Professional Documents

Culture Documents

ISO9001 GAP Analysis

Uploaded by

Rahull GsalmanCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

ISO9001 GAP Analysis

Uploaded by

Rahull GsalmanCopyright:

Available Formats

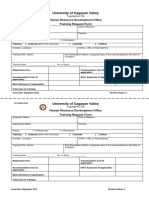

AS/NZS ISO 9001:2000

GAP ANALYSIS CHECKLIST

ISO 9001:2000 Gap Analysis

Checklist

Type:

Assessor:

ISO 9001 REQUIREMENTS

4 Quality Management System

STATUS

4.1 General Requirements

Processes needed for the quality management system and

their application throughout Company X have been

determined.

The sequence and interaction of these processes have

been determined.

Criteria and methods needed to ensure that both the

operation and control of these processes are effective have

been determined.

The availability of resources and information necessary to

support the operation and monitoring of these processes are

ensured.

These processes are monitored, measured and analysed.

Actions necessary to achieve planned results and continual

improvement of these processes are implemented.

4.2 Documentation Requirements

4.2.2 Quality Manual

A quality manual has been established and is maintained.

The scope of the manual includes details of and justification

for any exclusions (exclusions are limited to clause 7).

The manual contains or references the documented

procedures established for the quality management system.

The manual contains a description of the interaction between

the processes of the quality management system.

4.2.3 Control Of Documents

All QMS documents are controlled.

A documented procedure is established to define the

controls needed to:

Approve documents for adequacy prior to issue.

Review and update as necessary and re-approve

documents.

Ensure that changes and the current revision status

of documents are identified.

Ensure that relevant versions of applicable

documents are available at points of use.

Ensure that documents remain legible and readily

identifiable.

Ensure that documents of external origin are

identified and their distribution controlled.

Prevent the unintended use of obsolete documents,

and to apply suitable identification to them if they are

retained for any purpose.

4.2.4 Control Of Records

Records are legible, readily identifiable and retrievable.

A documented procedure has been established to define the

controls needed for the identification, storage, protection,

retrieval, retention time and disposition of records.

ACTION/COMMENTS

AS/NZS ISO 9001:2000

GAP ANALYSIS CHECKLIST

5.1 Management Commitment

Top management has communicated the importance of

meeting customer, statutory and regulatory requirements.

Quality policy is established.

Quality objectives are established.

5.2 Customer Focus

Top management shall ensure that customer requirements

are determined and are met with the aim of enhancing

customer satisfaction (see 7.2.1 and 8.2.1).

5.3 Quality Policy

Policy is appropriate to the purpose of Company X.

Policy includes a commitment to comply with requirements

and continually improve the effectiveness of the QMS.

Policy provides a framework for establishing and reviewing

quality objectives.

Policy is communicated and understood.

Policy is reviewed for continuing suitability.

5.4 Planning

5.4.1 Quality Objectives

Quality objectives, including those needed to meet

requirements for product, are established at relevant

functions and levels within Company X.

The quality objectives are measurable and consistent with

the quality policy.

5.4.2 Quality Management System Planning

QMS planning is carried out in order to meet the requirements

given in 4.1, as well as the quality objectives.

The integrity of the QMS is maintained when changes to the

QMS are planned and implemented.

5.5 Responsibility, Authority And Communication

5.5.1 Responsibility And Authority

Responsibilities and authorities are defined and

communicated.

5.5.2 Management Representative

The Quality Systems Manager reports to top management on

the performance of the QMS and any need for improvement.

The Quality Systems Manager ensures the promotion of

awareness of customer requirements throughout Company

X.

5.5.3 Internal Communication

Appropriate communication processes are established.

Communication takes place regarding the effectiveness of

the QMS.

5.6 Management Review

5.6.1 General

Top management reviews the QMS at planned intervals, to

ensure its continuing suitability, adequacy & effectiveness.

The review includes assessing opportunities for

improvement and the need for changes to the QMS, including

the quality policy and quality objectives.

Records from management reviews are maintained.

5.6.2 Review Input

Includes results of audits.

Includes customer feedback.

Includes process performance and product conformity.

Includes status of preventive and corrective actions.

AS/NZS ISO 9001:2000

GAP ANALYSIS CHECKLIST

reviews.

Includes changes that could affect the QMS.

Includes recommendations for improvement.

5.6.3 Review Output

Includes improvement of the effectiveness of the QMS and

its processes.

Includes improvement of product related to customer

requirements.

Includes resource needs.

6 Resource Management

6.1 Provision Of Resources

Company X determines and provides the resources needed

to implement and maintain the QMS and continually improve

its effectiveness.

Company X determines and provides the resources needed

to enhance customer satisfaction by meeting customer

requirements.

6.2 Human Resources

6.2.1 General

Personnel performing work affecting product quality are

competent on the basis of appropriate education, training,

skills and experience.

6.2.2 Competence, Awareness And Training

The necessary competence of personnel to perform work

affecting product quality has been determined.

Training has been provided or other actions taken to satisfy

these competency/awareness/training needs.

The effectiveness of the actions taken has been evaluated.

Personnel are aware of the relevance and importance of

their activities and how they contribute to the achievement of

the quality objectives.

Records of education, training, skills and experience are

maintained.

6.3 Infrastructure

Company X has determined, provided and maintained the

infrastructure needed to achieve conformity to product

requirements. (This includes, as applicable, buildings,

workspace, utilities, process equipment and supporting

services)

6.4 Work Environment

Company X has determined and manages the work

environment to achieve conformity to product requirements.

7 Product Realization

7.1 Planning Of Product Realization

Company X has planned and developed the processes

needed for product realization. Planning of product

realization is consistent with the requirements of the other

processes of the QMS.

In planning product realization, the organization shall

determine the following, as appropriate:

Quality objectives and requirements for the product.

The need to establish processes, documents, and

provide resources specific to the product.

Required verification, validation, monitoring,

inspection and test activities specific to the product

and the criteria for product acceptance.

AS/NZS ISO 9001:2000

GAP ANALYSIS CHECKLIST

Records needed to provide evidence that the

realization processes and resulting product meet

requirements.

The output of this planning is in a form suitable for Company

X's method of operations.

7.2 Customer-Related Processes

7.2.1 Determination Of Requirements Related To The

Product

The requirements specified by the customer, including the

requirements for delivery and post-delivery activities are

determined.

The requirements not stated by the customer but necessary

for specified or intended use, where known, are determined.

The statutory and regulatory requirements related to the

product are determined.

Additional requirements determined by the organization are

determined.

7.2.2 Review Of Requirements Related To The

Product

Company X reviews the requirements related to the product.

This review is conducted prior to Company Xs commitment

to supply a product to the customer (e.g. submission of

tenders, acceptance of contracts or orders, acceptance of

changes to contracts or orders).

The review ensures that:

Product requirements are defined.

Contract or order requirements differing from those

previously expressed are resolved.

The organization has the ability to meet the defined

requirements.

Records of the results of the review and actions arising

from the review are maintained.

Where the customer provides no documented statement of

requirement, the customer requirements are confirmed by

Company X before acceptance.

Where product requirements are changed, Company X

ensures that relevant documents are amended and that

relevant personnel are made aware of the changed

requirements.

7.2.3 Customer Communication

Company X has determined and implemented effective

arrangements for communicating with customers in relation

to:

Product information.

Enquiries, contracts or order handling, including

amendments.

Customer feedback, including customer complaints.

7.3 Design And Development

7.3.1 Design And Development Planning

Company X plans and controls the design and development

of product.

During the design and development planning, Company X

determines the:

Design and development stages.

Review, verification and validation that are

appropriate to each design and development stage.

Responsibilities and authorities for design and

AS/NZS ISO 9001:2000

GAP ANALYSIS CHECKLIST

Company X manages the interfaces between different

groups involved in design and development to ensure

effective communication and clear assignment of

responsibility.

Planning output is updated, as appropriate, as the design and

development progresses.

7.3.2 Design And Development Inputs

Inputs relating to product requirements are determined and

records maintained.

Product requirement inputs include:

Functional and performance requirements.

Applicable statutory and regulatory requirements.

Where applicable, information derived from previous

similar designs.

Other requirements essential for design and

development.

These inputs are reviewed for adequacy. Requirements are

complete, unambiguous and not in conflict with each other.

7.3.3 Design And Development Outputs

The outputs of design and development are provided in a

form that enables verification against the design and

development input and shall be approved prior to release.

Design and development outputs:

Meet the input requirements for design and

development.

Provide appropriate information for purchasing,

production and for service provision.

Contain or reference product acceptance criteria.

Specify the characteristics of the product that are

essential for its safe and proper use.

7.3.4 Design And Development Review

At suitable stages, systematic reviews of design and

development are performed in accordance with planned

arrangements to:

Evaluate the ability of the results of design and

development to meet requirements.

Identify any problems and propose necessary

actions.

Participants in such reviews include representatives of

functions concerned with the design and development

stage(s) being reviewed.

Records of the results of the reviews and any necessary

actions are maintained.

7.3.5 Design And Development Verification

Verification is performed in accordance with planned

arrangements to ensure that the design and development

outputs met the design and development input requirements.

Records of the results of the verification and any necessary

actions are maintained.

7.3.6 Design And Development Validation

Design and development validation is performed in

accordance with planned arrangements so that the resulting

product is capable of meeting the requirements for the

specified application or intended use, where known.

Wherever practicable, validation is completed prior to the

delivery or implementation of the product.

Records of the results of validation and any necessary

AS/NZS ISO 9001:2000

GAP ANALYSIS CHECKLIST

7.3.7 Control Of Design And Development Changes

Design and development changes are identified and records

maintained.

The changes are reviewed, verified and validated, as

appropriate, and approved before implementation.

The review of design and development changes is included

in evaluation of the effect of the changes on constituent

parts and product already delivered.

Records of the results of the review of changes and any

necessary actions are maintained.

7.4 Purchasing

7.4.1 Purchasing Process

Company X ensures that purchased product conforms to

specified purchase requirements.

The type and extent of control applied to the supplier and the

purchased product is dependent upon the effect of the

purchased product on subsequent product realization or the

final product.

Company X evaluates and selects suppliers based on their

ability to supply product in accordance with Company Xs

requirements.

Criteria for the selection, evaluation and re-evaluation of

suppliers are established.

Records of the results of evaluations and any necessary

actions arising from the evaluation are maintained.

7.4.2 Purchasing Information

Purchasing information describes the product to be

purchased.

Where appropriate, purchasing information includes:

Requirements for approval of product, procedures,

processes and equipment.

Requirements for qualification of personnel.

Quality management system requirements.

Company X ensures the adequacy of specified purchase

requirements prior to their communication to the supplier.

7.4.3 Verification Of Purchased Product

Company X has established and implemented the inspection,

or other activities, necessary for ensuring that purchased

product meets specified purchase requirements.

Where Company X or its customer intends to perform

verification at the supplier's premises, Company X states the

intended verification arrangements and method of product

release in the purchasing information.

7.5 Production And Service Provision

7.5.1 Control Of Production And Service Provision

Company X plans and carries out production and service

provision under controlled conditions.

Controlled conditions include, as applicable, the:

Availability of information that describes the

characteristics of the product.

Availability of work instructions, as necessary.

Use of suitable equipment.

Availability and use of monitoring and measuring

devices.

Implementation of monitoring and measurement.

Implementation of release, delivery and post-delivery

AS/NZS ISO 9001:2000

GAP ANALYSIS CHECKLIST

7.5.2 Validation Of Processes For Production And

Service Provision

Company X validates any processes for production and

service provision where the resulting output cannot be

verified by subsequent monitoring or measurement. (This

includes any processes where deficiencies become

apparent only after the product is in use or the service has

been delivered)

Validation demonstrates the ability of these processes to

achieve planned results.

The organization has established arrangements for these

processes including, as applicable:

Defined criteria for review & approval of the

processes.

Approval of equipment & qualification of personnel.

Use of specific methods and procedures.

Requirements for records.

Revalidation.

7.5.3 Identification And Traceability (In some industry

sectors, configuration management is a means by which

identification and traceability are maintained)

Where appropriate, Company X has identified the product by

suitable means throughout product realization.

Company X identifies the product status with respect to

monitoring and measurement requirements.

Where traceability is a requirement, Company X controls and

records the unique identification of the product.

7.5.4 Customer Property (can include intellectual

property)

Company X exercises care with customer property while it

is under Company Xs control or being used by Company X.

Company X identifies, verifies, protects and safeguards

customer property provided for use or incorporation into the

product.

If any customer property is lost, damaged or otherwise

found to be unsuitable for use, this is reported to the

customer and records maintained.

7.5.5 Preservation Of Product

Company X preserves the conformity of product during

internal processing and delivery to the intended destination.

This preservation includes identification, handling, packaging,

storage and protection.

Preservation also applies to the constituent parts of a

product.

7.6 Control Of Monitoring And Measuring Devices

Company X determines the monitoring and measurement to

be undertaken and the monitoring and measuring devices

needed to provide evidence of conformity of product to

determined requirements.

Company X has established processes to ensure that

monitoring and measurement can be carried out and are

carried out in a manner that is consistent with the monitoring

and measurement requirements.

Where necessary to ensure valid results, measuring

equipment is:

Calibrated or verified at specified intervals, or prior to

use, against measurement standards traceable to

AS/NZS ISO 9001:2000

GAP ANALYSIS CHECKLIST

where no such standards exist, the basis used for

calibration or verification is recorded.

Adjusted or re-adjusted as necessary.

Identified to enable the calibration status to be

determined.

Safeguarded from adjustments that would invalidate

the measurement result.

Protected from damage and deterioration during

handling, maintenance and storage.

Company X assesses and records the validity of the

previous measuring results when the equipment is found not

to conform to requirements.

Company X takes appropriate action on the equipment and

any product affected.

Records of the results of calibration and verification are

maintained.

When used in the monitoring and measurement of specified

requirements, the ability of computer software to satisfy the

intended application is confirmed. This is undertaken prior to

initial use and reconfirmed as necessary.

8 Measurement, Analysis And Improvement

8.1 General

Company X plans and implements the monitoring,

measurement, analysis and improvement processes needed

to:

Demonstrate conformity of the product.

Ensure conformity of the quality management system.

Continually improve the effectiveness of the quality

management system.

This includes determination of applicable methods, including

statistical techniques, and the extent of their use.

8.2 Monitoring And Measurement

8.2.1 Customer Satisfaction

As one of the measurements of the performance of the

QMS, Company X monitors information relating to customer

perception as to whether Company X has met customer

requirements.

The methods for obtaining and using this information has

been determined.

8.2.2 Internal Audit

Internal audits are conducted at planned intervals.

Internal audits determine whether the QMS:

Conforms to the planned arrangements (see 7.1), to

the requirements of ISO 9001 and to the QMS

requirements established by Company X.

Is effectively implemented and maintained.

The audit programme is planned, taking into consideration the

status and importance of the processes and areas to be

audited, as well as the results of previous audits.

The audit criteria, scope, frequency & methods are defined.

Selection of auditors and conduct of audits ensure

objectivity and impartiality of the audit process.

Auditors do not audit their own work.

The responsibilities and requirements for planning and

conducting audits, and for reporting results and maintaining

records are defined in a documented procedure.

AS/NZS ISO 9001:2000

GAP ANALYSIS CHECKLIST

ensure that actions are taken without undue delay to

eliminate detected nonconformities and their causes.

Follow-up activities include the verification of the actions

taken and the reporting of verification results.

8.2.3 Monitoring And Measurement Of Processes

Company X applies suitable methods for monitoring and,

where applicable, measurement of the QMS processes.

These methods demonstrate the ability of the processes to

achieve planned results.

When planned results are not achieved, correction and

corrective action are taken, as appropriate, to ensure

conformity of the product.

8.2.4 Monitoring And Measurement Of Product

Company X monitors and measures the characteristics of

the product to verify that product requirements have been

met.

This is carried out at appropriate stages of the product

realization process in accordance with the planned

arrangements.

Evidence of conformity with the acceptance criteria is

maintained.

Records indicate the person(s) authorizing release of

product.

Product release and service delivery do not proceed until the

planned arrangements (see 7.1) have been satisfactorily

completed, unless otherwise approved by a relevant

authority and, where applicable, by the customer.

8.3 Control Of Nonconforming Product

Company X ensures that product which does not conform to

product requirements is identified and controlled to prevent

its unintended use or delivery.

The controls and related responsibilities and authorities for

dealing with nonconforming product are defined in a

documented procedure.

Company X deals with nonconforming product by one or

more of the following ways:

By taking action to eliminate the detected

nonconformity.

By authorizing its use, release or acceptance under

concession by a relevant authority and, where

applicable, by the customer.

By taking action to preclude its original intended use

or application.

Records of the nature of nonconformities and any

subsequent actions taken, including concessions obtained,

are maintained.

When nonconforming product is corrected it is subject to reverification to demonstrate conformity to the requirements.

When nonconforming product is detected after delivery or use

has started, the organization takes action appropriate to the

effects, or potential effects, of the nonconformity.

8.4 Analysis Of Data

Company X has determined, collected and analysed

appropriate data to demonstrate the suitability and

effectiveness of the QMS and has evaluated where continual

improvement of the effectiveness of the QMS can be made.

(This includes data generated as a result of monitoring and

measurement and from other relevant sources)

AS/NZS ISO 9001:2000

GAP ANALYSIS CHECKLIST

Customer satisfaction (see 8.2.1).

Conformity to product requirements (see 7.2.1).

Characteristics and trends of processes and products

including opportunities for preventive action.

Suppliers.

8.5 Improvement

8.5.1 Continual Improvement

Company X continually improves the effectiveness of the

quality management system through the use of the quality

policy, quality objectives, audit results, analysis of data,

corrective and preventive actions and management review.

8.5.2 Corrective Action

Company X takes action to eliminate the cause of

nonconformities in order to prevent recurrence.

Corrective actions are appropriate to the effects of the

nonconformities encountered.

A documented procedure is established to define requirements

for:

Reviewing nonconformities (including customer

complaints).

Determining the causes of nonconformities.

Evaluating the need for action to ensure that

nonconformities do not recur.

Determining and implementing action needed.

Records of the results of action taken.

Reviewing corrective action taken.

8.5.3 Preventive Action

Company X determines action to eliminate the causes of

potential nonconformities in order to prevent their occurrence.

Preventive actions are appropriate to the effects of the

potential problems.

A documented procedure is established to define requirements

for:

Determining potential nonconformities and their causes.

Evaluating the need for action to prevent occurrence of

nonconformities.

Determining and implementing action needed.

Records of results of action taken (see 4.2.4).

Reviewing preventive action taken.

You might also like

- ISO 9001 Requirements ExplainedDocument18 pagesISO 9001 Requirements ExplaineddesurkarbNo ratings yet

- Qms Gap Analysis Checklist FinalDocument18 pagesQms Gap Analysis Checklist FinalMohamed ShabirNo ratings yet

- Final AssignmentDocument6 pagesFinal Assignmentmhk665No ratings yet

- ISO 9001-2015 Client-Transition-Checklist - Add Your Co NameDocument11 pagesISO 9001-2015 Client-Transition-Checklist - Add Your Co NameTomBerendsenNo ratings yet

- F-440-001 QMS-ProcessesDocument7 pagesF-440-001 QMS-ProcessesFERNANDO MORANTES100% (1)

- Quality Management System Checklist Iso 9001Document13 pagesQuality Management System Checklist Iso 9001Ayman Hamed MalahNo ratings yet

- Iso 9001:2015Document27 pagesIso 9001:2015kevin21790No ratings yet

- Integrated Management Systems: QMS, EMS, OHSMS, FSMS including Aerospace, Service, Semiconductor/Electronics, Automotive, and FoodFrom EverandIntegrated Management Systems: QMS, EMS, OHSMS, FSMS including Aerospace, Service, Semiconductor/Electronics, Automotive, and FoodNo ratings yet

- Company Name: Quality System ManualDocument21 pagesCompany Name: Quality System ManualBrett BensleyNo ratings yet

- Management Responsibility Draft 4 10 March 2014Document101 pagesManagement Responsibility Draft 4 10 March 2014mkpqNo ratings yet

- ISO 9001 ChecklistDocument3 pagesISO 9001 Checklisttottenham359No ratings yet

- Compare ISO 9001 and ISO 13485Document2 pagesCompare ISO 9001 and ISO 13485umarNo ratings yet

- Excerpt From Table of Contents For Quality Manual of Aerospace CompanyDocument1 pageExcerpt From Table of Contents For Quality Manual of Aerospace CompanyluzmindaNo ratings yet

- Proform Laser Services LTD QP01 Integrated Management System ManualDocument32 pagesProform Laser Services LTD QP01 Integrated Management System Manualdas_joydeb100% (1)

- Change Management and ISO 9001Document7 pagesChange Management and ISO 9001Siddique Mansoor100% (3)

- QMS 3Document11 pagesQMS 3Ram MohanNo ratings yet

- 9.2 Internal Audit: Why Perform Internal Audits?Document6 pages9.2 Internal Audit: Why Perform Internal Audits?Albert Ocno AlmineNo ratings yet

- COMP-OPP-02 Procedure For Control and Validation of Service ProvisionDocument6 pagesCOMP-OPP-02 Procedure For Control and Validation of Service ProvisionISODCC DSPINo ratings yet

- Audit Plan 2018 lbc1Document23 pagesAudit Plan 2018 lbc1r0wanNo ratings yet

- QHSEP-01 Control of Documents & RecordsDocument7 pagesQHSEP-01 Control of Documents & RecordsMohamed Eid AbassNo ratings yet

- Form 1 - Application FormDocument1 pageForm 1 - Application FormPearly Grace Resano0% (1)

- Strategic Direction ProcedureDocument2 pagesStrategic Direction Procedurejaxf001No ratings yet

- MRF Management ReviewDocument4 pagesMRF Management ReviewhastinkakaNo ratings yet

- Draft - Iso 9001-2015 QmsDocument2 pagesDraft - Iso 9001-2015 QmsHamidNo ratings yet

- PM - 7.01 Product Realization PlanDocument2 pagesPM - 7.01 Product Realization PlanMangBedjoNo ratings yet

- ISO 9001-2015 Transition Checklist C 01 Rev ADocument4 pagesISO 9001-2015 Transition Checklist C 01 Rev Avikkasverma.in100% (1)

- Template ProcedureDocument4 pagesTemplate ProcedureRobbyTeresaNo ratings yet

- N Quality Management System Planning Section 14Document3 pagesN Quality Management System Planning Section 14Ngonidzashe ZvarevasheNo ratings yet

- Audit Management PDCA ApproachDocument28 pagesAudit Management PDCA ApproachThant AungNo ratings yet

- ISO 9001 Quality Management AssessmentDocument24 pagesISO 9001 Quality Management AssessmentNuragus HariyadiNo ratings yet

- ISO 9001 2015 Mock AuditDocument15 pagesISO 9001 2015 Mock AuditMadan R HonnalagereNo ratings yet

- Excel de Checklist+ISO9001Document22 pagesExcel de Checklist+ISO9001Jaime Verdugo100% (1)

- CPA Compliance ChecklistDocument25 pagesCPA Compliance ChecklistFizz FirdausNo ratings yet

- Audit Schedule - Department WiseDocument10 pagesAudit Schedule - Department WiseashishvaidNo ratings yet

- Iso 9001 10 Clauses InterpretationDocument34 pagesIso 9001 10 Clauses InterpretationJojo DollolasaNo ratings yet

- ISO 9001, 14001 and 4001 Context of The OrganizationDocument8 pagesISO 9001, 14001 and 4001 Context of The OrganizationJordin SladekNo ratings yet

- QMS ChecksDocument35 pagesQMS Checksjaga deeshNo ratings yet

- 014 IITS Internal AuditDocument5 pages014 IITS Internal AuditSirajul IslamNo ratings yet

- 10 Tips Internal AuditisoDocument9 pages10 Tips Internal AuditisoRicardo BocusNo ratings yet

- Requirement For Iso 9001 2015Document3 pagesRequirement For Iso 9001 2015Anonymous r2EiqSrBNo ratings yet

- APG InternalAudit2015 PDFDocument4 pagesAPG InternalAudit2015 PDFBulmaro SanchezNo ratings yet

- Quality Manual.4Document53 pagesQuality Manual.4dcol13100% (1)

- Audit ReportDocument11 pagesAudit ReportbasukirachmatNo ratings yet

- Revision Record Sheet: TitleDocument4 pagesRevision Record Sheet: TitleSanjay MalhotraNo ratings yet

- ISO 9001 Operational Procedure QOP-56-01 Management Review PT ASADocument5 pagesISO 9001 Operational Procedure QOP-56-01 Management Review PT ASAqidohsNo ratings yet

- Guidance On The Concept and Use of The Process Approach For Management SystemsDocument11 pagesGuidance On The Concept and Use of The Process Approach For Management SystemsDiana SchinkelNo ratings yet

- Alabama Specialty Products, Inc.Document24 pagesAlabama Specialty Products, Inc.qmicertificationNo ratings yet

- UoE Internal Audit ProcedureDocument20 pagesUoE Internal Audit Proceduredanaka007No ratings yet

- ISO 9001 2015 Bill Mizak PDFDocument35 pagesISO 9001 2015 Bill Mizak PDFblitzkrigNo ratings yet

- Comparative Matrix QMS 2015 and QMS 2008Document21 pagesComparative Matrix QMS 2015 and QMS 2008lenvfNo ratings yet

- Change Request FormDocument1 pageChange Request FormAnonymous K7J0qVndDNo ratings yet

- Summary of Quality Objectives and Targets - TemplateDocument4 pagesSummary of Quality Objectives and Targets - TemplateNoli NarvadezNo ratings yet

- Training Request Form OriginalDocument2 pagesTraining Request Form OriginalGlynish MacapiaNo ratings yet

- Audit Report of SRF Date 16.9.11Document6 pagesAudit Report of SRF Date 16.9.11yash272No ratings yet

- R-11 Intrested PartiesDocument5 pagesR-11 Intrested PartiesSandeep PhatakNo ratings yet

- Understanding - Iso 9000 Quality Management SystemDocument24 pagesUnderstanding - Iso 9000 Quality Management SystemManikandanNo ratings yet

- Amt 654 Iso 9001 2008 2009 Revised 2015Document16 pagesAmt 654 Iso 9001 2008 2009 Revised 2015Tristan PesaNo ratings yet

- Greenhouse UpdatedDocument44 pagesGreenhouse UpdatedRahull GsalmanNo ratings yet

- Fourwheelsinthewainofenglishnovel 180108165911Document20 pagesFourwheelsinthewainofenglishnovel 180108165911Rahull GsalmanNo ratings yet

- DR .FaustusDocument6 pagesDR .FaustusRahull GsalmanNo ratings yet

- Ignou NovelDocument7 pagesIgnou NovelRahull GsalmanNo ratings yet

- AlchemistDocument2 pagesAlchemistRahull GsalmanNo ratings yet

- Letter WritingDocument1 pageLetter WritingRahull GsalmanNo ratings yet

- Letter WritingDocument1 pageLetter WritingRahull GsalmanNo ratings yet

- Success Stories of Papaya, Marigold and Mango Cultivation under RKVYDocument16 pagesSuccess Stories of Papaya, Marigold and Mango Cultivation under RKVYRahull GsalmanNo ratings yet

- Unveristies DetailsDocument1 pageUnveristies DetailsRahull GsalmanNo ratings yet

- James Brodie Character Briefing EssayDocument1 pageJames Brodie Character Briefing EssayRahull GsalmanNo ratings yet

- Lettter Writing To Get Admission Details For Vocational InstitutesDocument2 pagesLettter Writing To Get Admission Details For Vocational InstitutesRahull GsalmanNo ratings yet

- English German Translation of Tecnical DocumentDocument1 pageEnglish German Translation of Tecnical DocumentRahull GsalmanNo ratings yet

- James Brodie Character Briefing EssayDocument1 pageJames Brodie Character Briefing EssayRahull GsalmanNo ratings yet

- Data To Write Answer For 5 QuestionDocument2 pagesData To Write Answer For 5 QuestionRahull GsalmanNo ratings yet

- Data To Write Answer For 5 QuestionDocument2 pagesData To Write Answer For 5 QuestionRahull GsalmanNo ratings yet

- DR FaustusDocument3 pagesDR FaustusRahull GsalmanNo ratings yet

- Passage To IndiaDocument16 pagesPassage To IndiaRahull GsalmanNo ratings yet

- GAP Analysis For E&a-RC-QA-QP01 - Procedure For Document and Data ControlDocument1 pageGAP Analysis For E&a-RC-QA-QP01 - Procedure For Document and Data ControlRahull GsalmanNo ratings yet

- Public Notice: (An Autonomous Organisation Under Department of School Education & Literacy, MHRD, Govt - of India)Document3 pagesPublic Notice: (An Autonomous Organisation Under Department of School Education & Literacy, MHRD, Govt - of India)Anonymous loKgurNo ratings yet

- Farm ManagerDocument3 pagesFarm ManagerRahull GsalmanNo ratings yet

- Samuel Richardson Was The First Writer To Produce A True Bestseller in The Modern SenseDocument5 pagesSamuel Richardson Was The First Writer To Produce A True Bestseller in The Modern SenseRahull GsalmanNo ratings yet

- Biswas Article of March 10Document6 pagesBiswas Article of March 10Shiawase AiNo ratings yet

- Procedure For Doc & Data Contrl.Document2 pagesProcedure For Doc & Data Contrl.Rahull GsalmanNo ratings yet