Professional Documents

Culture Documents

EM P 06 Energy Systems Analysis Slides

Uploaded by

Tiago HenriquesCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

EM P 06 Energy Systems Analysis Slides

Uploaded by

Tiago HenriquesCopyright:

Available Formats

Energy Management :: 2007/2008

Class # 6P

Energy Systems Analysis

Dr. Joo Parente

joao.parente@dem.ist.utl.pt

Energy Management

Energy systems analysis

Basic concepts

The block diagram is a simplified relation between the input and output of a physical system. As an input we consider

the product to be transform, and as an output the final product and associate residues.

Specific energy consumption in A:

cA = (Energy use in A) / (Useful production) = E / Out

Residues formation factor in A :

SA = 1 / (Resource use ratio) = (In1 + In2) / Out

Inlet n flow ratio:

E

In1

A

f1 = In1 / (Total inlet flow in A) = In1 / (In1 + In2)

Out

In2

R

Class # 6P :: Energy Systems Analysis

Slide 2 of 53

Energy Management

Energy systems analysis

1) Sequential connection

c4 = cc + Sc*c3

c3 = cB + SB*c2

c2 = cA + SA*c1

2) Convergent connection

1

3) Divergent connection

2

2

C

Class # 6P :: Energy Systems Analysis

c5 = cc + Sc*(f2*c2 + f4*c4)

c2 = c4 = cA + SA*c1

c2 = cA + SA*c1

c3 = cB + SB*c2

c4 = cB + SB*c3

c5 = cB + SB*c4

Slide 3 of 53

Energy Management

Energy systems analysis

EXAMPLE 01 - Sequential connection

Consider a system composed only by an oven, selection of products without deficiencies and storage. The specific

energy consumption of the oven is 200 kJ/kg, while the selection of the products is characterized by a specific energy

consumption of 5 kJ/kg. The raw materials embrace an energy consumption of 50 kJ/kg in transformation process. The

heating process promotes the volatilization of some components of the raw material, around 5% of the original material.

The selection process disposes around 10% of the oven production and the storage losses are around 1%. Determine

the specific energy consumption of the final product.

EXAMPLE 02 - Convergent connection

A company in the biological oil production imports 60% of the raw material, while the remaining raw material is from

national production. The imported oil is transported by boat with a travel distance ~ 1000 km, while the national oil is

transported by truck with a travel distance ~ 200 km. The oil refinery process presents a specific energy consumption of

100 kJ/kg. The mass rejection in the oil refinery process is ~ 90%. The specific consumption associated to the transport

is 0.025 kJ/kg*km by truck and 0.010 kJ/kg*km by boat. The oil losses in the transport are 1% by truck and 0.1% by

boat. Determine the specific energy consumption associated to the refined oil.

EXAMPLE 03 - Divergent connection

A glass oven presents a mass loss by volatilization ~7%. From the glass produced in the oven, 40% is employed in the

production of 0.33 cl bottles, and the rest to the production of 0.75 cl bottles. The conformation of the 0.33 cl bottles has

a rupture ratio of 2%, while the 0.75 cl bottles has a rupture ratio of 3%. The sand used in the glass production has an

energy value of 10kJ/kg. The specific consumption are, 200 kJ/kg in the oven , in the conformation 20 kJ/kg for the 0.33

cl bottle and 25 kJ/kg for the 0.75 cl bottles. Determine the specific energy consumption for each type of bottle.

Class # 6P :: Energy Systems Analysis

Slide 4 of 53

Energy Management

Energy systems analysis

SOLUTION EXAMPLE 01 - Sequential connection

Specific energy consumption of the final product: c4 = cST + SST*(cS + SS*(cO + SO*c1)

SST = 1 / (1 0.01) = 1.01 kg3/kg4

SS = 1 / (1 0.10) = 1.11 kg3/kg4

SO = 1 / (1 0.05) = 1.05 kg3/kg4

Losses

Losses

cST = 20 kJ/kg4

cS = 5 kJ/kg3

1 Raw materials

cO = 200 kJ/kg2

Oven

(2)

Selection

(3)

(4) Final Product

STorage

Boundary

c4 = 20 + 1.01*(5 + 1.11*(200 + 1.05*50) = 308 kJ / kg4

Class # 6P :: Energy Systems Analysis

Slide 5 of 53

Energy Management

Energy systems analysis

SOLUTION EXAMPLE 02 - Convergent connection

Specific energy consumption of the final product: c5 = cR + SR*(f2*(cB + SB*c1) + f4*(cT + ST*c3))

SR = 1 / (1 0.90) = 10 (kg2 + kg4) /kg5

SB = 1 / (1 0.001) = 1.001 kg1/kg2

ST = 1 / (1 0.01) = 1.01 kg3/kg4

Losses

(1) Imported oil

cR = 100 kJ/kg5

Transport

Boat

2

Refinery

cB = 0.010 kJ/(kg*km) * 1000 km = 10 kJ/kg2

cT = 0.025 kJ/(kg*km) * 200 km = 5 kJ/kg4

c1 = c3 = 0 kJ/kg

(3) National oil

Transport

Truck

(5) Refined oil

4

Boundary

c5 = 100 + 10*(0.6*10 + 0.4*5) = 180 kJ/kg5

Class # 6P :: Energy Systems Analysis

Slide 6 of 53

Energy Management

Energy systems analysis

SOLUTION EXAMPLE 03 - Divergent connection

Specific energy consumption of the final product: c3 = cA + SA*c2 ; c5 = cB + SB*c4 ;

c2 = c4 = cO + SO*c1

SA = 1 / (1 0.02) = 1.020 kg2/kg3

SB = 1 / (1 0.03) = 1.031 kg4/kg5

SO = 1 / (1 0.07) = 1.075 kg1/(kg2 + kg4)

(1) Sand

c2 = c4 =200 + 1.075*10 = 210.75 kJ/kg2 ou 4

c3 = 20 + 1.02*210.75 = 235 kJ / kg3

c5 = 25 + 1.031*210.75 = 242.3 kJ / kg5

Class # 6P :: Energy Systems Analysis

Conf.

A_0.33cl

(3) 0.33cl bottles

Conf.

B_0.33cl

(5) 0.75cl bottles

Glass Oven

4

Boundary

Slide 7 of 53

Energy Management

Energy systems analysis

Residues treatment

The residues formation induces an increase in the final product specific energy consumption as follows:

1) the energy consumption in the unitary process are higher, given the increase in upstream flows;

2) there is an energy consumption associated to the residues treatment process.

Treatment

Residues treatment is an unitary process where the specific energy

consumption indicator is defined per unit of inlet product at the unitary

process.

ctc = (Energy use in C) / (production flow to treat) [kJ/kg4]

SAC = (residues produced in A to C) / (Useful production in A) [kg4/kg2]

Recycling

Recycling

There is an energy interest in recycling when the energy used in

the recycling process is less then the energy required to produce

an equivalent product.

C

4

Class # 6P :: Energy Systems Analysis

Slide 8 of 53

Energy Management

Energy systems analysis

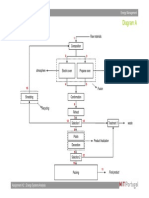

PROBLEM 01 Residues treatment

The following systems uses as raw material the flow in 3, produces the final product flow in 6, and treats the residues

flow 7. Determine the specific consumption associated to the flow 6:

Treatment

10

Class # 6P :: Energy Systems Analysis

11

Waste

Energy

Final

Slide 9 of 53

Energy Management

Energy systems analysis

SOLUTION PROBLEM 01 Residues treatment

Considering that the operations D and E do not generate any type of residues, the final product specific energy

consumption is given by:

c6 = ce + cD + (cC + SCF*ct7) + SC*c3 + ccapital

The specific energy consumption for the treatment of the flow in 7 is:

ct7 = ctF + (ft8* ct8 + ft10* ct10)

ct8 = ctG + ct9 , where ct9 = ctEnergy

ct10 = ctH + ct11 , where ct11 = ctWaste

Class # 6P :: Energy Systems Analysis

Slide 10 of 53

Energy Management

Energy systems analysis

PROBLEM 02 Complex system (recycling)

Consider the following system:

Recycling

14

13

12

Treatment

10

15

Class # 6P :: Energy Systems Analysis

11

Waste

Energy

Final

Slide 11 of 53

Energy Management

Energy systems analysis

PROBLEM 02 Complex system (recycling)

a)

Determine in which conditions the operation H is reasonable from an energy point of view.

b)

What is the specific energy consumption associated to the product 7?

c)

What is the final energy balance to the recycling operation?

Class # 6P :: Energy Systems Analysis

Slide 12 of 53

Energy Management

Energy systems analysis

SOLUTION PROBLEM 02 Complex system (recycling)

a) The operation H corresponds to the materials separation to recycle or waste disposal. In this sense, the operation H

allows the recycling process, that can only be justified in energy terms if the specific consumption in 4 with recycling is

lower then the specific consumption in 4 without recycling.

b) The specific energy consumption in 7 corresponds to the energy consumption requested to treat 1 kg of product 7

(residue). This value, considering that the operations F, G and H might also produce some residues, can be determined

by:

ct7 = ctF + StF*(ft8* ct8 + ft10* ct10)

ct8 = ctG + StG*ct9 , where ct9 = ctEnergy

ct10 = ctH + StH*ct11 , where ct11 = ctWaste

c) With recycling the specific energy consumption in 4 is:

c4 = (cC + StC*ct7) + SC*(f3*c3 +f16*c16)

c3 = cB + SB*(f2*c2 + f15*c15) ;

c16 = cJ + SJ*c13 ;

c15 = cK + SK*c14 ;

c2 = cA + SA*c1

c13 = cI + SI*c12

c14 = c16

Without recycling, f3 = f2 = StH = 1and f15 = f16 = 0.

Class # 6P :: Energy Systems Analysis

Slide 13 of 53

Energy Management

Energy Management :: 2007/2008

Class # 6P

Energy Systems Analysis

Dr. Joo Parente

joao.parente@dem.ist.utl.pt

Class # 6P :: Energy Systems Analysis

Slide 14 of 53

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (589)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (842)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5806)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- QLT m10 Asl Parts Book 2012Document46 pagesQLT m10 Asl Parts Book 2012Tiago Henriques100% (1)

- XH200 Spec Sheet USLETTER PrintDocument2 pagesXH200 Spec Sheet USLETTER PrintTiago HenriquesNo ratings yet

- Applied Thermal Engineering: Minje Park, Daebong Jung, Minjae Kim, Kyoungdoug MinDocument9 pagesApplied Thermal Engineering: Minje Park, Daebong Jung, Minjae Kim, Kyoungdoug MinTiago HenriquesNo ratings yet

- Atlas Copco RH 656 PartsDocument16 pagesAtlas Copco RH 656 PartsTiago HenriquesNo ratings yet

- EM P 12 MicrogenerationDocument7 pagesEM P 12 MicrogenerationTiago HenriquesNo ratings yet

- EM Ass 05 BlockDiagramDocument4 pagesEM Ass 05 BlockDiagramTiago HenriquesNo ratings yet

- EM Ass 04 Annex 2 DataDocument3 pagesEM Ass 04 Annex 2 DataTiago HenriquesNo ratings yet

- Energy Management AssignmentDocument1 pageEnergy Management AssignmentTiago HenriquesNo ratings yet

- S Intermediate Input Final Demand: 0 #Value! #Value!Document2 pagesS Intermediate Input Final Demand: 0 #Value! #Value!Tiago HenriquesNo ratings yet

- Energy Management AssignmentDocument1 pageEnergy Management AssignmentTiago HenriquesNo ratings yet

- Energy Management AssignmentDocument1 pageEnergy Management AssignmentTiago HenriquesNo ratings yet

- Energy Management AssignmentDocument1 pageEnergy Management AssignmentTiago HenriquesNo ratings yet

- S Intermediate Input Final DemandDocument2 pagesS Intermediate Input Final DemandTiago HenriquesNo ratings yet

- 04 - ClimaDocument8 pages04 - ClimaTiago HenriquesNo ratings yet

- EM Ass 02 Annex 1 BlockDiagramDocument4 pagesEM Ass 02 Annex 1 BlockDiagramTiago HenriquesNo ratings yet

- Energy Management 2 AssignmentDocument1 pageEnergy Management 2 AssignmentTiago HenriquesNo ratings yet

- 02 - Thermal ComfortDocument16 pages02 - Thermal ComfortTiago HenriquesNo ratings yet