Professional Documents

Culture Documents

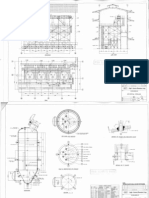

Refuse Dumping Gate (Mechanical Specification) .0007

Uploaded by

andryani octavia sari nasution0 ratings0% found this document useful (0 votes)

4 views1 pageA

Original Title

(2) Refuse Dumping Gate (Mechanical Specification).0007

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentA

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

4 views1 pageRefuse Dumping Gate (Mechanical Specification) .0007

Uploaded by

andryani octavia sari nasutionA

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

ii) Tolerance limit for welding defects

Non-conformity ‘Tolerance ‘Countermeasures

‘Throat thickness | Less than 1.3 timos of and move than | If too thiok, remove

specified thickness (throat thickness | the excess hy grinder,

Jess than specified not permissible) _| if too thin, re-weld

Inadequate Wold:swelling less than specified, | 1) Increase weld if not

weld-swelling

not permissible

Maximum-weld-ewelling

Board thickness of] Height of

parent metal | weld-swelling |

12mm or less 1.5mm

‘More than 12mm

To25mmoriess | _~>™™

More than 25mm. 3.5mm

‘To 50mm or less.

More than 50mm 4.0mm

enough

2) Remove the excess by

grinder

Leg length Minimum: 0.95 times of the specified | 1) Increase weld if not

leg length, enough

‘Maximum: 1.3 times of the specified |2) Remove the excess by

leg length, grinder

Under cut Depth: 0.3 times of the board ‘Draw bead on

thickness (max. 0.3mm) undercut

Overlap Depth = 1.5mm ‘Remove by grinder or

draw bead

‘Cmck in bead Should not exist ‘Remove crack(s)

cater or completely and apply

blowhole additional welding

(defect part only)

Slag inclusion Should not exist, Remove slag

completely, apply

additional welding

Spatter Should not exist Remove spatter

Weld-ond defects | Should be applied thoroughly Apply additional

welding and get end

connected to opposite

welding line smoothly

(continue boxing)

Intermittent Weld longth: “6 to+ 10mm Apply additional

fillet weld failure | Pitch: $10 to + 5mm welding

You might also like

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- WIKA Pressure Gauge Model 612.20.160 PDFDocument2 pagesWIKA Pressure Gauge Model 612.20.160 PDFandryani octavia sari nasutionNo ratings yet

- Basic Deaerator PDFDocument50 pagesBasic Deaerator PDFMan Fenix100% (1)

- Storage Tank Spesification: Operating/Design Data Nozzles/Connections MarkDocument4 pagesStorage Tank Spesification: Operating/Design Data Nozzles/Connections Markandryani octavia sari nasutionNo ratings yet

- ATM Tank Calc (Converted)Document7 pagesATM Tank Calc (Converted)andryani octavia sari nasutionNo ratings yet

- DS PM0212 en Co 3730 (Datasheet)Document3 pagesDS PM0212 en Co 3730 (Datasheet)Anonymous FZs3yBHh7No ratings yet

- Tube EN10216-2 P235GH TC1 For Water WallDocument1 pageTube EN10216-2 P235GH TC1 For Water Wallandryani octavia sari nasutionNo ratings yet

- Buka File Excel Yang Cellnya DiprotectDocument2 pagesBuka File Excel Yang Cellnya Diprotectandryani octavia sari nasutionNo ratings yet

- BOILERS Heat BalanceDocument71 pagesBOILERS Heat Balanceandryani octavia sari nasutionNo ratings yet

- Heat TransferDocument32 pagesHeat TransferFebrianti MawaddahNo ratings yet

- Refuse Dumping Gate (Mechanical Specification) .0009Document1 pageRefuse Dumping Gate (Mechanical Specification) .0009andryani octavia sari nasutionNo ratings yet

- Refuse Dumping Gate (Mechanical Specification) .0010Document1 pageRefuse Dumping Gate (Mechanical Specification) .0010andryani octavia sari nasutionNo ratings yet

- Sabtu Minggu: Month Agustus Month SeptemberDocument3 pagesSabtu Minggu: Month Agustus Month Septemberandryani octavia sari nasutionNo ratings yet

- Refuse Dumping Gate (Mechanical Specification) .0013Document1 pageRefuse Dumping Gate (Mechanical Specification) .0013andryani octavia sari nasutionNo ratings yet

- Refuse Dumping Gate (Mechanical Specification) .0008Document1 pageRefuse Dumping Gate (Mechanical Specification) .0008andryani octavia sari nasutionNo ratings yet

- Refuse Dumping Gate (Mechanical Specification) .0006Document1 pageRefuse Dumping Gate (Mechanical Specification) .0006andryani octavia sari nasutionNo ratings yet

- Refuse Dumping Gate (Mechanical Specification) .0001Document1 pageRefuse Dumping Gate (Mechanical Specification) .0001andryani octavia sari nasutionNo ratings yet

- Storage Tank Spesification: Operating/Design Data Nozzles/Connections MarkDocument4 pagesStorage Tank Spesification: Operating/Design Data Nozzles/Connections Markandryani octavia sari nasutionNo ratings yet

- Membran WallDocument2 pagesMembran Wallandryani octavia sari nasutionNo ratings yet

- Coal Char LuwukDocument2 pagesCoal Char Luwukandryani octavia sari nasutionNo ratings yet

- Perhitungan Asme Streight CalculationDocument22 pagesPerhitungan Asme Streight Calculationandryani octavia sari nasutionNo ratings yet

- Elevation Side View: FFB Conveyor NoDocument2 pagesElevation Side View: FFB Conveyor Noandryani octavia sari nasutionNo ratings yet

- Perhitungan Asme Streight CalculationDocument22 pagesPerhitungan Asme Streight Calculationandryani octavia sari nasutionNo ratings yet

- Stub ConnectionDocument1 pageStub Connectionandryani octavia sari nasutionNo ratings yet

- Super Simple LearningDocument7 pagesSuper Simple Learningandryani octavia sari nasutionNo ratings yet

- InterpretationsDocument705 pagesInterpretationsAxe ProneNo ratings yet

- Economizer DesignDocument2 pagesEconomizer Designandryani octavia sari nasutionNo ratings yet

- Super Simple LearningDocument7 pagesSuper Simple Learningandryani octavia sari nasutionNo ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (120)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)