Professional Documents

Culture Documents

Seiri - Sorting Out

Seiri - Sorting Out

Uploaded by

Vikas NigamOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Seiri - Sorting Out

Seiri - Sorting Out

Uploaded by

Vikas NigamCopyright:

Available Formats

5S is basically a structured and rational approach to methodical housekeeping built on a sound economic

basis. 5S became a company wide practice in Japanese industries in the early 80s which demonstrated

to be a powerful technique to enhance Productivity and Quality Improvement. This is a Japanese concept

using 5 simple steps involving all employees including top management to create a conducive work

atmpsphere.

By effective use of this technique one can get significant beneficial results in personal life also.

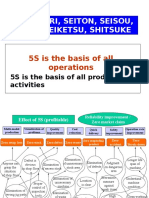

SEIRI - Sorting out

SEITON - Systematic arrangement

SEISO - Spic and span

SEIKETSU - Serene atmosphere

SHITSUKE - Stick to self discipline

SEIRI - Sorting Out

Looking at ones worl place and home we find many things which are not needed are mixed and kept

together with required ones. This occupies valuable space, account for record keeping costs making it

difficult to trace needful things and surroundings become untidy.

SEITON - Systematic Arrangement

Once the things are sorted out a little effort is required in arranging them. Otherwise, out of several needy

things it would consume more time in taking out the thing you need at any point of time. Hence, plan

rationally about the placement, location of each item, properly identify them to reduce the time of searching

and for easy accessibility and traceability during the time of need.

SEISO - Spic and Span

This is basically to keep the place, surroundings and all items belongings there in clean and tip-top

condition for a beautiful outward appearance but also exposes sources of trouble like oil leakage and

cracks on machine, equipment, walls thus enabling immediate corrective action.

This in turn increases the morale, confidence and inculcates a sense of pride in all employees.

5S

SEIKETSU - Serene atmosphere

Serene atmosphere can be established and maintained by following the above three steps along with

maintenance of safe and hygienic work conditions as per norms.

Developing the habit of wearing clean clothes and following safety rules.

All electrical equipments should be in proper working conditions by which safety can be ensured.

Sanitary conditions in wash rooms, locker rooms, canteens, kitchen, should be maintained.

The work place should be clean, orderly and safe.

Stick to SHITSUKE Self-discipline

This is the most important aspect of 5S as the effective implementation of the first 4S depends on how

disciplined an individual is. Thus mathematically we can explain this as: -

SEIRI, SEITON, SEISO, SEIKETSU = f (SHITSUKE)

A self-disciplined individual only can get a cumulative (effect of the 1st 4S. Hence, 1st 4S is a function of the 5th S.

It thus become mandatory to follow the rules for working as per standard, which becomes the key attribute

towards the success should be conducted to detect and correct any deviations from standards.

REDUCTION IN

COST OF

PRODUCTION

BETTER QUALITY

SYSTEM

IMPROVED WORK

HIGH EMPLOYEE

SAFER WORK PLACE

CONDUCTIVE WORK PLACE

SEIRI SORTING OUT

SEITON SYSTEMATIC

ARRANGEMENT

SEISO SPIC AND SPAN

SEIKETSU SERENE ATMOSPHERE

SHITSUKE STICK TO SELF DISCIPLINE

FOUNDATION 80%

The base or foundation of 5S is Shitsuke i.e. Self discipline, which contributes to 80%, this

should be strong and made stronger for effective implementation of the lst 4S which

contributes 20% as cumulative.

By effective implementing the 5S technique with some creativity, common sense and

professionalism one can achieve a Reduction in cost of Production to have a competitive

edge in the market. This indeed the first step towards contineous improvement

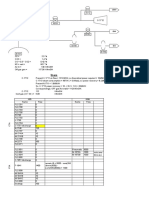

DATE : 29, June, 2000

NO

1 5S and Stop Leakage

Due to leakage of CTA from sealing of P-1756, gear box bearing

has been damaged and we shut down both Plant for around half day.

In this connection I would like to emphasize importance of 5s activity

and any leakage of fluid should be stopped or some countermeasure taken

to minimize leakage.

Never ignore leakage, such as acetic acid, PTA, water and steam, any kind of fluid.

If it is impossible to stop perfectly, countermeasure as follows shall be taken :

1) Install backet or hose avoid spread out

2) Install plate to avoid contacting to surrounding devices

All employees are requested to conduct 5S activity 30 minutes in shift from 30th

to 3rd July. Shift engineer is a leader to decide cleaning area and report to

daily report.

1st Shift : 13;00 - 13:30, 2nd shift : 18:00 - 18:30, 3rd Shift : 3:00 - 3:30 (for Example)

All oil gauges should be cleaned and make it easy to find out abnormal oil condition.

OVER N. Fukuda

JOB INSTRUCTION ( CTA / PTA )

INSTRUCTION NOTE

OPERATOR S / I STAFF CHIEF SR MGR

You might also like

- Omni AccidentDocument27 pagesOmni AccidentVikas NigamNo ratings yet

- 5S in Apparel IndustryDocument9 pages5S in Apparel IndustryRamyaJudes100% (2)

- Bow Tie Analysis - Incident-InvestigationDocument46 pagesBow Tie Analysis - Incident-InvestigationVikas Nigam100% (1)

- 5S Summary: 5S Original Japanese Meaning in EnglishDocument5 pages5S Summary: 5S Original Japanese Meaning in Englishprabu06051984No ratings yet

- Five SDocument60 pagesFive SShrikant MojeNo ratings yet

- Amity University: Five S (Operations and Quality Management)Document32 pagesAmity University: Five S (Operations and Quality Management)Surbhi BithelNo ratings yet

- Team Spirit.: 5S Gives You A Workplace Which Is Clean,, Safe, AndorganizedDocument6 pagesTeam Spirit.: 5S Gives You A Workplace Which Is Clean,, Safe, AndorganizedPuja PrasadNo ratings yet

- Lesson 8Document10 pagesLesson 8Princess Czarina Delas AlasNo ratings yet

- Team Spirit.: 5S Gives You A Workplace Which Is Clean,, Safe, AndorganizedDocument6 pagesTeam Spirit.: 5S Gives You A Workplace Which Is Clean,, Safe, AndorganizedPuja PrasadNo ratings yet

- 5s MethodologyDocument5 pages5s MethodologySer Crz JyNo ratings yet

- Presented by A.Kalyana SundaramDocument26 pagesPresented by A.Kalyana SundaramsiccppNo ratings yet

- 5 S GuideDocument28 pages5 S GuideNataliaCampeloNo ratings yet

- TransliteratedDocument4 pagesTransliteratedDeboshri JashNo ratings yet

- 5s and 3rsDocument30 pages5s and 3rsrazzberiNo ratings yet

- Principles of 5 S: SeiriDocument4 pagesPrinciples of 5 S: SeiriravishuklaNo ratings yet

- Bulletin EQM 89 - 5S PDFDocument23 pagesBulletin EQM 89 - 5S PDFMgn SanNo ratings yet

- 5S Methodology: A Japanese Concept For Maximum EfficiencyDocument14 pages5S Methodology: A Japanese Concept For Maximum EfficiencySofertoutaNo ratings yet

- 5 S Seiri, Seiton, Seisou, Seiketsu, Shitsuke: 5S Is The Basis of All OperationsDocument21 pages5 S Seiri, Seiton, Seisou, Seiketsu, Shitsuke: 5S Is The Basis of All OperationsAtul SharmaNo ratings yet

- Lean Management Ass2Document15 pagesLean Management Ass2Nain TikaryaNo ratings yet

- 5s, Sixsigma, TPM, PQM, Pert Etc.Document17 pages5s, Sixsigma, TPM, PQM, Pert Etc.manpreetsodhi08No ratings yet

- 5S Presentation 2Document38 pages5S Presentation 2anbuskp100% (2)

- Advanced Production TechDocument9 pagesAdvanced Production TechNashon MutuaNo ratings yet

- Sort and Remove Unnecessary ItemsDocument4 pagesSort and Remove Unnecessary ItemsAnthony GozoNo ratings yet

- Implementation of 5S &reduction of Seven WastageDocument22 pagesImplementation of 5S &reduction of Seven WastageShashwata BhowmikNo ratings yet

- 5 S Training MaterialDocument10 pages5 S Training Materialkumar100% (1)

- Toyota Tps 5sDocument36 pagesToyota Tps 5sKawadasan100% (1)

- 5S Definition and BenefitsDocument16 pages5S Definition and Benefitsnatrix029No ratings yet

- Productivity Improvement by Implementing 5s SystemDocument15 pagesProductivity Improvement by Implementing 5s SystemRadha KrishnanNo ratings yet

- Implementation of 5S in Scientific Equipment Company: Shaman Gupta, Pankaj ChandnaDocument5 pagesImplementation of 5S in Scientific Equipment Company: Shaman Gupta, Pankaj ChandnarpbiradarNo ratings yet

- Management Theory and PracticeDocument12 pagesManagement Theory and PracticeRitik GuptaNo ratings yet

- 32 Oki C3894098319Document5 pages32 Oki C3894098319Omar AlexanderNo ratings yet

- The 5s of Ideal HousekeepingDocument16 pagesThe 5s of Ideal HousekeepingKarenSantiago-VillanuevaNo ratings yet

- 5SDocument23 pages5SReetu Sri100% (1)

- Introduction To 5S: Introduction To 5S What Is 5S Why Implement 5S How To Implement 5S Learn More About 5SDocument6 pagesIntroduction To 5S: Introduction To 5S What Is 5S Why Implement 5S How To Implement 5S Learn More About 5SVigneshNo ratings yet

- Applicability of "5S" What Is "5S": Key To Succeed "5S" in AGSDocument20 pagesApplicability of "5S" What Is "5S": Key To Succeed "5S" in AGSmaroli_yogeshNo ratings yet

- 5SDocument11 pages5SAnkita Raj100% (3)

- III Methodologies: III-1 5S Principles and The Activities III-1-1 DefinitionsDocument53 pagesIII Methodologies: III-1 5S Principles and The Activities III-1-1 DefinitionsOnal RautNo ratings yet

- 5S Executive Summary Radi Rifki FaujiDocument4 pages5S Executive Summary Radi Rifki FaujiDyanaNo ratings yet

- 5S DetailsDocument10 pages5S DetailsHemalakshmiNo ratings yet

- PFMP Spring07 WasteDocument6 pagesPFMP Spring07 WasteMohamad SukriNo ratings yet

- History of 5sDocument4 pagesHistory of 5sakanshavermaNo ratings yet

- 5S PresentationDocument31 pages5S PresentationManoj Pandey100% (2)

- 5S & Housekeeping: Training For TrainersDocument35 pages5S & Housekeeping: Training For TrainersSunilNo ratings yet

- 5S MethodologyDocument2 pages5S MethodologyEmeth TeoNo ratings yet

- 5 S Workplace OrganisationDocument11 pages5 S Workplace Organisationdolores gallardoNo ratings yet

- Metodologia de Las 5SDocument8 pagesMetodologia de Las 5SANTONIO LEOBARDO CRUZ CRUZNo ratings yet

- The 5 S'S: Japanese Transliterated EnglishDocument4 pagesThe 5 S'S: Japanese Transliterated EnglishRishita TandonNo ratings yet

- New Japanese 5s MethodologyDocument18 pagesNew Japanese 5s Methodologymarkcel NomoNo ratings yet

- 5 S Good Housekeeping PrinciplesDocument50 pages5 S Good Housekeeping PrinciplesSanthosh Kumar60% (5)

- Introduction To 5S: - The 5S List Is As FollowsDocument5 pagesIntroduction To 5S: - The 5S List Is As FollowsYijun SunNo ratings yet

- Essential in The Lean Manufacturing Structure Is 5SDocument2 pagesEssential in The Lean Manufacturing Structure Is 5Sarnella_hNo ratings yet

- Reported By: Maricel E. Cotanda Lorraine Marie Oaferina Beed-3ADocument9 pagesReported By: Maricel E. Cotanda Lorraine Marie Oaferina Beed-3AMaricel Cotanda EginaNo ratings yet

- Fdocuments - in 5s-MethodologyDocument23 pagesFdocuments - in 5s-MethodologySamuel MergaNo ratings yet

- Simco Spinning & Textiles Limited.: Poka-YokeDocument5 pagesSimco Spinning & Textiles Limited.: Poka-YokeKamal PashaNo ratings yet

- Framework of 5SDocument31 pagesFramework of 5STapesh100% (21)

- 5s LearningDocument35 pages5s LearningAnkur100% (1)

- Introduction To 5SDocument5 pagesIntroduction To 5SKundan Kumar MishraNo ratings yet

- Project ReportDocument32 pagesProject ReportShilp VachhaniNo ratings yet

- Lecture-02 (TQM-5S System) PDFDocument17 pagesLecture-02 (TQM-5S System) PDFZahid Hasan OpuNo ratings yet

- The Secret To: Japanese SuccessDocument44 pagesThe Secret To: Japanese Successmaria neneng bulakNo ratings yet

- 5S- The True Mean to Enhance Productivity and Work Value for Customers: Toyota Production System ConceptsFrom Everand5S- The True Mean to Enhance Productivity and Work Value for Customers: Toyota Production System ConceptsRating: 5 out of 5 stars5/5 (1)

- SMED – How to Do a Quick Changeover?: Toyota Production System ConceptsFrom EverandSMED – How to Do a Quick Changeover?: Toyota Production System ConceptsRating: 4.5 out of 5 stars4.5/5 (2)

- Toughpad Fz-X1 Atex: Atex Zone 2 Certified 5" Handheld Tablet With BCR, Data & VoiceDocument2 pagesToughpad Fz-X1 Atex: Atex Zone 2 Certified 5" Handheld Tablet With BCR, Data & VoiceVikas NigamNo ratings yet

- HAZOP, SIL and LOPA Course: Kermanshah Polymer CompanyDocument92 pagesHAZOP, SIL and LOPA Course: Kermanshah Polymer CompanyVikas NigamNo ratings yet

- How Do You Maintain Process Safety in Times of Change?Document4 pagesHow Do You Maintain Process Safety in Times of Change?Vikas NigamNo ratings yet

- Guide To Chemical-Resistant Best Gloves: 2008 EditionDocument17 pagesGuide To Chemical-Resistant Best Gloves: 2008 EditionVikas NigamNo ratings yet

- Safety in PlantsDocument18 pagesSafety in PlantsVikas NigamNo ratings yet

- Aegex Intrinsically Safe Tablet: 10.1" WUXGA Display Powered by Intel Atom Quad Core Windows 10 Intel Security SuiteDocument2 pagesAegex Intrinsically Safe Tablet: 10.1" WUXGA Display Powered by Intel Atom Quad Core Windows 10 Intel Security SuiteVikas NigamNo ratings yet

- Uniform Vendors DetailsDocument2 pagesUniform Vendors DetailsVikas NigamNo ratings yet

- Osha3844 PDFDocument432 pagesOsha3844 PDFVikas NigamNo ratings yet

- Hazard Assessment Before Lab WorkDocument22 pagesHazard Assessment Before Lab WorkVikas NigamNo ratings yet

- Bulletin 14 - Replacement of Extraction Cum Condensing Turbine With Back Pressure Turbine PDFDocument2 pagesBulletin 14 - Replacement of Extraction Cum Condensing Turbine With Back Pressure Turbine PDFVikas NigamNo ratings yet

- Minutes of The Meeting For Confined Space Painting SopDocument2 pagesMinutes of The Meeting For Confined Space Painting SopVikas NigamNo ratings yet

- IG BalanceDocument2 pagesIG BalanceVikas NigamNo ratings yet

- Pcv715 OpenDocument21 pagesPcv715 OpenVikas NigamNo ratings yet

- Motor Solo Run RecordDocument2 pagesMotor Solo Run RecordVikas NigamNo ratings yet

- Checking Point of Field Daily Patrol: MakingDocument2 pagesChecking Point of Field Daily Patrol: MakingVikas NigamNo ratings yet

- PSSRDocument163 pagesPSSRVikas Nigam100% (1)

- Checking Point of Field Daily Patrol: MakingDocument14 pagesChecking Point of Field Daily Patrol: MakingVikas NigamNo ratings yet

- Am VS LevelDocument16 pagesAm VS LevelVikas NigamNo ratings yet

- ATEX-Guide - 1087 en Version 2Document61 pagesATEX-Guide - 1087 en Version 2Vikas NigamNo ratings yet