Professional Documents

Culture Documents

AGIP STD - Valves Specification Sheet

Uploaded by

halim_kaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

AGIP STD - Valves Specification Sheet

Uploaded by

halim_kaCopyright:

Available Formats

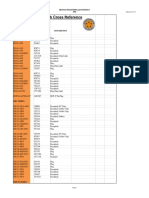

AGIP

04511.PIP.MEC.SDS

INTERNAL NORMALIZATION

Revisions

PIPING PROJECT SPECIFICATION

Sheet

of

SERVICE : NON CORROSIVE HYDROCARBONS - GLYCOL - BLOW

ITEM

DOWN - VENTS - DRAINS (T < 120C)

REFERENCE SPECIFICATIONS

E 02

1500 # RJ

20377.PIP.MEC.FUN

DRIP RINGS

15011

A 105

MATERIALS (if not otherw.stated)

ASTM STANDARDS

SPECTACLE BLINDS

15038

A 105

15039

A 105

14380

---

SPACERS & BLINDS

THDD FITTINGS

14381 A 105 / 6000# NPT

---

TEMP. STRAINERS 15050-15007

NORMAL (from pipe)

14383 API 5L Gr.B / SMLS

---

SWAGES (from pipe)

14382 API 5L Gr.B / SMLS

NIPPLES

S.W. FITTINGS

PIPES

INCH

WALL THK.

mm

SCHEDULE

MATERIAL

FLANGES

14355

SOCKET WELD

14356

THREADED

14357

SLIP ON

14358

LAP JOINT

14359

BLIND

14360

14365

STUD BOLTS & NUTS

14368

VALVES

GASKETS

1/2

ON / OFF

15801

MANUAL CONTROL

15801

CHECK

15801

STSC

RTSC

STSC

STSC

STEE

T

U

B

0

0

2

DN"

HEADER SIZE

1"

2"

4"

6"

8"

10" 12"

P - bar

----

50

230,0

----

----

100

230,0

----

----

120

230,0

----

----

-------

-------

-------

-------

14"

16" 18" 20" 24" 30" 36"

---

---

---

---

---

XXS XXS XXS XXS

---

---

---

---

---

160

160

160

160

160

160

160

160

160

160

SMLS

A 105 / 1500# RJ

A 105 / 1500# RJ

81 A 05

A 193 Gr.B7 / A 194 Gr.2H (ZINC COATING) (1)

VB 637 AG 6R1 - NPT

VB 517 AG 1C1 RJ (R.B.) O VB 517 AG 4C1 RJ (R.B. TOP ENTRY)

VB 517 AG 5C2 - RJ

(2) VB 517 AG 2C1 RJ (F.B.) O VB 517 AG 3C1 RJ (F.B. TOP ENTRY)

VD 437 AG 7R1 - NPT

VD 317 AG A01 - RJ

VD 317 AG 5C1 - RJ (5)

VDR 837 AG 3R1 - NPT

VDR 717 AG 6C1- RJ (WAFER)

VDR 717 AG 9C1- RJ (10)

FT 937 AG 5R1 - NPT

FT 917 AG 3C2 - RJ

90-45 ELBOWS

14370

A 234 Gr.WPB

CONC.REDUCTIONS

14372

A 234 Gr.WPB

ECC.REDUCTIONS

14372

A 234 Gr.WPB

ELLIPT.CAPS

14374

A 234 Gr.WPB

LJ STUB ENDS

14375

PIPE BENDS

15023

METER ELBWS

15020

15021

Mark

STEE

INTERSECTIONS

STEE

SWLT

10

3"

T - C

----

STEE

TLET

NLET

2"

P - bar

230,0

7,47 7,82 9,09 10,16 8,74 9,52 11,13 13,49 18,26 23,01 28,58 33,32 35,71 40,49

STEE

RTEE

STEE

12

Components

Material

STEE STRAIGHT BW TEE

14371

A 234 Gr.WPB

RTEE REDUCTION BW TEE

14371

A 234 Gr.WPB

STSC STRAIGHT THDD TEE

14381

A 105

RTSC REDUCTION THDD TEE

14381

A 105

STSW STRAIGHT SW TEE

14380

18

RTSW REDUCTION SW TEE

14380

20

SWLT SWEEPOLETS

15003

24

WLET WELDOLETS

15004

30

TLET THREDOLETS

14381

36

SLET SOCKOLETS

14380

NLET NIPOLETS THDD

14381

PTOP PIPE TO PIPE

15012

STEE

14

16

STEE

STEE

1/2 3/4 1 1 2

4

F

G

1"

T - C

-29 38

A 105 / 1500# RJ

15701

STSC

3/4

1/2" 3/4"

----

10,16 11,07

SMLS (THDD & CPLD)

WELDING NECK

" Y " STRAINERS

9,09

DESIGN CONDITIONS

API 5L Gr.B

14350

MANIFACTURE

M

E

C

Dimensions : ASME B 16.5 / B 16.34

WELDS EXAMINATION

7,82

1 mm

CODES - Design : ASME B 31.3

----

7,47

CORR.ALLOWANCE

MAT.

15017

5

Date

A 105

RED. S.O. FLG.S

mm

15016

20367.PIP.MEC.FUN

THICKNESS

RED. THDD FLG.S

PIPING CLASS

NOMINAL SIZE

M

O

D

COMPONENTS

20376 / 20368.PIP.MEC.FUN

06--97

Rating & Facing

WELDING AND HEAT TREATMENT

Compiled

6

DN"

10

12

14

16

BRANCH SIZE

18

20

24

30

36

A 105

A 105

A 105

NOTES:

1) All carbon steel bolting on flanges, valves & "Y" strainers shall be zinc coating

(hot-dip) to ASTM A-153.

2) To be used where required by P&I drawings only.

5) Angle valve.

10) Depressurization "NOZZLE CHECK" type valve.

Company's sole property document . Company will protect his right by law.

You might also like

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- Piping Project Specification for Non-Corrosive Hydrocarbon ServiceDocument1 pagePiping Project Specification for Non-Corrosive Hydrocarbon Servicehalim_kaNo ratings yet

- AGIP STD - Valves Specification SheetDocument1 pageAGIP STD - Valves Specification Sheethalim_kaNo ratings yet

- Specification for weakly corrosive hydrocarbon piping systemDocument1 pageSpecification for weakly corrosive hydrocarbon piping systemhalim_ka100% (1)

- AGIP STD - Valves Specification SheetDocument1 pageAGIP STD - Valves Specification Sheethalim_kaNo ratings yet

- AGIP STD - Valves Specification SheetDocument1 pageAGIP STD - Valves Specification Sheethalim_kaNo ratings yet

- AGIP STD - Valves Specification SheetDocument1 pageAGIP STD - Valves Specification Sheethalim_kaNo ratings yet

- AGIP STD - Valves Specification SheetDocument1 pageAGIP STD - Valves Specification Sheethalim_kaNo ratings yet

- AGIP STD - Valves Specification SheetDocument1 pageAGIP STD - Valves Specification Sheethalim_kaNo ratings yet

- AGIP Piping Project Specification for Non Corrosive Hydrocarbons - Glycol Blow Down - Vents - Drains (T < 120°CDocument1 pageAGIP Piping Project Specification for Non Corrosive Hydrocarbons - Glycol Blow Down - Vents - Drains (T < 120°Chalim_kaNo ratings yet

- AGIP STD - Valves Specification SheetDocument1 pageAGIP STD - Valves Specification Sheethalim_kaNo ratings yet

- Internal Normalization Piping Project Specification for Low Pressure Steam, Condensate & Boiler Feed Water SystemsDocument1 pageInternal Normalization Piping Project Specification for Low Pressure Steam, Condensate & Boiler Feed Water Systemsliviu_dovaNo ratings yet

- Internal Normalization Piping Project Specification for Weakly Corrosive HydrocarbonsDocument1 pageInternal Normalization Piping Project Specification for Weakly Corrosive Hydrocarbonsliviu_dovaNo ratings yet

- A09Document1 pageA09liviu_dovaNo ratings yet

- D11Document1 pageD11liviu_dovaNo ratings yet

- AGIP STD - Valves Specification SheetDocument1 pageAGIP STD - Valves Specification Sheethalim_kaNo ratings yet

- Piping Project Specification for Mean Pressure Steam and Steam Condensate ServiceDocument1 pagePiping Project Specification for Mean Pressure Steam and Steam Condensate Servicehalim_kaNo ratings yet

- A17Document1 pageA17liviu_dovaNo ratings yet

- AGIP STD - Valves Specification SheetDocument1 pageAGIP STD - Valves Specification Sheethalim_kaNo ratings yet

- A11Document1 pageA11liviu_dovaNo ratings yet

- 0 1 2 3 4 06 - 97 Service: Item: Internal NormalizationDocument1 page0 1 2 3 4 06 - 97 Service: Item: Internal Normalizationliviu_dovaNo ratings yet

- AGIP STD - Valves Specification SheetDocument1 pageAGIP STD - Valves Specification Sheethalim_kaNo ratings yet

- AGIP STD - Valves Specification SheetDocument1 pageAGIP STD - Valves Specification Sheethalim_kaNo ratings yet

- AGIP STD - Valves Specification SheetDocument1 pageAGIP STD - Valves Specification Sheethalim_kaNo ratings yet

- AGIP STD - Valves Specification SheetDocument1 pageAGIP STD - Valves Specification Sheethalim_kaNo ratings yet

- AGIP STD - Valves Specification SheetDocument1 pageAGIP STD - Valves Specification Sheethalim_kaNo ratings yet

- AGIP 04061.PIP.MEC.SDS INTERNAL NORMALIZATION PIPING PROJECT SPECIFICATIONDocument1 pageAGIP 04061.PIP.MEC.SDS INTERNAL NORMALIZATION PIPING PROJECT SPECIFICATIONhalim_kaNo ratings yet

- 61502YDocument9 pages61502YbalajivangaruNo ratings yet

- Thread o Ring Flanged FittingDocument4 pagesThread o Ring Flanged FittingsureshisisisNo ratings yet

- Caterpillar Deutsch Cross Reference ChartDocument7 pagesCaterpillar Deutsch Cross Reference ChartWilliam RoarkNo ratings yet

- 1000 PDFDocument34 pages1000 PDFMykola TitovNo ratings yet

- 11422Document10 pages11422balajivangaruNo ratings yet

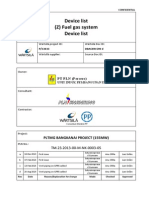

- Device List Fuel Gas SystemDocument7 pagesDevice List Fuel Gas SystemOto RushNo ratings yet

- Boiler Pipe Information List - Avantgarde Shipping & Tuff Offshore - FPSO CYRUSDocument2 pagesBoiler Pipe Information List - Avantgarde Shipping & Tuff Offshore - FPSO CYRUSzarni77No ratings yet

- Reemplazo de Transistores Peavey PDFDocument27 pagesReemplazo de Transistores Peavey PDFvicente velasquezNo ratings yet

- GD 930 & GD 930S2: Parts ListDocument24 pagesGD 930 & GD 930S2: Parts ListAngel De la TorreNo ratings yet

- Токарный инструмент IscarDocument250 pagesТокарный инструмент IscarstctoolNo ratings yet

- Bomba Blackmer GX2.5Document4 pagesBomba Blackmer GX2.5Arturo VillenaNo ratings yet

- Transistores PeaveyDocument27 pagesTransistores PeaveyJuan Carlos PerdomoNo ratings yet

- rc91261 G10-UscDocument8 pagesrc91261 G10-Usceww08No ratings yet

- 2.25.e.rp45 Pressure Reducing Valve DN15-100-EnDocument5 pages2.25.e.rp45 Pressure Reducing Valve DN15-100-EnMa KiepNo ratings yet

- Hai Linh LNG Receivingterminal and Regasification: Request For NDT-PTDocument4 pagesHai Linh LNG Receivingterminal and Regasification: Request For NDT-PTTran Van DangNo ratings yet

- Medical Gas Outlets OverviewDocument28 pagesMedical Gas Outlets OverviewArcade LdsNo ratings yet

- Job No.: Client: Project: Region:: Sl. No. EIL Ref. No. PO No. PO DescriptionDocument6 pagesJob No.: Client: Project: Region:: Sl. No. EIL Ref. No. PO No. PO DescriptionSuyog GawandeNo ratings yet

- Jite PCB Connectors and Cinch Terminal Strips SEO-Optimized TitleDocument24 pagesJite PCB Connectors and Cinch Terminal Strips SEO-Optimized TitleKenon FlemingsNo ratings yet

- Ep31492 PDFDocument11 pagesEp31492 PDFJilJilNo ratings yet

- Comprehensive Title for Piping Class Design DocumentDocument9 pagesComprehensive Title for Piping Class Design Documenteww08No ratings yet

- VCA03 FH2 CE Fire HydrantDocument2 pagesVCA03 FH2 CE Fire HydrantSenghy MaoNo ratings yet

- Transistores PeaveyDocument27 pagesTransistores PeaveyLuis Enrique Bejarano CastilloNo ratings yet

- VAL Team Adca: Steam Distribution Manifold MASDocument4 pagesVAL Team Adca: Steam Distribution Manifold MASEdgar León100% (2)

- rc33026 D12-UscDocument7 pagesrc33026 D12-Usceww08No ratings yet

- Class A1D1Document8 pagesClass A1D1SalimNo ratings yet

- Final Equipment Testing Report 02/06/2014Document4 pagesFinal Equipment Testing Report 02/06/2014prateek0291No ratings yet

- Harman Kardon Model hk870 Manual Provides Specs and Service InstructionsDocument26 pagesHarman Kardon Model hk870 Manual Provides Specs and Service InstructionskoleszkowiecNo ratings yet

- All-in-One Manual of Industrial Piping Practice and MaintenanceFrom EverandAll-in-One Manual of Industrial Piping Practice and MaintenanceRating: 5 out of 5 stars5/5 (1)

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsFrom EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsRating: 4.5 out of 5 stars4.5/5 (10)

- Contractor's Guide for Installation of Gasketed PVC Pipe for Water / for SewerFrom EverandContractor's Guide for Installation of Gasketed PVC Pipe for Water / for SewerRating: 5 out of 5 stars5/5 (1)

- Abu Dhabi Oil Refining Company Testing Laboratory SpecificationDocument17 pagesAbu Dhabi Oil Refining Company Testing Laboratory Specificationhalim_kaNo ratings yet

- AGIP STD - Valve Data SheetDocument1 pageAGIP STD - Valve Data Sheethalim_kaNo ratings yet

- VDR 718 Ag Ac: BS 5352 Trim Materials Manuf. STD Piston Check Valve Item VDR With SpringDocument1 pageVDR 718 Ag Ac: BS 5352 Trim Materials Manuf. STD Piston Check Valve Item VDR With Springhalim_kaNo ratings yet

- 15391E01 Valve Data SheetDocument1 page15391E01 Valve Data Sheethalim_kaNo ratings yet

- 15414E01 - Valve Data SheetDocument1 page15414E01 - Valve Data Sheethalim_kaNo ratings yet

- 15378E01Document1 page15378E01halim_kaNo ratings yet

- 15413E01 - Valve Data SheetDocument1 page15413E01 - Valve Data Sheethalim_kaNo ratings yet

- VDR 731 Ag 1U: BS 1868 Trim MaterialsDocument1 pageVDR 731 Ag 1U: BS 1868 Trim Materialshalim_kaNo ratings yet

- AGIP STD - Valve Data SheetDocument1 pageAGIP STD - Valve Data Sheethalim_kaNo ratings yet

- VDR 731 Ag 1U: BS 1868 Trim MaterialsDocument1 pageVDR 731 Ag 1U: BS 1868 Trim Materialshalim_kaNo ratings yet

- VDR 715 Ag 9C: BS 1868 Trim MaterialsDocument1 pageVDR 715 Ag 9C: BS 1868 Trim Materialshalim_kaNo ratings yet

- 15397E01 Valve Data SheetDocument1 page15397E01 Valve Data Sheethalim_kaNo ratings yet

- VDR 717 Ag Ac: BS 5352 Trim MaterialsDocument1 pageVDR 717 Ag Ac: BS 5352 Trim Materialshalim_kaNo ratings yet

- 15396E01 Valve Data SheetDocument1 page15396E01 Valve Data Sheethalim_kaNo ratings yet

- 15391E01 Valve Data SheetDocument1 page15391E01 Valve Data Sheethalim_kaNo ratings yet

- AGIP STD - Valve Data SheetDocument1 pageAGIP STD - Valve Data Sheethalim_kaNo ratings yet

- 15397E01 Valve Data SheetDocument1 page15397E01 Valve Data Sheethalim_kaNo ratings yet

- VDR 715 Ag 9C: BS 1868 Trim MaterialsDocument1 pageVDR 715 Ag 9C: BS 1868 Trim Materialshalim_kaNo ratings yet

- Appendix B. Sample Problem: Chevron Corporation B-1 March 1991Document2 pagesAppendix B. Sample Problem: Chevron Corporation B-1 March 1991halim_kaNo ratings yet

- 15414E01 - Valve Data SheetDocument1 page15414E01 - Valve Data Sheethalim_kaNo ratings yet

- VDR 715 Ag 9C: BS 1868 Trim MaterialsDocument1 pageVDR 715 Ag 9C: BS 1868 Trim Materialshalim_kaNo ratings yet

- 15413E01 - Valve Data SheetDocument1 page15413E01 - Valve Data Sheethalim_kaNo ratings yet

- 15396E01 Valve Data SheetDocument1 page15396E01 Valve Data Sheethalim_kaNo ratings yet

- VDR 731 Ag 1U: BS 1868 Trim MaterialsDocument1 pageVDR 731 Ag 1U: BS 1868 Trim Materialshalim_kaNo ratings yet

- 15397E01 Valve Data SheetDocument1 page15397E01 Valve Data Sheethalim_kaNo ratings yet

- VDR 715 Ag 9C: BS 1868 Trim MaterialsDocument1 pageVDR 715 Ag 9C: BS 1868 Trim Materialshalim_kaNo ratings yet

- VDR 718 Ag Ac: BS 5352 Trim Materials Manuf. STD Piston Check Valve Item VDR With SpringDocument1 pageVDR 718 Ag Ac: BS 5352 Trim Materials Manuf. STD Piston Check Valve Item VDR With Springhalim_kaNo ratings yet

- 15391E01 Valve Data SheetDocument1 page15391E01 Valve Data Sheethalim_kaNo ratings yet

- 15378E01Document1 page15378E01halim_kaNo ratings yet

- VDR 717 Ag Ac: BS 5352 Trim MaterialsDocument1 pageVDR 717 Ag Ac: BS 5352 Trim Materialshalim_kaNo ratings yet