Professional Documents

Culture Documents

Sgs Ind NDT TC MT A4 en 11

Sgs Ind NDT TC MT A4 en 11

Uploaded by

Ravindra Kumar0 ratings0% found this document useful (0 votes)

6 views2 pagesndt

Original Title

Sgs Ind Ndt Tc Mt a4 en 11

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentndt

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

6 views2 pagesSgs Ind NDT TC MT A4 en 11

Sgs Ind NDT TC MT A4 en 11

Uploaded by

Ravindra Kumarndt

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 2

Magnetic Particle Inspection (MT)

This method involves the component

under inspection being magnetized, this

magnetization process is supplemented

by the application of ferromagnetic

particles to the already magnetized

surface.

The magnetic particles are attracted

to areas of flux leakage (escaping

magnetism) and indications formed at

that point. This method is used to test

welds, castings, and forgings for

surface or slightly subsurface defects.

www.sgs.com/ndt-training

However MT can only be used

to inspect materials that can be

magnetized, i.e. ferromagnetic

materials.

We can provide Magnetic Particle

training courses and examinations

suitable for any of the following

certification schemes

n PCN / EN 473 / ISO 9712

Level 1, 2, and 3

n SNT-TC-1A in accordance with

your company written practice

We can also provide

n Preparation training for ASNT Level 3

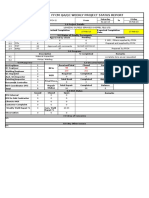

An example of the syllabus that is used

for magnetic particle training courses is

shown below for Level 1 and Level 2.

SGS can tailor make the syllabus

to satisfy the requirements of an

individuals company specific

written practice if requested.

Magnetic Particle Inspection (MT)

Level 1

Specific Theory

Practical Examination

Application of the Method and use of

Codes, Specifications and Procedures,

applicable to the company, including

the relevant control checks.

Follow written instructions and process

the inspection test pieces, record and

report defects from known datum

markers, carry out pre-test calibration

checks and post-test procedures.

General Theory

Specific Theory

Practical Examination

(in addition to the Level 1 Syllabus above)

n Safety Precautions

n Testing Procedures

n Detectability of Defects

n Interpretation and Reporting

n Post Test Procedures

n Calculations

n Selection of Appropriate

Techniques

Application of the Method to the

specific requirements of the company,

in particular making reference to those

Codes, Specifications and Procedures

used by the Company, including the

relevant control checks.

Production of written instruction,

determine the best inspection

techniques for the individual parts,

process the inspection test pieces,

record and report defects from know

datum markers, carry out pre test

calibration checks, post test

procedures.

General Theory

n

n

n

n

n

n

n

n

n

Safety Precautions

Basic Principles of Magnetic

Particle Inspection

Methods of Magnetisation

Inspection and Detection of

Indications

Checks and Calibrations

Equipment

Test Procedures

Detectability of Defects

Standards and Specifications

LeveL 2

Product technology of the products

for the relevant sector, i.e. welds,

castings, forgings, this includes,

manufacturing processes, defect

formation and detection.

CONTACT US

01/2011 SGS. All rights reserved.

SGS NDT Training & Examination Centre

2F, Building 8, No. 69, 1159, East

Kangqiao Road, Pudong District

Shanghai 201319, P. R. China

T +86 21 6818 3905

F +86 21 6818 3265

ndt.training@sgs.com

www.sgs.com/ndt-training

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5814)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (845)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- AS 1100 Part 301 Architectural DrawingDocument24 pagesAS 1100 Part 301 Architectural DrawingHao Much100% (3)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- English Paper 1 Mark Scheme: Stage 9Document10 pagesEnglish Paper 1 Mark Scheme: Stage 9Hiede Rodil64% (14)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Flow Chart For Handling Incoming DocumentsDocument1 pageFlow Chart For Handling Incoming Documentsmusaismail8863100% (1)

- 02 MechanicalDocument44 pages02 Mechanicalmusaismail8863No ratings yet

- Material Specification Sheet Saarstahl - C40E (Ck40)Document2 pagesMaterial Specification Sheet Saarstahl - C40E (Ck40)musaismail8863No ratings yet

- FFCM-MSI QAQC Weekly Project Status Report (07.02. 15-13 02 15)Document1 pageFFCM-MSI QAQC Weekly Project Status Report (07.02. 15-13 02 15)musaismail8863100% (1)

- Abs Guide Rules For Fpso ConversionDocument1 pageAbs Guide Rules For Fpso Conversionmusaismail8863No ratings yet

- Risks in Facility Build Quality and Project Handover: What Happened?Document3 pagesRisks in Facility Build Quality and Project Handover: What Happened?musaismail8863No ratings yet

- MDR NDT Drawing Tembikai As of 08.11.2014Document1 pageMDR NDT Drawing Tembikai As of 08.11.2014musaismail8863100% (1)

- 232 50Document2 pages232 50musaismail8863No ratings yet

- Instruction Manual - Dial Thickness Gauge Kit How Replica Tape WorksDocument6 pagesInstruction Manual - Dial Thickness Gauge Kit How Replica Tape Worksmusaismail8863No ratings yet

- 16 - Metal and SpecialtyDocument12 pages16 - Metal and Specialtymusaismail8863No ratings yet

- Apartment Harga SederhanaDocument3 pagesApartment Harga Sederhanamusaismail8863No ratings yet

- Determination of Peak Hour RidershipDocument22 pagesDetermination of Peak Hour RidershipApoorva PrakashNo ratings yet

- Digital Media Assignment Lesson PlanDocument2 pagesDigital Media Assignment Lesson Planapi-245443624No ratings yet

- Educadores Ejovem SQLDocument8 pagesEducadores Ejovem SQLAlessandro FeitozaNo ratings yet

- Latin American InstrumentsDocument3 pagesLatin American InstrumentsVictoria Reenna CañeteNo ratings yet

- Release RTWlanUDocument10 pagesRelease RTWlanUNicolas FournierNo ratings yet

- Overview of Geophysical MethodsDocument41 pagesOverview of Geophysical MethodsVaqas Ali KhanNo ratings yet

- MCQ CPWA Code Chapter-10Document14 pagesMCQ CPWA Code Chapter-10Biswajit JenaNo ratings yet

- Emc Connectrix DS-300BDocument4 pagesEmc Connectrix DS-300Bamr_salah944No ratings yet

- Setting Up A Tissue Culture Lab:: Transfer AreaDocument6 pagesSetting Up A Tissue Culture Lab:: Transfer AreaAjay KumarNo ratings yet

- VCP-NV 6.2 - ExampsDocument45 pagesVCP-NV 6.2 - ExampsvipertheheroNo ratings yet

- Hot Cracking2Document470 pagesHot Cracking2Ashish PatelNo ratings yet

- English 2021Document15 pagesEnglish 2021katehughes332No ratings yet

- CassendraDocument21 pagesCassendraNikhil Erande100% (1)

- Olga Ujhelly, PHD During My Science in Biotalentum, Gödöllő, Hungary 25-29.1Document12 pagesOlga Ujhelly, PHD During My Science in Biotalentum, Gödöllő, Hungary 25-29.1My Science Programme for Young JournalistsNo ratings yet

- 74 HCT 148Document11 pages74 HCT 148Merényi OszkárNo ratings yet

- Week 2 Needs AnalysisDocument44 pagesWeek 2 Needs AnalysisIzzati che harrisNo ratings yet

- ACN-part 1Document3 pagesACN-part 1aarohiNo ratings yet

- PCS 7 Water Templates V902 enDocument115 pagesPCS 7 Water Templates V902 enABI RAJESH GANESHA RAJANo ratings yet

- White Genoa ID ResearchDocument7 pagesWhite Genoa ID ResearchКлиментий РанчуковNo ratings yet

- VMStudy GuideDocument15 pagesVMStudy GuideSrinivas KumarNo ratings yet

- Toshiba KCD-10 X-Ray - Installation ManualDocument18 pagesToshiba KCD-10 X-Ray - Installation Manualkizen_5100% (2)

- FE Credit System SyllabusDocument36 pagesFE Credit System SyllabusHarshvardhanUpadhyayNo ratings yet

- Neonatal HypocalcemiaDocument8 pagesNeonatal HypocalcemiaCristina Fernández ValenciaNo ratings yet

- Mini ProjetDocument4 pagesMini ProjetgangshNo ratings yet

- Management in Problematic SoilsDocument7 pagesManagement in Problematic SoilsBalaji KartheekNo ratings yet

- TM 5Document18 pagesTM 5Himani KhatriNo ratings yet

- Lab 4Document7 pagesLab 4HEMANILASHINII A P R THARMALINGAMNo ratings yet

- EPD Mineral Wool Panel PRMDocument7 pagesEPD Mineral Wool Panel PRMAhmed Ben HmidaNo ratings yet

- Sanet - CD 11011011011011Document26 pagesSanet - CD 11011011011011Leopoldo DelgadoNo ratings yet