Professional Documents

Culture Documents

IADC Dull Bit Grading

IADC Dull Bit Grading

Uploaded by

abhijitrathiCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

IADC Dull Bit Grading

IADC Dull Bit Grading

Uploaded by

abhijitrathiCopyright:

Available Formats

TM

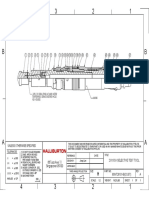

IADC Code Roller Cone Tooth Bit Comparison Chart

Features

Milled Tooth Bits

Soft formations

with low compression

strength and high

drillability

Y11 R1 DSJ XN1

Medium to medium-hard

formations with high

compressive strength

Hard semiabrasive or

abrasive formations

V2J

XN4

L4H

XN5

Security

Smith

Hughes

ReedHycalog

XLX-1, GT-G1H

GT-G1, STX-1

MX-1, STR-1

MFDSH, FDSH+, MFDSSH, FDS+2

FDSS+2, FGS+, FGS+2, FGSH+

FDSS+, FGSS+2, XR+, FGSSH+, FGXi

XS1, XL1

D13, HP13G

MX-3

FDGH, MFDGH

XS3, XL3

HP21G

ATJ-G4

FVH

XS4, XL4

T11

EMS11G

ETS11G

GTX-G1, MAX-GT1

MX-1

MSDSH, MSDSSH

GGSSH+, MGSH+

XT1 HP11

HP12

FDT

SL12, HP12

GTX-3 MCG+

T13

EMS13G

ETS136

GTX-G3, MAX-GT3

MX-3

SDGH, MSDGH

MGGH+

XT3 HP13

FDG

SVH, MSVH

XT4

FV

ATJ-4

FDS

FDSS+

Security

Smith

Hughes

GT-1

Sealed Friction Bearing and Gauge Protection

GTX-1 SDS

DTJ

Y13 R3 DGJ XN3

ReedHycalog

Security

Friction Bearing

Smith

Hughes

ReedHycalog

Sealed Roller Bearing and Gauge Protection

Security

Smith

Hughes

ReedHycalog

Sealed Bearing

Security

Smith

Hughes

Formations

ReedHycalog

Type

Series

Standard Roller

SL11, TC10

TC11, TD11

D11

DR5

R7

ATJ-G8

Cutting Structure

Inner

Outer

Dull Characteristics

Location

IADC Dull Bit Grading

1

2

Inner cutting structure

(all inner rows)

Outer cutting structure

(gauge row only)

In columns 1 and 2, a linear scale from 0 to 8 is

used to describe the condition of the cutting

structure according to the following:

Steel tooth bits

A measure of lost tool height resulting from

abrasion and/or damage.

0 No loss of tooth height.

8 Total loss of tooth height.

Insert bits

A measure of total cutting structure reduction

resulting from lost, worn and/or broken inserts.

0 No lost, worn and/or broken inserts.

8 All inserts lost, worn and/or broken.

Fixed cutter bits

A measure of lost, worn and/or broken cutting

structure.

0 No lost, worn and/or cutting structure.

8 All of cutting structure Lost, worn and/or

broken.

Bearings/Seals

Gauge

Other Dull Characteristics

Reason Pulled

Dull characteristics

(Use only cutting structure related codes.)

Roller cone

N nose row

M middle row

G gauge row

A all rows

BC

broken cone

BF bond failure

BT broken teeth/cutters

BU balled up bit

CC cracked cone

CD cone dragged

CI cone Interference

CR cored

CT chipped teeth/cutters

ER erosion

FC flat crested wear

HC heat checking

JD junk damage

LC lost cone

LN lost nozzle

LT lost teeth/cutters

OC off-center wear

PB pinched bit

PN plugged nozzle/flow passage

RG rounded gauge

RO ring out

SD shirttail damage

SS self-sharpening wear

TR tracking

WO washed out bit

WT worn teeth/cutters

NO no dull characteristic

Show Cone number or numbers under location

Location

Fixed rutter

C cone

N nose

T taper

7

Cone no.

1

2

3

S shoulder

G gauge

A all areas

Bearings/seals

Nonsealed bearings

A linear scale estimating bearing

life used. (0 No life used, 8 All

life used, i.e., no bearing life

remaining.)

Sealed bearings

E seals effective

F seals failed

N not able to grade

X fixed cutter bit (bearingless)

Gauge measure in 116 of an inch.

I In gauge

1 16 1 16 in. out of gauge

2 16 1 8 in. out of gauge

4 16 14 in. out of gauge

Other dull characteristic

Refer to column three codes.

Reason pulled or run terminated

BHA

DMF

DTF

DSF

DST

LOG

LIH

RIG

CM

CP

DP

FM

HP

HR

PP

PR

TD

TQ

TW

WC

change bottomhole assembly

downhole motor failure

downhole tool failure

downhole string failure

drill stem test

run logs

left in hole

rig repair

condition mud

core point

drill plug

formation change

hole problems

hours on bit

pump pressure

penetration rate

total depth/casing depth

torque

twist off

weather conditions

Jet Nozzle Flow Areas

Note: Bits shown are based on individual manufacturers published availabilty data. Comparisons may differ in particular drilling areas. Your ReedHycalog representative can provide specific data for your needs.

Nozzle

Size

(in. [mm])

Nozzle

Number

Flow Area

of One Nozzle

(in.2 [mm 2])

Flow Area

of Two Nozzles

(in.2 [mm 2])

Flow Area

of Three Nozzles

(in.2 [mm 2])

Flow Area

of Four Nozzles

(in.2 [mm 2])

7 32 [5.5]

0.0376 [24.3]

0.0752 [48.5]

0.1127 [72.9]

0.1503 [97.0]

14 [6.4]

0.0491 [31.7]

0.0982 [63.4]

0.1473 [95.0]

0.1963 [126.1]

9 32 [7.1]

0.0621 [40.1]

0.1242 [80.1]

0.1864 [120.2]

0.2485 [160.3]

5 16 [7.9]

10

0.0767 [49.5]

0.1534 [99.0]

0.2301 [148.4]

0.3068 [197.9]

11 32 [8.7]

11

0.0928 [59.5]

0.1856 [119.7]

0.2784 [179.6]

0.3712 [239.5]

3 8 [9.5]

12

0.1104 [71.2]

0.2209 [142.5]

0.3313 [213.7]

0.4418 [285.0]

13 32 [10.3]

13

0.1296 [83.6]

0.2592 [167.2]

0.3889 [250.9]

0.5185 [334.5]

7 16 [11.1]

14

0.1503 [97.0]

0.3007 [194.0]

0.4510 [291.0]

0.6013 [388.0]

15 32 [11.9]

15

0.1726 [111.4]

0.3451 [222.8]

0.5177 [334.2]

0.6903 [445.4]

1 2 [12.7]

16

0.1963 [126.6]

0.3927 [253.2]

0.5890 [379.8]

0.7854 [506.7]

9 16 [14.3]

18

0.2485 [160.3]

0.4970 [320.6]

0.7455 [481.0]

0.9940 [641.3]

5 8 [15.9]

20

0.3068 [197.9]

0.6136 [395.9]

0.9204 [593.8]

1.2272 [791.8]

11 16 [17.5]

22

0.3712 [239.5]

0.7424 [479.0]

1.1137 [718.5]

1.4849 [958.1]

3 4 [19.0]

24

0.4418 [285.0]

0.8836 [570.1]

1.3254 [855.0]

1.7672 [1140.2]

7 8 [22.2]

28

0.6013 [387.9]

1.2026 [775.9]

1.8040 [1163.7]

2.4053 [1551.9]

Bit Size

(in. [mm])

Recommended

Roller Cone

Makeup Torque

API Pin Size

(in. [mm])

Recommended Torque

(lbt-ft [Newton])

33 441 2 [95.2114.3]

23 8 [60.3]

3,0003,500 [4,0004,800]

45 85 [117.5127.0]

27 8 [73.0]

6,0007,000 [8,0009,500]

51 873 8 [136.5187.3]

31 2 [88.9

7,0009,000 [9,50012,000]

75 89 [193.7228.6]

41 2 [114.3]

12,00016,000 [16,00022,000]

91 226 [241.3660.4]

65 8 [168.3]

28,00032,000 [38,00043,000]

143 426 [374.6660.4]

75 8 [193.7]

34,00040,000 [46,00054,000]

Revision Date :5-19-04

You might also like

- Casing ScrapersDocument2 pagesCasing ScrapersthetrevanianNo ratings yet

- ObjectionDocument10 pagesObjectionMy-Acts Of-SeditionNo ratings yet

- Critical Care NursingDocument1 pageCritical Care NursingMelissa David0% (1)

- MLT Torque Ring Field Make-Up HandbookDocument44 pagesMLT Torque Ring Field Make-Up HandbookKolawole Adisa100% (2)

- H09095 - SuperFill Surge Reduction EquipDocument4 pagesH09095 - SuperFill Surge Reduction EquipAQUILES CARRERANo ratings yet

- Drilling Abbreviations For ReportingDocument10 pagesDrilling Abbreviations For ReportingLeon Monsalve100% (1)

- Catalogo Ramde ColombiaDocument16 pagesCatalogo Ramde ColombiaSharay Villanova100% (1)

- Drill Pipe Thread DataDocument4 pagesDrill Pipe Thread Datakahutzed666No ratings yet

- Parveen Well Head PDFDocument25 pagesParveen Well Head PDFRatnakar PatilNo ratings yet

- Floating EquipmentDocument9 pagesFloating Equipmentkaveh-bahiraeeNo ratings yet

- Rubicon D455 Safety JointsDocument12 pagesRubicon D455 Safety JointsEmad JamshidiNo ratings yet

- 3-1/16" 10K Gate Valve Type FC, Api-6a, Petrotrim ServicesDocument1 page3-1/16" 10K Gate Valve Type FC, Api-6a, Petrotrim ServicesPetrotrim ServicesNo ratings yet

- Trip Sheet For RigDocument1 pageTrip Sheet For Rigankurume1984100% (1)

- Type - DH Block: Dimensional ChartDocument1 pageType - DH Block: Dimensional ChartHarzanyi MaldonadoNo ratings yet

- Itco Releasing Spear PDFDocument20 pagesItco Releasing Spear PDFnasr yassinNo ratings yet

- Summary of SEJ Gold Mining ConcessionDocument26 pagesSummary of SEJ Gold Mining ConcessionAgni NovasandiNo ratings yet

- Ton MileDocument106 pagesTon MileAbdul Hameed OmarNo ratings yet

- Drilco Spiral Drill Collar PsDocument1 pageDrilco Spiral Drill Collar Psyojan35No ratings yet

- VAM Catalog 2011Document116 pagesVAM Catalog 2011Anoop SVNo ratings yet

- Ton Miles Calculation 1Document17 pagesTon Miles Calculation 1Alexander Armando Clemente Andrade100% (1)

- SB Drill CollarDocument51 pagesSB Drill CollarJeff ZhangNo ratings yet

- Failure Analysis of IEU Drill Pipe Wash OutDocument6 pagesFailure Analysis of IEU Drill Pipe Wash OutDerry RahmaNo ratings yet

- OpenText Extended ECM For SAP Solutions 16.2 - Installation and Upgrade Guide English (ERLK160200-00-IGD-En-01)Document184 pagesOpenText Extended ECM For SAP Solutions 16.2 - Installation and Upgrade Guide English (ERLK160200-00-IGD-En-01)Praveen RaoNo ratings yet

- SWACO 90-90-080 (Rev. A)Document125 pagesSWACO 90-90-080 (Rev. A)rlk2806No ratings yet

- Bit HydraulicsDocument11 pagesBit HydraulicstibismtxNo ratings yet

- Drill Pipe Usa - Drill Pipe Thread DataDocument5 pagesDrill Pipe Usa - Drill Pipe Thread DataBahman MatouriNo ratings yet

- Bit Weight ChartDocument1 pageBit Weight ChartY.EbadiNo ratings yet

- 20-1718 Rig Tongs AOTDocument10 pages20-1718 Rig Tongs AOTRahul M.R100% (1)

- Optimal Spacing For Casing Centralizer PDFDocument10 pagesOptimal Spacing For Casing Centralizer PDFimampranadipaNo ratings yet

- Tom Mile Calculation PDFDocument6 pagesTom Mile Calculation PDFBeni N SoloNo ratings yet

- Tuazon v. FuentesDocument2 pagesTuazon v. FuentesJay jogsNo ratings yet

- Mud PumpsDocument16 pagesMud PumpsNigin Parambath100% (1)

- 9 - What Is A Special Drift CasingDocument2 pages9 - What Is A Special Drift CasingLuis David Concha CastilloNo ratings yet

- Iadc Bit GradingDocument1 pageIadc Bit GradingBilly WilsonNo ratings yet

- RC Dull GradingDocument106 pagesRC Dull GradingAbdelkader FattoucheNo ratings yet

- 2-36, TMC Jar, OpDocument15 pages2-36, TMC Jar, OpAli HosseiniNo ratings yet

- VodafoneDocument12 pagesVodafonedipanparmarNo ratings yet

- Araña BJ 350 Ton 13 3-8Document60 pagesAraña BJ 350 Ton 13 3-8ceciliachableNo ratings yet

- Mdi 813Document1 pageMdi 813pendexxNo ratings yet

- Know The Maximum Ton Miles You Can Actually Run Drill Line Before A Slip/cut?Document16 pagesKnow The Maximum Ton Miles You Can Actually Run Drill Line Before A Slip/cut?ashadNo ratings yet

- Product Catalog - Digger Downhole ToolsDocument70 pagesProduct Catalog - Digger Downhole ToolsDigger Downhole ToolsNo ratings yet

- X-Selective Test ToolDocument3 pagesX-Selective Test Toolsong Li100% (3)

- Iadc Bit GradingDocument1 pageIadc Bit GradinganarkasisNo ratings yet

- IADC Dull Grading - Roller Cone BitsDocument2 pagesIADC Dull Grading - Roller Cone BitsYasir IrfanNo ratings yet

- Hydril GK Annular DataDocument2 pagesHydril GK Annular DataAndrés Ramírez100% (3)

- Tric Dull Grade SIIDocument57 pagesTric Dull Grade SIICamila Palacios100% (1)

- Prem ConnectionDocument2 pagesPrem ConnectionJan Arild SkappelNo ratings yet

- 10 BVDM Mediastandard Print 2016Document78 pages10 BVDM Mediastandard Print 2016Duy KhoaNo ratings yet

- Drill Collar According To DS1Document1 pageDrill Collar According To DS1Hayder Habib100% (1)

- 4-Way Valves in The Accumulator (KoomeyDocument5 pages4-Way Valves in The Accumulator (Koomeyfeka niniNo ratings yet

- DC Make-Up TorqueDocument5 pagesDC Make-Up TorquepatelsujanNo ratings yet

- Api Flange Bolt & Ring Chart: PO BOX 639 - Bakersfield, CA 93302Document1 pageApi Flange Bolt & Ring Chart: PO BOX 639 - Bakersfield, CA 93302Prasetiyo SholehNo ratings yet

- Mud Gas Separator InfoDocument2 pagesMud Gas Separator InfoHIPAPNo ratings yet

- KickOff Plug Job Procedure 1Document6 pagesKickOff Plug Job Procedure 1محمد سعيدNo ratings yet

- IRI-044 IRI Parts Manual Non-Controlled Rev - 2 - 0 10-09-2015 - 9901910937 - 01 - 6375912 - 01Document68 pagesIRI-044 IRI Parts Manual Non-Controlled Rev - 2 - 0 10-09-2015 - 9901910937 - 01 - 6375912 - 01Tanyawat Sahsakmontri100% (2)

- Circulating SwagesDocument1 pageCirculating Swageskaveh-bahiraee100% (1)

- Chap EDocument44 pagesChap ERANJITH K PNo ratings yet

- Casing Cup TesterDocument3 pagesCasing Cup TesterWei ShangNo ratings yet

- Halliburton: VR Safety JointDocument2 pagesHalliburton: VR Safety Jointsaeed65No ratings yet

- Oil Casing and Tubing Data TableDocument3 pagesOil Casing and Tubing Data TableAlexandru AndreiNo ratings yet

- Deadline Anchors BrochureDocument3 pagesDeadline Anchors Brochurejlmunozv100% (2)

- 4) Iwcf l3 & 4 Surface Kick Sheet 1Document3 pages4) Iwcf l3 & 4 Surface Kick Sheet 1shaNo ratings yet

- Super Seal II Floating Equipment: CementingDocument4 pagesSuper Seal II Floating Equipment: CementingJuan Miguel RobledoNo ratings yet

- 003 Casing & Tubing Hanger PDFDocument4 pages003 Casing & Tubing Hanger PDFalaliali88No ratings yet

- Calificacion de TrepanosDocument1 pageCalificacion de TrepanosFelix Julio Céspedes SotoNo ratings yet

- Introduction To Dull Bit Grading 1Document35 pagesIntroduction To Dull Bit Grading 1ToroboxNo ratings yet

- TACACS+ in Alteon 27.0.1Document42 pagesTACACS+ in Alteon 27.0.1Istaque Ahmed LaskarNo ratings yet

- Will Benjamin FranklinDocument9 pagesWill Benjamin FranklinMichael KovachNo ratings yet

- The Strenghts and Weaknesses of The Recording ProcessDocument2 pagesThe Strenghts and Weaknesses of The Recording ProcessSUSILAWATI ISMAILNo ratings yet

- Beyond Multitenancy Beyond Multitenancy Container-Based Application Factory Container-Based Application FactoryDocument94 pagesBeyond Multitenancy Beyond Multitenancy Container-Based Application Factory Container-Based Application FactoryafonsoNo ratings yet

- Fossil Fuels - BioNinjaDocument2 pagesFossil Fuels - BioNinjaDaniel WalshNo ratings yet

- Kyzer New New 201Document45 pagesKyzer New New 201Kyzer Clint BaqueroNo ratings yet

- Econ 90 - Chapter 9 ReportDocument11 pagesEcon 90 - Chapter 9 ReportAnn Marie Abadies PalahangNo ratings yet

- History of US Copyright Law1Document28 pagesHistory of US Copyright Law1Prajval RathodNo ratings yet

- Report For Missing Sealing PlateDocument9 pagesReport For Missing Sealing PlateFazalmin shahNo ratings yet

- API 5L X52 Pipe Specification (PSL1 & PSL2) - Octal SteelDocument11 pagesAPI 5L X52 Pipe Specification (PSL1 & PSL2) - Octal SteelMULAYAM SINGH YADAVNo ratings yet

- LAND BANK OF THE PHILIPPINES vs. SPOUSES PLACIDODocument18 pagesLAND BANK OF THE PHILIPPINES vs. SPOUSES PLACIDOAnne ObnamiaNo ratings yet

- DG Job AidDocument22 pagesDG Job AidSHERIEFNo ratings yet

- SBD-E-Commerce and Internet MarketingDocument12 pagesSBD-E-Commerce and Internet MarketingjacvillarbaNo ratings yet

- Material, Vincent M. (NCP in ICP)Document7 pagesMaterial, Vincent M. (NCP in ICP)vincent materialNo ratings yet

- The Effects of Organizational Size and Complexity On Managerial Role Structure: An Exploratory AnalysisDocument6 pagesThe Effects of Organizational Size and Complexity On Managerial Role Structure: An Exploratory AnalysisBrandi WilliamsNo ratings yet

- Liam Wildman: All Saints Catholic Centre For LearningDocument1 pageLiam Wildman: All Saints Catholic Centre For LearningLiamWildmanNo ratings yet

- MNPD ResponseDocument5 pagesMNPD ResponseAnonymous GF8PPILW5No ratings yet

- TutorialDocument478 pagesTutorialKelsyNo ratings yet

- The Hydration of and H Dicalcium SilDocument11 pagesThe Hydration of and H Dicalcium SilMILON KUMAR HORENo ratings yet

- Solution of The Elements of Statistical Learning Ch6Document3 pagesSolution of The Elements of Statistical Learning Ch6zhoujing37210% (1)

- Che1-L04C675B511 Software Upgrade GuidelineDocument6 pagesChe1-L04C675B511 Software Upgrade GuidelinePrem BoharaNo ratings yet

- Theres Some Flaws in This HouseDocument6 pagesTheres Some Flaws in This HouseClarence TongNo ratings yet

- Sales QuotasDocument9 pagesSales QuotasDr-Faheem SiddiquiNo ratings yet