Professional Documents

Culture Documents

Titanium alloy for high temperature jet engines

Uploaded by

ivanlawms67450 ratings0% found this document useful (0 votes)

42 views1 pagey

Original Title

Titanium Ti SF61

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documenty

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

42 views1 pageTitanium alloy for high temperature jet engines

Uploaded by

ivanlawms6745y

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

Titanium alloys

Category:

AADDVVAANNCCEEDDMMAATTEERRIAIALLSSTTEECCHHNNOOLLOOGGYY

high temperature

Titanium alloy Ti-SF61

Titanium Ti-SF61 is a new generation high temperature Titanium alloys. Because of its alloying element

Yttrium that forms high temperature stable Oxides, it shows high fatigue strength at elevated temperatures

and excellent creep resistance. Standard processing is triple vacuum arc melting for rotor grade quality. TiSF61 is the most advanced conventional high temperature Titanium alloy. Developed to replace Ti-6242Si

and Ti-834 for jet engine application. Due to its excellent properties it has also potential for high performance

automotive applications.

General properties:

Comparison with Standard alloy Ti-6242Si:

High strength at elevated temperatures

Excellent creep resistance

Wide processing window

Advantages:

- Higher fatigue strength

- Higher creep resistance

- None

Disadvantages:

Material composition

Chemical Composition: Ti-5.9Al-2.7Sn-4Zr-0.45Mo-0.35Si-0.22Y

Mechanical properties

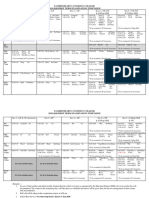

Alloy

UTS

Mpa

Ti-SF61

1068

Ti-SF60

1058

Timetal-834 1040

Ti-6242

1020

YS

Rt

Mpa

1050

989

945

910

El

UTS

%

11

14

12

12

Mpa

752

674

654

560

YS

600C

Mpa

655

553

510

485

El

Fatigue

760C

Residual

%

16

23

15

15

Mpa, 10^7

%

0.029

0.079

0.082

0.154

195

176

142

138

E-Modulus

Microstructure

Gpa

120

121

119

116

Equiaxed, a+btrans

Bi-modal

Equiaxed, a+btrans

-

Strain*

*After creep exposure at 600, 150 Mpa, 100h.

Physical data

Hardness:

Density:

Elastic modulus:

CTE:

Thermal conductivity:

32-35 HRC

4.56 g/cm

120 GPa

8.3x10-6

8 W/mK

Applications

-

Inlet and outlet valves

Compressor discs

Compressor blades

Delivery form

-

Bars

Plates

Forged valve blanks

AMT Advanced Materials Technology

Street: Huegelstrasse 9

Zip, City: 64404 Bickenbach

Germany

Tel.: +49-6257-505-1790

Fax.: +49-6257-505-1792

Mail: DB-AMT@web.de

You might also like

- Weld Like a Pro: Beginning to Advanced TechniquesFrom EverandWeld Like a Pro: Beginning to Advanced TechniquesRating: 4.5 out of 5 stars4.5/5 (6)

- Oxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonFrom EverandOxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonNo ratings yet

- Titanio y AleacionesDocument7 pagesTitanio y AleacionesMarioNo ratings yet

- Titanium and Its Alloys: Mahros Darsin Universitas JemberDocument31 pagesTitanium and Its Alloys: Mahros Darsin Universitas JemberAsyar Guns100% (1)

- Aluminium Titanate: Chemical FormulaDocument6 pagesAluminium Titanate: Chemical FormulaaadhanNo ratings yet

- A330 PylonsDocument21 pagesA330 Pylonsosamoz100% (2)

- Khanna 2015Document29 pagesKhanna 2015nishanth124acharyaNo ratings yet

- Aerospace Materials GuideDocument6 pagesAerospace Materials Guidesnuffit11No ratings yet

- Materiales Aeroespaciales Conventional Titanium Alloys Aeros2Document19 pagesMateriales Aeroespaciales Conventional Titanium Alloys Aeros2filibertonvNo ratings yet

- Titanium Alloys Jan2020.6310.1581071494.6551Document43 pagesTitanium Alloys Jan2020.6310.1581071494.6551EudoNo ratings yet

- Tic and Al2024Document7 pagesTic and Al2024mohamed moradNo ratings yet

- C 2920 35 PDFDocument140 pagesC 2920 35 PDFHarish ChandrashekarNo ratings yet

- Titanium Alloys and Its PropertiesDocument26 pagesTitanium Alloys and Its PropertiesAnand Prabhu100% (1)

- High Speed CuttingDocument4 pagesHigh Speed Cuttingsakthistory1922No ratings yet

- Developments in Gas Turbine MaterialsDocument39 pagesDevelopments in Gas Turbine MaterialsGrk GuptaNo ratings yet

- DonGrahamIMTS48 PDFDocument82 pagesDonGrahamIMTS48 PDFnick amirNo ratings yet

- Titanium & AlloysDocument28 pagesTitanium & AlloysPramod MallarNo ratings yet

- What Is AlloyticDocument1 pageWhat Is AlloyticProject Sales CorpNo ratings yet

- Titanium Grades PDFDocument7 pagesTitanium Grades PDFMatt AgonyaNo ratings yet

- Miller Welding TitaniumDocument20 pagesMiller Welding TitaniumrcpretoriusNo ratings yet

- Materials For Gas Turbines An OverviewDocument23 pagesMaterials For Gas Turbines An OverviewNgân LêNo ratings yet

- Gas Turbine MaterialsDocument15 pagesGas Turbine MaterialsTemesgen Debelo DesissaNo ratings yet

- Titanium Alloy GuideDocument48 pagesTitanium Alloy GuidePatrick DominguezNo ratings yet

- Titanium Grade Overview PDFDocument6 pagesTitanium Grade Overview PDFAhmadreza AminianNo ratings yet

- Titanium For Automotive Engine ApplicationsDocument5 pagesTitanium For Automotive Engine ApplicationsBg AnoopNo ratings yet

- St. Joseph'S College of Engineering: Chennai 119Document43 pagesSt. Joseph'S College of Engineering: Chennai 119Praba KaranNo ratings yet

- ISO Certified Heavy Steel Forging ManufacturerDocument4 pagesISO Certified Heavy Steel Forging ManufacturerNirmit GandhiNo ratings yet

- Tirasteel Machinery SteelDocument36 pagesTirasteel Machinery SteelAndieka Cool AndieNo ratings yet

- Recent Advances in The Machining of Titanium Alloys Using Minimum Quantity Lubrication (MQL) Based Techniques PDFDocument13 pagesRecent Advances in The Machining of Titanium Alloys Using Minimum Quantity Lubrication (MQL) Based Techniques PDFramakrishna09304No ratings yet

- Titanium The ChoiceDocument24 pagesTitanium The Choiceinfo7595100% (1)

- Titanium - Welding and Heat Treating: Topics CoveredDocument13 pagesTitanium - Welding and Heat Treating: Topics CoveredSisira ChandrasomaNo ratings yet

- Titanium Guide PDFDocument48 pagesTitanium Guide PDFthanghanvicoNo ratings yet

- Materials For Gas Turbines - An OverviewDocument23 pagesMaterials For Gas Turbines - An OverviewBerkath Ali KhanNo ratings yet

- Aerospace Standard Materials - Mechanical Properties - Issue 12 - 2015Document6 pagesAerospace Standard Materials - Mechanical Properties - Issue 12 - 2015Leandro González De CeccoNo ratings yet

- High Speed Steel PDFDocument1 pageHigh Speed Steel PDFYogesh PatelNo ratings yet

- InTech-Materials For Gas Turbines An Overview (Modified)Document23 pagesInTech-Materials For Gas Turbines An Overview (Modified)Hasan AdelNo ratings yet

- About Titanium WeldingDocument6 pagesAbout Titanium Weldingckkashyap0007No ratings yet

- The Performance of Uncoated Tungsten Carbide Insert in End Milling Titanium Alloy Ti-6Al 4V Through Work Piece PreheatingDocument8 pagesThe Performance of Uncoated Tungsten Carbide Insert in End Milling Titanium Alloy Ti-6Al 4V Through Work Piece PreheatingRizal FahrezaNo ratings yet

- HeliCoil Titanium InsertsDocument2 pagesHeliCoil Titanium InsertsAce Industrial SuppliesNo ratings yet

- Engine MaterialsDocument33 pagesEngine MaterialsMirtunjay KumarNo ratings yet

- Application Notes Titanium EnglishDocument6 pagesApplication Notes Titanium EnglishXEFTAXNo ratings yet

- Heat Resistant Materials Applications in IndustryDocument10 pagesHeat Resistant Materials Applications in IndustrysavanchandranNo ratings yet

- Heat Treatment of Titanium and Titanium AlloysDocument6 pagesHeat Treatment of Titanium and Titanium AlloysAmyRapaNo ratings yet

- Paduan AluminumDocument37 pagesPaduan AluminumRial RjgkgkNo ratings yet

- The New Generation Tata TisconDocument5 pagesThe New Generation Tata TisconJitendra KasotiaNo ratings yet

- Titanium 1Document12 pagesTitanium 1Farid AhmadiNo ratings yet

- Kroll ProcessDocument5 pagesKroll ProcessNavarro SalgadoNo ratings yet

- AluminiumDocument48 pagesAluminiumGhiffariAwliyaMuhammadAshfaniaNo ratings yet

- Oxy-Acetylene Welding and Cutting Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonFrom EverandOxy-Acetylene Welding and Cutting Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonNo ratings yet

- Proceedings of the 8th International Symposium on Superalloy 718 and DerivativesFrom EverandProceedings of the 8th International Symposium on Superalloy 718 and DerivativesNo ratings yet

- Wine ListDocument203 pagesWine Listivanlawms6745No ratings yet

- Twghs Wong Fut Nam College 2021 Summer Uniform Price List: Order Date: Delivery Date: 17Document1 pageTwghs Wong Fut Nam College 2021 Summer Uniform Price List: Order Date: Delivery Date: 17ivanlawms6745No ratings yet

- Wo2019111306 Pamph 20190613 6534Document27 pagesWo2019111306 Pamph 20190613 6534ivanlawms6745No ratings yet

- Exploded ViewDocument2 pagesExploded Viewivanlawms6745No ratings yet

- HP 4338B ServiceDocument58 pagesHP 4338B Serviceivanlawms6745No ratings yet

- Service: ManualDocument113 pagesService: Manualivanlawms6745No ratings yet

- Rectangular Linear Voice Coil Actuators (Vca) ConfigurationsDocument7 pagesRectangular Linear Voice Coil Actuators (Vca) Configurationsivanlawms6745No ratings yet

- US5127236Document8 pagesUS5127236ivanlawms6745No ratings yet

- 2013 09 002 002 enDocument58 pages2013 09 002 002 enStefan Ilic80% (5)

- Ash Michael Ash Irene Handbook of Pharmaceutical Additives PDFDocument2,995 pagesAsh Michael Ash Irene Handbook of Pharmaceutical Additives PDFivanlawms6745100% (1)

- GG Pricelist Baltics Oct 2016-1Document78 pagesGG Pricelist Baltics Oct 2016-1ivanlawms6745No ratings yet

- GG Pricelist Baltics Oct 2016-1Document78 pagesGG Pricelist Baltics Oct 2016-1ivanlawms6745No ratings yet

- Operator'S Manual: Original Operating InstructionsDocument68 pagesOperator'S Manual: Original Operating Instructionsivanlawms6745No ratings yet

- Doppler/GPS Navigation Set: AN/ASN-157Document2 pagesDoppler/GPS Navigation Set: AN/ASN-157ivanlawms6745No ratings yet

- Cylindrical Housed Linear Voice Coil Actuator (Vca) ConfigurationsDocument2 pagesCylindrical Housed Linear Voice Coil Actuator (Vca) Configurationsivanlawms6745No ratings yet

- Cylindrical Semi-Housed Linear Voice Coil Actuators (Vca) : SpecificationsDocument2 pagesCylindrical Semi-Housed Linear Voice Coil Actuators (Vca) : Specificationsivanlawms6745No ratings yet

- Cylindrical Frameless Linear Voice Coil Actuators (Vca) : SpecificationsDocument2 pagesCylindrical Frameless Linear Voice Coil Actuators (Vca) : Specificationsivanlawms6745No ratings yet

- There's No Silent Majority in Hong Kong, Only A Terri Ed Minority While The Rest Are Ne With Mob Rule and AnarchyDocument4 pagesThere's No Silent Majority in Hong Kong, Only A Terri Ed Minority While The Rest Are Ne With Mob Rule and Anarchyivanlawms6745No ratings yet

- DS600-51 - 396800 Variable Bleed Valve Gear Motor PDFDocument2 pagesDS600-51 - 396800 Variable Bleed Valve Gear Motor PDFivanlawms6745No ratings yet

- 26984284Document36 pages26984284ivanlawms6745100% (1)

- Handbook of Cosmetic and Personal Care Additives, Volume 1 and 2Document2,044 pagesHandbook of Cosmetic and Personal Care Additives, Volume 1 and 2MARCOS100% (5)

- INTEGRATED 10/100/1000M ETHERNET Controller For Usb ApplicationsDocument33 pagesINTEGRATED 10/100/1000M ETHERNET Controller For Usb Applicationsivanlawms6745No ratings yet

- EC 20 MOTOR SPECSDocument1 pageEC 20 MOTOR SPECSivanlawms6745No ratings yet

- eHDD MG08 Product ManualDocument15 pageseHDD MG08 Product Manualivanlawms6745No ratings yet

- Seagate, HGST and WD Hard Drive Capacity and Model Comparison ChartDocument29 pagesSeagate, HGST and WD Hard Drive Capacity and Model Comparison Chartivanlawms6745No ratings yet

- S1 S5 First Term Examination Timetable 1920 3 PDFDocument2 pagesS1 S5 First Term Examination Timetable 1920 3 PDFivanlawms6745No ratings yet

- S1 S5 First Term Examination Timetable 1920 3 PDFDocument2 pagesS1 S5 First Term Examination Timetable 1920 3 PDFivanlawms6745No ratings yet

- History and Future of Hitachi's Plasma Etching System: Hiromichi Enami Yoshifumi Ogawa Masaru Izawa Takaaki SaitoDocument5 pagesHistory and Future of Hitachi's Plasma Etching System: Hiromichi Enami Yoshifumi Ogawa Masaru Izawa Takaaki Saitoivanlawms6745No ratings yet

- Core Loss Measurement Technique for High Phase Angle MaterialsDocument20 pagesCore Loss Measurement Technique for High Phase Angle Materialsivanlawms6745No ratings yet

- S1 S5 First Term Examination Timetable 1920 3 PDFDocument2 pagesS1 S5 First Term Examination Timetable 1920 3 PDFivanlawms6745No ratings yet