Professional Documents

Culture Documents

LFMH 8

Uploaded by

Ahmad Syazni Bin MoktarOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

LFMH 8

Uploaded by

Ahmad Syazni Bin MoktarCopyright:

Available Formats

Manufacturing Processes Lab MEM564 / LS04/Ziyadi Rev.

01-2014

UNIVERSITI TEKNOLOGI MARA

FAKULTI KEJURUTERAAN MEKANIKAL

Program : Bachelor of Mechanical Engineering(Manufacturing)(Hons)(EM221/241)

Bachelor of Engineering(Hons)Mechanical(EM220)

Course : Manufacturing Processes Laboratory

Course Code : MEM564

Course Outcome: CO1,CO2,CO3,CO4

LAB SHEET NO: 4

1.0 TITLE: Profile Measurement

2.0 INTRODUCTION

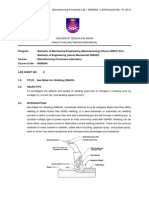

The profile projector is an optical a projection apparatus that can produce an enlarged projection

shadow of an object. The projection methods of examination are well adapted to the examination of

form tools, profile gauges, press-tools, gear teeth, screw thread etc. Sizes of the object may be

checked by direct measurement on the enlarged shadow and subsequent division by the

multiplication factor. The magnification factor is accurate and that the design of the apparatus permits

maximum latitude in holding and adjusting the object.

Manufacturing Processes Lab MEM564 / LS04/Ziyadi Rev. 01-2014

3.0 OBJECTIVE

To check the profile and measure the geometrical parameters of the given specimen i.e

(screw thread) by using profile projector.

4.0 APPARATUS

Screw Thread Plug Gauge (as specimen)

Profile Projector (Horizontal/Vertical)

5.0 METHOD OF APPROACH

A briefing session will be conducted prior to students carrying out the measurement on the specimen.

Please take note of the procedures for setting up the specimen on the profile projector.Using suitable

magnification,adjust the focusing knob to ensure the shadow obtained is sharp and clear. Movements

can be made through micrometer adjustment. Parameters to be measured on the specimen are:

Major diameter

Minor diameter

Effective diameter

6.0 LAB REPORT PREPARATION:

The report should include the following items:

Tabulation of reading parameters (min 3 readings) and overall results.

Calculation of the percentage of error for each of those parameters.

Evaluation of by comparing with the theoretical value by (refer to Metric Standard table for

screw thread (ISO 6H))

Comment on the shortcomings of measurement involving measurement using optical system

such as the effect of helix screw thread.

*Student should use the standard cover page.

*The report content should base on 10 items highlighted in standard report descriptions.

You might also like

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Amirul Bin Abd Rashid: Faculty of Mechanical Engineering, University Teknologi MARADocument32 pagesAmirul Bin Abd Rashid: Faculty of Mechanical Engineering, University Teknologi MARAAhmad Syazni Bin MoktarNo ratings yet

- Tensile TestDocument23 pagesTensile TestAhmad Syazni Bin MoktarNo ratings yet

- 1 Intro Tqm-Nhs 224440914Document119 pages1 Intro Tqm-Nhs 224440914Ahmad Syazni Bin MoktarNo ratings yet

- ( ( ( ( Instructions ) ) ) )Document1 page( ( ( ( Instructions ) ) ) )Ahmad Syazni Bin MoktarNo ratings yet

- FAQ Isiswa88Document5 pagesFAQ Isiswa88Ahmad Syazni Bin MoktarNo ratings yet

- WC1Document12 pagesWC1Ahmad Syazni Bin MoktarNo ratings yet

- WC3Document36 pagesWC3Ahmad Syazni Bin MoktarNo ratings yet

- 4.0 Handling LoadsDocument7 pages4.0 Handling LoadsAhmad Syazni Bin MoktarNo ratings yet

- How Students Can Enroll in A Class (Using A Turnitin Software) Instruction To Students (First Time User)Document1 pageHow Students Can Enroll in A Class (Using A Turnitin Software) Instruction To Students (First Time User)Ahmad Syazni Bin MoktarNo ratings yet

- Laptops Thundermatch 2Document1 pageLaptops Thundermatch 2Zulfahmi De Geliung SkipperNo ratings yet

- 8.0 Lab Sheet Welding 8klDocument2 pages8.0 Lab Sheet Welding 8klAhmad Syazni Bin MoktarNo ratings yet

- Log Sheet: Mec532 Mechanical Engineering Design IiDocument1 pageLog Sheet: Mec532 Mechanical Engineering Design IiAhmad Syazni Bin MoktarNo ratings yet

- MEM603 Industrial Visit Report AssessmentDocument1 pageMEM603 Industrial Visit Report AssessmentAhmad Syazni Bin MoktarNo ratings yet

- LFMH 8Document2 pagesLFMH 8Ahmad Syazni Bin MoktarNo ratings yet

- NTM JuriDocument40 pagesNTM JuriAhmad Syazni Bin MoktarNo ratings yet

- 2.0 MEM564 Assessment FORMDocument3 pages2.0 MEM564 Assessment FORMFad TajudinNo ratings yet

- 047 Dalhousie UniversityDocument8 pages047 Dalhousie UniversityAlberto RuizNo ratings yet

- Fluid - Lab.2.report ASHDocument6 pagesFluid - Lab.2.report ASHYana YiNo ratings yet

- Meeting Minutes No:: Items in Minutes Are What The Group Does (Tasks) To Complete The ProjectDocument2 pagesMeeting Minutes No:: Items in Minutes Are What The Group Does (Tasks) To Complete The ProjectAhmad Syazni Bin MoktarNo ratings yet

- SEB External Scholarship Programme Application FormDocument3 pagesSEB External Scholarship Programme Application FormAhmad Syazni Bin MoktarNo ratings yet

- Topic 2Document55 pagesTopic 2Ahmad Syazni Bin MoktarNo ratings yet

- ObjectiveDocument8 pagesObjectiveAhmad Syazni Bin MoktarNo ratings yet

- Academic Sessions 2014-2015 UitmDocument2 pagesAcademic Sessions 2014-2015 UitmsilentsioNo ratings yet

- Manufacturing Processes Lab - MEM564 / LS03/Ziyadi Rev. 01-2014Document3 pagesManufacturing Processes Lab - MEM564 / LS03/Ziyadi Rev. 01-2014Ahmad Syazni Bin MoktarNo ratings yet

- ME649 Flat Plate ExperimentDocument3 pagesME649 Flat Plate Experimentkush_mech9657No ratings yet

- LBFDocument2 pagesLBFAhmad Syazni Bin MoktarNo ratings yet

- 1.0-Lab Sheet Foundry - 1Document2 pages1.0-Lab Sheet Foundry - 1atheerahfarahNo ratings yet

- CFG PumpDocument17 pagesCFG PumpAhmad Syazni Bin MoktarNo ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (120)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)