Professional Documents

Culture Documents

Curving Steelwork: Steel Industry Guidance Notes

Uploaded by

Jasmine SmithOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Curving Steelwork: Steel Industry Guidance Notes

Uploaded by

Jasmine SmithCopyright:

Available Formats

STEEL INDUSTRY

GUIDANCE NOTES

The information given in this Steel Industry Guidance Note is for general information

only and the reader should always seek specific advice on any particular issue.

D158 SIGNS 16/12/05 2:03 pm Page 1

SN42 02/2010

Curving Steelwork

This SIGNS introduces the processes used to curve steelwork, describes the effects of the

process and highlights the design issues that need to be considered. This guidance note does

not cover cambering because the effects of the curvature are small, and can be ignored. In

most cases, curving of structural members is to a relatively modest radius with small effects.

The effects of curving steel are signifcant at smaller radii, but these sorts of curves are more

often used in architectural steelwork rather than primary loadbearing members. In all aspects

of curving steelwork, the general advice is to contact the specialists contact details are given

overleaf.

Curving processes

There are two primary processes cold bending and

induction bending. Cold bending is accomplished by

passing the steel member back and forth between sets

of rolls as shown in Figure 1. The point load applied by

the central roller is suffcient to take the steel past its yield

point and introduce a permanent set.

Figure 1 Cold bending

Because the point load is often suffcient to buckle the

web, some arrangement of additional rollers is used

to support the web, or to apply tension to the web, as

shown in Figure 1. The rolls used must suit the section,

demanding a different tooling arrangement for each profle.

From Figure 1, it is clear that the rolling process cannot

extend to the very end of the member there is always

a short straight length. This straight length can often be

utilised in the design, or may need to be discarded.

Induction bending is shown diagrammatically in Figure 2.

An electric coil, shaped to suit the profle, heats and softens

a short section of the member. After the steel has been

heated and curved, water or air (or a combination of

both) is used to cool the steel. As the member is pushed

through the induction coil, the leading end is forced to

follow a curve set by a pivot arm.

In general, induction bending is used to curve to small

radii relative to the section size.

Figure 2 Induction bending

The effects of curving steel

The temperature changes during induction bending

can lead to changes in metallurgical properties, but this

is dependent on the properties of the straight material.

Post-bending heat treatment can usually be undertaken

to restore the properties if necessary.

Cold bending obviously takes the material past the frst

yield point which will strain harden the steel to some

degree. Some of the yield plateau will have been used,

so in general plastic design is not recommended. The

toughness of the steel may also have been changed,

particularly at small radii. It is worth emphasising again

that at most radii found in structural applications, the

changes are modest.

The more important effects of the curving process

may be aesthetic, rather than structural. The steel on

the outside of the curve tends to get stretched (and

therefore thinner) whilst the steel on the inside of the curve

tends to become thicker. Some distortion of the section

geometry is likely. In some cases, for example with thin

hollow sections, the bending process can cause visible

ripples on the concave face. A section with a thicker wall

The information given in this Steel Industry Guidance Note is for general information

only and the reader should always seek specifc advice on any particular issue.

The information given in this SIGNS is up-to-date as at January 2010.

A

A

Additional rolls

Section A-A

Further Sources of Information

D158 SIGNS 16/12/05 2:03 pm Page 2

Key Points

The specialist contractors can be consulted for

advice on curving steelwork, including the visual

appearance of a curved section.

For most structural applications, the changes in

material properties are modest.

If bending causes compression on the convex face

of a member curved in elevation, the member is

less stable than a straight member the buckling

resistance must be reduced

For members curved on plan, a hollow section is

preferred.

may be more appropriate. Specialist contractors have

much experience in this area, and are happy to advise

on choice of section.

Many engineers are concerned about the residual stresses

left in the steelwork as a result of the curving process.

Because the curving induces strains in excess of yield,

the residual stresses after the curving process are not

additive to the residual stresses in the straight member.

The residual stresses can be deduced by subtracting

the elastic stress distribution (as the member comes free

of the rolls) from the plastic stress distribution (as the

member passes through the rolls). The result depends on

the ratio of the elastic modulus and plastic modulus. In

the major axis, this means that the residual stresses are

generally no more than those found in a straight beam

in the minor axis they are larger, but generally are not a

design issue as serviceability tends to govern, reducing

stress levels.

Design issues curved steel in elevation

The frst modest effect is that as shown in Figure 3, the

direct stresses in the member have a radial component.

This radial component introduces out-of-plane bending

in the fanges, which introduces additional stresses not

present in a straight beam.

Using Von Mises expression, a reduced yield stress can

be calculated to allow for these additional stresses. The

out-of-plane stresses are generally very small.

Figure 3 Out-of-plane fange bending

When curved steel is subject to a bending moment,

revised calculations are required. If the bending causes

compression on the convex face, the member is less

stable than a straight member, which must be taken

into account. Conversely, although compression on the

concave face increases the member stability this benefcial

effect is generally ignored.

Design issues steel curved on plan

Use a hollow section! This is good practical advice, as

members curved on plan are often subject to torsion.

Open sections will carry torsion, but never as effectively

as a hollow section. If an open section is necessary, the

direct stresses induced in the member due to the vertical

loads cause out-of-plane bending in the fanges and

these should be allowed for in design. A simple approach

is to consider the fanges acting alone, subject to direct

stresses and out-of-plane stresses.

Specialist contractors: The Angle Ring Company Ltd http://www.anglering.com/

Barnshaws Steel Bending http://www.barnshaws.com/

Design issues: Design of Curved Steel, P281, SCI

Radial

Loads

1

Elevation

Radial loads Bending moments

1

1 1

You might also like

- Various Perception Criteria For Occupant ComfortDocument1 pageVarious Perception Criteria For Occupant ComfortskkongNo ratings yet

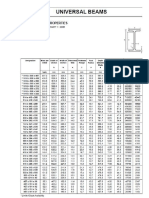

- UB DetailsDocument1 pageUB DetailsskkongNo ratings yet

- Design Check For PEB.Document1 pageDesign Check For PEB.skkongNo ratings yet

- Height Requirement For BungalowsDocument1 pageHeight Requirement For BungalowsskkongNo ratings yet

- Roofing InstallationDocument1 pageRoofing InstallationskkongNo ratings yet

- PEB Building-1Document1 pagePEB Building-1skkongNo ratings yet

- Roof Sheets FixingDocument1 pageRoof Sheets FixingskkongNo ratings yet

- PEB Load CombinationsDocument1 pagePEB Load CombinationsskkongNo ratings yet

- Moment Rotation CurveDocument1 pageMoment Rotation CurveskkongNo ratings yet

- PEB Components-1Document1 pagePEB Components-1skkongNo ratings yet

- CFD Analysis of Tall BuildingsDocument1 pageCFD Analysis of Tall BuildingsskkongNo ratings yet

- BS 6472Document1 pageBS 6472skkongNo ratings yet

- Data Centre CostDocument1 pageData Centre CostskkongNo ratings yet

- Cantilever Carport 1Document1 pageCantilever Carport 1skkongNo ratings yet

- SAP2000 - Ghost StructureDocument1 pageSAP2000 - Ghost StructureskkongNo ratings yet

- Curtain Wall Assemblies - PPVCDocument1 pageCurtain Wall Assemblies - PPVCskkongNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5796)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (589)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Criteria For ExtempoDocument2 pagesCriteria For Extempoaljon tusingNo ratings yet

- Spare Parts Catalogue: AXLE 20.43 REF: 572755Document8 pagesSpare Parts Catalogue: AXLE 20.43 REF: 572755marcelo sampaioNo ratings yet

- ATHE Level 3 Diploma in AccountingDocument32 pagesATHE Level 3 Diploma in AccountingPartho DhakaNo ratings yet

- Aip 2023 San Diego Elementary School 121172 Leo Robedillo FinalDocument10 pagesAip 2023 San Diego Elementary School 121172 Leo Robedillo Finalruskyjeth16No ratings yet

- Journal Homepage: - : Manuscript HistoryDocument13 pagesJournal Homepage: - : Manuscript HistoryIJAR JOURNALNo ratings yet

- Discrete Functions MCR3U Unit 8 (May 2015)Document18 pagesDiscrete Functions MCR3U Unit 8 (May 2015)Shanaz ParsanNo ratings yet

- De Orbitis PlanetarumDocument18 pagesDe Orbitis PlanetarumGustavo Adolfo OspinaNo ratings yet

- DrivingJTurn English RecurdynDocument43 pagesDrivingJTurn English RecurdynAnh Tuan LeNo ratings yet

- M-25 Def Tech Corp Reloadable Stun Grenade Patent PDFDocument6 pagesM-25 Def Tech Corp Reloadable Stun Grenade Patent PDFJuanK ANo ratings yet

- Wicking Bed Notes 1Document9 pagesWicking Bed Notes 1Mak NNo ratings yet

- Goodman, Nelson - On StarmakingDocument3 pagesGoodman, Nelson - On StarmakingAilin DurrutyNo ratings yet

- Saep 146 PDFDocument19 pagesSaep 146 PDFRami ElloumiNo ratings yet

- Physics ProjectDocument5 pagesPhysics ProjectPrajvi0% (1)

- Laurels in The Month of January:: School Excellence Award of 2019Document13 pagesLaurels in The Month of January:: School Excellence Award of 2019noob 2 proNo ratings yet

- Momentum Conservation: 1. AbstractDocument9 pagesMomentum Conservation: 1. AbstractDương Quang MinhNo ratings yet

- ELEC4810: Introduction To Biosensors and Bioinstrumentation: Lecture Notes - Set #10Document17 pagesELEC4810: Introduction To Biosensors and Bioinstrumentation: Lecture Notes - Set #10Kwan ChanNo ratings yet

- Anshika Project ReportDocument36 pagesAnshika Project ReportLakshaya TeotiaNo ratings yet

- Introduction PDFDocument23 pagesIntroduction PDFNeil Ian Dador DumangasNo ratings yet

- AP European History 2005 Free-Response Questions Form B: The College Board: Connecting Students To College SuccessDocument9 pagesAP European History 2005 Free-Response Questions Form B: The College Board: Connecting Students To College SuccessRich SevillaNo ratings yet

- M E Room DimensionsDocument3 pagesM E Room DimensionsPujayantha KumarNo ratings yet

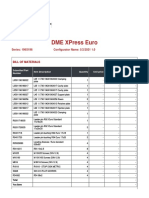

- Dme Xpress Euro: Series: 196X196 Configurator Name: 5/2/2021 1.0Document3 pagesDme Xpress Euro: Series: 196X196 Configurator Name: 5/2/2021 1.0Ahmed SamirNo ratings yet

- 30 Footwear Developer Interview Questions and AnswersDocument16 pages30 Footwear Developer Interview Questions and Answersthanh2501No ratings yet

- Disorders and Diseases Related To Cell Malfunction During The Cell CycleDocument41 pagesDisorders and Diseases Related To Cell Malfunction During The Cell CycleVenice Kate BuizonNo ratings yet

- Grade Point Average: What's Wrong and What's The Alternative?Document12 pagesGrade Point Average: What's Wrong and What's The Alternative?annisa AnnisaNo ratings yet

- Internal Audit Checklist - Tool ManufacturingDocument1 pageInternal Audit Checklist - Tool ManufacturingSachin Ramdurg100% (3)

- Siddaganga Institute Technology: Injection MouldingDocument12 pagesSiddaganga Institute Technology: Injection MouldingPRAVEEN BOODAGOLINo ratings yet

- Community Project Report Women in Literature, Society & Culture-1Document35 pagesCommunity Project Report Women in Literature, Society & Culture-1Saurav GuptaNo ratings yet

- LVL Users Guide - Canada v0415Document32 pagesLVL Users Guide - Canada v0415hahaerNo ratings yet

- DISC 322-Optimization Methods For Management Science - Sec 2 - Dr. Muhammad Tayyab - Spring 2020 PDFDocument6 pagesDISC 322-Optimization Methods For Management Science - Sec 2 - Dr. Muhammad Tayyab - Spring 2020 PDFMuhammad UsmanNo ratings yet