Professional Documents

Culture Documents

InternalAuditSOP 012413

InternalAuditSOP 012413

Uploaded by

noormuddassirkhanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

InternalAuditSOP 012413

InternalAuditSOP 012413

Uploaded by

noormuddassirkhanCopyright:

Available Formats

Laboratory Name and contact

information

Title: Internal Audit Standard Operating Procedure and Simplified

Quality System Checklist

Doc. No. 2

Rev. No. 2

Date: 01/24/13

Page: 1 of 29

Approved by:

Technical Director

______________________________ (Name)

______________________________ (Signature)

_______________ (Initials)

_________________ (Date)

Quality Assurance Officer

______________________________ (Name)

______________________________ (Signature)

_______________ (Initials)

_________________ (Date)

Controlled Document

Laboratory Name and contact

information

Title: Internal Audit Standard Operating Procedure and Simplified

Quality System Checklist

Doc. No. 2

Rev. No. 2

Date: 01/24/13

Page: 2 of 29

Revision History

Rev

Date

Description of Change

9/5/07

Name

Initial Release

01/13/13

Name

Updated all sections. Reformatted

Appendix A.

Distribution List / Location

This SOP is to be distributed to those individuals involved in the internal audit process of

the lab.

Controlled Document

Laboratory Name and contact

information

Title: Internal Audit Standard Operating Procedure and Simplified

Quality System Checklist

Doc. No. 2

Rev. No. 2

Date: 01/24/13

Page: 3 of 29

Annual Review (The review is to be documented if the document has not been revised in

the past 12 months)

_______________________

Signature

____________________

Title

_______

Date

______________________

Signature

____________________

Title

_______

Date

___________________

Signature

____________________

Title

_______

Date

______________________

Signature

____________________

Title

_______

Date

___________________

Signature

____________________

Title

_______

Date

Training Record

The following laboratory staff have read and agree to follow the latest version of the SOP.

_____________________

______________________ _______

_______

Signature

Name

Initials

Date

_____________________

Signature

______________________

Name

_______

Initials

_______

Date

_____________________

Signature

______________________

Name

_______

Initials

_______

Date

_____________________

Signature

______________________

Name

_______

Initials

_______

Date

_____________________

Signature

______________________

Name

_______

Initials

_______

Date

Controlled Document

Laboratory Name and contact

information

Title: Internal Audit Standard Operating Procedure and Simplified

Quality System Checklist

Doc. No. 2

Rev. No. 2

Date: 01/24/13

Page: 4 of 29

Table of Contents

1. Purpose...........................................................................................................................5

2. Scope...............................................................................................................................5

3. Responsibilities...............................................................................................................5

4. Procedure........................................................................................................................6

5. Related Documentation and References......................................................................8

6. Definitions.......................................................................................................................8

APPENDIX A.....................................................................................................................9

Controlled Document

Laboratory Name and contact

information

Title: Internal Audit Standard Operating Procedure and Simplified

Quality System Checklist

Doc. No. 2

Rev. No. 2

Date: 01/24/13

Page: 5 of 29

1. Purpose

To ensure that the procedures in the quality manual, related to quality systems, and the

labs method manual, related to testing activities, are being followed.

To determine the effectiveness of the labs procedures in controlling the quality of data

reported

To identify, correct, and implement any changes needed in any of the quality system

and testing activities procedures found to be deficient

To ensure all deficiencies in the labs quality system and testing activities are

documented though its corrective action process

2. Scope

The internal audit SOP and associated checklist is used to audit, on an annual basis, the

labs quality system, policies and procedures, work instructions, analytical records, and

reports. In addition, the lab audits its testing activities (each method-technology) on an

annual basis.

3. Responsibilities

Quality Assurance (QA) Manager or QA Officer (QAO):

is knowledgeable and trained in quality system requirements, including internal

audits

initiates all internal audits and ensures they are conducted in an efficient and timely

manner

delegates responsible, trained staff, if applicable, to carry out specific audits of

testing activities

notifies laboratory management , including the technical director, of any

deficiencies (findings) in the quality system or testing activities

documents and monitors corrective actions

documents and tracks staff who have completed auditor training

Auditor:

has completed auditor training

Controlled Document

Laboratory Name and contact

information

Title: Internal Audit Standard Operating Procedure and Simplified

Quality System Checklist

Doc. No. 2

Rev. No. 2

Date: 01/24/13

Page: 6 of 29

has sufficient experience in performing audits

performs audits in an efficient and timely manner

reports all findings to the QAO

4. Procedure

4.1 The Audit Team

The Quality Assurance Manager or QA Officer (QAO) selects trained staff, if applicable, to

perform the audits defined in this procedure. If trained staff is limited, the QAO and/or

technical director may perform the audits. If trained staff is not limited, the QAO will

designate one of the trained staff to serve as the lead auditor. When ever possible, auditors

are selected from a function not directly involved in the audit.

4.2 Training

Auditors are trained in auditing techniques. Training consists of reading and

understanding this procedure and reference material related to internal auditing, and where

possible, shadowing a trained auditor or completing a formal, external training course. The

auditors are also provided with the applicable auditing guidelines and checklists. Both

quality system and method-specific checklists are to be provided to the auditor.

Evidence of the training includes a signature that the auditor has read and understands this

procedure (see page 3). It may also include documentation of any external seminars or

course work related to quality system auditing. All training records are to be kept for a

minimum of five years.

4.3 Audit Plan

The entire quality system, including testing activities, is audited on an annual basis. The

maximum interval between audits is twelve months. The frequency may be adjusted for

new procedures or deficiencies that resulted from complaints.

The QAO creates the audit schedule. The audit schedule defines the following:

timeframe of the audit

scope of audit

elements and/ or areas to be audited

4.4 Performing the Audit

The QAO notifies the supervisors of the areas to be audited at least a month in advance.

Controlled Document

Laboratory Name and contact

information

Title: Internal Audit Standard Operating Procedure and Simplified

Quality System Checklist

Doc. No. 2

Rev. No. 2

Date: 01/24/13

Page: 7 of 29

The QAO briefs the auditors on the audit procedures and the areas to be audited. The

auditors are to prepare prior to the audit by familiarizing themselves with the audit

procedures.

During the audit, auditors use applicable checklists. They record all findings on the

checklists. The findings are discussed with the staff responsible for performing the function

that was found to be deficient.

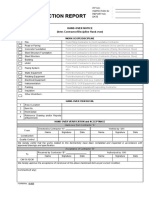

4.5 Deficiency Report and Corrective Action Response

A deficiency report is generated by the auditor for each legitimate finding. The QAO

makes the final decision as to whether the finding is legitimate if it can not be resolved

between the auditor and the staff audited. The QAO presents the final report to the

audited staff, as well as, laboratory management, including the technical director.

The audited staff responds to the deficiency report in a manner prescribed by the labs

corrective action procedures, which are included in the Quality Manual. The corrective

action must be completed within 90 days of the date of the finding.

When deficiencies cast doubt on the correctness or validity of the calibration or test results

reported, the lab needs to immediately notify its clients of the situation. A record of the

client notification must be maintained.

4.6 Closing an Audit

Audit findings are closed upon completion of an effective corrective action for each of the

findings. All documents related to the audit, including checklists, deficiency reports,

corrective action responses, are maintained by the QAO.

4.7 Review and Evaluation

The QAO verifies successful implementation of the corrective action by observing

objective evidence supplied by the audited staff as part of the corrective action process.

Follow-up is performed by the QAO, or designated staff, as part of the next scheduled

audit to verify the effectiveness of the corrective actions that were implemented. IN

addition, the QAO reviews the audit report with laboratory management, including the

technical director, as part of the labs annual management review.

5. Related Documentation and References

Audit Plan

Controlled Document

Laboratory Name and contact

information

Title: Internal Audit Standard Operating Procedure and Simplified

Quality System Checklist

Doc. No. 2

Rev. No. 2

Date: 01/24/13

Page: 8 of 29

Audit Checklists, including method-specific checklists

Deficiency (Audit) Report

Corrective Action Response (CAR)

Corrective Action Procedures as noted in Quality Manual

National Environmental Laboratory Accreditation Conference (NELAC), 2003 NELAC Standard,

Approved June 5, 2003, Effective July 1, 2003, 324 pp (EPA/600/R-04/003).

National Environmental Laboratory Accreditation Conference (NELAC), 2009 NELAC Standard,

Approved August 24, 2009, Effective July 1, 2011.

New York State Department of Health (NYS DOH) Environmental Laboratory Approval Program

(ELAP), method-specific checklists,

http://www.wadsworth.org/labcert/elapcert/appforms.htm

New York State Department of Health (NYS DOH), NYCRR Subpart 55-2, Approval of

Laboratories Performing Environmental Analysis, Sections 55-2.1 through 55-2.12 effective

November 17, 2004, and Section 55-2.13 effective October 6, 2004.

6. Definitions

Audit Finding - A conclusion of importance based on observation(s). An undesirable

deviation or nonconformity.

Corrective Action - Action taken to eliminate the root cause(s) and the symptom(s) of an

existing undesirable deviation or nonconformity to prevent recurrence.

Objective Evidence - Verifiable qualitative or quantitative observations, information,

records, or statements of fact pertaining to the quality of a product or service or to the

existence and implementation of quality system element.

Quality Audit - Systematic and independent examination to determine whether quality

activities and related results comply with planned arrangements and whether these

arrangements are implemented effectively and are suitable to achieve objectives

Controlled Document

Laboratory Name and contact

information

Title: Internal Audit Standard Operating Procedure and Simplified

Quality System Checklist

Doc. No. 2

Rev. No. 2

Date: 01/24/13

Page: 9 of 29

APPENDIX A

TOPIC

Organization & Management

1.) Does the laboratory have a policy to ensure its personnel are

free from any commercial, financial and other undue pressures,

which might adversely affect the quality of the work?

2.) Does the laboratory specify and document the responsibility,

authority, and interrelation of all personnel who manage,

perform or verify work affecting the quality of calibrations and

tests in job descriptions for all positions.

3.) Does the laboratory have documented certifications that

personnel performing all tests for which the laboratory is

accredited have the appropriate educational and/or technical

backgrounds?

4.) Does the laboratory nominate deputies in the case of absence

of the technical director or QA officer?

5.) Does the laboratory have documented policies and

procedures to ensure the protection of clients' confidential

information and proprietary rights?

Quality System

1.) Is the quality documentation available to, understood by, and

implemented by all laboratory personnel?

2.) Does the quality manual and related quality documentation

include the objectives and commitments by top management?

N/A

Controlled Document

Comments

Laboratory Name and contact

information

Title: Internal Audit Standard Operating Procedure and Simplified

Quality System Checklist

Doc. No. 2

Rev. No. 2

Date: 01/24/13

Page: 10 of 29

3.) Does the quality manual and related quality documentation

include the organization and management structure of the

laboratory, its place in any parent organization, and relevant

organizational charts?

4.) Does the quality manual and related quality documentation

include procedures to ensure that all records required under

NELAC are retained?

5.) Does the quality manual and related quality documentation

include procedures for control and maintenance of

documentation through a document control system which

ensures that all standard operating procedures, manuals, or

documents clearly indicate the time period during which the

procedure or document was in force?

6.) Does the quality manual and related quality documentation

include procedures for achieving traceability of measurements?

7.) Does the quality manual and related quality documentation

include a list of all methods under which the laboratory performs

its accredited testing?

8.) Does the quality manual and related quality documentation

include mechanisms for ensuring that the laboratory reviews all

new work to ensure that it has the appropriate facilities and

resources before commencing such work?

9.) Does the quality manual and related quality documentation

include reference to the calibration and/or verification test

procedures used?

10.) Does the quality manual and related quality documentation

include procedures for handling submitted samples?

Controlled Document

Laboratory Name and contact

information

Title: Internal Audit Standard Operating Procedure and Simplified

Quality System Checklist

Doc. No. 2

Rev. No. 2

Date: 01/24/13

Page: 11 of 29

11.) Does the quality manual and related quality documentation

include reference to the major equipment and reference

measurement standards used as well as the facilities and services

used by the laboratory in conducting tests?

12.) Does the quality manual and related quality documentation

include reference to procedures for calibration, verification and

maintenance of equipment?

13.) Does the quality manual and related quality documentation

include reference to verification practices including interlaboratory comparisons, proficiency testing programs, use of

reference materials, and internal quality control schemes?

14.) Does the quality manual and related quality documentation

include procedures to be followed for feedback and corrective

action for failed quality control samples, or when departures

from documented policies, procedures, or NELAC standards

occur?

15.) Does the quality manual and related quality documentation

include procedures for dealing with complaints?

16.) Does the quality manual and related quality documentation

include processes/procedures for establishing that personnel are

adequately experienced in the duties they are expected to carry

out and/or receive any needed training?

17.) Does the quality manual and related quality documentation

include processes and procedures for educating and training

personnel in their ethical and legal responsibilities including the

potential punishments and penalties for improper, unethical, or

illegal actions?

Controlled Document

Laboratory Name and contact

information

Title: Internal Audit Standard Operating Procedure and Simplified

Quality System Checklist

Doc. No. 2

Rev. No. 2

Date: 01/24/13

Page: 12 of 29

18.) Does the quality manual and related quality documentation

include reference to procedures for reporting analytical results?

19.) Does the quality manual and related quality documentation

include a Table of Contents, and applicable lists of references

and glossaries, and appendices?

20.) Does the QA officer keep the quality manual current?

21.) Does the QA officer arrange for or conduct internal audits

on the entire technical operation annually and notify laboratory

management of deficiencies in the quality system and monitor

corrective action

22.) Where a complaint, or any other circumstance, raises doubt

concerning the laboratory's compliance with the laboratory's

policies or procedures, or with the requirements of this Standard

or otherwise concerning the quality of the laboratory's

calibrations or tests, does the laboratory ensure that those areas

of activity and responsibility involved are promptly audited?

23.) Does the laboratory have a procedure for the annual

management review of the quality system?

24.) Is an annual review of the quality system completed by

management to evaluate its continuing suitability and

effectiveness and make any necessary changes or improvements?

25.) Does the annual review take into account reports from

managerial and supervisory personnel, the outcome of recent

internal audits, assessments by external bodies, the results of

interlaboratory comparisons or proficiency tests, any changes in

the volume and type of work undertaken, feedback from clients,

corrective actions and other relevant factors?

Controlled Document

Laboratory Name and contact

information

Title: Internal Audit Standard Operating Procedure and Simplified

Quality System Checklist

Doc. No. 2

Rev. No. 2

Date: 01/24/13

Page: 13 of 29

26.) Are all audits and review findings and any corrective actions

that arise from them documented?

27.) Does the laboratory management ensure that corrective

actions are discharged within the agreed time frame?

28.) Does the laboratory implement checks to monitor the

quality of laboratory results using:

_a__ Internal quality control procedures (using statistical

techniques whenever possible);

_b__ Participation in PT or other interlaboratory comparisons;

_c__ Reference material and/or in-house quality control using

secondary reference materials;

_d__ Replicate testing;

_e__ Re-testing of retained samples; and/or

_f__ Correlation of results for different parameters of a sample.

29.) Does the laboratory have general procedures to be followed

when there are departures from documented policies,

procedures, and QC have occurred?

30.) Do the procedures to be followed when there is a departure

from documented policies, procedures, and QC include but not

limited to:

a___ Identify the individuals responsible for assessing each QC

data type;

b___ Identify the individuals responsible for initiating and/or

recommending corrective actions;

c___ Define how the analyst should treat the data set if the

associated QC measurements are unacceptable;

d___ Specify how out-of-control situations and subsequent

corrective actions are to be documented; and

Controlled Document

Laboratory Name and contact

information

Title: Internal Audit Standard Operating Procedure and Simplified

Quality System Checklist

Doc. No. 2

Rev. No. 2

Date: 01/24/13

Page: 14 of 29

e___ Specify procedures for management (including the QA

officer) to review corrective action reports.

31.) Is a corrective action log maintained, up-to-date?

32.) If a QC measure is out of control and the data is to be

reported, are data qualifiers reported with samples associated

with failed QC measures?

33.) Are all quality control measures assessed and evaluated on

an on-going basis, and quality control acceptance limits used to

determine the usability of the data?

34.) Does the laboratory have procedures for the development

of acceptance/rejection criteria where no method or regulatory

criteria exist?

35.) Are the quality control protocols specified by the

laboratorys method manual followed?

Training

1.) Are training records available for all technical staff that

include:

a___ Evidence that the employee has read, understands, and is

using the latest version of the labs in-house quality

documentation;

b___ Training courses or workshops on specific equipment,

analytical techniques, or lab procedures;

c___ Training courses in ethical and legal responsibilities

including the potential punishments & penalties for violations.

d___ Evidence that the employee has read; acknowledges, and

understands their personal & legal responsibilities including

Controlled Document

Laboratory Name and contact

information

Title: Internal Audit Standard Operating Procedure and Simplified

Quality System Checklist

Doc. No. 2

Rev. No. 2

Date: 01/24/13

Page: 15 of 29

potential punishments & penalties for violations; and

e___ Documentation certifying that the employee has read,

understands, and agrees to use the latest version of a test

method used; and

2.0 Are initial demonstrations, continuing demonstrations and

method certification documented through the use of the forms in

the latest approved NELAC document in Appendix C?

3.) Does the laboratory use another approach, documented in its

Quality Manual, to demonstrate capability for analytes for which

spiking is not an option and for which quality control samples

are not readily available?

4.) Does the laboratory retain all associated supporting data

necessary to reproduce the analytical results summarized in the

IDC certification statement?

5.) Is a copy of the initial demonstration of Capability Certificate

(IDC) in the personnel records for each employee performing a

test method?

6.) Do the training records of each of the technical staff include

documentation of continuing proficiency by at least one of the

following:

___ Acceptable performance of a blind sample;

___ Another demonstration of capability;

___ Successful analysis of a blind performance sample on a

similar test method using the same technology; a

___ Analysis of at least 4 consecutive lab control samples with

acceptable levels of precision and accuracy; or

___ If one of the above can be performed, the analysis of

authentic samples that have been analyzed by another trained

Controlled Document

Laboratory Name and contact

information

Title: Internal Audit Standard Operating Procedure and Simplified

Quality System Checklist

Doc. No. 2

Rev. No. 2

Date: 01/24/13

Page: 16 of 29

analyst with statistically indistinguishable results.

7.) Does the laboratory complete a new demonstration of

capability whenever there is a significant change in instrument

type, personnel, or test method?

8.) Has the laboratory management developed a proactive

program for the detection of improper, unethical, or illegal

actions?

Equipment

1.) Are maintenance procedures documented?

2.) Is each item of equipment including reference materials

labeled, marked or otherwise identified to indicate its calibration

status, when appropriate?

3.) Are maintenance records available?

Support Equipment Calibration and Traceability

1.) Does the laboratory have an established program for the

calibration and verification of its measuring and test equipment

including balances, thermometers and control standards?

2.) Are measurements made by the labs traceable to national

standards of measurement where available?

3.) Does the laboratory maintain records of all certificates that

indicate traceability to national standards of measurement and/or

statements of compliance with an identified metrological

specification?

4.) Is all support equipment calibrated annually, using NIST

traceable references when available, over the entire range in

which the equipment is used?

5.) Are the results of support equipment calibration within the

Controlled Document

Laboratory Name and contact

information

Title: Internal Audit Standard Operating Procedure and Simplified

Quality System Checklist

Doc. No. 2

Rev. No. 2

Date: 01/24/13

Page: 17 of 29

specifications required of the application for which it is used?

6.) Is support equipment removed from service until repaired or

is a deviation curve prepared and all measurements corrected for

the deviation when the calibration is not within acceptance

limits?

7.) Does the laboratory maintain records of established

correction factors to correct measurements?

8.) Are all raw data records retained to document equipment

performance?

9.) Prior to use on each working day, are balances, ovens,

refrigerators, freezers, incubators and water baths checked with

NIST traceable references (where possible) in the expected use

range?

10.) Are mechanical volumetric devices checked for accuracy on

a quarterly basis?

11.) Demonstration of sterilization for biological tests provided

by use of a continuous temperature recording or with the

frequent use of spore strips?

SOPS and Test Methods

1.) Does the laboratory have SOPs for all test methods?

2.) Are all instructions, standards, manuals and reference data

relevant to the work of the laboratory maintained up-to-date and

readily available to the staff?

3.) Are copies of SOPs assessable to all personnel?

4.) Does each SOP clearly indicate:

a___ Effective date of the SOP

b___ Revision number

Controlled Document

Laboratory Name and contact

information

Title: Internal Audit Standard Operating Procedure and Simplified

Quality System Checklist

Doc. No. 2

Rev. No. 2

Date: 01/24/13

Page: 18 of 29

c___ Signature(s) of approving authority

5.) Does the laboratory have an in-house method manual for

each accredited analyte or test method that clearly describes the

labs method?

6.) In cases where modifications are made to published methods

or where the reference test method is ambiguous or provides

insufficient detail, are any modifications, changes, or

clarifications clearly indicated?

7.) Are the practices specified by the laboratorys method

manual followed by all analysts?

8.) Are all essential quality control measures incorporated in the

labs method manual?

9.) Are all quality control measures assessed and evaluated on an

on-going basis?

10.) Does the laboratory have procedures for developing

acceptance/rejection criteria for each test method?

11.) Do the SOPs or the test method SOP reference the details

of the initial calibration procedures, including calculations

integrations, and acceptance criteria associated statistics?

12.) Is the criteria for the acceptance of an initial calibration

established (correlation coefficient or relative percent

difference)?

13.) Are the details of the continuing instrument calibration

procedure, calculations, and associated statistics included or

referenced in the test method SOP?

14.) Does the laboratory establish Standard Operating

Procedures to ensure that the reported data is free from

Controlled Document

Laboratory Name and contact

information

Title: Internal Audit Standard Operating Procedure and Simplified

Quality System Checklist

Doc. No. 2

Rev. No. 2

Date: 01/24/13

Page: 19 of 29

transcription and calculation errors?

15.) Does the laboratory establish Standard Operating

Procedures to ensure that all quality control measures are

reviewed, and evaluated before data is reported?

16.) Are calculations and data transfers subject to checks as

established in the laboratorys SOP?

17.) Do documented procedures exist for the purchase,

reception and storage of consumable materials used for the

technical operations of the laboratory?

18.) Does the laboratory retain records for all standards,

including manufacturer/vendor, the manufacturers Certificate of

Analysis or purity (if supplied), date of receipt, recommended

storage conditions, and an expiration date after which the

material shall not be used unless verified by the laboratory?

19.) Are original reagent containers labeled with the expiration

date?

20.) Are detailed records maintained on reagent and standard

preparation?

21.) Do the records of reagent and standard preparation indicate

traceability to purchased stocks or neat compounds, and include

the date of preparation and preparer's initials?

22.) Are containers of prepared reagents and standards uniquely

identified and include an expiration date and can it be linked to

the documentation of its preparation?

Sample Handling

1.) Does the laboratory have a documented system for uniquely

identifying the items to be tested, to ensure that there can be no

Controlled Document

Laboratory Name and contact

information

Title: Internal Audit Standard Operating Procedure and Simplified

Quality System Checklist

Doc. No. 2

Rev. No. 2

Date: 01/24/13

Page: 20 of 29

confusion regarding the identity of such items at any time?

2.) Does the laboratory assign a unique identification (ID) code

to each sample container received in the laboratory?

3.) Is the laboratory ID code placed on the sample container as a

durable label?

4.) Is the laboratory ID code entered into the laboratory records

(see 5.11.3.d) and does the link that associate the sample with

related laboratory activities such as sample preparation or

calibration?

5.) Does the laboratory have a written sample acceptance policy

that clearly outlines the circumstances under which samples will

be accepted?

6.) Is data from any sample which does not meet the policy

criteria flagged in an unambiguous manner clearly defining the

nature and substance of the variation?

7.) Is the sample acceptance policy made available to sample

collecting personnel and does it include at a minimum all the

policy criteria?

8.) Upon receipt, is the condition of the sample, including any

abnormalities or departures from standard condition as

prescribed in the relevant test method, recorded?

9.) Are all items specified in sample acceptance policy criteria

checked?

10.) Are all samples, which require thermal preservation,

considered acceptable if the arrival temperature is either within

+/-2C of the required temperature or in the method specified

range?

Controlled Document

Laboratory Name and contact

information

Title: Internal Audit Standard Operating Procedure and Simplified

Quality System Checklist

Doc. No. 2

Rev. No. 2

Date: 01/24/13

Page: 21 of 29

11.) For samples with a specified temperature of 4C, are

samples maintained within a temperature of just above freezing

to 6C?

12.) In cases where samples are hand delivered to the laboratory

immediately after collection and do not meet the temperature

criteria considered acceptable, is there evidence that the chilling

process has begun such as arrival on ice?

13.) Does the laboratory have procedures for checking chemical

preservation using readily available techniques, such as pH, free

chlorine or temperature, prior to or during sample preparation

or analysis?

14.) Does the laboratory implement procedures for checking

chemical preservation using readily available techniques, such as

pH, free chlorine or temperature, prior to or during sample

preparation or analysis?

15.) Are the results of all checks recorded?

16.) If the sample does not meet the sample receipt acceptance

criteria does the laboratory do any of the following:

___ Retain correspondence and/or records of conversations

concerning the final disposition of rejected

___ Fully document any decision to proceed with the analysis of

samples not meeting acceptance criteria

___ Is the condition of these samples, at a minimum, noted on

the chain of custody or transmittal form and laboratory receipt

documents?

___ Is the analysis data of these samples appropriately

"qualified" on the final report?

Controlled Document

Laboratory Name and contact

information

Title: Internal Audit Standard Operating Procedure and Simplified

Quality System Checklist

Doc. No. 2

Rev. No. 2

Date: 01/24/13

Page: 22 of 29

17.) Does the laboratory utilize a permanent, sequential log,

such as a logbook or electronic record, to document receipt of

all sample containers?

18.) Is the following information recorded in the laboratory

chronological log?

a___ Client/Project Name

b___ Date and time of laboratory receipt of sample

c___ Unique laboratory ID code (see 5.11.1)

d___ Signature or initials of the person making the entries

19.) Are samples stored away from all standards, reagents, food

and other potentially contaminating sources in such a manner as

to prevent cross contamination?

20.) Are samples, sample fractions, extracts, leachates or other

sample preparation fractions stored according to the conditions

specified by preservation protocols or according to the test

method?

21.) Does the laboratory have standard operating procedures for

the disposal of samples, digestates, leachates and extracts or

other sample preparation products?

Records

1.) Does the laboratory retain on record all original

observations, calculations and derived data, calibration records

and a copy of the test report for five years?

2.) Does the record keeping system allow historical

reconstruction of all laboratory activities that produced the

resultant sample analytical data?

3.) Is the history of the sample readily understood through the

Controlled Document

Laboratory Name and contact

information

Title: Internal Audit Standard Operating Procedure and Simplified

Quality System Checklist

Doc. No. 2

Rev. No. 2

Date: 01/24/13

Page: 23 of 29

documentation including inter-laboratory transfers of samples

and/or extracts?

4.) Do the records include the identity of personnel involved in

sampling, preparation, calibration or testing?

5.) Are all documentation entries signed or initialed by

responsible staff with the reason for the signature or initial

clearly indicated in the records? (Ex. sampled by, prepared

by, reviewed by)

6.) Are all generated data, except those that are generated by

automated data collection systems, recorded directly, promptly

and legibly in permanent ink?

7.) Are entries in records not obliterated by methods such as

erasures, overwritten files or markings?

8.) Are all corrections to record-keeping errors made by one line

marked through the error and the individual making the

correction signing (or initialing) and dating the correction?

9.) Do records that are stored or generated by computers or

personal computers (PCS) have hard copy or write-protected

backup copies?

10.) Does the laboratory have a record management system for

control of laboratory notebooks; instrument logbooks; standards

logbooks; and records for data reduction, validation storage and

reporting?

11.) Is access to archived information documented with an

access log?

12.) Is archived information protected against fire, theft, loss,

environmental deterioration, and vermin and, in the case of

Controlled Document

Laboratory Name and contact

information

Title: Internal Audit Standard Operating Procedure and Simplified

Quality System Checklist

Doc. No. 2

Rev. No. 2

Date: 01/24/13

Page: 24 of 29

electronic records, electronic or magnetic sources?

Reports

1.) Does the test report contain all information necessary for the

interpretation of the test results and all information required by

the method used?

2.) Does the facility management ensure that the appropriate

report items are in the report to the regulatory authority if the

report is prepared by another individual within the organization.

3.) Where the certificate or report contains results of tests

performed by sub-contractors, are these results clearly identified

by subcontractor name or applicable accreditation number?

4.) Does the laboratory certify that the test results meet all

requirements of NELAC or provide reasons and/or justification

if they do not?

Chemistry Quality Control

(To be used with the method checklist)

1.) Is a method blank performed 1 per batch, per matrix type per

sample extraction or preparation method?

2.) Is the analysis stopped, corrected and the problem eliminated

if the blank contamination is greater than 1/10th of the measured

sample contamination or 1/10th of the regulatory limit; or are

the results reported with appropriate data qualifying codes?

3.) Is an LCS (a sample matrix free of analytes of interest spiked

with a verified known amount of analyte) analyzed at a

minimum of 1 per batch of 20 or less samples per matrix, per

sample extraction or preparation method except for analytes for

which spiking solutions are not available?

Controlled Document

Laboratory Name and contact

information

Title: Internal Audit Standard Operating Procedure and Simplified

Quality System Checklist

Doc. No. 2

Rev. No. 2

Date: 01/24/13

Page: 25 of 29

4.) Is a matrix spike (sample prepared by adding a known mass

of target analyte to a specific amount of matrix sample)

performed at a frequency of 1 in 20 samples per matrix, per

sample extraction or preparation method?

5.) Is a matrix spike duplicate (MSD) or laboratory duplicate

performed at a frequency of 1 in 20 samples per matrix, per

sample extraction or preparation method?

6.) Is the initial instrument calibration used directly for

quantitation?

7.) Is the continuing instrument calibration verification used to

confirm the continued validity of the initial calibration?

8.) Are all initial calibrations verified with a standard obtained

from a second source?

9.) If the results of samples are not bracketed by the initial

calibration, are the results reported as having less certainty

(defined qualifiers, flags, or explanation in the case narrative)?

10.) Is the lowest calibration standard of the initial calibration

above the detection limit?

11.) When an initial calibration is not performed on the day of

analysis, does the laboratory verify the validity of the initial

calibration prior to the analysis of samples by analyzing a

continuing instrument calibration verification sample?

12.) Is continuing instrument calibration verification repeated at

the beginning and end of each analytical batch? (If an internal

standard is used, only one continuing calibration verification

must be analyzed per analytical batch)

13.) Are the concentrations of the continuing calibration

Controlled Document

Laboratory Name and contact

information

Title: Internal Audit Standard Operating Procedure and Simplified

Quality System Checklist

Doc. No. 2

Rev. No. 2

Date: 01/24/13

Page: 26 of 29

standard varied within the established calibration range?

14.) Are sufficient raw data records retained to permit

reconstruction of the initial calibration including:

a___ Calibration date

b___ Test method

c___ Instrument

d___ Analysis date

e___ Each analyte name

f___ Concentration

g___ Response

h___ Calibration curve or response factor

15.) Does the laboratory use detection limits that are determined

by the protocol in the mandated test method or applicable

regulation?

16.) Is the quality of water sources monitored and documented

to meet method specified requirements?

Quality Control for Bacteriology

(To be used with the method checklist)

1.) Are temperatures of incubators and water baths recorded

twice daily (morning & afternoon) as required by the methods as

indicated below:

a. ____

b. ____

Total Coliform bacteria incubation at 35.0 +/- 0.5

degrees Celsius (SM9221B, SM9221D,

SM9222B & EPA-600/8-78-017)

Fecal Coliform bacteria incubation at 44.5 +/- 0.2

degrees Celsius (SM9221E, SM9222D, & EPA600/8-78-017)

Controlled Document

Laboratory Name and contact

information

Title: Internal Audit Standard Operating Procedure and Simplified

Quality System Checklist

Doc. No. 2

Rev. No. 2

Date: 01/24/13

Page: 27 of 29

c. ____

Total Coliform & Escherichia coli (E. coli)

incubation at 35.0 +/- 0.5 degrees Celsius

(SM9223 + UV; Colilert, Idexx-18, & Colisure)

d. ____

E. coli incubation at 44.5 +/- 0.2 degrees Celsius

(EC with MUG or Nutrient Agar with MUG)

2.) Is the following support equipment associated with

microbiological testing checked with NIST traceable materials

(where possible)

a. ____ pH meter

b. ____ Balance(s)

c. ____ Conductivity meter

d. ____ Refrigerator(s) for sample storage and/or media

storage

e. ____ Incubators

f. ____ Water baths

3.) Is a minimum of one uninoculated control prepared and

analyzed?

4.) When the same equipment is used to prepare multiple

samples does the laboratory prepare at least one blank at the

beginning, one at the end, with additional blanks inserted after

every 10 samples?

5.) Is a known negative culture analyzed with each set of

samples.

6.) Is each lot of media tested on a monthly basis with at least

one pure culture of a known positive reaction (positive control)?

(Not required if the laboratory has at least one known positive

result of the appropriate organism during the month).

Controlled Document

Laboratory Name and contact

information

Title: Internal Audit Standard Operating Procedure and Simplified

Quality System Checklist

Doc. No. 2

Rev. No. 2

Date: 01/24/13

Page: 28 of 29

7.) Is the positive control test tested with a sample test batch?

8.) Are at least 5% of the suspected positive samples analyzed in

duplicate?

9.) In laboratories with more than one analyst performs the

testing does each analyst make parallel analyses on at least one

positive sample per month?

10.) Are the calculations, data reduction and statistical

interpretations specified by each method followed?

11.) Where the method specifies colony counts, such as

membrane filter or colony counting, is the ability of individual

analysts to count colonies verified at least once per month, by

having two or more analysts count colonies from the same

plate?

12.) In order to demonstrate traceability and selectivity, does the

laboratory use reference cultures of microorganisms obtained

from a recognized national collection or an organization

recognized by the assessor body?

13.) Are the graduations of the temperature measuring devices

appropriate for the required accuracy of measurement?

14.) Are records maintained on all laboratory reagent water

monitoring activities as below when dilution water and/or media

are prepared in house:

a_ Residual Chlorine < 1.0 mg/L.

b_ Conductivity < 2.0 umho/cm at 25 degrees Celsius

c_ Heterotrophic Plate Count < 1000 cfu per mL.

d_ Bacteriological ratio 0.8 3.0.

e_ Cd, Cr, Cu, Ni, Pb, Zn each < 0.05 mg/L, collectively

Controlled Document

Laboratory Name and contact

information

Title: Internal Audit Standard Operating Procedure and Simplified

Quality System Checklist

Doc. No. 2

Rev. No. 2

Date: 01/24/13

Page: 29 of 29

< 0.1 mg/L.

f_ Records maintained for the past five years?

Controlled Document

You might also like

- 3.9 SOP Internal Audit v1Document11 pages3.9 SOP Internal Audit v1Pramod AthiyarathuNo ratings yet

- Monastery of The Seven Rays - Year 1Document193 pagesMonastery of The Seven Rays - Year 1Lykathea Harmony Pax100% (5)

- Internal Audit SOPDocument4 pagesInternal Audit SOPIftikhar Khan100% (1)

- 'Account StatementDocument11 pages'Account StatementSikander Qazi100% (2)

- All About AvanadeDocument16 pagesAll About AvanadeSunil PatidarNo ratings yet

- Internal Quality Audit ProcedureDocument3 pagesInternal Quality Audit ProcedureAcholonu Emeka Jp100% (2)

- Sample Management Review ChecklistDocument4 pagesSample Management Review Checklistpoetoet100% (1)

- QMS 010 Classification Definition and Approval Matrix of GMP Documents SampleDocument5 pagesQMS 010 Classification Definition and Approval Matrix of GMP Documents SampleRosella Planta100% (1)

- Internal Audit SOPDocument2 pagesInternal Audit SOPNazmun100% (3)

- Q2-760-01-Control of Monitoring and Measuring DevicesDocument5 pagesQ2-760-01-Control of Monitoring and Measuring DevicesAlineNo ratings yet

- Stock VerificationDocument11 pagesStock Verificationrockyrr100% (1)

- QMS 065 SampleDocument6 pagesQMS 065 SamplebaluchakpNo ratings yet

- Internal Audit ISO 9001-2008 Checklist 1-20-12Document43 pagesInternal Audit ISO 9001-2008 Checklist 1-20-12TravisNo ratings yet

- VMware vSAN Network Design PDFDocument169 pagesVMware vSAN Network Design PDFFederico MiliaccaNo ratings yet

- Star Magazine - 18 November 2013Document74 pagesStar Magazine - 18 November 2013LouieLongNeckNo ratings yet

- AM-QMS-05-Internal Quality Audit Procedure - Ver 1Document6 pagesAM-QMS-05-Internal Quality Audit Procedure - Ver 1Deepan TravellerNo ratings yet

- InternalAuditSOP 012413Document8 pagesInternalAuditSOP 012413zubair90No ratings yet

- QSP 02 - Record Control ProcedureDocument5 pagesQSP 02 - Record Control ProcedureVivek V100% (1)

- ESCL-SOP-018, Inspection and Test Procedure For Egba Split-ClampsDocument6 pagesESCL-SOP-018, Inspection and Test Procedure For Egba Split-ClampsadiqualityconsultNo ratings yet

- Competency SOPDocument10 pagesCompetency SOPD Tech Dental Technologies100% (1)

- QP-004 Management Review ProcessDocument3 pagesQP-004 Management Review Processesraa asemNo ratings yet

- ISO 13485 PurchasingDocument5 pagesISO 13485 PurchasingSubhashNo ratings yet

- Example of An Internal Audit SOPDocument3 pagesExample of An Internal Audit SOPVeronica Sebald100% (1)

- Quality Assurance (QA) Management Procedures: By: Pharma Tips - Views: 14415 - Date: 06-May-2012Document6 pagesQuality Assurance (QA) Management Procedures: By: Pharma Tips - Views: 14415 - Date: 06-May-2012SrinivasNo ratings yet

- Sop (Internal Audit)Document6 pagesSop (Internal Audit)Arijit Pattanayak100% (2)

- Minutes of Management Review Meeting OkDocument3 pagesMinutes of Management Review Meeting Okdidar100% (4)

- Internal Audit ProcedureDocument1 pageInternal Audit ProcedureXi MoNo ratings yet

- Form IA-002A (Audit Plan) (07-13-2012)Document2 pagesForm IA-002A (Audit Plan) (07-13-2012)granburyjohnstevens100% (1)

- Procedure For Preventive ActionDocument6 pagesProcedure For Preventive ActionHamzah Abbass Sibai100% (1)

- Sample SOP of Internal Audit of A ProcessDocument10 pagesSample SOP of Internal Audit of A Processsarvjeet_kaushalNo ratings yet

- Document Control Effectiveness in ISO 15189 Accredited LaboratoriesDocument12 pagesDocument Control Effectiveness in ISO 15189 Accredited LaboratoriesinventionjournalsNo ratings yet

- Internal Audit Planning and Scheduling Sample FormatDocument3 pagesInternal Audit Planning and Scheduling Sample Formatsameh100% (2)

- Sop PurchasingDocument5 pagesSop PurchasingSteven TanNo ratings yet

- Internal Audit ProceduresDocument15 pagesInternal Audit ProceduresTait G MafuraNo ratings yet

- Iso22000 - Internal Audit ChecklistDocument2 pagesIso22000 - Internal Audit ChecklistGidion Jeffri PoerbaNo ratings yet

- Auditee Feedback Form: Internal Audit DepartmentDocument2 pagesAuditee Feedback Form: Internal Audit DepartmentNiomi GolraiNo ratings yet

- SOP-03 (Employee Performance Monitoring)Document6 pagesSOP-03 (Employee Performance Monitoring)FarhanNo ratings yet

- QSP 8.3.1 Nonconforming Product - SampleDocument3 pagesQSP 8.3.1 Nonconforming Product - SampleGladys Calvo100% (2)

- Objectives and Goals of Auditing Vendors and Production DepartmentDocument15 pagesObjectives and Goals of Auditing Vendors and Production DepartmentFfwms SpainNo ratings yet

- QP-72-03 Customer CommunicationDocument3 pagesQP-72-03 Customer CommunicationSamsudin AhmadNo ratings yet

- G Corrective Action Section 7Document3 pagesG Corrective Action Section 7Ngonidzashe Zvarevashe100% (1)

- ISODocument11 pagesISOaiswaryacdas9853No ratings yet

- How Can ISO 13485 Clause 7.4, Purchasing, Enhance ProcurementDocument3 pagesHow Can ISO 13485 Clause 7.4, Purchasing, Enhance ProcurementPavan MujawdiyaNo ratings yet

- SOPSP05 VendorSelection BSDocument3 pagesSOPSP05 VendorSelection BStroubledsoul100% (1)

- Quality Management System Master18 February 2014Document27 pagesQuality Management System Master18 February 2014shani5573No ratings yet

- QSP-001633 - Rev 04 - Luminus Testing Laboratory Quality Manual207Document34 pagesQSP-001633 - Rev 04 - Luminus Testing Laboratory Quality Manual207SureshNo ratings yet

- New Supplier Survey FormDocument14 pagesNew Supplier Survey Formsutharitessh100% (1)

- Internal Audit NC ReportDocument1 pageInternal Audit NC Reportmorshed_mahamud7055No ratings yet

- Internal Audit Flow ChartDocument1 pageInternal Audit Flow ChartstevierayoNo ratings yet

- Evaluation Reporting of ResultsDocument16 pagesEvaluation Reporting of ResultspurnachandrashekarNo ratings yet

- Procedure On Document ManagementDocument13 pagesProcedure On Document Managementndayiragije JMVNo ratings yet

- Internal Quality Audit Plan Dilg Region 10Document8 pagesInternal Quality Audit Plan Dilg Region 10Cess AyomaNo ratings yet

- Process Audit ChecklistDocument15 pagesProcess Audit ChecklistAbi ParillaNo ratings yet

- Control of Monitoring and Measuring EquipmentDocument3 pagesControl of Monitoring and Measuring EquipmentLinda Setya WatiNo ratings yet

- FDA Volume II - Audits Ora-Lab.4.14Document7 pagesFDA Volume II - Audits Ora-Lab.4.14nilayNo ratings yet

- SOP-4.3-2-0 Creation, Revision and Approval of DocumentsDocument4 pagesSOP-4.3-2-0 Creation, Revision and Approval of DocumentsclairealbertiniNo ratings yet

- QMS Internal External AuditDocument5 pagesQMS Internal External AuditNesanNo ratings yet

- Quality AuditsDocument15 pagesQuality AuditsPrachi PandeyNo ratings yet

- SOP-03 Management Review MeetingsDocument3 pagesSOP-03 Management Review Meetingstrivesh100% (1)

- Purchasing PolicyDocument9 pagesPurchasing PolicyAyman AliNo ratings yet

- E 178 Iso17025 ChecklistDocument19 pagesE 178 Iso17025 ChecklistShweta Rawal VijNo ratings yet

- Auditing Gas Analysis LaboratoriesDocument14 pagesAuditing Gas Analysis LaboratorieshentadwyNo ratings yet

- NQA Aerospace Workshop Webinar 02.10.2020Document53 pagesNQA Aerospace Workshop Webinar 02.10.2020Rony LesbtNo ratings yet

- Form JO Foundation ChecklistDocument1 pageForm JO Foundation ChecklistRony LesbtNo ratings yet

- NQA Webinar - Cyber Security Risk and Assurance in The Supply Chain (WMCRC & Tuned To RISK) 21.04.21Document36 pagesNQA Webinar - Cyber Security Risk and Assurance in The Supply Chain (WMCRC & Tuned To RISK) 21.04.21Rony LesbtNo ratings yet

- NQA Webinar PAS 2060 Carbon Neutrality 30-04-2021Document38 pagesNQA Webinar PAS 2060 Carbon Neutrality 30-04-2021Rony LesbtNo ratings yet

- TBM FormDocument1 pageTBM FormRony LesbtNo ratings yet

- Hand Out Shop Inspection - ISBL - OSBL 210527Document3 pagesHand Out Shop Inspection - ISBL - OSBL 210527Rony LesbtNo ratings yet

- Summary RFI of FDT UG PipeDocument2 pagesSummary RFI of FDT UG PipeRony LesbtNo ratings yet

- Cause Analysis For Spun Pile Crack and BrokenDocument11 pagesCause Analysis For Spun Pile Crack and BrokenRony LesbtNo ratings yet

- 35 - HS-78005 - Isolation ProcedureDocument3 pages35 - HS-78005 - Isolation ProcedureRony LesbtNo ratings yet

- DCC-F9 - Format Job DescriptionDocument1 pageDCC-F9 - Format Job DescriptionRony LesbtNo ratings yet

- TgBin TTB B0 HS 78045 Handling SRCC Documentation and DistributionDocument15 pagesTgBin TTB B0 HS 78045 Handling SRCC Documentation and DistributionRony LesbtNo ratings yet

- Course Assessment Form Date .. . Course Title: . Facilitator: Location: .. 1Document1 pageCourse Assessment Form Date .. . Course Title: . Facilitator: Location: .. 1Rony LesbtNo ratings yet

- Name Target # of Abnormality Finding (# of Mudawalk/month) Week 1 Week 2 Week 3Document3 pagesName Target # of Abnormality Finding (# of Mudawalk/month) Week 1 Week 2 Week 3Rony LesbtNo ratings yet

- Register of Operation On ProcessDocument18 pagesRegister of Operation On ProcessRony LesbtNo ratings yet

- Sop Billing ProcessDocument9 pagesSop Billing ProcessRony Lesbt0% (1)

- P-OkiPL1-100-15-PRO-0002 HSE Induction ProcedureDocument14 pagesP-OkiPL1-100-15-PRO-0002 HSE Induction ProcedureRony Lesbt100% (2)

- P OkiPL1 100 15 PRO 0003 Emergency Preparedness and Emergency ResponseDocument13 pagesP OkiPL1 100 15 PRO 0003 Emergency Preparedness and Emergency ResponseRony LesbtNo ratings yet

- Inter Job Handed OverDocument1 pageInter Job Handed OverRony LesbtNo ratings yet

- WI - Interdiscipline Handed OverDocument5 pagesWI - Interdiscipline Handed OverRony LesbtNo ratings yet

- P-OkiPL1-100-15-PRO-0001 Legal and Other Requirements ProcedureDocument11 pagesP-OkiPL1-100-15-PRO-0001 Legal and Other Requirements ProcedureRony LesbtNo ratings yet

- UT Training Schedule Angkatan Ke-11Document1 pageUT Training Schedule Angkatan Ke-11Rony LesbtNo ratings yet

- Jobmigas 19 August 2013Document2 pagesJobmigas 19 August 2013Rony LesbtNo ratings yet

- Training Traveling Targeting: Welding Inspector - BNSP (Saturday and Sunday, 19.00Document2 pagesTraining Traveling Targeting: Welding Inspector - BNSP (Saturday and Sunday, 19.00Rony LesbtNo ratings yet

- IEE STD C37.104-2002 IEEE Guide For Automatic Reclosing PDFDocument55 pagesIEE STD C37.104-2002 IEEE Guide For Automatic Reclosing PDFJohnatan HernándezNo ratings yet

- Ackermannand Chen 2013 Developing Academic Collocation List AuthorsmanuscriptDocument31 pagesAckermannand Chen 2013 Developing Academic Collocation List AuthorsmanuscriptaridNo ratings yet

- DPP 05Document4 pagesDPP 05urmomNo ratings yet

- End of Term 2 Test A: Grammar VocabularyDocument3 pagesEnd of Term 2 Test A: Grammar VocabularyAngela Lobato MañanesNo ratings yet

- Chemical and Mechanical DesignDocument460 pagesChemical and Mechanical DesignNuriman K-monNo ratings yet

- Effects of Operating Parameters On Nitrogen Oxides Emissions For A Natural GasDocument9 pagesEffects of Operating Parameters On Nitrogen Oxides Emissions For A Natural GasMudhafar MudhafarNo ratings yet

- Introduction To PEG (Parsing Expression Grammar) in PythonDocument71 pagesIntroduction To PEG (Parsing Expression Grammar) in Pythonrwanda0% (1)

- Applied Mechanics I - Fall 2013 PDFDocument4 pagesApplied Mechanics I - Fall 2013 PDFRajeshGupta100% (1)

- Question BankDocument13 pagesQuestion BankFirozNo ratings yet

- Kuji in KanjiDocument25 pagesKuji in Kanjidcamu37100% (3)

- Request For TransferDocument3 pagesRequest For TransferDiomedes ColarNo ratings yet

- 20120229000242SMA3013 - Chapter 1Document105 pages20120229000242SMA3013 - Chapter 1Nurul Hana BalqisNo ratings yet

- Textbook PMDocument46 pagesTextbook PMLai QuocNo ratings yet

- Quays: Healy Power Quarries LTDDocument48 pagesQuays: Healy Power Quarries LTDmwmccarthyNo ratings yet

- Analisis Sootblower Terhadap Head TransferDocument5 pagesAnalisis Sootblower Terhadap Head TransferRDSetyawanNo ratings yet

- Product Info WISI-GT-31-W V3.0 enDocument2 pagesProduct Info WISI-GT-31-W V3.0 enDiego MattaNo ratings yet

- Agency Enrollment FormDocument1 pageAgency Enrollment FormRaymond TenchavezNo ratings yet

- Weld Overlay Cladding1Document3 pagesWeld Overlay Cladding1Yetkin ErdoğanNo ratings yet

- Indian Contract ActDocument18 pagesIndian Contract ActShubhi MittalNo ratings yet

- Kissing FishDocument11 pagesKissing FishkohlerfernandaNo ratings yet

- Razr Iron Scorpions MC Series Book 1 Motorcycle Club Mafia Romance Crossover Universe Book 3 Harley Diamond All ChapterDocument66 pagesRazr Iron Scorpions MC Series Book 1 Motorcycle Club Mafia Romance Crossover Universe Book 3 Harley Diamond All Chapterphillip.mesias887100% (5)

- Study Guide Unit 2.2 - Dna Replication & Protein SynthesisDocument35 pagesStudy Guide Unit 2.2 - Dna Replication & Protein SynthesisGraceNo ratings yet

- GRP WRKDocument5 pagesGRP WRKrheaNo ratings yet

- Uploading 8 23Document12 pagesUploading 8 23Shannara21No ratings yet

- WeldingDocument23 pagesWeldingSuneel Kumar MeenaNo ratings yet