Professional Documents

Culture Documents

Volvo I Shift

Volvo I Shift

Uploaded by

estherpgvOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Volvo I Shift

Volvo I Shift

Uploaded by

estherpgvCopyright:

Available Formats

VOLVO

I-SHIFT

Transmission

I-Shift, AT2412C, is a 12-speed manual gearbox with an automatic gearchanging system. IShift is designed for tourist, intercity, regional and route operations, where it provides high driving and ride comfort and excellent fuel economy.

I-Shift is a fast-responding gearchanging system with mini-

and a performance mode with a kickdown function that utilises

mum interruption in torque delivery during changes and a wide

the engines capacity to the maximum.

ratio span, a combination that offers impressive resources for

The transmission is a compact, lightweight unit. It is divided

high average speeds. The system consists of a non-synchro-

into a base unit and a range-change unit. The base unit, range

mesh manual gearbox with an electronically regulated pneu-

section and clutch housing are made of aluminium, which con-

matic gearchanging system and an automatic clutch.

tributes to the low weight. The transmission is factory-prepared

The gear selector is integrated with the drivers seat and

for installation with or without a compact retarder (VR3250).

gearchanges are fully automated. Starting ratio is selected

Long oil-change intervals mean low operating costs and less

automatically in response to road gradient and gross vehicle

environmental effect. When special oils are used, oil and filter

weight. I-Shift is available with a choice of program packages

changes take place after a maximum of 400,000 km or every

and various functions. Among them is a facility for choosing

third year.

between fully automatic gearchanges and manual selection,

The gear lever can be folded forward when the vehicle is at a

standstill, placed alongside the seat cushion so it is not in the

way when the driver wants to move around.

All the shafts, bearings and gears are sturdily dimensioned for high operating

reliability and long service life.

Product benefits

Fully automated gearchanging system that selects the appropriate gear in response to current operating conditions.

Different program packages that optimise the bus for its application area.

Performance program and kickdown exploit the engines resources.

The option of selecting gears manually and locking a gear makes for added flexibility.

Low weight and low frictional losses make for a compact installation and good fuel economy.

BED 00345 2007-09-27 EN

volvo buses. when productivity counts

Electronic control for high operating reliability

The gear selector and lever are conveniently integrated with the

drivers seat. There are two variants, with or without the option of manual changes. The gear lever has no mechanical contact with the gearbox; instead, the levers movements act on a number of sensors in

the gear selector.

The gear control system is integrated into the base unit and contains an electronic control unit, solenoid valves, gearchanging cylinders, shift forks and sensors.

Flexible gearchanging system gives good

driveability

I-Shift is a flexible gearchanging system supported by extremely powerful software. Since the clutch function is regulated by the gearchanging system, there is no clutch pedal. The graphic display shows

the driving program selected, the available ratios up and down, the

levers position and the selected gear.

In the A setting, gearchanges take place entirely automatically, even

when the cruise control is activated. The M setting locks the current

gear or permits manual changes.

In Automatic mode, the driver can choose between the Economy

and Performance programmes. The Limp-Home function makes it

possible to continue driving the vehicle even if there is a fault with the

transmissions or the clutchs position sensor.

The various program packages have different functions that optimise the bus for its particular application area. EcoRoll with Smart Cruise

Control for tourist coaches, for instance, is a function that gives additional fuel savings, while Launch Control helps the driver both when

starting on an uphill gradient and when manoeuvring at low speeds.

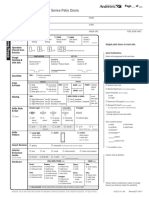

Specifications

Type designation

Max incoming torque

Weight without oil

Weight without oil incl. retarder

Type

Number of forward gears

Number of reverse gears

Gear selector positions:

R

N

A

M

Driving programs:

E

P

L

Oil-change volume

Sturdily dimensioned components

The base unit contains three base ratios, an integrated splitter gear

and reverse gears. The range-change section contains a range gear

of planetary type. The splitter and range gears are synchronised, while the base unit has no mechanical synchromesh. Revs are instead

synchronised with the help of the engines and the transmissions control units before the next gear is engaged.

All the shafts, bearings and gears are sturdily dimensioned for high

operating reliability and long service life. All the gears are made of

special steel that has been case-hardened to provide considerable

strength. The gears in the base unit are helical, so more teeth are in

mesh with each other at any one time. This results in quiet operation

and high operating reliability.

Integrated splitter gear and range-change gear of

planetary type

The splitter gear, which is a compact and sturdily journalled unit, is

fitted on the input shaft in the base units forward section. The splitter

gear halves the ratio between two base gears. The range-change gear

consists of a sturdily dimensioned planetary unit with helical gears and

a new synchromesh system, fitted after the base unit.

Factory-prepared for retarder

The transmission is factory-prepared for installation of hydraulic retarder VR3250, which offers high braking power of 400 to 600 kW.

Certain program packages have a function called Enhanced Shift

Strategy. It momentarily applies the wheel brakes as the transmission

changes down during engine braking. This function is combined with

the Electronic Brake System (EBS) to provide powerful and gentle

engine braking.

AT2412C

2400 Nm

269 kg

369 kg

Automatic splitter/

range-change transmission

12

4

Reverse

Neutral

Automatic

Manual/Hold

Economy program

Performance program

Limp Home function

approx. 13 l

A flange-mounted clutch valve unit and integrated

clutch cylinder including a position sensor replace

the system with the externally fitted clutch cylinder.

Equipment that is shown or mentioned in this factsheet may be available as options or accessories and may vary from one country to another. We retain the right to alter product specifications without prior notification.

You might also like

- VOLVO I-Shift AT2612DDocument2 pagesVOLVO I-Shift AT2612Dfdpc198790% (10)

- Pre-Driving Orientation For Motorcycles: (DL Code A)Document51 pagesPre-Driving Orientation For Motorcycles: (DL Code A)Jerry Cane80% (5)

- Camshaft, ServiceDocument31 pagesCamshaft, ServiceIzz Bahar100% (7)

- Air in The Fuel System, CheckDocument16 pagesAir in The Fuel System, CheckIzz Bahar100% (3)

- Cat Forklift Gp30 Schematic Service Operation Maintenance ManualDocument27 pagesCat Forklift Gp30 Schematic Service Operation Maintenance Manualfrankstewart270488qny99% (83)

- PV776-20175621 (Cylinder Head Replacement) D12 VOLVODocument29 pagesPV776-20175621 (Cylinder Head Replacement) D12 VOLVOCEVegaO100% (2)

- Ishift and Powertronioc Training PDFDocument265 pagesIshift and Powertronioc Training PDFsengottaiyan100% (4)

- Perodua Kancil Repair ManualDocument3 pagesPerodua Kancil Repair ManualSyed Hakimie Al-Yahya18% (17)

- FH FM GearboxesDocument16 pagesFH FM GearboxesKoper94% (31)

- Injection Pump, Setting On EngineDocument2 pagesInjection Pump, Setting On EngineSherzad Chem86% (7)

- Volvo Engine BrakeDocument7 pagesVolvo Engine BrakeIzz Bahar100% (2)

- Volvo Engine Brake PDFDocument7 pagesVolvo Engine Brake PDFIzz Bahar100% (2)

- I-Shift, Design and FunctionDocument59 pagesI-Shift, Design and FunctionSherzad Chem94% (17)

- Fuel D13Document12 pagesFuel D13Eduardo Pai Tocarlo90% (42)

- Technical Journal: Rough Shifts, 5-4 Downshift, Neutral Control, N-D And/or DTC P089500, TF80SCDocument3 pagesTechnical Journal: Rough Shifts, 5-4 Downshift, Neutral Control, N-D And/or DTC P089500, TF80SCMohamed amashaNo ratings yet

- Volvo Truck Service Schedule Maintenace 1Document95 pagesVolvo Truck Service Schedule Maintenace 1sengottaiyan100% (2)

- Ishift and Powertronioc TrainingDocument265 pagesIshift and Powertronioc TrainingSherzad Chem100% (26)

- Engine Brake, Fault TracingDocument21 pagesEngine Brake, Fault TracingWilson Bueno97% (36)

- Ecu Info Land RoverDocument54 pagesEcu Info Land Rovertzskojevac100% (3)

- ATO2612F Eng 01 306008981Document4 pagesATO2612F Eng 01 306008981husan shahNo ratings yet

- VOLVO AT2412D IshiftDocument16 pagesVOLVO AT2412D IshiftSaray Aljure Ospino100% (2)

- Service Manual Trucks: Volvo 5.7, 6.7 Ton Front Axle VTDocument56 pagesService Manual Trucks: Volvo 5.7, 6.7 Ton Front Axle VTErnesto Turpo50% (2)

- Engine Idle Shutdown FH4 FM4Document1 pageEngine Idle Shutdown FH4 FM4jose breno vieira silvaNo ratings yet

- VCADS User Manual VolvoDocument64 pagesVCADS User Manual VolvoHenry Huayhua77% (22)

- Electronically Controlled Brake System (EBS)Document18 pagesElectronically Controlled Brake System (EBS)Sherzad Chem100% (4)

- 431-228 I-Shift Generation C Design and Function PDFDocument31 pages431-228 I-Shift Generation C Design and Function PDFJosiney Hungaro CardosoNo ratings yet

- SPO2812 Eng 03 306420309Document3 pagesSPO2812 Eng 03 306420309Shane LinNo ratings yet

- UFO Section 7 Allison TransmissionDocument569 pagesUFO Section 7 Allison TransmissionAram MorenoNo ratings yet

- Suzuki Shogun R 125 Service ManualDocument2 pagesSuzuki Shogun R 125 Service ManualChristinaMalahayatiLaksamana50% (10)

- AT2612E Eng 02 1685346Document2 pagesAT2612E Eng 02 1685346frank mutaleNo ratings yet

- Volvos I - ShiftDocument60 pagesVolvos I - ShiftStephenson100% (8)

- Presentation 1Document48 pagesPresentation 1mohammadNo ratings yet

- Valves and JAK, AdjustDocument6 pagesValves and JAK, AdjustSherzad ChemNo ratings yet

- Volvo D13A Engine SensorsDocument1 pageVolvo D13A Engine Sensorsram_thriveni100% (1)

- 431-168 Input Shaft, Overhaul FM9, FM12, FH12, FH16, FH, FM PDFDocument7 pages431-168 Input Shaft, Overhaul FM9, FM12, FH12, FH16, FH, FM PDFautoeletricamalaquiaNo ratings yet

- Volvo D16 Engine Family: Volvo Trucks. Driving ProgressDocument6 pagesVolvo D16 Engine Family: Volvo Trucks. Driving ProgressinduramNo ratings yet

- Cajas en InglesDocument25 pagesCajas en InglesJose sQ100% (1)

- Bleeding Fuel SystemDocument2 pagesBleeding Fuel SystemSherzad Chem100% (1)

- Cylinder Balancing, Fault TracingDocument8 pagesCylinder Balancing, Fault TracingIzz BaharNo ratings yet

- Valves & Unit Injectors AdjustingDocument14 pagesValves & Unit Injectors AdjustingZibao JumaNo ratings yet

- Retarder - Oil Change - pdf2Document3 pagesRetarder - Oil Change - pdf2Hariyanto oknesNo ratings yet

- Service Manual Trucks: MID 249, Bodybuilder Module Fault Codes VHD Version2 From Build Date 11.2002Document28 pagesService Manual Trucks: MID 249, Bodybuilder Module Fault Codes VHD Version2 From Build Date 11.2002Abdelhak EzzahriouiNo ratings yet

- AC System ComponentsDocument19 pagesAC System ComponentsSherzad ChemNo ratings yet

- Service Manual Trucks: Fault Codes Vehicle Control Unit (VECU) MID 144Document176 pagesService Manual Trucks: Fault Codes Vehicle Control Unit (VECU) MID 144naftaliNo ratings yet

- VOLVO Oil Pump Replacement D13Document13 pagesVOLVO Oil Pump Replacement D13Miguel Angel Sancho100% (1)

- Engine BrakeDocument8 pagesEngine BrakeIzz Bahar100% (1)

- 450 Dxi Rocker Arms Adjustment PDFDocument12 pages450 Dxi Rocker Arms Adjustment PDFvaleriy89% (9)

- I-Shift - Optidrive Dual-Clutch Transmission Volvo - Renault - Rema - GermanyDocument5 pagesI-Shift - Optidrive Dual-Clutch Transmission Volvo - Renault - Rema - Germanylibertyplus100% (1)

- 21414-3 Valves and Unit Injectors, AdjustDocument11 pages21414-3 Valves and Unit Injectors, AdjustTeguh Imam Adri100% (1)

- Veb PDFDocument11 pagesVeb PDFIzz Bahar100% (1)

- Cruise Control, Fault TracingDocument12 pagesCruise Control, Fault TracingIzz BaharNo ratings yet

- 221-42 Oil Pressure Fault-TracingDocument8 pages221-42 Oil Pressure Fault-TracingElio Custodio HuachacaNo ratings yet

- Mid 185 - Ppid 294 - Fmi 8Document4 pagesMid 185 - Ppid 294 - Fmi 8AkbarNo ratings yet

- Lubrication and Oil SystemDocument6 pagesLubrication and Oil SystemIzz BaharNo ratings yet

- 431-305 Main Shaft, OverhaulDocument18 pages431-305 Main Shaft, Overhauljmbad2100% (3)

- 8090 I 04 - 12 en - Servocom - Servotest 100 - China - 8095 - 8097 - 8098Document42 pages8090 I 04 - 12 en - Servocom - Servotest 100 - China - 8095 - 8097 - 8098joe blow100% (2)

- Air Supply Description and FunctionDocument12 pagesAir Supply Description and Functionirfan100% (1)

- SPO2812 Eng 04 331467037Document3 pagesSPO2812 Eng 04 331467037محمد رضاییNo ratings yet

- Report DSGDocument37 pagesReport DSGashu04771% (7)

- Automatic GearboxDocument38 pagesAutomatic GearboxCristian IfrimNo ratings yet

- Manual Transmissions: Transmission Motor Vehicle Clutch Torque Engine Gear SelectorDocument10 pagesManual Transmissions: Transmission Motor Vehicle Clutch Torque Engine Gear SelectorJayvee PoliranNo ratings yet

- Multitronic 01JDocument100 pagesMultitronic 01JAlex Dosoftei100% (1)

- 36 Ranbir SinghDocument5 pages36 Ranbir SinghBbaPbaNo ratings yet

- enDocument84 pagesenRegistr Registr100% (11)

- Automatic Gear BoxDocument19 pagesAutomatic Gear BoxInquiry XEEPLNo ratings yet

- AT2412 Eng 02 324355777Document3 pagesAT2412 Eng 02 324355777bandanyimba738No ratings yet

- Eletromagnet Gear ShiftingDocument35 pagesEletromagnet Gear ShiftingPraveen Mathias0% (1)

- Kalmar Genuine Parts.: When The Right Part MattersDocument3 pagesKalmar Genuine Parts.: When The Right Part MattersEjaz EjazNo ratings yet

- Components: 1. Front BumperDocument12 pagesComponents: 1. Front BumperdiemnganNo ratings yet

- D 65e-8 Acak DemoDocument11 pagesD 65e-8 Acak Demosonjisahuri33% (3)

- Transmission Servicing atDocument15 pagesTransmission Servicing athectorie100% (2)

- Herramientas ToyotaDocument24 pagesHerramientas ToyotaMaynor LópezNo ratings yet

- Data ScriptDocument5 pagesData ScriptNydia Evelina HermawanNo ratings yet

- ck100 Auto Key Programmer Car List PDFDocument28 pagesck100 Auto Key Programmer Car List PDFjose luis choque pichaNo ratings yet

- D20 25 30 33 35NXP Stage-V (Sb1800e)Document768 pagesD20 25 30 33 35NXP Stage-V (Sb1800e)Yuda PratamaNo ratings yet

- Power Supply, Ground & Circuit Elements: SectionDocument50 pagesPower Supply, Ground & Circuit Elements: SectionEduardo Colin100% (1)

- CX 8Document4 pagesCX 8Bintang BinNo ratings yet

- Diagnosis and TestingDocument12 pagesDiagnosis and TestingRepuesto GeneralNo ratings yet

- Andersen Measurement-Guide-Tear-Pad-400-200-100-Series-Patio-Door-9052510Document3 pagesAndersen Measurement-Guide-Tear-Pad-400-200-100-Series-Patio-Door-9052510miculinicNo ratings yet

- PiecesGoaGlxNEF2 6TM4BDCONLINEDocument143 pagesPiecesGoaGlxNEF2 6TM4BDCONLINEEsteban González100% (1)

- Štatistika Registrácií 02.2011Document10 pagesŠtatistika Registrácií 02.2011Dennik SMENo ratings yet

- New Holland T4 LP I I I: T4.75 LP T4.85 LP T4.95 LP T4.105 LPDocument12 pagesNew Holland T4 LP I I I: T4.75 LP T4.85 LP T4.95 LP T4.105 LPGorazdNo ratings yet

- Update Stock Coil 4 Agustus 2023Document2 pagesUpdate Stock Coil 4 Agustus 2023Wulan Brigita JacobNo ratings yet

- Roadtrek Zion 2021Document6 pagesRoadtrek Zion 2021Kelsie JacksonNo ratings yet

- 308.8161.3.4-2 Agrotron X 720 ENDocument2 pages308.8161.3.4-2 Agrotron X 720 ENMarian TarasNo ratings yet

- ABB EVI PresentationDocument93 pagesABB EVI PresentationFernando SalvadorNo ratings yet

- YaRIS cLEAR DTC TIS - TOYOTA 2016-2019 Yaris Repair Manual (RM26M0U)Document5 pagesYaRIS cLEAR DTC TIS - TOYOTA 2016-2019 Yaris Repair Manual (RM26M0U)VishyNo ratings yet

- Da30 Da40 PDFDocument20 pagesDa30 Da40 PDFRiri MukhtarNo ratings yet

- Body Control System Xterra N50Document20 pagesBody Control System Xterra N50muki461100% (1)

- 7300 CXT SSDocument2 pages7300 CXT SSGus GarciaNo ratings yet