Professional Documents

Culture Documents

Fundamentals of Metals and Alloys Theory

Fundamentals of Metals and Alloys Theory

Uploaded by

Jason RossOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Fundamentals of Metals and Alloys Theory

Fundamentals of Metals and Alloys Theory

Uploaded by

Jason RossCopyright:

Available Formats

1

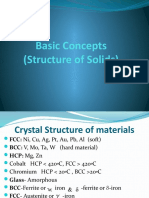

Theme 1. Fundamentals of metals and alloys theory

Crystalline structure of metals and alloys

All metals are crystalline substances having a particular system of ions

arrangement in space, which is characterized by a crystal lattice.

The majority of metals used in engineering, has a lattice of one of following types:

space-centered cubic, face-centered cubic and close-packed hexagonal (fig. 1.1).

a

a

a

Fig. 1.1. Types of crystal lattices: a space-centered cubic; b - face-centered cubic;

c - close-packed hexagonal.

The crystal lattice is characterized not only by the type of a low level cell, but also

by sizes or parameters (in a fig. 1.1 - sizes a and c). The lattice parameters are measured

in angstroms: 1=10-10 m.

Some metals, for example, titanium, iron, stannum can have different crystalline

structure at miscellaneous temperatures. Each modification of crystalline structure is

stable in particular temperature range and is marked by small characters of the Greek

alphabet (, , , , etc.), for example: -titanium, -titanium, -iron. The transferring of

one crystalline structure in another is called as polymorphism or allotropy (the

polymorphic transformation takes place).

The pure metal does not satisfy the requirements to construction materials.

Therefore not pure metals, but their alloys are mainly applied in engineering.

The concepts of alloy and phase are used at alloys composition research. Alloy is a

composition obtained by alloying or sintering of two or more substances. The substances

that are included in compound structure, called as components. A phase is a part of alloy

with fixed chemical structure, with the same modular condition, identical type of a crystal

lattice and interface with other parts of alloy.

The atoms of two or more elements participate in alloy formation. At their

interaction can arise following component: liquid solutions, solid solutions, chemical

compounds, intermediate phases and mechanical mixtures. Overwhelming number of

metals unrestrictedly dissolve in each other in liquid state. Solid solution - single-phase

structure with a crystal lattice formed by atoms of alloy components. Component, which

crystal lattice is saved, called as a solvent. Component, that does not save own crystal

lattice, but returns the atoms in a solvent lattice, is called as miscible.

The main types of solid solutions: substitutional solid solutions (SSS) and

interstitial solid solution (ISS). SSS can be of restricted and unlimited oxygen solubility.

SSS are formed by replacement of solvent crystal lattice atoms with the atoms of

dissolved component (fig. 1.2, a, b). ISS are formed by arranging of dissolving

component atoms in free interspaces between atoms of solvent crystal lattice (fig. 1.2, c).

Fig. 1.2. Lattice distortion at solid solutions formation: a - atomic radius of dissolving

metal is greater than atomic radius of a solvent in SSS; b - atomic radius of dissolving

metal is less than atomic radius of a solvent in SSS; c - formation of ISS.

Principles of crystallization

Crystallization is a metal and alloy conversion from liquid to solid state. This

transformation is accompanied by formation of certain crystal lattice. The beginning of

crystallization is accompanied by occurring of nucleus center in a melt. The further

increase of crystals quantity and their sizes begins from these centers.

The crystallization process is quantitatively characterized by nuclei generation rate

Vcc (measured in mm-3s-1) and solidification rate Vcg (measured in mm/s) - the fig. 1.3.

Fig. 1.3. Model of crystallization process

At cooling of alloy up to chilling point a nuclei generation rate Vcc and

solidification rate Vcg grow up. At certain degree of a supercooling they reach maxima,

after that reduce to zero. Thus a nuclei generation rate Vcc and the number of nucleus

centers grows faster, than solidification rate Vcg (fig. 1.4).

The greater the nuclei generation rate and the less the solidification rate, the less is

the size of a crystal. In this case the structure of metal will be more fine-grained.

The size of metal grain greatly influences on viscosity and toughness of metal.

Heating temperature of molten metal, its chemical composition and presence at metal of

ectogenic admixtures cause large effect on a grain size.

V

VC C

VC g

T

Fig. 1.4. Relationship between nuclei generation rate Vcc , solidification rate Vcg and

degree of alloy supercooling

The equilibrium diagrams

It is necessary to know structure of alloy in a stable condition and during heat and

cooling for definition of alloys properties and their melting temperatures, for selection of

methods and conditions of heat treatment. In this case equilibrium diagrams in

coordinates "temperature - density" of alloy can be defined experimentally. With the help

of the thermal analysis can be received the alloy cooling curves in coordinates

"temperature of alloy - time of cooling" (fig. 1.5, b). Inflection points and horizontal

sections, which characterize critical temperatures of alloys, can be discovered on these

curves. Critical points of alloys transformation then must be plotted in coordinates

"temperature density" and smoothly connected with one another. There are some

techniques of equilibrium diagrams plotting for multicomponent alloys. Let's consider for

simplicity two-component systems.

The equilibrium diagram of the first kind

This diagram describes crystallization of alloys with components, dissolved

unlimitedly in each other only in liquid state. Components cannot dissolve in each other

and do not form chemical combinations in solid state. During process of crystallization

alloy components form mechanical mixture called as eutectic. Examples of such

components: lead-stibium, tin-zinc, lead-silver etc. General view of the first kind

equilibrium diagram for components A and B is shown in a fig. 1.5, a.

B

I

1

o

t C

A

L

m

L+A

t2

10

20

30

3

0

t1

B + (A + B )

A + (A + B )

A

L+B

t oC

40

50

60

70

80

B

90 100

Fig. 1.5. The equilibrium diagram of the first kind (a) with relevant cooling curve (b)

The line ACB is called as a liquidus line. It is a geometrical place of points where

alloys crystallization begins. The crystals of component A crystallize from a liquid melt L

on a line AC. Crystallization of component A finishes on a line ADC. The crystals of

component B crystallize from a liquid melt L on a line BC. Crystallization of component

B finishes on a line DCE. The line DCE is called as a solidus line. The eutectic mixture

of crystals (A+B) is formed on a line DCE in any point at constant temperature. A point

C corresponds to alloy of eutectic composition. In this point the eutectic mixture (A+B)

crystallizes only. Alloys with components concentration more to the left of a point C are

called as hypoeutectic. Alloys with components concentration relevant to point C are

called as eutectic. Alloys with components concentration more to the right of a point C

are called as hypereutectic.

The amount and composition of phases in alloy is determined by a rule of cuts.

This rule can be used only in two-phase area of the diagram. Conode (horizontal line) is

carried out up to intersection with liquidus and solidus lines at temperature t 1 for alloy of

I-concentration in area BCE of diagram. The cut nt1 is taking as 100 %. According to the

rule of cuts for definition of the fluid phase amount qlp in percentage it is necessary: to

relate a cut mt1, opposite to a liquidus line, to all length of a cut and multiplicate it on

100%, i.e.

qp

mt 1

100% .

nt 1

Similarly the solid phase amount qsp can be determined in percentage by the ratio

of cuts mn and nt1:

qsp

mn

100% .

nt 1

The second part of cuts rule consists in following: the projections of conode

intersection points with liquidus and solidus lines on concentration axis give necessary

values of liquid phases and solid phases densities.

The equilibrium diagram of the second kind

This diagram describes crystallization of alloys with components, dissolved

unlimitedly in each other both in solid and in liquid state. Examples of such alloys: iron nickel, iron - chrome, copper - nickel. The equilibrium diagram of the second kind is

shown in fig. 1.6.

Let's consider a crystallization of alloy I. Point C marks the moment of appearing

of solid solution crystals in a fluid phase L with density of point 1. Solid solution crystals

having density of point 2 appear at temperature t. In a point D solid solution crystals of

point E density will conform to the density of alloy I. Thus, during crystallization from a

fluid phase the crystals of variable composition may originate.

L

t,o C

C

3

t

2

D

E

0

10

20

30

40

50

B ,%

60

70

80

90

100

Fig. 1.6. The equilibrium diagram of the second kind. Line ACB - a liquidus, line ABD - a

solidus.

The equilibrium diagram of the third kind

This diagram describes crystallization of alloys with components, dissolved

unlimitedly in each other in liquid state. In a solid state they are dissolved limitedly and

form a eutectic at crystallization. Figure 1.7 illustrates the equilibrium diagram of the

second kind.

In this diagram the pure components A and B cant crystallize. Solid solution of

component A is called . Solid solution of component B is called . Line DCE shows the

moment when mechanical mixture of solid solutions crystals is formed during

crystallization of fluid phase with point C density. As solubility B in A can vary, line DK

reflects temperature dependence of abundant crystals extraction. II - phase enriched with

a component B.

t, oC

I

L+

L+

11

K

0

3

10

20

30

40

50

B ,%

60

F

70

80

90

100

Fig. 1.7. The equilibrium diagram of the third kind. Line ACB - a liquidus, line ADCEBa solidus. DCE- a line of eutectic transformation. DK- a line of a limited solubility of

component B in component A. EF- a line of a marginal solubility of component A in a

component B.

The equilibrium diagram of the fourth kind

The equilibrium diagram of the fourth kind characterizes alloys, which components

A and B can resolve unlimitedly in each other in liquid state. Those components are

insoluble in a solid state and form steady chemical combinations. The equilibrium

diagram of the fourth kind is shown in a fig. 1.8.

The line CE in a fig. 1.8 refers to chemical compound AnBm. A point C corresponds

to melting point of chemical compound AnBm. The diagram has 2 eutectic points D and

D. The constant melting point and fixed components ratio are typical to chemical

compound AnBm.

t ,o C

C

A

A n Bm

D

100% A

100% B

Fig. 1.8. The equilibrium diagram of the fourth kind

The diagram composition of property

The analysis of the equilibrium diagrams allows studying dependence of alloys

properties from their structure. N.S. Kurnakov designed the method of the diagram

composition of property ploting. On these diagrams on a horizontal the composition of

alloy, and on verticals - amount of components A and B in alloys varies. With the help of

these diagrams the alloys for particular purpose are selected. For example, the alloys with

large electrical resistance belong to solid solutions. The alloys for a casting should be

selected among eutectic alloys. The alloys of high hardness should be selected among

alloys forming chemical compounds.

You might also like

- Phase Diagrams & Heat Treatment of Carbon SteelDocument84 pagesPhase Diagrams & Heat Treatment of Carbon SteelTanmay DuttaNo ratings yet

- Coordinate Systems Used in Flight DynamicsDocument9 pagesCoordinate Systems Used in Flight DynamicsJason RossNo ratings yet

- Phase Diagrams - Equilibrium Microstructural Development: 38 WT % PBDocument45 pagesPhase Diagrams - Equilibrium Microstructural Development: 38 WT % PBpetember100% (1)

- Solidification, Phase Diagrams and Phase TransformationDocument35 pagesSolidification, Phase Diagrams and Phase TransformationkrishnasaiNo ratings yet

- Eng Mat Chapter 4Document126 pagesEng Mat Chapter 4VC Chua Yee LeongNo ratings yet

- Aerodynamics of Lifting SurfacesDocument8 pagesAerodynamics of Lifting SurfacesJason RossNo ratings yet

- Handbook No.1Document125 pagesHandbook No.1Dhinakar AnnaduraiNo ratings yet

- Mce 203. Phase Equilibrium.Document7 pagesMce 203. Phase Equilibrium.samuelodeyemi3000No ratings yet

- FL&O Section 10Document24 pagesFL&O Section 10Muhammad FaizNo ratings yet

- Terminology For Mechanical PropertiesDocument75 pagesTerminology For Mechanical PropertiesibrahimNo ratings yet

- Lesson 5 PDFDocument32 pagesLesson 5 PDFMajak MarialNo ratings yet

- Unit - III: Me432P: Material EnggDocument37 pagesUnit - III: Me432P: Material Engghans groupNo ratings yet

- Metallurgical EngineeringDocument49 pagesMetallurgical EngineeringMatab ThamerNo ratings yet

- Met 01 Metals Structure - Steel MakingDocument22 pagesMet 01 Metals Structure - Steel MakingRaghu vamshiNo ratings yet

- Che 414Document21 pagesChe 414Looking forwardNo ratings yet

- Assignment WEEK 5 SolutionsDocument5 pagesAssignment WEEK 5 SolutionsPeeka Prabhakara RaoNo ratings yet

- Binary 6Document6 pagesBinary 6حسين كاظم ياسينNo ratings yet

- Material Engineering QUESTION BANKDocument13 pagesMaterial Engineering QUESTION BANKFUNTUBENo ratings yet

- Solidification of Single-Phase Alloys - 2007Document12 pagesSolidification of Single-Phase Alloys - 2007pkn_pnt9950No ratings yet

- 2 5391019718461098174Document7 pages2 5391019718461098174Motaz TharwatNo ratings yet

- Alloy Systems and Phase DiagramsDocument11 pagesAlloy Systems and Phase DiagramsarugeetNo ratings yet

- Emm HandoutsDocument58 pagesEmm HandoutsDr.A.Maniram KumarNo ratings yet

- 2-Alloy SystemsDocument23 pages2-Alloy SystemsHussein SaeedNo ratings yet

- Chapter 2 - TTA - TTT - DiagramsDocument13 pagesChapter 2 - TTA - TTT - DiagramsPrasad Mhatre100% (1)

- Interstitial Solid Solution L.C. H.L.Document14 pagesInterstitial Solid Solution L.C. H.L.ombuilder92No ratings yet

- Question BankDocument4 pagesQuestion BankParameswara RajaNo ratings yet

- Chapter 9 ReportDocument16 pagesChapter 9 ReportG. Dancer GhNo ratings yet

- Question & Answer Set-7Document12 pagesQuestion & Answer Set-7eeng.ali651550% (2)

- Engineering Materials Unit 1Document23 pagesEngineering Materials Unit 1Kandasamy VenkatachalamNo ratings yet

- Structure of Engineering MaterialsDocument12 pagesStructure of Engineering Materialsjust_killing_pplNo ratings yet

- IPM Note CompressedDocument59 pagesIPM Note CompressedNouhaila HajjoumNo ratings yet

- Phase Diagram ExDocument23 pagesPhase Diagram ExTey KaijingNo ratings yet

- Slides - 4Document55 pagesSlides - 4Rahul PandeyNo ratings yet

- Unit-2: Phase DiagramDocument37 pagesUnit-2: Phase DiagramPrasad Govind KumbharNo ratings yet

- EM Five Units Notes PDFDocument85 pagesEM Five Units Notes PDFRajesh ChidambaramNo ratings yet

- Phase DiagramsDocument50 pagesPhase DiagramsIbrahim MalikNo ratings yet

- MSM SolutionDocument12 pagesMSM SolutionAnil ChauvanNo ratings yet

- Material Engineering AssignmentDocument60 pagesMaterial Engineering Assignmentjunaid hassanNo ratings yet

- Monotectic AlloysDocument8 pagesMonotectic Alloysandrea usugaNo ratings yet

- Biomaterials II Lec 5Document13 pagesBiomaterials II Lec 5m9trdk92ksNo ratings yet

- Actividad Fundametal 2Document10 pagesActividad Fundametal 2Altsuki SKNo ratings yet

- Mechanical Properties 4Document12 pagesMechanical Properties 4FrancisNo ratings yet

- 9A03301 Materials Science and EngineeringDocument4 pages9A03301 Materials Science and EngineeringsivabharathamurthyNo ratings yet

- Chapter 4: Imperfections in SolidsDocument46 pagesChapter 4: Imperfections in SolidsJesse De LeonNo ratings yet

- Lecture2-Structure of Materials & Influence On PropertiesDocument50 pagesLecture2-Structure of Materials & Influence On PropertiesKamal SurenNo ratings yet

- Crystal Imperfection CH 4Document44 pagesCrystal Imperfection CH 4anapguerraNo ratings yet

- Engineering Metallurgy NotesDocument89 pagesEngineering Metallurgy NotesYuvaraja Yuva100% (1)

- Capili Jefferson 9Document13 pagesCapili Jefferson 9Christian Al EncarnacionNo ratings yet

- Edge Dislocation Means That One of The Atoms in A Unit Cell Is Absent or Replaced or Added As An Extra ThatDocument4 pagesEdge Dislocation Means That One of The Atoms in A Unit Cell Is Absent or Replaced or Added As An Extra ThatAshok PradhanNo ratings yet

- Basic Metallurgy - Chap2Document117 pagesBasic Metallurgy - Chap2AhmedNo ratings yet

- PhaseDocument6 pagesPhasefarooq_bagbanNo ratings yet

- MM Question BankDocument22 pagesMM Question BankDr.A.Maniram KumarNo ratings yet

- The Iron Iron Carbide Phase Diagram A Practical GuDocument6 pagesThe Iron Iron Carbide Phase Diagram A Practical GuMuhammad Irfan SalahuddinNo ratings yet

- Two Marks With AnswersDocument19 pagesTwo Marks With AnswersNallappan Rajj ANo ratings yet

- Ch-27.1 Basic Concepts On Structure of SolidsDocument45 pagesCh-27.1 Basic Concepts On Structure of SolidsdSGDASUDNo ratings yet

- Chem 1Document23 pagesChem 1Adi SoNo ratings yet

- Note CHP 2-Material Science 281 Uitm Em110Document74 pagesNote CHP 2-Material Science 281 Uitm Em110bino_rye100% (1)

- Infrared Spectroscopy of Triatomics for Space ObservationFrom EverandInfrared Spectroscopy of Triatomics for Space ObservationNo ratings yet

- Razdel 7 Eng ReviewedDocument24 pagesRazdel 7 Eng ReviewedJason RossNo ratings yet

- Fuselage Geometrical ParametersDocument10 pagesFuselage Geometrical ParametersJason RossNo ratings yet

- Chapter2 Kinematics of FluidsDocument43 pagesChapter2 Kinematics of FluidsJason RossNo ratings yet

- Aerodynamics of Lifting SurfacesDocument10 pagesAerodynamics of Lifting SurfacesJason RossNo ratings yet

- The Polar DiagramDocument7 pagesThe Polar DiagramJason RossNo ratings yet

- Section 3. Aerodynamics of An AirplaneDocument13 pagesSection 3. Aerodynamics of An AirplaneJason RossNo ratings yet

- Theme 15 PDFDocument17 pagesTheme 15 PDFJason RossNo ratings yet

- Equations of Airplane Motion in Trajectory Coordinate System in Particular Cases. Aerodynamic Calculation of An Aircraft. Zhukovsky Method of ThrustsDocument10 pagesEquations of Airplane Motion in Trajectory Coordinate System in Particular Cases. Aerodynamic Calculation of An Aircraft. Zhukovsky Method of ThrustsJason RossNo ratings yet

- Multiple Pipe SystemsDocument10 pagesMultiple Pipe SystemsJason Ross0% (1)

- Center of Pressure and Aerodynamic CenterDocument4 pagesCenter of Pressure and Aerodynamic CenterJason RossNo ratings yet

- y x, iΨ y x,: Complex potentialDocument2 pagesy x, iΨ y x,: Complex potentialJason RossNo ratings yet

- Principal Hypotheses and Assumptions in Strength of MaterialsDocument9 pagesPrincipal Hypotheses and Assumptions in Strength of MaterialsJason Ross100% (1)

- Thomson Theorem About Circulation ConstancyDocument5 pagesThomson Theorem About Circulation ConstancyJason RossNo ratings yet

- Fluid Vortex-Type Flow, Vortex Line, Vortexline, Vortex Tube, Vortex CoreDocument3 pagesFluid Vortex-Type Flow, Vortex Line, Vortexline, Vortex Tube, Vortex CoreJason RossNo ratings yet

- Airworthiness StandardsDocument15 pagesAirworthiness StandardsJason RossNo ratings yet

- Calculation of Aircraft Aerodynamic Characteristics (Sem6)Document10 pagesCalculation of Aircraft Aerodynamic Characteristics (Sem6)Jason RossNo ratings yet

- First Helmholtz Vortex TheoremDocument2 pagesFirst Helmholtz Vortex TheoremJason RossNo ratings yet