Professional Documents

Culture Documents

Determination of Stress Intensity Factor For A Crack Emanating From A Hole In-Libre

Determination of Stress Intensity Factor For A Crack Emanating From A Hole In-Libre

Uploaded by

Ali AbbasovOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Determination of Stress Intensity Factor For A Crack Emanating From A Hole In-Libre

Determination of Stress Intensity Factor For A Crack Emanating From A Hole In-Libre

Uploaded by

Ali AbbasovCopyright:

Available Formats

International Journal of Mechanical

Engineering

and Technology (IJMET),

ISSN 0976

INTERNATIONAL

JOURNAL

OF MECHANICAL

ENGINEERING

6340(Print), ISSN 0976 6359(Online) Volume 4, Issue 2, March - April (2013) IAEME

AND TECHNOLOGY (IJMET)

ISSN 0976 6340 (Print)

ISSN 0976 6359 (Online)

Volume 4, Issue 2, March - April (2013), pp. 373-382

IAEME: www.iaeme.com/ijmet.asp

Journal Impact Factor (2013): 5.7731 (Calculated by GISI)

www.jifactor.com

IJMET

IAEME

DETERMINATION OF STRESS INTENSITY FACTOR FOR A CRACK

EMANATING FROM A HOLE IN A PRESSURIZED CYLINDER USING

DISPLACEMENT EXTRAPOLATION METHOD

AKASH.D.A (1), Anand.A (2), G.V.GNANENDRA REDDY(3), SUDEV.L.J(4)

(1)

Department of Mechanical Engineering, SJCIT Chickaballapur, 562101

Department of Mechanical Engineering, Vidyavardhaka College of engineering, Mysore, 570002

(3)

Department of Mechanical Engineering, SJCIT Chickaballapur, 562101

(4)

Department of Mechanical Engineering, Vidyavardhaka College of engineering, Mysore, 570002

(2)

ABSTRACT

The machine elements with cylindrical profile such as pressure vessel, cylindrical

shells, which have been used extensively as the structural configuration in aerospace and

shipping industries needs to be leak proof. But however its not possible to fabricate 100%

leak proof pressure vessel / cylindrical shell as the industrial materials do not have uniform

composition. Thus defects or cracks are inevitable in their substructure, also during their

service life a crack may initiate on an internal/external boundary of circular cylinder which

has important influence on stress distribution in the structure. Hence the structural

assessments of hallow cylinders ranging from thick walled pressure vessel to thin walled

pipes has to be carried out, that in-turn relays on availability of Stress Intensity Factor (

S.I.F) for fracture analysis. The magnitude of the S.I.F determines the propagation of crack.

In this paper, Considerable effort has been devoted for computation of the S.I.F of crack

emanating from a hole in pressurized cylinder. The objective of this work is to determine SIF

(Plane Strain) for a crack emanating from a hole in a Pressurised cylinder using Finite

Element Method (FEM). From this study it was observed that the value of SIF rises suddenly

when the crack tip is near to the hole and it stabilises as the crack tip move far from the hole.

The SIF values evaluated for different crack length using FEM is normalised with the

analytical values obtained from theoretical equation with respect to (a/D) ratio which

provides important information for subsequent studies such as the crack growth rate

determination and prediction of residual strength with plane strain and plane stress

conditions.

373

International Journal of Mechanical Engineering and Technology (IJMET), ISSN 0976

6340(Print), ISSN 0976 6359(Online) Volume 4, Issue 2, March - April (2013) IAEME

Keywords: Fracture Mechanics, S.I.F and crack emanating from Hole

1.

INTRODUCTION

Pressure vessel and cylindrical shells have been used extensively as the structural

configuration in aerospace and shipping industries needs to be leak proof. However new

advancement in computers has made Finite Element Analysis (FEA) a practical tool in the

study of pressure vessels [1], especially in determining stresses in local areas such as

penetrations and service holes. The most likely places for crack initiating and development of

cracks are the service holes. Due to the high stress concentration in this area cracks may grow in

time, leading to a loss of strength and the reduction of the lifetime of the product as shown in

Figure1. If the structure is concerned with different loading, the crack behaviour must be assessed

in order to avoid catastrophic failures. For this, the knowledge of the crack size, service stress,

material properties and Stress Intensity Factor (SIF) is required [2]. Hence the structural

assessments of hallow cylinders /shell ranging from thick walled pressure vessel to thin

walled pipes has to be done, that in-turn relays on availability of stress intensity factor for

fracture and fatigue analysis. Thus it has been recognized that the stress intensity factor is an

important parameter to determine the safety of a cracked component, but the basic practical

problem a designer faces, is to make a decision to opt the method for determining stress

intensity factors. It is not easy to strike a balance between the accuracy of the method, time

required to get a solution, and cost. Numerous equations for stress intensity factors are

available in the literature [1 6]. These factors represent various geometries and loading

conditions of fundamental importance in the prediction of structural failure of cracked

cylindrical bodies. In all there are probably more than 600 formulas for calculating K values

for different crack configurations, body geometries, and loading situations.

Here the objective of the work is to determine S.I.F for a crack emanating from a hole in

a pressurized cylinder.

Fig.1: Larger crack formed by the link-up of fatigue cracks at adjacent rivets.

2. FRACTURE MECHANICS

Fracture mechanics involves a study of the presence of the cracks on overall properties

and behaviour of the engineering component. The process of fracture may be initiated at defect

locations like micro-cracks, voids, and the cavities at the grain boundaries. These defects can

lead to the formation of a crack due to the rupture and disentanglement of molecules, rupture of

atomic bonds or dislocation slip [3].

Cracked body can be subjected to three modes of loads as shown in Figure 2. In some

cases, body may experience combination of the three modes:

374

International Journal of Mechanical Engineering and Technology (IJMET), ISSN 0976

6340(Print), ISSN 0976 6359(Online) Volume 4, Issue 2, March - April (2013) IAEME

1. Opening mode: The principal load is applied normal to the crack surfaces, which tends

to open the crack. This is also referred as Mode I loading (Figure 2a).

2. In-plane shear mode: This mode corresponds to in-plane shear loading which tends to

slide

One crack surface with respect to the other. This is also referred as Mode II loading

(Figure2b).

3. Out-of-plane shear mode: This is the tearing and anti-plane shear mode where the crack

surfaces move relative to one another and parallel to the leading edge of the crack (Figure 2c).

(a)

(b)

(c)

Fig. 2: Three modes of loading that can be applied to a crack

The Stress Intensity Factor (SIF) is one the most important parameters in fracture

mechanics analysis. It defines the stress field close to the crack tip and provides fundamental

information of how the crack is going to propagate. In this study, A typical and practical point

matching technique, called Displacement Extrapolation Method (DEM) is chosen for the

numerical analysis method. Plane strain assumption is valid for very thin-walled structures; the

evaluation of S.I.F (KI) by Displacement Extrapolation Method (DEM) is as discussed bellow for

plane strain condition.

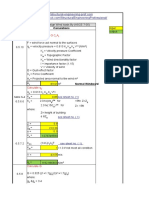

The stress intensity factors at a crack for a linear elastic fracture mechanics analysis may

be computed using the KCALC command. The analysis uses a fit of the nodal displacements in

the vicinity of the crack. The actual displacements at and near a crack for linear elastic materials

are

K

r

(1 + k )

u = + 11

(1)

2G 2

v=+

K1

2G

w =+

r

(1 + k )

2

2 K 111

G

(2)

r

2

(3)

375

International Journal of Mechanical Engineering and Technology (IJMET), ISSN 0976

6340(Print), ISSN 0976 6359(Online) Volume 4, Issue 2, March - April (2013) IAEME

Where:

u, v, w = displacements in a local Cartesian coordinate system as shown in figure 3

r, = coordinates in a local cylindrical coordinate system as shown in figure 3.

G = shear modulus

In Plane Stress

(4)

K=

1+ v

K= 3 - 4 In Plane strain..(5)

= Poisson's ratio

For Mode-1, SIF at crack tip is expressed as

G V

(6)

K1 = 2

1+ k r

Where v, are the motions of one crack face with respect to the other.

Then A and B are determined so that

V

= A + Br

(7)

r

At points J and K.

Next, let r approach 0

V

lim r 0

=A

(8)

r

Fig. 3: Nodes Used for the Approximate Crack-Tip Displacements for Full crack Model

Thus, Equation 5 becomes:

2GA N

mm

K 1 = 2

1 + k mm 2

(9)

3. OBJECTIVE OF WORK AND METHODOLOGY

The objective of this work is to determine S.I.F for a longitudinal crack emanating from a

hole in a pressurized cylinder as shown in figure 4. The objective is achieved by developing a

model of a cylinder with hole and a through crack using CATIA V5 software .The CATIA model

is imported to ANSYS.The FE model is meshed using 8-node quadrilateral doubly curved

SHELL 93 elements in the pre-processor of the ANSYS software . Further as a part of the finite

element work, a mesh sensitivity Study was conducted.

376

International Journal of Mechanical Engineering and Technology (IJMET), ISSN 0976

6340(Print), ISSN 0976 6359(Online) Volume 4, Issue 2, March - April (2013) IAEME

A shell with a longitudinal crack was meshed using three different mesh densities.

Mainly, the area around the imperfection was modelled with a finer mesh. Further the crack

tip singular elements were created using KSCON command. For this model there are 36

singular elements around the crack tip and the radius of the first row elements is a (Where a =

a/100).The model is then solved (Static Analysis) by subjecting it to an internal pressure of 1MPa

load with appropriate boundary conditions. Then the S.I.F is evaluated in general postprocessor

by using KCALC command.

The geometry of the meshed test model with crack tip singular elements in ANSYS 12 is

as shown in the Figure 5.The material considered is 304 steel (ASME). The material is assumed

to be linear elastic with youngs modulus of 2.5GPa and poisons ratio 0.3

Where,

D= Diameter of the hole (20mm),

a= Half Crack length

=applied hoop stress (Pr/t)

P= Internal pressure 1MPa

t=Thickness of the cylindrical shell

10mm

Fig.4: Geometry of model

(a)

(b)

(c)

Fig. 5: (a) Finite Element Model meshed with Boundary Condition (b) Zoomed View of

elements near crack tip (c) Zoomed View of Crack Tip Singular Elements

377

International Journal of Mechanical Engineering and Technology (IJMET), ISSN 0976

6340(Print), ISSN 0976 6359(Online) Volume 4, Issue 2, March - April (2013) IAEME

4. VALIDATION OF PROPOSED METHODOLOGY

The methodology proposed to determine Mode-1 S.I.F in previous section is validated

using the practical problem Determination of S.I.F of longitudinal cracks in a pressurized

cylindrical shell from reference 3.A cylindircal shell with varying longitudinal crack length given

in reference 3 is as shown in Figure 6.

Fig.6: Longitudinal crack in internally pressurized cylinder

Mode I S.I.F (KI) is given by

KI(Theo)= a. f 1 ( ) (10)

Where

f1 ( ) = (1 + 0.52 x + 1.29 x 2 0.07 x 3 )

x=

a

( Rt )

The half crack length was varied from 20mm to maximum half crack length of 439.53mm .The

maximum crack length in a given dimensions of cylindrical shell was determined using curvature

parameter [9]

a 4

12(1 2 ) .(11)

Rt

if =8 for longitudinal cracks , thickness of the cylindrical shell is 10mm and radius of the

cylindrical shell is 1000mm then the maximum crack length for given set of cylindrical shell

dimension is 439.53mm.

The values of S.I.F obtained by the theoretical and FEA is given in table 1.

378

International Journal of Mechanical Engineering and Technology (IJMET), ISSN 0976

6340(Print), ISSN 0976 6359(Online) Volume 4, Issue 2, March - April (2013) IAEME

Table 1: Mode-1 S.I.F (KI) Using FEA and theoretical KI(Theo) for different Half Crack

lengths (a)

Half Crack

Length (a)

mm

20

40

60

80

100

120

140

180

220

260

300

340

380

400

439.532

Mode -I SIF by

FEA

MPa

mm

Mode -I SIF

by Analytical

MPa

821.49

1282.6

1749.6

2265.4

2831.4

3448.9

4114.8

5570.8

7168.4

8886.5

10711

12634

14608

15685

17798

% error

mm

851.322

1330.62

1828.751

2352.63

2931.63

3555.117

4221.655

5669.381

7247.292

8933.523

10710.546

12561.166

14471.544

15446.58

17398.911

3.50

3.61

4.33

3.71

3.42

2.99

3.42

1.74

1.09

0.53

0.00

-0.58

-0.94

-1.54

-2.29

Fig.7: variation of theoretical and FEA values of S.I.F Vs crack length for longitudinal

crack in Pressurized cylinder

From the Fig 7 it is indicated that the results which were obtained by using the finite

element method are in good agreement with theoretical equation for a longitudinal through crack

emanating in internally pressurized cylindrical shell with an average percentage of error 1.53%

which is negligible. Thus the proposed methodology to determine the Mode-1 S.I.F for

longitudinal cracks in pressurised cylindrical shell is validated against a standard Procedure.

379

International Journal of Mechanical Engineering and Technology (IJMET), ISSN 0976

6340(Print), ISSN 0976 6359(Online) Volume 4, Issue 2, March - April (2013) IAEME

5. RESULTS AND DISCUSSIONS

For the problem Determination of SIF for a Crack Emanating from a Hole in a

Pressurized cylinder the test models containing a through crack emanating from a hole are

meshed and with plane strain condition it was internally pressurized and respective SIFs are

calculated.Theoritical Mode-1 is calculated using the relation

K1 (Theo ) = a eff

N

mm 2

mm (12)

The variation of normalized Stress Intensity Factor (KI/KO) (By Plane Strain Method)

with respect to a/D ratio [actual crack length (a) to the Diameter of the hole (D)] is as shown in

Figure 8. The normalized SIF (KI/KO) is used to obtain the characteristic curve of SIF which

depends only on the geometrical factor and its variation within the given domain (a/D).

Its observed that as the crack is near to the hole the stress concentration around holes has

a strong influence on the SIF value. For a/D ratio 0.5 there is a steep rise in SIF KI, this is due to

crack is small and the crack tip is near to stress concentration at the hole from which crack in

emanating. As the crack grows further (for a/D ranging from 0.1 to 25) the crack tip moves far

from the stressed areas hence the value of SIF increases the system will fail with increase in crack

length.

Table 2: The normalized Stress Intensity Factor (KI/KO) with respect to a/D ratio

Half

Crack

Length (a)

Hole

dia(D)

mm

mm

10

20

40

60

80

140

180

200

220

260

300

320

380

400

20

20

20

20

20

20

20

20

20

20

20

20

20

20

a/D

0.50

1.00

2.00

3.00

4.00

7.00

9.00

10.00

11.00

13.00

15.00

16.00

19.00

20.00

Mode -I SIF by

FEA(KI)

aeff

Mode -I SIF by

Theoritical(Ko)

MPa mm

mm

MPa mm

743.96

853.01

1085.8

1310.4

1540.1

2302.5

2881.6

3191.3

3514.8

4200.3

4932.1

5313.5

6519.8

6938.3

15

20

30

40

50

80

100

110

120

140

160

170

200

210

686.51

792.72

970.88

1121.07

1253.40

1585.43

1772.57

1859.09

1941.75

2097.33

2242.14

2311.15

2506.79

2568.70

380

KI / Ko

1.08368

1.076059

1.118372

1.168882

1.228742

1.452284

1.625663

1.716596

1.810118

2.002688

2.199727

2.299075

2.600855

2.701098

International Journal of Mechanical Engineering and Technology (IJMET), ISSN 0976

6340(Print), ISSN 0976 6359(Online) Volume 4, Issue 2, March - April (2013) IAEME

Fig.8: Variation of normalized S.I.F for a crack emanating from circular hole in

pressurized cylinder Vs a/D

The Deformed Geometries for crack length (a) of 20 mm is as shown in Figures 9, The

maximum Von-Misses stress is found to be at crack tip.

Fig 9: (a) VonMises Stress Distribution for Pressurised cylinder containing hole dia

D=20mm and crack length a=20mm

6. CONCLUSION

The problem of determining stress intensity factors for a crack emanating from a hole in a

pressurized cylinder is of prime importance in damage tolerance analysis. In the present study

ANSYS12, unified FEA software is chosen. It has the required pre-processing capabilities

for finite element modeling and analysis of cracked shell structures as demonstrated in this

paper.

381

International Journal of Mechanical Engineering and Technology (IJMET), ISSN 0976

6340(Print), ISSN 0976 6359(Online) Volume 4, Issue 2, March - April (2013) IAEME

The variation of normalized S.I.F (Ki/Ko) with respect to a/D ratio is used to obtain the

characteristic curve of SIF which depends only on the geometrical factor and its variation within

the given domain (a/D).

The fracture mechanics analysis on effects of pressure bulging near the crack on the

stress intensity factor is described in this paper that provides an explanation for the lower

strength of cracked cylinders.

The presented stress intensity factors in this paper are essential to predict

(1) Mixed mode fracture under static, dynamic and sustained loads

(2) Residual strength

(3) Crack growth life under cyclic loading conditions.

However there is a clear need to verify the predictions using experimental

investigations, but the method used in this paper can be utilized for calculating the stress

intensity factor for many other loading cases and many values of the crack length. This provides

important information for subsequent studies, especially for fatigue loads, where stress intensity

factor is necessary for the crack growth rate determination.

REFERENCES

[1]

[2]

Heckman david: Finite element analysis of pressure vessels, MBARI 1998

Chuin-Shan Chen, Paul A. Wawrzynek, and Anthony R. Ingraffea, 1999, Crack Growth

Simulation and Residual Strength Prediction in Airplane Fuselages, NASA/CR-1999-209115.

[3] Fracture mechanics-Fundamentals and Applications by T.L.Anderson published by Taylor

and Francis group 2005

[4] Gustavo V. Guinea, Jaime Planas and Manuel Elices, 2000, KI Evaluation by the

Displacement Extrapolation Technique, Engineering Fracture Mechanics 66 (2000), pp. 243255.

[5] Miloud Souiyah, A. Muchtar, Abdulnaser Alshoaibi and A.K. Ariffin, 2009, Finite Element

Analysis of the Crack Propagation for Solid Materials American Journal of Applied Sciences 6

(7), pp. 1396-1402.

[6] Craig A. Barwell, Lorenz.,A Study of Failure in Small Pressurized Cylindrical Shells

Containing a Crack., NASA/CR-1998-208454

[7] Yao-Chen Li, 1984, The Finite Element Method By Employing The Singular Element With

Concordant Displacement At The Crack Tip Engineering Fracture Mechanics, Vol. 19, No. 5,

pp. 959-972.

[8] Agne Karlsson and Jan Backlund, 1978, Summary of SIF Design Graphs for Cracks

Emanating From Circular Holes International Journal of Fracture, Vol. 14, No. 6

[9] Richard D. YoungNon-linear local bending response and bulging factors for longitudinal

and circumferential cracks in pressurised cylindrical shells.

[10] Kannan.P, K.Balamurugan and K. Thirunavukkarasu, Experimental Investigation on the

Influence of Silver Interlayer in Particle Fracture of Dissimilar Friction Welds, International

Journal of Mechanical Engineering & Technology (IJMET), Volume 3, Issue 2, 2012,

pp. 32 - 37, ISSN Print: 0976 6340, ISSN Online: 0976 6359.

[11] I.M.Jamadar, S.M.Patil, S.S.Chavan, G.B.Pawar and G.N.Rakate, Thickness Optimization of

Inclined Pressure Vessel using Non Linear Finite Element Analysis using Design by Analysis

Approach, International Journal of Mechanical Engineering & Technology (IJMET), Volume

3, Issue 3, 2012, pp. 682 - 689, ISSN Print: 0976 6340, ISSN Online: 0976 6359.

382

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5810)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Calculus For Beginners and ArtistDocument128 pagesCalculus For Beginners and Artists_rank90No ratings yet

- Wind Loads Calculations by ASCE7 05 For Any BuildingDocument12 pagesWind Loads Calculations by ASCE7 05 For Any BuildingshubhamdereNo ratings yet

- Lifting Sling Load EquationsDocument2 pagesLifting Sling Load EquationsFabio Okamoto100% (1)

- Sugar Technology: Technologie GMBHDocument8 pagesSugar Technology: Technologie GMBHBala MuruganNo ratings yet

- Calibration of InstrumentsDocument32 pagesCalibration of InstrumentsEsha Naveed100% (2)

- A Study On Talent Management and Its Impact On Employee Retention in Selected It Organizations in ChennaiDocument16 pagesA Study On Talent Management and Its Impact On Employee Retention in Selected It Organizations in ChennaiIAEME PublicationNo ratings yet

- Statistical Theory of Heat: Florian ScheckDocument240 pagesStatistical Theory of Heat: Florian ScheckJeffrey Barcenas100% (1)

- Modeling and Analysis of Surface Roughness and White Later Thickness in Wire-Electric Discharge Turning Process Through Response Surface MethodologyDocument14 pagesModeling and Analysis of Surface Roughness and White Later Thickness in Wire-Electric Discharge Turning Process Through Response Surface MethodologyIAEME PublicationNo ratings yet

- Impact of Emotional Intelligence On Human Resource Management Practices Among The Remote Working It EmployeesDocument10 pagesImpact of Emotional Intelligence On Human Resource Management Practices Among The Remote Working It EmployeesIAEME PublicationNo ratings yet

- Broad Unexposed Skills of Transgender EntrepreneursDocument8 pagesBroad Unexposed Skills of Transgender EntrepreneursIAEME PublicationNo ratings yet

- Voice Based Atm For Visually Impaired Using ArduinoDocument7 pagesVoice Based Atm For Visually Impaired Using ArduinoIAEME PublicationNo ratings yet

- Influence of Talent Management Practices On Organizational Performance A Study With Reference To It Sector in ChennaiDocument16 pagesInfluence of Talent Management Practices On Organizational Performance A Study With Reference To It Sector in ChennaiIAEME PublicationNo ratings yet

- Attrition in The It Industry During Covid-19 Pandemic: Linking Emotional Intelligence and Talent Management ProcessesDocument15 pagesAttrition in The It Industry During Covid-19 Pandemic: Linking Emotional Intelligence and Talent Management ProcessesIAEME PublicationNo ratings yet

- A Study On The Impact of Organizational Culture On The Effectiveness of Performance Management Systems in Healthcare Organizations at ThanjavurDocument7 pagesA Study On The Impact of Organizational Culture On The Effectiveness of Performance Management Systems in Healthcare Organizations at ThanjavurIAEME PublicationNo ratings yet

- A Multiple - Channel Queuing Models On Fuzzy EnvironmentDocument13 pagesA Multiple - Channel Queuing Models On Fuzzy EnvironmentIAEME PublicationNo ratings yet

- Application of Frugal Approach For Productivity Improvement - A Case Study of Mahindra and Mahindra LTDDocument19 pagesApplication of Frugal Approach For Productivity Improvement - A Case Study of Mahindra and Mahindra LTDIAEME PublicationNo ratings yet

- Optimal Reconfiguration of Power Distribution Radial Network Using Hybrid Meta-Heuristic AlgorithmsDocument13 pagesOptimal Reconfiguration of Power Distribution Radial Network Using Hybrid Meta-Heuristic AlgorithmsIAEME PublicationNo ratings yet

- A Study of Various Types of Loans of Selected Public and Private Sector Banks With Reference To Npa in State HaryanaDocument9 pagesA Study of Various Types of Loans of Selected Public and Private Sector Banks With Reference To Npa in State HaryanaIAEME PublicationNo ratings yet

- EXPERIMENTAL STUDY OF MECHANICAL AND TRIBOLOGICAL RELATION OF NYLON/BaSO4 POLYMER COMPOSITESDocument9 pagesEXPERIMENTAL STUDY OF MECHANICAL AND TRIBOLOGICAL RELATION OF NYLON/BaSO4 POLYMER COMPOSITESIAEME PublicationNo ratings yet

- Various Fuzzy Numbers and Their Various Ranking ApproachesDocument10 pagesVarious Fuzzy Numbers and Their Various Ranking ApproachesIAEME PublicationNo ratings yet

- Role of Social Entrepreneurship in Rural Development of India - Problems and ChallengesDocument18 pagesRole of Social Entrepreneurship in Rural Development of India - Problems and ChallengesIAEME PublicationNo ratings yet

- Knowledge Self-Efficacy and Research Collaboration Towards Knowledge Sharing: The Moderating Effect of Employee CommitmentDocument8 pagesKnowledge Self-Efficacy and Research Collaboration Towards Knowledge Sharing: The Moderating Effect of Employee CommitmentIAEME PublicationNo ratings yet

- Dealing With Recurrent Terminates in Orchestrated Reliable Recovery Line Accumulation Algorithms For Faulttolerant Mobile Distributed SystemsDocument8 pagesDealing With Recurrent Terminates in Orchestrated Reliable Recovery Line Accumulation Algorithms For Faulttolerant Mobile Distributed SystemsIAEME PublicationNo ratings yet

- Moderating Effect of Job Satisfaction On Turnover Intention and Stress Burnout Among Employees in The Information Technology SectorDocument7 pagesModerating Effect of Job Satisfaction On Turnover Intention and Stress Burnout Among Employees in The Information Technology SectorIAEME PublicationNo ratings yet

- A Proficient Minimum-Routine Reliable Recovery Line Accumulation Scheme For Non-Deterministic Mobile Distributed FrameworksDocument10 pagesA Proficient Minimum-Routine Reliable Recovery Line Accumulation Scheme For Non-Deterministic Mobile Distributed FrameworksIAEME PublicationNo ratings yet

- Analysis of Fuzzy Inference System Based Interline Power Flow Controller For Power System With Wind Energy Conversion System During Faulted ConditionsDocument13 pagesAnalysis of Fuzzy Inference System Based Interline Power Flow Controller For Power System With Wind Energy Conversion System During Faulted ConditionsIAEME PublicationNo ratings yet

- Formulation of The Problem of Mathematical Analysis of Cellular Communication Basic Stations in Residential Areas For Students of It-PreparationDocument7 pagesFormulation of The Problem of Mathematical Analysis of Cellular Communication Basic Stations in Residential Areas For Students of It-PreparationIAEME PublicationNo ratings yet

- A Review of Particle Swarm Optimization (Pso) AlgorithmDocument26 pagesA Review of Particle Swarm Optimization (Pso) AlgorithmIAEME PublicationNo ratings yet

- A Overview of The Rankin Cycle-Based Heat Exchanger Used in Internal Combustion Engines To Enhance Engine PerformanceDocument5 pagesA Overview of The Rankin Cycle-Based Heat Exchanger Used in Internal Combustion Engines To Enhance Engine PerformanceIAEME PublicationNo ratings yet

- Financial Literacy On Investment Performance: The Mediating Effect of Big-Five Personality Traits ModelDocument9 pagesFinancial Literacy On Investment Performance: The Mediating Effect of Big-Five Personality Traits ModelIAEME PublicationNo ratings yet

- Quality of Work-Life On Employee Retention and Job Satisfaction: The Moderating Role of Job PerformanceDocument7 pagesQuality of Work-Life On Employee Retention and Job Satisfaction: The Moderating Role of Job PerformanceIAEME PublicationNo ratings yet

- Prediction of Average Total Project Duration Using Artificial Neural Networks, Fuzzy Logic, and Regression ModelsDocument13 pagesPrediction of Average Total Project Duration Using Artificial Neural Networks, Fuzzy Logic, and Regression ModelsIAEME PublicationNo ratings yet

- Analysis On Machine Cell Recognition and Detaching From Neural SystemsDocument9 pagesAnalysis On Machine Cell Recognition and Detaching From Neural SystemsIAEME PublicationNo ratings yet

- Ion Beams' Hydrodynamic Approach To The Generation of Surface PatternsDocument10 pagesIon Beams' Hydrodynamic Approach To The Generation of Surface PatternsIAEME PublicationNo ratings yet

- Sentiment Analysis Approach in Natural Language Processing For Data ExtractionDocument6 pagesSentiment Analysis Approach in Natural Language Processing For Data ExtractionIAEME PublicationNo ratings yet

- Evaluation of The Concept of Human Resource Management Regarding The Employee's Performance For Obtaining Aim of EnterprisesDocument6 pagesEvaluation of The Concept of Human Resource Management Regarding The Employee's Performance For Obtaining Aim of EnterprisesIAEME PublicationNo ratings yet

- Vibration Testing of Shipping Containers: Standard Test Methods ForDocument6 pagesVibration Testing of Shipping Containers: Standard Test Methods Foromar alvaradoNo ratings yet

- Pipe Flow ReviewDocument12 pagesPipe Flow ReviewsamadonyNo ratings yet

- Ola Al QasemDocument212 pagesOla Al QasemMadalina-Alexandra PuscasuNo ratings yet

- Deaerators AutosavedDocument5 pagesDeaerators AutosavedMagdalena100% (1)

- Alternating CurrentDocument17 pagesAlternating CurrentShinjiNo ratings yet

- Shannon Theory For Compressed SensingDocument201 pagesShannon Theory For Compressed SensingchetanNo ratings yet

- Goud-Umashankar2018 Article InterfaceShearStrengthPropertiDocument14 pagesGoud-Umashankar2018 Article InterfaceShearStrengthPropertiJPDGLNo ratings yet

- Full Control of A QuadrotorDocument6 pagesFull Control of A QuadrotorLuis Orlando Silva VásquezNo ratings yet

- Determination of Copper Content in Drinking Water by Using AAS (1) Rev 1Document16 pagesDetermination of Copper Content in Drinking Water by Using AAS (1) Rev 1Yin Ling LamNo ratings yet

- Visual Color Evaluation Metamerism (Based On ASTM D-4086)Document3 pagesVisual Color Evaluation Metamerism (Based On ASTM D-4086)T AaaNo ratings yet

- Chapter 1 IntroductionDocument37 pagesChapter 1 IntroductionKiran ZinjadeNo ratings yet

- Form 1.measurementDocument8 pagesForm 1.measurementFrancis MdhaminNo ratings yet

- Chapter 14 NotesDocument3 pagesChapter 14 NotesklerinetNo ratings yet

- The Effects of Wake Splitter Plates On The Flow Past A Circular Cylinder in The Range 10R5101973Journal of Fluid MechanicsDocument12 pagesThe Effects of Wake Splitter Plates On The Flow Past A Circular Cylinder in The Range 10R5101973Journal of Fluid MechanicsDeepak RajpurohitNo ratings yet

- Copmplexo Titration Cu EDTADocument3 pagesCopmplexo Titration Cu EDTAJay JayNo ratings yet

- Steklo I Keramika Eng 1961 V18 N7 P349Document4 pagesSteklo I Keramika Eng 1961 V18 N7 P349FreedomInYourEyesNo ratings yet

- Solving Multicollinearity Problem: Int. J. Contemp. Math. Sciences, Vol. 6, 2011, No. 12, 585 - 600Document16 pagesSolving Multicollinearity Problem: Int. J. Contemp. Math. Sciences, Vol. 6, 2011, No. 12, 585 - 600Tiberiu TincaNo ratings yet

- DX X X X X X: Log (Ax+b)Document10 pagesDX X X X X X: Log (Ax+b)RobertBellarmineNo ratings yet

- Sand Aging Field Study PDFDocument12 pagesSand Aging Field Study PDFKen LiewNo ratings yet

- Tutorial10 Introduction PDFDocument11 pagesTutorial10 Introduction PDFJohanWilshireNo ratings yet

- TOPAS 1000: Power Network AnalyserDocument8 pagesTOPAS 1000: Power Network AnalyserFranz Montero RamirezNo ratings yet

- ph251 17Document6 pagesph251 17Maria HerreraNo ratings yet

- Yulian Firmana Arifin and Tom Schanz Rev 03052017Document6 pagesYulian Firmana Arifin and Tom Schanz Rev 03052017yfarifinNo ratings yet

- Cowan - Aachen14 - 1 - Statistical Methods For Particle PhysicsDocument72 pagesCowan - Aachen14 - 1 - Statistical Methods For Particle Physicsbirdie namnamNo ratings yet