM

Fault finding - Interpretation of XR25 bargraphs

38

BOSCH

ABS 5.3

AFTER

REPAIR

13

CONT

Bargraph 13 permanently illuminated on the LH on vehicles equipped with a passenger compartment

connection unit (UC BIC)

Bargraph 13 permanently illuminated LH on vehicles equipped with a relay fuse unit

(not UC BIC)

- Check the condition and adjustment of the brake light switch. Replace it if necessary.

- Check the operation of the brake light switch contact (contact closed between 1 and 3). Replace the

brake light switch if there is permanent continuity between these two tracks.

- Check and ensure insulation from 12 volts of the connection between track 3 of the brake light switch

connector and track 14 of the ABS computer connector .

Intermediate connections (internal connection to the passenger compartment connection unit) :

- track B4 of the P14 connector.

- track 19 of the P17 connector.

Intermediate connection(s) : R36 ABS / dashboard or R254 + R255 on the Scnic and on right hand

drive vehicles.

- Check the condition and adjustment of the brake light switch. Replace it if necessary.

- Check the operation of the brake light switch contact (closed contact between tracks 1 and 3). Replace

the brake light switch if there is permanent continuity between these two tracks.

- Check and ensure insulation from 12 volts of the connection between track 3 of the brake light switch

connector and track 14 of the ABS computer connector.

Intermediate connections :

- ABS / dashboard R36 (or R254 + R255 on the Scnic and on right hand drive vehicles)

- Dashboard / rear LH R2.

Carry out a road test followed by a check using the XR25.

38-30

Order of

operations

Function to be checked Action Bargraph Display and notes

1 Dialogue with XR25

D11

(selector on

S8)

2 Computer conformity #12

3

Operation of the ABS

warning light-

computer initialisation

check

Ignition

turned on

Warning light illuminates for 2

seconds when the ignition is

turned on (refer to fault finding

if it remains illuminated or if it

does not illuminate).

4

Recognition of brake

pedal not pressed

5

Recognition of brake

pedal pressed down

Press brake

pedal

13

13

ABS 53641.0

ELECTRONICALLY CONTROLLED HYDRAULIC SYSTEM

Fault finding - Checking conformity

38

BOSCH

ABS 5.3

Carry out this conformity check only after a complete check using the XR25.

NOTES

38-31

ABS 53641.0

ELECTRONICALLY CONTROLLED HYDRAULIC SYSTEM

Fault finding - Aid

38

BOSCH

ABS 5.3

USING THE COMMAND MODES :

Controlling the solenoid valves for a hydraulic test : G03* to G06*

Lift the vehicle to allow the wheels to be turned and check that they rotate freely.

Keep the brake pedal pressed down to prevent the wheel being tested rotating if when it is being

moved by hand (do not brake too hard so as to be at the releasing limit).

Enter G0X* Ten cycles of unlocking / locking must be noted on the wheel concerned.

Controlling the pump motor : G08*

Enter G08* and press down on the brake pedal The motor should operate for

2 seconds.

Controlling the pump motor and the solenoid valves : G20*

Enter G20* and press down on the brake pedal The motor and solenoid valves should

operate briefly.

Bleeding the hydraulic circuits : G15*3* Front LH / G15*4* Front RH / G15*5* Rear LH / G15*6* Rear

RH

Apply the procedure described in the "Bleeding the circuits" section of the Technical Note.

38-32

ELECTRONICALLY CONTROLLED HYDRAULIC SYSTEM

Fault finding - Customer complaints

38

BOSCH

ABS 5.3

ABS 53641.0

FAULTS FOUND IN THE WARNING LIGHT OPERATION

The ABS warning light does not illuminate for 3 seconds after the ignition is switched on. Chart 1

Chart 2 Permanent illumination of the ABS warning light when the ignition is switched on

Chart 3

BRAKING FAULTS NOTICED WITH ABS REGULATION

Locking of one or more wheels. Chart 7

Pulling.

Chart 9 Wandering.

Chart 10

Unexpected ABS operation when special equipment used

(carphone, CB...).

Chart 12

Only refer to these customer complaints after carrying out a complete check using

the XR25.

NOTES

Re-illumination of the ABS and / or brake warning light after engine started.

Unexpected ABS operation at low speed and low brake pedal force.

Unexpected ABS operation on poor road surface.

Extended brake pedal travel following a regulation phase

(with irregular pedal when regulation begins)

Chart 8

Chart 11

Chart 13

Spongy pedal.

Noise from pump, pipes or hydraulic assembly.

Chart 14

Chart 15

Chart 16

Chart 3 ABS and / or brake warning light illuminates temporarily when driving.

Chart 4 The brake warning light does not illuminate for 1 second when the ignition is switched on.

Chart 5 Permanent illumination of the brake warning light when the ignition is switched on.

Chart 6 Permanent illumination of the ABS and brake warning lights when the ignition is on.

Brake pedal vibration.

38-33

ELECTRONICALLY CONTROLLED HYDRAULIC SYSTEM

Fault finding - Customer complaints

38

BOSCH

ABS 5.3

ABS 53641.0

Only refer to these customer complaints after carrying out a complete check using

the XR25.

NOTES

OTHER CASES

The ABS and brake warning lights do not illuminate, computer disconnected. Chart 17

No communication with ABS computer. Chart 18

38-34

ELECTRONICALLY CONTROLLED HYDRAULIC SYSTEM

Fault finding - Fault charts

38

BOSCH

ABS 5.3

ABS 53641.0

AFTER

REPAIR

Carry out a road test then check using the XR25.

yes

THE ABS WARNING LIGHT DOES NOT ILLUMINATE FOR 3

SECONDS WHEN THE IGNITION IS SWITCHED ON

Chart 1

Only refer to these customer complaints after carrying out a complete check using

the XR25.

NOTES

Check the condition of the ABS warning

light bulb and its power supply.

Ensure the continuity of the connection

between track 20 of the computer

connector and the ABS warning light.

If the fault persists, check the operation of

the instrument panel.

Check the connections on the 31 track

connector.

Replace the computer if the fault persists.

no

Check the 15A fuse for the instrument

panel on the passenger compartment fuse

board

(if the problem is general to all instrument

panel operations).

Switch off the ignition.

Disconnect the computer then switch the

ignition on again.

Does the ABS warning light illuminate?

38-35

ELECTRONICALLY CONTROLLED HYDRAULIC SYSTEM

Fault finding - Fault charts

38

BOSCH

ABS 5.3

ABS 53641.0

AFTER

REPAIR

Carry out a road test then check using the XR25.

yes

ABS WARNING LIGHT ILLUMINATED PERMANENTLY,

IGNITION ON (without a fault being declared on the XR25)

Chart 2

Only refer to these customer complaints after carrying out a complete check using

the XR25.

NOTES

Search for a short circuit to earth of the

connection between track 10 of connector

R36 / R255 and the ABS warning light.

Search for a fault on the shunt or a short

circuit to earth of the connection between

track 20 of the computer connector and

R36 / R255 on track 10.

no

Disconnect the computer and check the

position of the shunt in the connector

(between track 19 and tracks 20 and 21).

Ensure on the computer side that a shunt

opening pin is present between tracks 19

and 20/21 of the computer connector.

Reconnect the computer .

Check that there is continuity between track

10 of connector R36 / R255 front engine /

ABS on the ABS side and earth.

Is continuity ensured?

38-36

ELECTRONICALLY CONTROLLED HYDRAULIC SYSTEM

Fault finding - Fault charts

38

BOSCH

ABS 5.3

ABS 53641.0

AFTER

REPAIR

Carry out a road test then check using the XR25.

RE-ILLUMINATION OF ABS AND/OR BRAKE WARNING

LIGHT AFTER ENGINE STARTED

TEMPORARY ILLUMINATION OF ABS AND/OR BRAKE

WARNING LIGHT WHEN DRIVING

Chart 3

Check the voltage of the computer power supply : 9.5 volts < correct voltage < 17.5 volts.

If necessary, carry out the following operations :

- Check the battery charge (check the charging circuit if necessary).

- Check the tightness and condition of the battery terminals.

- Check the ABS earths (tightness of the two earth bolts above the ABS assembly).

Disconnect the computer and check the condition of the connection and the position of the shunt in the

31 track connector (between track 19 and tracks 20 and 21).

On the computer side,check the condition of the opening pin of this shunt.

Only refer to these customer complaints after carrying out a complete check using

the XR25.

NOTES

38-37

ELECTRONICALLY CONTROLLED HYDRAULIC SYSTEM

Fault finding - Fault charts

38

BOSCH

ABS 5.3

ABS 53641.0

AFTER

REPAIR

Carry out a road test then check using the XR25.

yes

THE BRAKE WARNING LIGHT DOES NOT ILLUMINATE FOR

1 SECOND WHEN THE IGNITION IS SWITCHED ON

Chart 4

Only refer to these customer complaints after carrying out a complete check using

the XR25.

NOTES

Check the connection on the computer

connector.

Replace the computer if the fault persists.

Switch off the ignition.

Disconnect the computer then switch the

ignition on again.

Does the brake warning light illuminate?

Check the condition of the brake warning

light bulb and its power supply.

Ensure the continuity of the connection

between track 21 of the computer

connector and the warning light.

If the fault persists, check the operation of

the instrument panel.

no

38-38

ELECTRONICALLY CONTROLLED HYDRAULIC SYSTEM

Fault finding - Fault charts

38

BOSCH

ABS 5.3

ABS 53641.0

AFTER

REPAIR

Carry out a road test then check using the XR25.

PERMANENT ILLUMINATION OF THE BRAKE WARNING

LIGHT, IGNITION ON

Chart 5

Only refer to these customer complaints after carrying out a complete check using

the XR25.

NOTES

Ensure insulation in relation to earth of the connection between track 21 of the computer connector and

the brake warning light.

As this is a multi-function warning light,

- check the position of the handbrake and the circuit of its switch.

- check the brake fluid level in the reservoir.

- check the level of brake pads wear.

38-39

ELECTRONICALLY CONTROLLED HYDRAULIC SYSTEM

Fault finding - Fault charts

38

BOSCH

ABS 5.3

ABS 53641.0

AFTER

REPAIR

Carry out a road test then check using the XR25.

PERMANENT ILLUMINATION OF THE ABS AND BRAKE

WARNING LIGHTS, IGNITION ON

Chart 6

Only refer to these customer complaints after carrying out a complete check using

the XR25.

NOTES

If the problem persists, refer to Chart 2 and Chart 5.

Check 5A ABS fuse on the passenger compartment fuse board.

Check the ABS earths (tightness of the two earth bolts above the hydraulic assembly).

Check that the computer and the intermediate connections R36 or R254 and R255 are correctly connected

(also check the condition of the connections).

Check that the computer is correctly fed :

- Ensure the presence of +after ignition on track 15 of the computer connector .

- Ensure the continuity with earth of tracks 16 and 19 of the computer connector .

38-40

ELECTRONICALLY CONTROLLED HYDRAULIC SYSTEM

Fault finding - Fault charts

38

BOSCH

ABS 5.3

ABS 53641.0

AFTER

REPAIR

Carry out a road test then check using the XR25.

LOCKING OF ONE OR MORE WHEELS

Chart 7

REMINDER: The locking of the wheels of a vehicle fitted with ABS or tyre squeal, which the customer

perceives to be the wheels locking, can be linked to a normal reaction of the system and

must not systematically be considered as a fault:

- Locking is allowed below 3.75 mph (6 km/h) (the system no longer triggers regulation).

- Braking with ABS regulation on very poor roads (high degree of tyre squeal).

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

Only refer to these customer complaints after carrying out a complete check using

the XR25.

NOTES

However, to check that the wheels really are locking , raise the vehicle so as to be able to rotate the wheels

and check for:

- A possible incorrect connection of the speed sensors.

Use functions #01, #02, #03 and #04 while rotating the associated wheels and ensure the coherence

of the results obtained.

If the value measured is zero, rotate the other wheels to confirm an incorrect electrical connection of

the sensors and repair the wiring.

- A possible incorrect connection of the pipes in the hydraulic assembly.

Use functions G03*, G04*, G05* and G06* whilst pressing the brake pedal and check for the presence

of ten locking/releasing cycles on the wheel in question (refer to the "Aid" section).

If the ten cycles do not occur on the wheel tested (wheel remains locked), see if they occur on another

wheel (if a bad connection is confirmed : repair).

If the ten cycles do not occur on a wheel without the pipes being incorrectly connected , replace the

hydraulic assembly.

Check the condition of the ABS targets and their conformity.

Also check the sensor / target air gap over one revolution of each wheel (check impossible on rear

axle assembly with drums) :

0.3 mm < air gap over one revolution of front wheel < 1.5 mm.

0.2 mm < air gap over one revolution of rear wheel < 1.4 mm (if disc brakes).

If the fault persists after these checks, replace the hydraulic assembly.

38-41

ELECTRONICALLY CONTROLLED HYDRAULIC SYSTEM

Fault finding - Fault charts

38

BOSCH

ABS 5.3

ABS 53641.0

AFTER

REPAIR

Carry out a road test then check using the XR25.

yes

PULLING

Chart 8

Only refer to these customer complaints after carrying out a complete check using

the XR25.

NOTES

Lift the vehicle so that the wheels can be

rotated and check for :

- a possible incorrect connection of the

speed sensors,

- a possible incorrect connection of the

pipes in the hydraulic assembly.

For both the tests, refer to and apply the

methods defined in Chart 7.

Check the condition of the ABS targets and

their conformity. Also check the sensor /

target air gap over one revolution of each

front + rear wheel if disc brakes.

If the fault persists, replace the hydraulic

assembly.

If the pedal travel is relatively long, bleed

the braking circuit.

If the travel is normal, check the tyre

pressures, the front axle assembly

or for any possible leaks in the circuit.

non

Disconnect one wheel sensor.

Start the engine and ensure that only the

ABS fault warning light is illuminated. If the

brake fault warning light is also illuminated,

do not drive the vehicle as the "braking

compensator" function is no longer

guaranteed.

Carry out a road test with the ABS not

operating.

Does the fault persist under these

conditions?

38-42

ELECTRONICALLY CONTROLLED HYDRAULIC SYSTEM

Fault finding - Fault charts

38

BOSCH

ABS 5.3

ABS 53641.0

AFTER

REPAIR

Carry out a road test then check using the XR25.

yes

WANDERING

Chart 9

Disconnect one wheel speed sensor.

Start the engine and ensure that only the

ABS fault warning light is illuminated. If the

brake warning light is also illuminated, do

not drive the vehicle since the "braking

compensator" function is no longer

ensured.

Carry out a road test with the ABS not

operating.

Does the fault persist under these

conditions?

Only refer to these customer complaints after carrying out a complete check using

the XR25.

NOTES

Normal behaviour linked to the operation

of the system in the regulation phase

essentially on uneven adherence or poor

road surfaces.

Fault in road holding not linked to the ABS

system.

Check the condition and conformity of the

brake linings, check the tyre pressure, the

front axle assembly, ...

no

38-43

ELECTRONICALLY CONTROLLED HYDRAULIC SYSTEM

Fault finding - Fault charts

38

BOSCH

ABS 5.3

ABS 53641.0

AFTER

REPAIR

Carry out a road test then check using the XR25.

UNEXPECTED ABS OPERATION AT LOW SPEED AND LOW

PEDAL FORCE

Chart 10

Vibrations can be felt at the brake pedal which may be linked to the reactions in the system in specific

situations:

- driving over speed bumps.

- rear inside wheel lifts off the ground on tight bends.

This feeling may be linked to the operation of the "braking compensator" when the pressure is limited at

the rear axle assembly.

If the problem is different to this, check the speed sensor connectors (micro-breaks) and the air gaps.

Only refer to these customer complaints after carrying out a complete check using

the XR25.

NOTES

38-44

ELECTRONICALLY CONTROLLED HYDRAULIC SYSTEM

Fault finding - Fault charts

38

BOSCH

ABS 5.3

ABS 53641.0

AFTER

REPAIR

Carry out a road test then check using the XR25.

UNEXPECTED ABS OPERATION UNDER POOR ROAD

CONDITIONS

Chart 11

On poor roads, it is normal to feel juddering and vibrations at the pedal as well as more tyre squeal than

when on a good road surface.

The result is an impression of a variation in efficiency which should be considered as being normal.

Only refer to these customer complaints after carrying out a complete check using

the XR25.

NOTES

38-45

ELECTRONICALLY CONTROLLED HYDRAULIC SYSTEM

Fault finding - Fault charts

38

BOSCH

ABS 5.3

ABS 53641.0

AFTER

REPAIR

Carry out a road test then check using the XR25.

UNEXPECTED ABS OPERATION WHEN SPECIAL

EQUIPMENT USED (carphone, CB...)

Chart 12

Check that the equipment causing the problem when being used is approved.

Check that this equipment has been correctly installed without modifying the original wiring, especially

that of the ABS (connections to earth and +after ignition / before ignition of the ABS not authorised).

Only refer to these customer complaints after carrying out a complete check using

the XR25.

NOTES

38-46

ELECTRONICALLY CONTROLLED HYDRAULIC SYSTEM

Fault finding - Fault charts

38

BOSCH

ABS 5.3

ABS 53641.0

AFTER

REPAIR

Carry out a road test then check using the XR25.

EXTENDED PEDAL TRAVEL FOLLOWING A REGULATION

PHASE

(with irregular pedal when entering a regulation phase)

Chart 13

Air leaking into the braking circuits from the regulation channels of the hydraulic assembly.

Bleed the circuits according to the procedure recommended in the Workshop Repair Manual (use of

command modes on the XR25).

After the operation, carry out a road test with ABS regulation

Only refer to these customer complaints after carrying out a complete check using

the XR25.

NOTES

If the fault persists, carry out the previous operation once or twice again.

If the customer complaint is particularly serious and if bleeding does not improve the situation, replace the

hydraulic assembly.

38-47

ELECTRONICALLY CONTROLLED HYDRAULIC SYSTEM

Fault finding - Fault charts

38

BOSCH

ABS 5.3

ABS 53641.0

AFTER

REPAIR

Carry out a road test then check using the XR25.

SPONGY PEDAL Chart 14

Air in the braking circuits.

Bleed the circuits in the normal way starting with the rear right brake, then the rear left brake, front left

brake then front right brake.

Repeat the operation if necessary.

Only refer to these customer complaints after carrying out a complete check using

the XR25.

NOTES

38-48

ELECTRONICALLY CONTROLLED HYDRAULIC SYSTEM

Fault finding - Fault charts

38

BOSCH

ABS 5.3

ABS 53641.0

AFTER

REPAIR

Carry out a road test then check using the XR25.

BRAKE PEDAL VIBRATION Chart 15

Normal reaction at the brake pedal during an ABS regulation phase or when pressure is limited on the rear

axle ("brake compensator" function).

Only refer to these customer complaints after carrying out a complete check using

the XR25.

NOTES

38-49

ELECTRONICALLY CONTROLLED HYDRAULIC SYSTEM

Fault finding - Fault charts

38

BOSCH

ABS 5.3

ABS 53641.0

AFTER

REPAIR

Carry out a road test then check using the XR25.

NOISE FROM THE PUMP, PIPES OR HYDRAULIC ASSEMBLY

Chart 16

- Vibration of the assembly : check the presence and condition of the insulating rubber assembly

mounting blocks.

- Vibration of the pipes : check that all pipes are properly clipped into their mounting clips and that there

is no contact between pipes or between the pipes and bodywork.

To determine the origin of the noise, the functions G03*, G04*, G05* and G06* on the XR25 can be used

(refer to the "Aid" section).

Only refer to these customer complaints after carrying out a complete check using

the XR25.

NOTES

38-50

ELECTRONICALLY CONTROLLED HYDRAULIC SYSTEM

Fault finding - Fault charts

38

BOSCH

ABS 5.3

ABS 53641.0

AFTER

REPAIR

Carry out a road test then check using the XR25.

THE ABS WARNING LIGHT DOES NOT ILLUMINATE,

COMPUTER DISCONNECTED

Chart 17

Disconnect the ABS computer .

Check for the presence of the shunt between track 19 and tracks 20 and 21 of the computer connector .

Only refer to these customer complaints after carrying out a complete check using

the XR25.

NOTES

38-51

ELECTRONICALLY CONTROLLED HYDRAULIC SYSTEM

Fault finding - Fault charts

38

BOSCH

ABS 5.3

ABS 53641.0

AFTER

REPAIR

Carry out a road test then check using the XR25.

NO COMMUNICATION WITH THE ABS COMPUTER

Chart 18

Only refer to these customer complaints after carrying out a complete check using

the XR25.

NOTES

If a dialogue is still not established after these various tests, replace the ABS computer.

Check that the diagnostic socket is receiving the correct power supply :

- + before ignition on track 16,

- earth on track 5.

Check the continuity and insulation of the diagnostic socket / ABS computer connection lines :

- between track 12 of the computer connector and track 15 of the diagnostic socket,

- between track 11 of the computer connector and track 7 of the diagnostic socket.

Check the presence and condition of the ABS fuse on the passenger compartment fuse board (5A).

Check the connection of the computer connector and the condition of its connections.

Check the connection of the 14 track R36 ABS / dashboard connection (R254 + R255 on the Scnic and on

right hand drive vehicles) in the scuttle panel near the battery and check the condition of its connections.

Check the ABS earths (tightness of the two earth bolts above the ABS assembly).

Check that the computer power supply is correct :

- earth on track 19 of the 31 track connector,

- +after ignition on track 15 of the 31 track connector.

Ensure that the XR25 is not the cause of the fault by trying to communicate with a computer on another

vehicle. If the XR25 is not the cause and dialogue cannot be established with any other computer on the

same vehicle, it may be that a faulty computer is disrupting the K and L fault finding bus. Disconnect the

computers in sequence to locate the faulty one.

Check that the ISO interface is in position S8 and that you are using the latest version of the XR25 cassette

and the correct access code.

Check the battery voltage and carry out any necessary repairs to obtain a correct voltage (9.5 volts < U

battery < 17.5 volts).

38-52

You might also like

- 207 1.4 VTi TorquesDocument16 pages207 1.4 VTi TorquesAli Khedireche100% (1)

- V6 Es9j4Document21 pagesV6 Es9j4Dusko Ivan50% (2)

- GPL Landi Renzo System - Renault - 6525A PDFDocument87 pagesGPL Landi Renzo System - Renault - 6525A PDFmoanna100% (1)

- JCB New Price ListDocument1,033 pagesJCB New Price ListTarang agrawal100% (4)

- Kangoo Fuse and Relay BoxDocument31 pagesKangoo Fuse and Relay Boxyanivyehezkel100% (1)

- Technical Note 3882A: Fault Finding Sequential GearboxDocument93 pagesTechnical Note 3882A: Fault Finding Sequential GearboxNvidia TV100% (1)

- Quick Start Guide Calibration ToolDocument21 pagesQuick Start Guide Calibration ToolVictor Costache100% (3)

- Upc Megan 2 2005Document22 pagesUpc Megan 2 2005Hesham MohamedNo ratings yet

- Pinout Dash Astra G 2003Document4 pagesPinout Dash Astra G 2003helder100% (1)

- Airbag Megane RC5Document88 pagesAirbag Megane RC5shadow_smdkNo ratings yet

- NV and Vanos DME PinoutsDocument4 pagesNV and Vanos DME Pinoutsrobertobaggio2009No ratings yet

- PEUGEOT 307 407 807 FaultCodes 0601Document1 pagePEUGEOT 307 407 807 FaultCodes 0601Electropartes Bill100% (1)

- Direccion Asistida Megane 2Document56 pagesDireccion Asistida Megane 2Christiam Ortega100% (1)

- Renault VISU 2014 ListDocument3 pagesRenault VISU 2014 ListJosé Antonio Ramírez Gómez0% (1)

- C4 CACTUS 1,2 e-THP-HNZ (EB2DT) 1.2 - (14-18)Document13 pagesC4 CACTUS 1,2 e-THP-HNZ (EB2DT) 1.2 - (14-18)Fabian Carrasco NaulaNo ratings yet

- TB-E0145 About QQ AMT Trouble CodeDocument9 pagesTB-E0145 About QQ AMT Trouble CodecgfcNo ratings yet

- mr453x7988c000 39937900Document90 pagesmr453x7988c000 39937900Ioana Adriana Hirsch100% (1)

- Peugeot 406 - Engine Type - RGX (Xu10j2cte) - Bosch Multipoint Injection MP3.2F - Wiring DiagramsDocument6 pagesPeugeot 406 - Engine Type - RGX (Xu10j2cte) - Bosch Multipoint Injection MP3.2F - Wiring DiagramsAilton Firmino100% (1)

- Renault UCH Pin Code Reading and Key ProgrammingDocument12 pagesRenault UCH Pin Code Reading and Key ProgrammingPerona PabloNo ratings yet

- VR6 Timing ChainDocument53 pagesVR6 Timing ChainRaca ZivkovicNo ratings yet

- K 4 M 744 CONECTOR2Document2 pagesK 4 M 744 CONECTOR2Andrea Vilches100% (1)

- Current Flow Diagram Seats Heating VW Golf 5Document5 pagesCurrent Flow Diagram Seats Heating VW Golf 5Marius NeaguNo ratings yet

- Corsa D EPSDocument1 pageCorsa D EPScork_ie100% (1)

- Cummins PT SystemsDocument5 pagesCummins PT Systemsasadiqbalansari75% (4)

- 3175a.pdfrefrigeracion Twingo FallasDocument27 pages3175a.pdfrefrigeracion Twingo FallasMiguel Alfredo Muñoz Morillo100% (2)

- Cherokee 2.5 TD PCMDocument4 pagesCherokee 2.5 TD PCMNazael Diaz0% (1)

- RENAULT Megane 2 Wiring Diagrams - Car Electrical Wiring DiagramDocument3 pagesRENAULT Megane 2 Wiring Diagrams - Car Electrical Wiring DiagramCristina Stoenescu100% (1)

- Renault Megane-Scenic 1600cc-E3-K4ma7 LPG EngDocument4 pagesRenault Megane-Scenic 1600cc-E3-K4ma7 LPG EngAleksandar Bakovic0% (1)

- Battery Fuses Megane 2Document18 pagesBattery Fuses Megane 2osdasoNo ratings yet

- Kangoo x76 2004 PlatfusiDocument30 pagesKangoo x76 2004 PlatfusiAnonymous OFfJVrQY6No ratings yet

- K4M RENAULT 1.6 - Overhaul The Engine..Document38 pagesK4M RENAULT 1.6 - Overhaul The Engine..Alex100% (1)

- 6 - Air ConditioningDocument142 pages6 - Air ConditioningHugo Mendes100% (2)

- Citroen Xsara Raspored Osigurača PDFDocument1 pageCitroen Xsara Raspored Osigurača PDFhusoNo ratings yet

- Renault Gearbox and Final Drive OilsDocument10 pagesRenault Gearbox and Final Drive OilsPhat0% (1)

- Berlingo Iii 9HF (Dv6dted) 1.6Document11 pagesBerlingo Iii 9HF (Dv6dted) 1.6Fabian Carrasco NaulaNo ratings yet

- Renault Valeo V40 / V42: For Writing Follow The Instructions On The Next PageDocument2 pagesRenault Valeo V40 / V42: For Writing Follow The Instructions On The Next PageMahmoud El-Megheny100% (2)

- Megane Transmission 23ADocument250 pagesMegane Transmission 23AMakis Kouiroukidis80% (5)

- 5 - Mechanisms and AccessoriesDocument119 pages5 - Mechanisms and AccessoriesHugo MendesNo ratings yet

- MP48 Dual Fuel System Installation ManualDocument26 pagesMP48 Dual Fuel System Installation ManualEduRoi100% (1)

- Webasto Telestart T90 Octavia Installation GuideDocument12 pagesWebasto Telestart T90 Octavia Installation GuidePavel CosminNo ratings yet

- Meg Uch Phii PDFDocument4 pagesMeg Uch Phii PDFPerona PabloNo ratings yet

- 1,8l Motronic (AGU)Document14 pages1,8l Motronic (AGU)Hernan Nuñez100% (1)

- MK4 B5 ColorMFA Install GuideDocument17 pagesMK4 B5 ColorMFA Install GuideAbdelouahab TOUATINo ratings yet

- Renault 19 Ulja I PodaciDocument51 pagesRenault 19 Ulja I PodaciVeljkoM100No ratings yet

- Diagnosis On The FlexRay - BMW - f30 320iDocument7 pagesDiagnosis On The FlexRay - BMW - f30 320iMARTIN VILARNo ratings yet

- Bosch 7.2 PinDocument1 pageBosch 7.2 PinVictor HernandezNo ratings yet

- F Relay Locations: LEXUS RX 350 / RX 270 (EM2262E)Document23 pagesF Relay Locations: LEXUS RX 350 / RX 270 (EM2262E)Echa DudoNo ratings yet

- Mk2 Punto Bosch ME7.3H4 Immo OffDocument1 pageMk2 Punto Bosch ME7.3H4 Immo Offkamaleon dorado50% (2)

- Fuses and Relay Renault Megane 2Document8 pagesFuses and Relay Renault Megane 2Alex AguilarNo ratings yet

- BM34 Engine Slave Unit 34 Fuse(s) - CONNNECTORDocument3 pagesBM34 Engine Slave Unit 34 Fuse(s) - CONNNECTORMohd Ropi Abdullah100% (2)

- Megane 2 HornDocument2 pagesMegane 2 Hornnicamarcos100% (1)

- Peugeot Fans Club - Peugeot 406 XU10J2CTE - Electrical and Wiring DiagramDocument5 pagesPeugeot Fans Club - Peugeot 406 XU10J2CTE - Electrical and Wiring Diagramluis vilela100% (1)

- W211 Cable Connections Engine Comp. Right PDFDocument2 pagesW211 Cable Connections Engine Comp. Right PDFTiago SantosNo ratings yet

- BOSCH ABS 5.3 Renault Espace PDFDocument51 pagesBOSCH ABS 5.3 Renault Espace PDFJoao SilvaNo ratings yet

- 3239a Abs Speed InformationDocument14 pages3239a Abs Speed InformationHorváthVargaLászlóNo ratings yet

- N.T. 3416A XXXX: Computer Type: 240.5Document56 pagesN.T. 3416A XXXX: Computer Type: 240.5Imade EmadeNo ratings yet

- Chassis: Tyre Pressure Monitor Power-Assisted Steering Anti-Lock Braking SystemDocument241 pagesChassis: Tyre Pressure Monitor Power-Assisted Steering Anti-Lock Braking SystemGoran JevticNo ratings yet

- BS 2Document4 pagesBS 2Allenson KalistaNo ratings yet

- Esp 204Document6 pagesEsp 204nguyenducdn1202No ratings yet

- Datasheet 262005259 Electronic Brake System EbsDocument3 pagesDatasheet 262005259 Electronic Brake System Ebsعبدالغني القباطيNo ratings yet

- AC102 Series: Multi-Purpose Accelerometer, Top Exit Connector / Cable, 100 MV/GDocument1 pageAC102 Series: Multi-Purpose Accelerometer, Top Exit Connector / Cable, 100 MV/GNessuno Crede Jr.No ratings yet

- Arraymate Operating Manual: Alere Technologies 2013Document20 pagesArraymate Operating Manual: Alere Technologies 2013Noel SamNo ratings yet

- Control Line Scale ModelingDocument133 pagesControl Line Scale Modelingamsci99No ratings yet

- Instructivo SEW PDFDocument84 pagesInstructivo SEW PDFtio_3110No ratings yet

- 01Air-Elect Feb2015 PDFDocument27 pages01Air-Elect Feb2015 PDFjuan100% (1)

- Frymaster PDFDocument48 pagesFrymaster PDFLuminita SirghiNo ratings yet

- Transworld RAT400 Automatic Antenna Tuner - Operator ManualDocument21 pagesTransworld RAT400 Automatic Antenna Tuner - Operator ManualAlexander J Rokowetz100% (1)

- Band Heaters Mica THINBANDDocument24 pagesBand Heaters Mica THINBANDEliasNo ratings yet

- 6SL3120 1TE21 8AA3 SINGLE MOTOR MODULE 9 - 7kW SINAMICS S120 SIEMENS MANUALDocument6 pages6SL3120 1TE21 8AA3 SINGLE MOTOR MODULE 9 - 7kW SINAMICS S120 SIEMENS MANUALArie Septian Pamungkas100% (1)

- Data Sheet 6GT2811-6AB20-0AA0: Product Type Designation Reader RF650R ETSIDocument2 pagesData Sheet 6GT2811-6AB20-0AA0: Product Type Designation Reader RF650R ETSIBerat GündoğanNo ratings yet

- Transtrar 2014 - GMDocument198 pagesTranstrar 2014 - GMGeorge GNo ratings yet

- Eim10 m8 Electrical MaterialsDocument16 pagesEim10 m8 Electrical MaterialsNoVoidNo ratings yet

- 2001 Nissan X Trail 52279 PDFDocument532 pages2001 Nissan X Trail 52279 PDFJunior SalazarNo ratings yet

- Ancon Tension Systems March 2008Document16 pagesAncon Tension Systems March 2008Slinky BillNo ratings yet

- Tang 2-Phong Dien HinhDocument6 pagesTang 2-Phong Dien Hinhleanh121No ratings yet

- Star Stec-510 Control Box OperationDocument168 pagesStar Stec-510 Control Box OperationT desNo ratings yet

- Ma 6410Document52 pagesMa 6410mahajoonNo ratings yet

- Pressure Transducers DeltaFox DMU 21 D Version For Differential Pressure Measurement BA enDocument2 pagesPressure Transducers DeltaFox DMU 21 D Version For Differential Pressure Measurement BA enj8164322No ratings yet

- JUMONG General (JMPS) Installation Manual - en - CMP200 - 20181129Document44 pagesJUMONG General (JMPS) Installation Manual - en - CMP200 - 20181129Juan Alberto RomeroNo ratings yet

- Ecodrive03 Drive Controllers: Project Planning ManualDocument344 pagesEcodrive03 Drive Controllers: Project Planning ManualhectorNo ratings yet

- Dubreq STYLOPHONE-GEN-R-8-manual-final PDFDocument11 pagesDubreq STYLOPHONE-GEN-R-8-manual-final PDFN NNo ratings yet

- Amplifier Card Euro Card Format UEIK 21 RSDDocument4 pagesAmplifier Card Euro Card Format UEIK 21 RSDLibinNo ratings yet

- Dometic 8700 Series MasterFlush Toilets Installation ManualDocument12 pagesDometic 8700 Series MasterFlush Toilets Installation ManualRussell HyzenNo ratings yet

- CXP-4MT-12: 4.3-10 Male Connector For 1/2" Annular CableDocument1 pageCXP-4MT-12: 4.3-10 Male Connector For 1/2" Annular CableCesar RinconNo ratings yet

- SSVC6 ManualDocument6 pagesSSVC6 ManualPaulo FoglianoNo ratings yet

- Price Cat-Respirator Fit TestingDocument10 pagesPrice Cat-Respirator Fit TestingdanielNo ratings yet

- USB Type-C Compliance Document Rev 1 2Document76 pagesUSB Type-C Compliance Document Rev 1 2JAVIER JIMMY TERREROS GALARZANo ratings yet

- Non-Electric Initiation System: CZECH REPUBLIC December 2019Document32 pagesNon-Electric Initiation System: CZECH REPUBLIC December 2019Yan Romulo Ribeiro OliveiraNo ratings yet

- Catalogue en - Lift Control Systems 01 - 2010Document23 pagesCatalogue en - Lift Control Systems 01 - 2010Anoop KumarNo ratings yet