Professional Documents

Culture Documents

WPS API1104 A516 GR 70

Uploaded by

Erick HoganOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

WPS API1104 A516 GR 70

Uploaded by

Erick HoganCopyright:

Available Formats

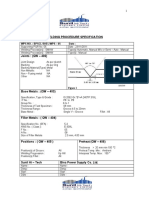

Doc No.

: TBA

Rev. No.: 0

3 May 2010

Date:

WELDING PROCEDURE SPECIFICATION (WPS)

TBA

PIPE / PLATE

WELDING PROCESS

BASE MATERIAL

SIZE / DIAMETER (mm)

THICKNESS (mm)

OTHER

Plate

GTAW / SMAW

A 516 Gr. 70

A 516 Gr. 70

350 x 150

350 x 150

12.0

12.0

N/A

N/A

CONSUMABLE ELECTRODE

A-NO.

1

GROUP NO.

3

AWS SPECIFICATION

A 5.1

AWS CLASSIFICATION

E7018

BRAND OF ELECTRODE

KOBELCO LB-52-18

SIZE OF ELECTRODE

2.6 & 3.2 mm

ELECTRODE FLUX (CLASS)

N/A

FLUX TRADE NAME

N/A

CONSUMABLE INSERT

N/A

POST WELD HEAT TREATMENT (PWHT)

HEATING RATE

N/A

SOAKING TEMPERATURE

N/A

HOLDING TIME

N/A

COOLING RATE

N/A

MIXTURE

FLOW RATE

N/A

N/A

N/A

N/A

N/A

N/A

JOINT DETAIL

Single Vee Butt Weld with Backing Strip

Yes

ASTM A 36

Tack Weld

Machining and/or grinding

JOINT DESIGN

BACKING

BACKING MATERIAL

METHOD OF FIT-UP

EDGE PREPARATION

SKETCH

60 5

B

2.0 mm

Backing Strip

1.5 - 3.0 mm

PREHEAT

60 C

280 C Max

N/A

N/A

GAS(ES) TYPE

N/A

N/A

N/A

PREHEAT TEMP. (Min)

INTERPASS TEMP. (Max)

PREHEAT MAINTENANCE

OTHER

GAS

SHIELDING

TRAILING

BACKING

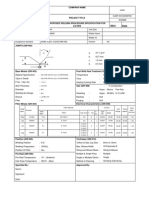

QUALIFIED DIAMETER GROUP

QUALIFIED THICKNESS GROUP

QUALIFIED MATERIAL GROUP

TYPE OF CONNECTION APPLICABLE

FLAME CHARACTERISTIC

TRADE

NAME

GAS TYPE

FLOW RATE

(L/min)

DIRECTION

Horizontal

Horizontal

Horizontal

Horizontal

CLASS

POSITION

2G

2G

2G

2G

AWS NO.

WELDING

PROCESS

SMAW

SMAW

SMAW

SMAW

2.6

3.2

3.2

3.2

5.1

5.1

5.1

5.1

E7018

E7018

E7018

E7018

L B-52-18

LB-52-18

LB-52-18

LB-52-18

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

NAME :

DATE :

DCEP

DCEP

DCEP

DCEP

60 - 90

80 - 120

80 - 120

100 - 150

20 - 24

22 - 30

22 - 30

25 - 32

10 - 18

15 - 20

15 - 20

16 - 28

10 Max

10 Max

10 Max

12 Max

QUALIFICATION RANGE

Outside Diameter (O.D) from 2.375 inch (60.3 mm) through 12.750 inch (323.9 mm). - TBA

Nominal pipe wall thickness from 0.188 inch (4.8 mm) through 0.750 inch (19.1 mm).

Specified min. yield strength greater than or equal to 65000 psi (448 Mpa).

Butt welding of pipes, fittings or valves of the above diameter, thickness and material group.

TIME LAPSE BETWEEN ALL PASSES

TYPE & REMOVAL OF LINE-UP CLAMP

N/A

STRING OR WEAVE BEAD

INITIAL/INTERPASS CLEANING METHOD

OSCILLATION

MULTIPLE OR SINGLE PASS (PER SIDE)

MULTIPLE OR SINGLE ELECTRODE(S)

MANUFACTURER

Plate

SHIELDING GAS

SIZE (mm)

WELD LAYER /

PASS

CONSUMABLE ELECTRODE

Root

Hot

Fill

Cap

HEAT INPUT

(KJ/cm)

TRAVEL SPEED

(cm/min)

SUPPORTING PQR NO.

TEST PIECE

VOLTAGE

(V)

API STANDARD 1104

AMPERAGE

(A)

POLARITY

REFERENCE STANDARD

5 - 10 Min MAX

N/A

TECHNIQUE

String and weave (Weave Max. 3 x Core of Electrode)

Wire brushing and/or grinding

N/A

CONTACT TUBE-WORK DISTANCE

Multiple

ORIFICE OR GAS CUP SIZE

Single

PEENING

INSPECTION AUTHORITY

CLIENT

NAME :

DATE :

NAME :

DATE :

N/A

N/A

N/A

You might also like

- PQR For 32 MM PlateDocument1 pagePQR For 32 MM PlateMuhammed MubeenNo ratings yet

- PQR Asme Template EDITABLEDocument6 pagesPQR Asme Template EDITABLErcpretoriusNo ratings yet

- Engineering Standards Manual - Welding Standards M Anual - Volume 3 Welding Procedure SpecificationsDocument3 pagesEngineering Standards Manual - Welding Standards M Anual - Volume 3 Welding Procedure Specificationslaz_k50% (2)

- Qw-482 Suggested Format For Welding Procedure Specifications (WPS) (See QW-200.1, Section IX, ASME Boiler and Pressure Vessel Code)Document8 pagesQw-482 Suggested Format For Welding Procedure Specifications (WPS) (See QW-200.1, Section IX, ASME Boiler and Pressure Vessel Code)Muhammad HannanNo ratings yet

- Report on Welding Procedure Specifications for Single V-Groove JointsDocument15 pagesReport on Welding Procedure Specifications for Single V-Groove JointsAvishek Gupta100% (1)

- Madina Trading WPS No. 017Document12 pagesMadina Trading WPS No. 017MAT-LIONNo ratings yet

- Welding Procedure Specification: Wps No.: Bpscl/Shel/Wps - 05 DateDocument2 pagesWelding Procedure Specification: Wps No.: Bpscl/Shel/Wps - 05 DateAmjad PathanNo ratings yet

- 004 Gtaw P5aDocument16 pages004 Gtaw P5aMuhammad Fitransyah Syamsuar Putra100% (1)

- WPQ Template (Asme Ix) No LogoDocument4 pagesWPQ Template (Asme Ix) No LogorcpretoriusNo ratings yet

- Ilcs-Smaw-D1.3-Deck (G) WPSDocument3 pagesIlcs-Smaw-D1.3-Deck (G) WPSRoss100% (1)

- WPS-PQR ListDocument1 pageWPS-PQR ListSandra SandersNo ratings yet

- WPS 2014-002 006 - 6G PipeDocument3 pagesWPS 2014-002 006 - 6G PipejeswinNo ratings yet

- 1035 03Document2 pages1035 03Anuj ShahiNo ratings yet

- WPS & PQRDocument24 pagesWPS & PQRtulasirao.nammiNo ratings yet

- WPS SampleDocument182 pagesWPS Sampleaymenfr23No ratings yet

- SS WPSDocument1 pageSS WPSMOHAMEDABBASNo ratings yet

- API Welding Procedure Specification PDFDocument3 pagesAPI Welding Procedure Specification PDFBob LeeNo ratings yet

- 2.QC Inspection Test Report With Procedure For MS Tank With FRP Lining - APPROVEDDocument9 pages2.QC Inspection Test Report With Procedure For MS Tank With FRP Lining - APPROVEDSripathi SeetharamanNo ratings yet

- WPS PQR-05Document10 pagesWPS PQR-05Ranjan KumarNo ratings yet

- Duplex Ss Welding PDF FreeDocument8 pagesDuplex Ss Welding PDF Freeel_sharkawy2011No ratings yet

- All Position Stainless Steel Welding ProcedureDocument6 pagesAll Position Stainless Steel Welding ProcedureJaime PatrónNo ratings yet

- Quality Oriented and ISO Approved Stainless Steel 904L Buttweld Pipe Fittings Manufacturer in IndiaDocument5 pagesQuality Oriented and ISO Approved Stainless Steel 904L Buttweld Pipe Fittings Manufacturer in IndiaPetromat Oil and Gas Equipment Pvt. Ltd.No ratings yet

- GMAWDocument12 pagesGMAWsushant47No ratings yet

- WPS Format For ASME IX - PQR-AllDocument3 pagesWPS Format For ASME IX - PQR-AllThe Welding Inspections Community100% (1)

- WELDER QUALIFICATION REPORTDocument2 pagesWELDER QUALIFICATION REPORTAkash Singh TomarNo ratings yet

- STD 1104 - Welding of Pipelines and Related FacilitiesDocument38 pagesSTD 1104 - Welding of Pipelines and Related FacilitiesGishnu SunilNo ratings yet

- Pwps Jo Wps Asme 016 Rev.001Document2 pagesPwps Jo Wps Asme 016 Rev.001Bagandi ManurungNo ratings yet

- WPS Resrvoire Sous Pression Smaw SawDocument6 pagesWPS Resrvoire Sous Pression Smaw SawDanem HalasNo ratings yet

- Joints (Qw-402) DetailsDocument3 pagesJoints (Qw-402) DetailsNaqqash SajidNo ratings yet

- WPQ Sample PrintoutDocument1 pageWPQ Sample PrintoutKannan VelNo ratings yet

- QW 483Document2 pagesQW 483delta lab sangliNo ratings yet

- Wps GT 9b Cvn90 Rev 1 PDFDocument6 pagesWps GT 9b Cvn90 Rev 1 PDFM. Zaki RahmaniNo ratings yet

- Wps Mma PipeDocument2 pagesWps Mma PipeDimitris NikouNo ratings yet

- Wps PQR Spec IndexDocument1 pageWps PQR Spec IndexTridib DeyNo ratings yet

- Ferrite Content ReportDocument2 pagesFerrite Content ReportJawad MunirNo ratings yet

- WPS List For Piping: (Asme Section Ix)Document2 pagesWPS List For Piping: (Asme Section Ix)Ali MoosaviNo ratings yet

- Welding Procedure Specification (WPS) : N.A N.ADocument1 pageWelding Procedure Specification (WPS) : N.A N.AMajdi JerbiNo ratings yet

- Wps 1010 IfrDocument28 pagesWps 1010 IfrSyed Mahmud Habibur RahmanNo ratings yet

- Duplex Stainless Steel - Part 2 - TWIDocument6 pagesDuplex Stainless Steel - Part 2 - TWItuanNo ratings yet

- Welding Procedure Specification: Aws D.1.1 / D.1.1 M - Structural Welding Code - SteelDocument3 pagesWelding Procedure Specification: Aws D.1.1 / D.1.1 M - Structural Welding Code - SteelBudi Setia RahmanNo ratings yet

- QCF312 WPQRDocument2 pagesQCF312 WPQRminhnnNo ratings yet

- Welding Inspection Consumables PDFDocument28 pagesWelding Inspection Consumables PDFJoseph PeterNo ratings yet

- 163 Gmaw Zug Asme (Sri Supatmi 3g) WPQDocument4 pages163 Gmaw Zug Asme (Sri Supatmi 3g) WPQMuhammad Fitransyah Syamsuar PutraNo ratings yet

- Wps For Aluminium WeldingDocument8 pagesWps For Aluminium WeldingMohammed MusaNo ratings yet

- WPS for Welding SA-335 P11 to SA-234 WP11Document3 pagesWPS for Welding SA-335 P11 to SA-234 WP11Ganesh rohitNo ratings yet

- Wps Sp14 Reva PDFDocument9 pagesWps Sp14 Reva PDFravi00098No ratings yet

- Welding Procedure Qualification Record: Shipyard LogoDocument4 pagesWelding Procedure Qualification Record: Shipyard LogoGökhan TEZCAN100% (1)

- WPS - 023Document10 pagesWPS - 023MAT-LION0% (1)

- WPS Format For Asme Ix - Wps - Gtaw - OverlayDocument1 pageWPS Format For Asme Ix - Wps - Gtaw - OverlayThe Welding Inspections Community100% (1)

- WPSPQRDocument11 pagesWPSPQR0502raviNo ratings yet

- WPS for FCAW Welding of SteelDocument2 pagesWPS for FCAW Welding of SteelHamid MansouriNo ratings yet

- CSM-QR-02-2, Medical Gas BPS TablesDocument8 pagesCSM-QR-02-2, Medical Gas BPS TablesaadmaadmNo ratings yet

- HHHHHHHHJJJJJJ: O O O ODocument1 pageHHHHHHHHJJJJJJ: O O O OAli MoosaviNo ratings yet

- WELDING PROCEDURE SPECIFICATION FOR STAINLESS STEELDocument4 pagesWELDING PROCEDURE SPECIFICATION FOR STAINLESS STEELAldeline SungahidNo ratings yet

- 145B9973 - Off Base Piping List of Lines PDFDocument4 pages145B9973 - Off Base Piping List of Lines PDFHumayun NawazNo ratings yet

- WPS PQRDocument51 pagesWPS PQRLuis Muñoz100% (1)

- WPS FormatDocument1 pageWPS FormatAbdullah AnsariNo ratings yet

- English Unit Spec SheetDocument3 pagesEnglish Unit Spec SheetDanang PrakosaNo ratings yet

- Air Filter Regulator CA Gas 94539Document2 pagesAir Filter Regulator CA Gas 94539mishtinilNo ratings yet

- WPS - D1.1 - Prequalified Procedures QSSLDocument26 pagesWPS - D1.1 - Prequalified Procedures QSSLfazeel mohammedNo ratings yet

- Bosch Solution 6000 Alarm System With 3 X Gen 2 Quad DetectorsDocument12 pagesBosch Solution 6000 Alarm System With 3 X Gen 2 Quad DetectorsErick HoganNo ratings yet

- Wall Street English - Phrasal VerbsDocument138 pagesWall Street English - Phrasal VerbsHou Sam100% (3)

- Collins - Cobuild Key Words For IELTS Book 3 Advanced PDFDocument384 pagesCollins - Cobuild Key Words For IELTS Book 3 Advanced PDFIris NguyễnNo ratings yet

- Bosch Solution 2000 Alarm System Fully Installed - Brilliant Technology SolutionsDocument5 pagesBosch Solution 2000 Alarm System Fully Installed - Brilliant Technology SolutionsErick HoganNo ratings yet

- Webster's Dictionary of English Usage PDFDocument994 pagesWebster's Dictionary of English Usage PDFAdam Frick98% (44)

- Idioms and Phra Sal VerbsDocument130 pagesIdioms and Phra Sal VerbsmissnancyrcNo ratings yet

- 550 English Phrasal VerbsDocument13 pages550 English Phrasal Verbsravi00098100% (1)

- Phrasal Verbs A To ZDocument94 pagesPhrasal Verbs A To Zravi00098No ratings yet

- Phrasal Verbs TesisDocument317 pagesPhrasal Verbs TesisEl Lauta100% (16)

- Barbara K. Gaines - Idiomatic American English, A Step-By-Step Workbook For Learning Everyday American Expressions (1986)Document123 pagesBarbara K. Gaines - Idiomatic American English, A Step-By-Step Workbook For Learning Everyday American Expressions (1986)Maciej Kassner80% (5)

- Usage Abusage PDFDocument382 pagesUsage Abusage PDFFaith DawnNo ratings yet

- Alex and His Everyday IdiomsDocument129 pagesAlex and His Everyday IdiomsAlex Marin100% (21)

- Illustrated Everyday Expressions With Stories 1 128pDocument128 pagesIllustrated Everyday Expressions With Stories 1 128pmonkeynotes100% (4)

- Ultimate Word Power PDFDocument66 pagesUltimate Word Power PDFjoemarNo ratings yet

- Dictionary of IdiomsDocument224 pagesDictionary of IdiomsDiridane96% (28)

- Cambridge English Vocabulary PDFDocument269 pagesCambridge English Vocabulary PDFErick HoganNo ratings yet

- Phrasal VerbDocument13 pagesPhrasal Verbravi00098No ratings yet

- Common Phrasal VerbsDocument12 pagesCommon Phrasal VerbsvladicabNo ratings yet

- 101 English Words Youll Never Learn in School 1Document55 pages101 English Words Youll Never Learn in School 1Luiza Sorice100% (2)

- DictionaryDocument301 pagesDictionaryflink100% (1)

- Phrasal Verbs Organiser PDFDocument151 pagesPhrasal Verbs Organiser PDFTamara Stojanović100% (3)

- Week13 Iron Carbon Phase DiagramDocument49 pagesWeek13 Iron Carbon Phase DiagramvishalNo ratings yet

- Business Phrasal VerbsDocument127 pagesBusiness Phrasal VerbsTiago Cuba100% (2)

- Welding Metallurgy PC 1 PPT 2 PDFDocument50 pagesWelding Metallurgy PC 1 PPT 2 PDFErick HoganNo ratings yet

- SS 304 A PDFDocument11 pagesSS 304 A PDFkanchanabalajiNo ratings yet

- Phrasal VerbsDocument33 pagesPhrasal VerbsblinblinwebboyNo ratings yet

- Welding Metallurgy - Detailed PDFDocument28 pagesWelding Metallurgy - Detailed PDFkarcoepm100% (1)

- Stainless Steel Five TypesDocument40 pagesStainless Steel Five Typessids82No ratings yet

- Iron Carbon Part1 PDFDocument33 pagesIron Carbon Part1 PDFErick HoganNo ratings yet

- Welding InconelDocument5 pagesWelding Inconelc_e_z_a_rNo ratings yet