Professional Documents

Culture Documents

Laying of Cables Brochure

Uploaded by

urs50 ratings0% found this document useful (0 votes)

26 views8 pagesLaying Of Cables Drums

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentLaying Of Cables Drums

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

26 views8 pagesLaying of Cables Brochure

Uploaded by

urs5Laying Of Cables Drums

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 8

OIA

PROFESSIONAL GUIDELINES FOR

LAYING OF CABLES

©

POLYCAG

INDEX

1.1. Cable inspection

1.2. Cables Damages in Transit

1.3 Cable Handling & Storage

2.1. Unreeling of cable from drum.

2.2 Special precautions for unreeling and

installation of Helogen free low smoke sheathed cables.

2.3 Laying Methods

2.4 Bonding Methods

2.5 Lugs and glands

Recommended Procedure For Testing of Cables at

Site After Laying and Commissioning.

1 PRE INSTALLATION

1.1 Gableinspection

+ The cable marking orlabelshallbe checked against the sze/type of cable lo avold possible labellg/marking erors by the packers anc also

the cable solectedis proper for designed application.

+ While opening the packing. a carefulwatch should bemadete eneure tools used in opening donat damage the lyersof cable,

+ Thecablehasnot been damaged intransitor unloading orstorage,

1.2Cable Damages in Transit

Transit Damage is a common problem which occurs during unloading /shiting of cable drums or during transshipment by transporter.

Damages in factory generally donot occur as drums are packed with wooden planks and handled using overnead cranes fois, To lentty

any uchdamagetocabledhum andl cable:

+ Inspect visually every cablereelagansl transit damage such as packing, damage before accepting the shipment

+ Be paricutaly alr for cable derrage i: I) Areol's Wing flat on ts sce. Several oals ave stacked one over the other ih Other treightis:

stacked onarclIV Gable drumsare without weodan planks or broken,

+ Acableene!sealis removed or damaged.

+ Machanicaldamages can cause: Tearing of Outer Sheath Il Bending /breakage of armour wires sts Damage ofinsulaton

+ IFthere are only smal sheath damages anc! armour is found intact the cable can be considered for use, after doing necessary repar on

‘Shoat and tostng the cable for High Pot tstorinsukatln tests (Moggar test)

* the testresuts of insulation resistance is fourd very less (Phase concluctor to armour sho, the cable shale cut a that portion and the

‘woplecesare to be again tested, Cable lengtns wth good megger values can be taker fo jointing and charging.

+ Incase of doulttultest results or major damages please:

the matterto Polycab Customer care |

store

re@polycab.com)

1.3 Cable Handling & Storage

carols takeninthe manufacturing ofcable to ensure qualty at every stage.

+ Handing ofcableat

damaged,

tls the next important factor to ensure that by mishandling the cable, the outer shea andl insulation shall nt get

‘Thehandling is generally cari outby unskilled or somi-skilod men, strict supenision shouktbe maintained so tat the cable, which can

‘be vor easly damagod, ishandled with great care.

Pra

\When offloading ross from a truck, Never crop reels. reels

lower reals caretuly using ‘must be rolled, lin

a hydraulic gate, ‘opposite draction of the

hoist o fort ruck cable weave to keep cable

from loosening on the rea

%

la forklifts used for handing and shitting the cable | | Do not allow the It orks to contact t

‘drumathe forks shall approach the real tom the Care must be taken by the fori

flange side, The forks all be ‘operator not to make eudden yt

tums of rope.

ppositoned such that the reals

When using a hoist, installa mandrel This may lead to the bending of the ree!

through the reel arbor holes and flanges and mashing the cable,

aitach a sling. Use a spreader bar

approximately 6 inches longer

than the overall eal width placed

between the sling ends just

above the reel flanges.

abe

Iited with both reel fanges.

s

mH

©

aH

EE eee Cea

Its alvaye safer to use a stong and well-draines

surface for storing crams. I possible, the orume

‘should be ra'sad fom the ground by the insertion of

wooden plans, ec, below and on both sides o the

drums : some check pieces should be placed s0 as

not to alow the drums tobe role,

bbosely and easily, Cable drums

‘should also be stored away trom

the rect sun and rains.

Reason : Direct suvays can

‘cause deterioration due to UV rays and rn can

‘cause damage to wooden cum, resuling dum

ccolzose after few months.

Muttole reels stacked on top of each other

("Pancake" storage is not recommended for cablo

cums. The weight of the stack can total thousands

of kgs. creatng an enormous load on the bottom

real. Also, damage tothe reel andor cable wil ikely

‘occur when the reels tipped for

transi. A concentration of stress

fon the reel lange may cause it

to break ang subsequent

damage the cable

Always use proper stoppers to

prevent the drum from roling,

When roling in the direction

of the arrow, never rll for

more than § metres

COtremise the cable may

become unfit for use,

Ensure stoppers for every drum, to prevent

mishaps during storage. Place the wedges by the

‘langas/tullwidt ofthe drum

© ge

I em

‘Allowthe drums to rollatany cost. Stack the drums.

‘onnon-trangular/non-square wedges

rae

During transportation, fasten

drums to the base through the

central hole

Fasten without taking a! Oe

care. Always use support, and

tie the drum from both the = ee

ine Om

Use a winch, forlit or makeshit ramp.

Se ee

‘Allow one drum to strike another.

Se 2%

cen

BN)

ACO

Ni Mirman Perea bending aca o cab

()

mt

2 INSTALLATION & LAYING

2.1 Unreeling (Cable Pulling)

+ For unreeling cable ‘tom a crum It should be mounted on cable jack. The drum should be lited above the ground with clearance of

'50-100rmm gothatwhilaunreelng the drum flanges shouldnot ouch the ground and get damaged.

+ Tre cum should never be Kept flat on its side on the ground and the cable unroele in coll rom the same. This invariably leads to

kinking andbia-caging

+ "Br-Caging'isadefect caused de to twist of cable during wrong unreeingtresuts ovtersheath crack or cuts andarmour sweling.

Photograph ofbirdeaging,

'+ The technique of puling cables is also an important, Sub-standlars and haphazard handling can cause damage to the cable which may

‘weaken the cable components, ancl cause a falue in due course. Care must be taken to select sultable poston forthe cable crum acs in

‘order lo ensure that the drum may be raised and rotated with full safely. The jacks should therefore be placed on a frm support of

thick boards,

* Care shoul be taken to ext a steady pull voicing ary jerks. Twisting or kinking or cable is vary dangerous as ths may cause damage to

the smal size of cable conductor, insulion and sheath, shiting and knife-edging of the armouring and damage to te serving, etc. Care

shouldbe taken toavord shortbends and coneequent staining of conductors

+ Properhancling of cables is ver/important both for safety as wellas longi ofthe instalation.

+ Themoet common causes of able faire are due to mshandling ofthe product installation etage

‘+ This canbe prevented by urinding the cabk by loading the crum on jacks pling the proper crection with stocking or puling eye

+ Ferpuling longo lengths and higher ameter of cables Puling Eyes canbe used.

+n case of smaller lengths, pulling is carrac! out by manual labour and when the fangth is longer by means. of winches or other

‘mechanealmeans.

+ While puling with arope,careis necessary to avoid bending ofthe cable a close watch should be maintained to ensure the cable runs freely

‘over the cable rollers and passes smooth without ubbing against any surface.

Recommended Minimum Bending Radius For HT Gables /LV Cables /Single Core Unsheathed.

HT ables: Shgle Core:20xD Multicore: 15xD

Lv Cables: Single Gore: 18xD Multicore: 12xD

Shgle Core Unsreathod: SingleCore:8xD —__WhereD=Diameterofcablein mm)

Recommended Safe oulling Fores With Stockings

‘a ForUnamoued Cable: P=5D2 Where

b) FerArmouedCabk: — P=902 (Where!

Recommended Safe Pulling Force When Pulled With Pulling Eye

a) For Aluminium Conductors S0Nimm2

Puling force)

Diameter ofcableinm)

1) ForCopper Conductor: SONmm2

Donot hammer metallic objects ke nailon the cable for fixing it. This leads to direct shorting and failure of cable.

©

ti

2.2 Special precautions for unreeling and installation of Helogen free law smoke sheathed cables.

Cables having Low helogen polymer (SOM sheath needs tolsehandled with more cave duringinetallason, While special adkstives are used in

formulation of LSOH compound to give the typical lame retardant charactertice of Zero halogen polmers some mechanical properties

detrirate, The folowing basic precautions arenecessary

+ Cablee should net be exposed te sunight for considerable period before netalaion. the temperature of cable sheath shouts be below

400 celsius

‘+ Profeably installation shallbe done when the ambient temperatures +5 Dey C1030 Deg,

+ Urveating alow temperature below 5 eg.G andigh temperature above 40 Deg, C. can cause sheath crackat bends.

+ Wire/ Rope should not beusedrectl on the cable sheath or pling.

+ When pllecion cable rays/or any uneven surface, specialattentonis naeded o weking or unusually rough trans

‘Rollers ancibands shoukinot have any sharpness which may damage sheath

2.3 Laying Methods

Formore details referIS 12

forlndian coneitons and detailed catalogue of manufacturer

Single Core Cables — Installed in Parallel

he Foloning rules mustbe observed

‘Cable shouldhave the same cross-sectonalarea,

+ Cables should nave the sametype & const

+ They shouldfollowthe same path

+ Theymustbectthe sams length substartialy.

‘+ They cannot bemadoto operate ndvidualy,

+ They mustnotinclude arybranch ccuits along theirroute.

Cable pertaning to the same phase shouki bo as far as pra

currents avoided For hvae single core cables per phase, thet

blo altoratod with those cable ofthe othor phase so that unequal division of

rect spositions are:

FOR SINGLE CORE CABLES

2.4 Bonding Methods:

Muticore cables

+ Alutcore cables shallbe boncied with both end bonding, as the phenomenon of culating curent

‘core cables only

1nd sheath votage related to single

For Single core cables: Single point bonding

+ Screens connected and earthed atoneand.

+ Noclosedcruit, hence screen cxculating curentis elminates.

+ Normally used for lang outelengthslabove 1.2 kM),

+ Tremaximum allowable sheath voltage shallbe 65 volts, or cables wit single point bonding

Both end bonding

+ Cable screen bonded and earthed at both end.

+ Results circulating curentin cable whichis clroctlyproportionaltocurent cariedlby consucto.

+ NoSheathvottage

+ Losses canbe minimized by ying cable in TREFOIL formation.

2.5 Lugs & Glands.

+ tis sean as a practice of fow ofthe users that they insert the conductor inthe lugs or the cable inside a gland and if found loose they

‘complain that he conductor/cableis undersized

+ Cablee of same ve has so many types of conductor conelructons with which the OD can vary to great extent Le, cables with round

stranded conductors, bunched concluctors, compact and shaped conductors et,

+ Soctor shaped conductors and compact round conductors ae the types which have minimum possible conductor ameter. When cables

are madewith ths conductors the OD willberinimum,

+ When such Conductors ao used for making XLPE insulated cablos, tho OD will be further reduced as te thickness of XLPE insulation is

{urtherless than thal of PVC.

+ Insuchcases tmay experienced thatlugs and glands etc are much boseto the conductors cables,

+ This practice is not the method to asses the size ofthe conductor or cable. Capacity ofthe conductors can be confemed by measuring

‘conclvcterresistance ofthe cable,

3. SITETESTING

Recommended procedure for testing cables at site after laying and commissioning,

1. Thecables shall visually checked forany hanling damages.

2. Afterunreeting the cables from drum and|ayingitto the desired locaton, prepare both the ends ofcablesfortestng

8. Remove approx 300 - 400 mm length of outer covering PVC Sheath Armour, Bedding et, separate the cores and remove conductor

insulation forapphying the voltage.

4 For cables up to 1000 vols rating, hsulation resistance ehall be measured with 1000 vols magger and values of each core shall be

recorded. These values shall not fer rom each other more than 10% to 15%,

5. For cables 86 KV and above - DC High voltage testing shall be cartlod out before making torminations in exder to find any laying /

hanaling damages.

‘8. Forscreonad cables, the copper seroon, somi-conducting layers shallbo removed approximately 150mm, rom both ends ofthe cabo

‘Thedemoisas below

Lv Cable HV screened cable

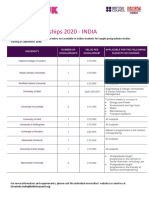

Following Test / Test Voltages shall be apple:

“Test requirements ater installation (Before Crergingh"*

Sr.No | Voltage Grade | Insulation Resistance | Observation WV test * Remarks

ofcable | Test (Megger Test) (iv DC Test)

1 | weiaw 1000 vats Ves ofeach coe | NotRecarmerded | coe o amour IRvabes

‘amour care ce shal be geval same fr

‘sal b ee, Mores esta othe cable

Chum elena

2 | sawn 25K Vues eteacieueto | skort | Coe esceevamour vals

8/660 vom aramau'and | and 05k | shale gerry sare te at

retnce sal | or BOK Gabe, | cae eas rb cal un

erected. | Duan 18 ines | erent, rsa

‘wand Veh

3 | easnw sky Vales each sore tek ‘ore sreeveraur

taseren or ameur and | Duaton 15 Virtes | Rvalie shale geeraly

oxo ove sal sae er a oes esto

be rece ‘he cable cum reg

sha estan HV et

4 ww 5h Vales teach cre sow ore screeveraur

‘ascren er amour and | Dualon 5 Vues | Rai shale general

‘etocue sane for a cores ste or

shal ree ‘he cble um leg

shal westand HV test

s | rareew sk us of each cee a5 caret sreierour

soem arama 2nd | Dual 5 Vrtes | vas sabe geval

ue sae a aes este or

shat eae. th cab du or nah,

salt Vel

6 sa sky \atus a each coe sony core sreearaur

twscren or amu and | Dyaton 15 Vrtes | vais sabe geal

fone ve al sae fe a aes eo or

ered tha cable du rng

ha tad Vt

~ OCHY Tes vag sper 1255 “or Cals above 3 kt Pave eer mauactrer Datasheet or peo gules.

“The cables shouldbe preferably tested before charging to avoid any damages inte intenaloflaying & charging,

Insome cases VLF Testing (AC. HV Testng)is alsorecommended

‘+ After DC test, the conductor of cable halle earthed for 2 minutes o for a auitable tne In order to remove any residual

charge fortheXLPE Insulation.

©

POLYCAG

‘CORPORATE OFFICE

POLYCAB WIRES PVTLID.

Polyab House, 771, Pant Sawaletar Mag, Mahim (W), Mumbai 40 06.

Te 91-22-2492 7070 4 6795 1400+ Fax: 91-22-2432 7075,

Weoste wir-poheab.com » Eall: nauny@poweab com

Follow us on: KE] wwefacebook com/Palyeablnd

G wotwtterconvPoycabindia

{ ninkesn comicompanyPoyead

You might also like

- Inner Recesses Outer Spaces MemoirsDocument419 pagesInner Recesses Outer Spaces MemoirsPraveen PeethambaranNo ratings yet

- All Art Is Propaganda PDFDocument2,708 pagesAll Art Is Propaganda PDFPau_Brand_25500% (2)

- Pro ControlDocument41 pagesPro Controlntpckaniha100% (2)

- Gas Turbine ManualDocument162 pagesGas Turbine ManualShivam Kumar100% (2)

- Greenwashing Nas EmpresasDocument37 pagesGreenwashing Nas EmpresasLara GagoNo ratings yet

- 388 1006 1 PBDocument20 pages388 1006 1 PBGabriel Evangelista dos SantosNo ratings yet

- Detail (1-1) To R.C. Strip Footing (Sf1) : A B E F H J KDocument1 pageDetail (1-1) To R.C. Strip Footing (Sf1) : A B E F H J KThomas Garcia0% (1)

- 5756867Document1,027 pages5756867Sách Việt Nam50% (2)

- Lagenda Violin PDFDocument2 pagesLagenda Violin PDFMarvin Jong0% (1)

- ElvisDocument1 pageElvismaui3No ratings yet

- Renault Inyección Electrónica Clio 1.4 Ac Delco Monopoint P PDFDocument2 pagesRenault Inyección Electrónica Clio 1.4 Ac Delco Monopoint P PDFGood CarNo ratings yet

- El Pastor - VihuelaDocument1 pageEl Pastor - VihuelaDamian Guardia SalazarNo ratings yet

- UTS ELT MDE S1 Coursebook Evaluation ChecklistDocument3 pagesUTS ELT MDE S1 Coursebook Evaluation ChecklistHanin Khalishah WaqqasNo ratings yet

- Los Mareados Arreglo Hernan PossettiDocument2 pagesLos Mareados Arreglo Hernan PossettiteomondejarmusicaNo ratings yet

- 113-SEW Brake DetailsDocument10 pages113-SEW Brake DetailsTarak Nath RakshitNo ratings yet

- PDF Parts Catalog Tvs Rockz - CompressDocument104 pagesPDF Parts Catalog Tvs Rockz - CompressaspareteNo ratings yet

- Business Startup Guides-Preparing Yourself Ver 2Document4 pagesBusiness Startup Guides-Preparing Yourself Ver 2Minh Huỳnh100% (1)

- Paradise Violín IIDocument2 pagesParadise Violín IIJavier Rubio PérezNo ratings yet

- 2020Document14 pages2020mintrikpalougoudjoNo ratings yet

- Calculus Cheat Sheet DerivativesDocument4 pagesCalculus Cheat Sheet DerivativesRajatNo ratings yet

- Planes APIDocument10 pagesPlanes APIManuel FigueroaNo ratings yet

- Aural RitmoDocument1 pageAural RitmofabioNo ratings yet

- Music To Watch Girls by MJDocument3 pagesMusic To Watch Girls by MJMarvin JongNo ratings yet

- Hecho Del PíncipeDocument11 pagesHecho Del PíncipeEdisson MoralesNo ratings yet

- Mix Trompeta ChilombianoDocument1 pageMix Trompeta ChilombianoDenise AlvaradoNo ratings yet

- Trompeta 1Document2 pagesTrompeta 1Mauricio TorresNo ratings yet

- 01 - Lista de Parametros SimplificadaDocument8 pages01 - Lista de Parametros SimplificadaLuis Felipe VidigalNo ratings yet

- Renault Inyección Electrónica Kangoo RL-RN 1.6 1999 Siemens Sirius 32b PDFDocument2 pagesRenault Inyección Electrónica Kangoo RL-RN 1.6 1999 Siemens Sirius 32b PDFOsvaldo LópezNo ratings yet

- Trompeta 2Document2 pagesTrompeta 2Mauricio TorresNo ratings yet

- Xsara 18 - Berlingo 18 - 18 Xu7jb PDFDocument2 pagesXsara 18 - Berlingo 18 - 18 Xu7jb PDFJorge Daniel DiazNo ratings yet

- Indian Express 19 AugustDocument20 pagesIndian Express 19 AugustTension Dene kaNo ratings yet

- Cicuta Tibia - TubaDocument2 pagesCicuta Tibia - TubaYohan Octavio Vera DelgadoNo ratings yet

- Ibfc 142 Engenheiro MecanicoDocument16 pagesIbfc 142 Engenheiro MecanicoJosé Maria junior100% (2)

- What A Wonderful World Eb - Bass Trombone PDFDocument1 pageWhat A Wonderful World Eb - Bass Trombone PDFJose HerreroNo ratings yet

- GM Inyección Electrónica S10 Blazer 2.2 Efi Delphi Multec emDocument2 pagesGM Inyección Electrónica S10 Blazer 2.2 Efi Delphi Multec emyayixdfuego131No ratings yet

- 6periostitisDocument10 pages6periostitisAntonioNo ratings yet

- 5Document2 pages5Abel Salazar PianoNo ratings yet

- 09 - Chapter 1Document20 pages09 - Chapter 1Dr. POONAM KAUSHALNo ratings yet

- Flow Design Formulas For Calculation - Exported From (HTM - 02 - 01 - Part - A)Document8 pagesFlow Design Formulas For Calculation - Exported From (HTM - 02 - 01 - Part - A)wesam allabadi50% (2)

- Extracto Destinos-Elementos-para-la-gestión-de-destinos-turisticosDocument76 pagesExtracto Destinos-Elementos-para-la-gestión-de-destinos-turisticosEnzo Navarrete UlloaNo ratings yet

- Strong Enough - DrumsDocument2 pagesStrong Enough - DrumsКолянсур ИвановNo ratings yet

- Tu Me Gustas Trompeta 1Document2 pagesTu Me Gustas Trompeta 1JonathanNo ratings yet

- GM Relés y Fusibles Corsa PDFDocument1 pageGM Relés y Fusibles Corsa PDFcorylinNo ratings yet

- Enfermeiro Ebsrh 2015Document10 pagesEnfermeiro Ebsrh 2015Neila Reis da SilvaNo ratings yet

- Charles D Ghilani - Paul R Wolf - Elementary Surveying - An Introduction To Geomatics-Pearson Prentice Hall (2012) - ExtractoDocument19 pagesCharles D Ghilani - Paul R Wolf - Elementary Surveying - An Introduction To Geomatics-Pearson Prentice Hall (2012) - ExtractoRodrigo DelBarrioNo ratings yet

- Mix Serpiente - BandaDocument53 pagesMix Serpiente - BandaJohn Carlos Vilca VelizNo ratings yet

- 101 Problems in AlgebraDocument160 pages101 Problems in AlgebraTrishaii Cuaresma96% (28)

- Tema 6. CULTURADocument7 pagesTema 6. CULTURAMarinaNo ratings yet

- Fiat CoupeDocument1 pageFiat CoupeJulio FaninNo ratings yet

- Elec 4 BlackDocument1 pageElec 4 Blackyudo08No ratings yet

- Como Quien Pierde Una Estrella VozDocument2 pagesComo Quien Pierde Una Estrella VozGerardo100% (2)

- All The Things You AreDocument1 pageAll The Things You ArePeppe LiottaNo ratings yet

- Taita Salasaca - Conga Drums 2Document2 pagesTaita Salasaca - Conga Drums 2Carlos XavierNo ratings yet

- Building ActDocument136 pagesBuilding ActVeronika RaušováNo ratings yet

- Excercise in FDocument2 pagesExcercise in FPaz Villahoz100% (2)

- Escort 18 16 ZetecDocument2 pagesEscort 18 16 ZetecOsvaldo LópezNo ratings yet

- MNRE DRC File f-1646300805213Document18 pagesMNRE DRC File f-1646300805213Praveen PeethambaranNo ratings yet

- Executive Post Graduate Certificate Programme in Operations ManagementDocument1 pageExecutive Post Graduate Certificate Programme in Operations ManagementPraveen PeethambaranNo ratings yet

- PhDregulations 2018Document29 pagesPhDregulations 2018ManilalPNo ratings yet

- Executive Post Graduate Certificate Programme in Operations ManagementDocument1 pageExecutive Post Graduate Certificate Programme in Operations ManagementPraveen PeethambaranNo ratings yet

- Great Scholarship 2020 Final 20 PDFDocument1 pageGreat Scholarship 2020 Final 20 PDFPraveen PeethambaranNo ratings yet

- M365 License FeaturesDocument4 pagesM365 License FeaturesPraveen PeethambaranNo ratings yet

- PythonDocument635 pagesPythonPraveen PeethambaranNo ratings yet

- Information Brochure 2019 AugustDocument26 pagesInformation Brochure 2019 AugustPraveen PeethambaranNo ratings yet

- DO113xA / DT113xA / DOT1131A Automatic Fire Detectors: Building TechnologiesDocument6 pagesDO113xA / DT113xA / DOT1131A Automatic Fire Detectors: Building TechnologiesPraveen PeethambaranNo ratings yet

- WT 050 455 000 de Ps Gms-Plus PDFDocument2 pagesWT 050 455 000 de Ps Gms-Plus PDFPraveen PeethambaranNo ratings yet

- Indian Institute of Technology, Palakkad Ph.D. Ordinances and Regulations OrdinancesDocument15 pagesIndian Institute of Technology, Palakkad Ph.D. Ordinances and Regulations OrdinancesShabana ferozNo ratings yet

- WT 050 455 000 de Ps Gms-Plus PDFDocument2 pagesWT 050 455 000 de Ps Gms-Plus PDFPraveen PeethambaranNo ratings yet

- Admission For PHD in Management (Practice Track) 2020: Academic EligibilityDocument2 pagesAdmission For PHD in Management (Practice Track) 2020: Academic EligibilityPraveen PeethambaranNo ratings yet

- maxDNA Training ScheduleDocument1 pagemaxDNA Training SchedulePraveen PeethambaranNo ratings yet

- Constant Settable Droop Design Standard of GEDocument4 pagesConstant Settable Droop Design Standard of GEPraveen PeethambaranNo ratings yet

- Customer TrainingDocument1 pageCustomer TrainingPraveen PeethambaranNo ratings yet

- 1 2014 Estt L PDFDocument2 pages1 2014 Estt L PDFPraveen PeethambaranNo ratings yet

- Nit Floated For Taxi Service 1578566908Document49 pagesNit Floated For Taxi Service 1578566908Praveen PeethambaranNo ratings yet

- AGM & Sr. Faculty Member (PMI) NTPC LTD.: Dr. K. V. VidyanandanDocument46 pagesAGM & Sr. Faculty Member (PMI) NTPC LTD.: Dr. K. V. VidyanandanPraveen PeethambaranNo ratings yet

- Governing SystemDocument70 pagesGoverning SystemPraveen Peethambaran100% (2)

- Genr Excitation SystemsDocument4 pagesGenr Excitation SystemsPraveen PeethambaranNo ratings yet

- Vipassana PDF ManualDocument4 pagesVipassana PDF ManualbenjaminzenkNo ratings yet

- Testing of Power TransformerDocument55 pagesTesting of Power Transformeroedis83% (12)

- Solution of Differential GamesDocument6 pagesSolution of Differential GamesPraveen PeethambaranNo ratings yet

- Ccat Booklet Cv1Document37 pagesCcat Booklet Cv1Abhilash KumarNo ratings yet

- Loss-Of-Excitation Protection For Synchronous GeneratorsDocument14 pagesLoss-Of-Excitation Protection For Synchronous GeneratorsPraveen PeethambaranNo ratings yet

- Testing of Power TransformerDocument55 pagesTesting of Power Transformeroedis83% (12)