Professional Documents

Culture Documents

Incoloy Alloy 825

Incoloy Alloy 825

Uploaded by

suresh_vikiCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Incoloy Alloy 825

Incoloy Alloy 825

Uploaded by

suresh_vikiCopyright:

Available Formats

www.specialmetals.

com

Table 2 - Physical Constants

Table 3 - Thermal Properties

Table 1 - Limiting Chemical Composition, % of INCOLOY alloy 825

Nickel ..........................................................................38.0-46.0

Iron...............................................................................22.0 min.

Chromium....................................................................19.5-23.5

Molybdenum ...................................................................2.5-3.5

Copper ............................................................................1.5-3.0

Titanium...........................................................................0.6-1.2

Carbon ........................................................................0.05 max.

Manganese ...................................................................1.0 max.

Sulfur ..........................................................................0.03 max.

Silicon ...........................................................................0.5 max.

Aluminum......................................................................0.2 max.

Physical Constants and Thermal

Properties

Some physical constants for INCOLOY alloy 825 are

listed in Table 2. Values for thermal expansion, thermal

conductivity, and electrical resistivity at various

temperatures are in Table 3. Modulus of elasticity and

Poissons ratio over a range of temperatures are given in

Table 4. Modulus values, which were determined

dynamically, were used to compute Poissons ratio.

The data contained in this publication is for informational purposes only and

may be revised at any time without prior notice. The data is believed to be

accurate and reliable, but Special Metals makes no representation or warranty of

any kind (express or implied) and assumes no liability with respect to the

accuracy or completeness of the information contained herein. Although the

data is believed to be representative of the product, the actual characteristics or

performance of the product may vary from what is shown in this publication.

Nothing contained in this publication should be construed as guaranteeing the

product for a particular use or application.

Temperature

Coefficient of

Expansiona

10-6in/inF

-250

-200

-100

0

78

100

200

400

600

800

1000

1200

1400

1600

1800

2000

7.8

8.3

8.5

8.7

8.8

9.1

9.5

9.7

-

m/mC

W/mC

-150

-100

0

25

100

200

300

400

500

600

700

800

900

1000

14.1

14.8

15.3

15.6

15.8

16.0

16.7

17.3

-

7.9

8.9

10.7

11.1

12.3

13.8

15.4

16.9

18.2

19.6

21.2

23.1

25.5

-

1.13

1.14

1.18

1.21

1.24

1.26

1.27

1.27

1.28

1.29

1.30

Thermal

Conductivity

Electrical

Resistivity

Btu-in/ft2hF ohmcirc mil/ft

55

59

66

72.6

76.8

78.4

85.0

97.5

109.6

119.7

130.9

141.8

154.9

171.8

192.0

-

678

680

687

710

728

751

761

762

765

775

782

793

Mean coefficient of linear expansion between 80F (27C) and

temperature shown.

Publication Number SMC-030

Copyright Special Metals Corporation, 2004 (Sept 04)

INCOLOY, INCONEL, INCO-WELD and 686CPT are

trademarks of the Special Metals Corporation group of

companies.

INCOLOY alloy 825

Density, lb/in3 .....................................................................0.294

Mg/m3 ....................................................................8.14

Melting Range, F .....................................................2500-2550

C .....................................................1370-1400

Specific Heat, Btu/lbF ....................................................0.105

J/kgC .........................................................440

Curie Temperature, F .......................................................<-320

C ......................................................<-196

Permeability at 200 oersted (15.9 kA/m)...........................1.005

INCOLOY alloy 825 (UNS N08825/W.Nr. 2.4858) is a

nickel-iron-chromium alloy with additions of

molybdenum, copper, and titanium. The alloys

chemical composition, given in Table 1, is designed to

provide exceptional resistance to many corrosive

environments. The nickel content is sufficient for

resistance to chloride-ion stress-corrosion cracking. The

nickel, in conjunction with the molybdenum and

copper, also gives outstanding resistance to reducing

environments such as those containing sulfuric and

phosphoric acids. The molybdenum also aids resistance

to pitting and crevice corrosion. The alloys chromium

content confers resistance to a variety of oxidizing

substances such as nitric acid, nitrates and oxidizing

salt. The titanium addition serves, with an appropriate

heat treatment, to stabilize the alloy against

sensitization to intergranular corrosion.

The resistance of INCOLOY alloy 825 to general

and localized corrosion under diverse conditions gives

the alloy broad usefulness. Applications include

chemical processing, pollution control, oil and gas

recovery, acid production, pickling operations, nuclear

fuel reprocessing, and handling of radioactive wastes.

Applications for alloy 825 are similar to those for

INCOLOY alloy 020.

INCOLOY alloy 825

Mechanical Properties

INCOLOY alloy 825 has good mechanical properties from cryogenic temperatures to moderately high temperatures. Exposure

to temperatures above about 1000F (540C) can result in microstructural changes (phase formation) that significantly lower

ductility and impact strength. For that reason, the alloy is not normally used at temperatures where creep-rupture properties

are design factors.

Tensile properties at room temperature are listed in Table 5. As indicated, the alloy can be strengthened substantially by

cold work.

High-temperature tensile properties are shown in Figure 1. The tests were conducted on cold-drawn rod of 0.75-in. (19mm) diameter annealed at 1725F (940C)/1 hr.

Compressive yield strength of the alloy is similar to tensile yield strength. Tests on annealed rod of 1.0-in. (25-mm)

diameter produced a compressive yield strength (0.2% offset) of 61,400 psi (423 MPa) compared with a tensile yield strength

of 57,500 psi (396 MPa). Ultimate tensile strength of the material was 104,500 psi (720 MPa).

INCOLOY alloy 825 has good impact strength at room temperature and retains its strength at cryogenic temperatures.

Table 6 gives the results of Charpy keyhole tests on plate.

Table 4 - Modulus of Elasticity (Hot Rolled and Annealed Plate)

103 ksi

103 ksi

100

200

300

400

500

600

700

800

900

1000

1100

1200

1300

1400

1500

1600

1700

1800

28.3

27.9

27.5

27.1

26.6

26.1

25.5

25.0

24.5

24.0

23.6

23.0

22.3

21.3

20.3

19.5

18.5

17.5

11.0

10.9

10.7

10.4

10.2

10.1

10.0

9.8

9.5

9.2

8.9

8.6

8.2

7.9

7.6

7.3

6.9

6.5

Temperature

Youngs

Modulus

Shear

Modulus

GPa

GPa

20

100

200

300

400

500

600

700

800

900

1000

196

192

187

181

174

168

162

154

142

131

118

76

75

72

70

68

65

61

57

53

49

44

0.29

0.28

0.29

0.30

0.30

0.29

0.28

0.28

0.29

0.30

0.33

0.34

0.35

0.35

0.34

0.34

0.34

0.34

ksi

Yield Strength

(0.2% Offset)

MPa

ksi

MPa

Elongation,

%

Tubing, Annealed

112

772

64

441

36

Tubing, Cold Drawn

Bar, Annealed

Plate, Annealed

Sheet, Annealed

145

100

96

110

1000

690

662

758

129

47

49

61

889

324

338

421

15

45

45

39

Table 6 - Charpy Keyhole Impact Strength of Plate

Temperature

Orientation

F

Room

Room

-110

-43

-320

-196

-423

-253

Longitudinal

Transverse

Longitudinal

Transverse

Longitudinal

Transverse

Longitudinal

Transverse

Impact Strengtha

ft-lb

79.0

83.0

78.0

78.5

67.0

71.5

68.0

68.0

107

113

106

106

91

97

92

92

Average of three tests.

Poissons

Ratio

0.29

0.28

0.30

0.29

0.28

0.29

0.33

0.35

0.34

0.34

0.34

Tensile Strength

Form and

Condition

Poissons

Ratio

120

100

200 300

Temperature, C

400 500 600 700

800

900 1000

700

100

Tensile Strength

600

80

500

60

400

Elongation

300

40

200

Yield Strength

(0.2% Offset)

20

100

0

0

200

400

600

800 1000 1200 1400 1600 1800

Temperature, F

2000

Figure 1. High-temperature tensile properties of annealed bar.

Indicates the typical usage range.

Stress, MPa

Shear

Modulus

Elongation, %

Youngs

Modulus

Stress, ksi

Temperature

Table 5 - Typical Room-Temperature Tensile Properties

INCOLOY alloy 825

Corrosion Resistance

The outstanding attribute of INCOLOY alloy 825 is its high level of corrosion resistance. In both reducing and oxidize

environments, the alloy resists general corrosion, pitting, crevice corrosion, intergranular corrosion, and stress-corrosion

cracking. Some environments in which INCOLOY alloy 825 is particularly useful are sulfuric acid, phosphoric acid, sulfurcontaining flue gases, sour gas and oil wells, and sea water.

For details on the corrosion resistance of alloy 825, refer to Special Metals publication Restistance to Aqueous

Corrosion, on the website, www.specialmetals.com.

Fabrication

INCOLOY alloy 825 products are heat treated during manufacturing at the mill to develop the optimum combination of

stabilization, corrosion resistance, mechanical properties, and formability. To maintain these properties during fabrication,

subsequent anneals should be performed between 1700 to 1800F (930 to 980C) followed by rapid air cooling or water

quenching. Heat treatment in the lower end of the range is acceptable for stabilization. However, annealing at temperatures

in the higher end of this range may be preferred for softness and grain structure for forming and deep-drawing while

maintaining corrosion resistance. Quenching is usually not necessary for parts of thin cross section (e.g., sheet, strip and wire),

but may be desired to avoid sensitization in products of heavier cross section. General procedures for heating, forming,

pickling, and finishing are found in the SMC bulletin Fabricating. Welding, brazing, and soldering techniques are discussed

in Joining. These bulletins are available on the website www.specialmetals.com.

Hot and Cold Forming

The hot-working range for INCOLOY alloy 825 is 1600 to 2150F (870 to 1180C). For optimum corrosion resistance, final

hot working should be done at temperatures between 1600 and 1800F (870 and 980C).

Cooling after hot working should be air cool or faster. Heavy sections may become sensitized during cooling from the

hot-working temperature, and therefore be subject to intergranular corrosion in certain media. A stabilizing anneal (see above)

restores resistance to corrosion. If material is to be welded or subjected to further thermal treatment and subsequently exposed

to an environment that may cause intergranular corrosion, the stabilizing anneal should be performed regardless of cooling

rate from the hot-working temperature.

Cold-forming properties and practices are essentially the same for INCOLOY alloy 825 as for INCONEL alloy 600.

Although work-hardening rate is somewhat less than for the common grades of austenitic stainless steels, it is still relatively

high. Forming equipment should be well powered and strongly built to compensate for the increase in yield strength with

plastic deformation.

Additional information on hot and cold forming can be obtained by visiting the website www.specialmetals.com.

Machining

Joining

All standard machining operations are readily performed on

INCOLOY alloy 825. The alloy normally has optimum

machining characteristics in the annealed temper. Tooling

and procedures described for Group C alloys should be used;

for more information refer to Special Metals publication

Machining, on the website, www.specialmetals.com.

INCOLOY alloy 825 has good weldability by all

conventional processes. For most applications, INCONEL

Welding Electrode 112 for shielded metal-arc welding and

INCONEL Filler Metal 625 for gas-shielded processes are

used. For applications that require highest resistance to

corrosion, INCO-WELD Welding Electrode 686CPT and

INCO-WELD Filler Metal 686CPT are used. Information on

surface preparation, joint design, and welding technique can

be obtained in the Special Metals publication Joining, on

the website, www.specialmetals.com.

Available Products and Specifications

INCOLOY Alloy 825 is designated as UNS N08825 and Werkstoff Number 2.4858. It is listed in NACE MR0175 for oil and

gas service. Alloy 825 is available as pipe, tube, sheet, strip, plate, round bar, flat bar, forging stock, hexagon and wire.

Rod, Bar, Wire and Forging Stock - BS 3076NA16, ASTM B 425, ASTM B 564, ASME SB 425, ASME SB 564, ASME

Code Case N-572, DIN 17752, DIN 17753, DIN 17754, VdTV 432, ISO 9723, ISO 9724, ISO 9725

Plate, Sheet and Strip - BS 3072NA16, BS 3073NA16, ASTM B 424, ASTM B 906, ASME SB 424, ASME SB 906, DIN

17750, VdTV 432, ISO 6208

Pipe and Tube - BS 3074NA16, ASTM B 163, ASTM B 423, ASTM B 704, ASTM B 705, ASTM B 751, ASTM B 775,

ASTM B 829, ASME SB 163, ASME SB 423, ASME SB 704, ASME SB 705, ASME SB 751, ASME SB 775, ASME SB

829, ASME Code Case 1936, DIN 17751, VdTV 432, ISO 6207

Others - ASTM B 366, ASME SB 366, DIN 17744

3

www.specialmetals.com

U.S.A.

France

Affiliated Companies

Special Metals Services SA

17 Rue des Frres Lumire

69680 Chassieu (Lyon)

Phone

+33 (0) 4 72 47 46 46

Fax

+33 (0) 4 72 47 46 59

Special Metals Welding

Products

Special Metals Corporation

Billet, rod & bar, flat

& tubular products

3200 Riverside Drive

Huntington, WV 25705-1771

Phone

+1 (304) 526-5100

+1 (800) 334-4626

Fax

+1 (304) 526-5643

Billet & bar products

4317 Middle Settlement Road

New Hartford, NY 13413-5392

Phone

+1 (315) 798-2900

+1 (800) 334-8351

Fax

+1 (315)798-2016

Atomized powder products

100 Industry Lane

Princeton, KY 42445

Phone

+1 (270) 365-9551

Fax

+1 (270) 365-5910

Shape Memory Alloys

4317 Middle Settlement Road

New Hartford, NY 13413-5392

Phone

+1 (315) 798-2939

Fax

+1 (315) 798-6860

United Kingdom

Special Metals Wiggin Ltd.

Holmer Road

Hereford HR4 9SL

Phone

+44 (0) 1432 382200

Fax

+44 (0) 1432 264030

Germany

Special Metals Deutschland Ltd.

Postfach 20 04 09

40102 Dsseldorf

Phone

+49 (0) 211 38 63 40

Fax

+49 (0) 211 37 98 64

Hong Kong

Special Metals Pacific Pte. Ltd.

Unit A, 17th Floor, On Hing Bldg

1 On Hing Terrace

Central, Hong Kong

Phone

+852 2439 9336

Fax

+852 2530 4511

Canada House

Bidavon Industrial Estate

Waterloo Road

Bidford-On-Avon

Warwickshire B50 4JN, U.K.

Phone

+44 (0) 1789 491780

Fax

+44 (0) 1789 491781

Controlled Products Group

590 Seaman Street, Stoney Creek

Ontario L8E 4H1, Canada

Phone

+1 (905) 643-6555

Fax

+1 (905) 643-6614

A-1 Wire Tech, Inc.

India

Special Metals Services Ltd.

No. 60, First Main Road, First

Block

Vasantha Vallabha Nagar

Subramanyapura Post

Bangalore 560 061

Phone

+91 (0) 80 2666 9159

Fax

+91 (0) 80 2666 8918

Italy

Special Metals Wire Products

Holmer Road

Hereford HR4 9SL

Phone

+44 (0) 1432 382556

Fax

+44 (0) 1432 352984

Special Metals Services SpA

Via Assunta 59

20054 Nova Milanese (MI)

Phone

+390 362 4941

Fax

+390 362 494224

China

The Netherlands

Special Metals Pacific Pte. Ltd.

Room 1802, Plaza 66

1266 West Nanjing Road

Shanghai 200040

Phone

+86 21 3229 0011

Fax

+86 21 6288 1811

Special Metals Service BV

Postbus 8681

3009 AR Rotterdam

Phone

+31 (0) 10 451 44 55

Fax

+31 (0) 10 450 05 39

Singapore

Special Metals Pacific Pte. Ltd.

Room 910, Ke Lun Mansion

12A Guanghua Road

Chaoyang District

Beijing 100020

Phone

+86 10 6581 8396

Fax

+86 10 6581 8381

1401 Burris Road

Newton, NC 28658, U.S.A.

Phone

+1 (828) 465-0352

+1 (800) 624-3411

Fax

+1 (828) 464-8993

Special Metals Pacific Pte. Ltd.

24 Raffles Place

#27-04 Clifford Centre

Singapore 048621

Phone

+65 6532 3823

Fax

+65 6532 3621

A Special Metals Company

4550 Kishwaukee Street

Rockford, IL 61109, U.S.A.

Phone

+1 (815) 226-0477

+1 (800) 426-6380

Fax

+1 (815) 226-0537

Rescal SA

A Special Metals Company

200 Rue de la Couronne des Prs

78681 Epne Cdex, France

Phone

+33 (0) 1 30 90 04 00

Fax

+33 (0) 1 30 90 02 11

DAIDO-SPECIAL METALS

Ltd.

A Joint Venture Company

Daido Shinagawa Building

6-35, Kohnan 1-chome

Minato-ku, Tokyo 108-0057, Japan

Phone

+81 (0) 3 5495 7237

Fax

+81 (0) 3 5495 1853

You might also like

- Visual Examination ReportDocument47 pagesVisual Examination ReportalouisNo ratings yet

- API 934 Minutes Fluor ATT CDocument28 pagesAPI 934 Minutes Fluor ATT CAnonymous rUs4PjYo5No ratings yet

- Reformer Component Management After An Overheating Incident That Resulted in Tube FailuresDocument12 pagesReformer Component Management After An Overheating Incident That Resulted in Tube FailuresGrootNo ratings yet

- A1021Document4 pagesA1021Aleksei AvilaNo ratings yet

- Weld Repair For Pressure Vessels Made From Cr-Mo SteelsDocument8 pagesWeld Repair For Pressure Vessels Made From Cr-Mo SteelsVedad ColakNo ratings yet

- Creep and Fatigue Damage During Boiler LifeDocument9 pagesCreep and Fatigue Damage During Boiler Lifevikas2510100% (3)

- Review of Creep Resistant SteelsDocument4 pagesReview of Creep Resistant SteelsAleš NagodeNo ratings yet

- Pérez2011 Article GraphitizationInLowAlloySteelPDocument7 pagesPérez2011 Article GraphitizationInLowAlloySteelPramzi5ben5ahmedNo ratings yet

- Effect of Heat Input On Microstructure and Mechanical Properties of The TIG Welded Joints of AISI 304Document10 pagesEffect of Heat Input On Microstructure and Mechanical Properties of The TIG Welded Joints of AISI 304Kaushik SenguptaNo ratings yet

- Chapter11 Mechanical BehaviorDocument31 pagesChapter11 Mechanical BehaviorDheivendranRamiah100% (1)

- 1 - A Study Concerning Intercritical HAZ Microstructure and Toughness in ...Document10 pages1 - A Study Concerning Intercritical HAZ Microstructure and Toughness in ...Filipe RenanNo ratings yet

- Materials Data for Cyclic Loading: Aluminium and Titanium AlloysFrom EverandMaterials Data for Cyclic Loading: Aluminium and Titanium AlloysRating: 1 out of 5 stars1/5 (1)

- Method of Statement For Sika Grout-215Document3 pagesMethod of Statement For Sika Grout-215Poru Man100% (5)

- The Role Stainless Steel in Industrial Heat ExchangersDocument46 pagesThe Role Stainless Steel in Industrial Heat ExchangerswholenumberNo ratings yet

- Friction Stir Welding of High Strength 7XXX Aluminum AlloysFrom EverandFriction Stir Welding of High Strength 7XXX Aluminum AlloysNo ratings yet

- Fracture Mechanics - Worked Examples - John KnottDocument119 pagesFracture Mechanics - Worked Examples - John Knottbaja2011100% (1)

- Titanium Guide PDFDocument48 pagesTitanium Guide PDFthanghanvicoNo ratings yet

- Metrode Welding Consumables For P92 and T23 Creep Resisting SteelsDocument17 pagesMetrode Welding Consumables For P92 and T23 Creep Resisting SteelsClaudia MmsNo ratings yet

- Mechanism of Failure by Hydrogen-Induced Cracking PDFDocument216 pagesMechanism of Failure by Hydrogen-Induced Cracking PDFsankhadipNo ratings yet

- As 5016-2004 Metallic Materials - Conversion of Hardness ValuesDocument10 pagesAs 5016-2004 Metallic Materials - Conversion of Hardness ValuesSAI Global - APAC0% (1)

- Epifanes System Guide - WebDocument60 pagesEpifanes System Guide - WebpagliasoNo ratings yet

- Microstructure and Mechanical Properties of ASTM A743 CA6NM Steel Welded by FCAW ProcessDocument8 pagesMicrostructure and Mechanical Properties of ASTM A743 CA6NM Steel Welded by FCAW ProcessretrogradesNo ratings yet

- Testbars Vs Casting PropertiesDocument36 pagesTestbars Vs Casting Propertiescastco@iafrica.comNo ratings yet

- A Review of Factors Affecting Toughness in Welded Steels PDFDocument23 pagesA Review of Factors Affecting Toughness in Welded Steels PDFsurendarNo ratings yet

- Limitations of The Use of Grossman Quench Severity FactorsDocument12 pagesLimitations of The Use of Grossman Quench Severity FactorsPedro Polastri PatriotaNo ratings yet

- Microstructure Degradation After Prolonged Exploitation of Heatresistant Steel 14mov6-3Document5 pagesMicrostructure Degradation After Prolonged Exploitation of Heatresistant Steel 14mov6-3IJMERNo ratings yet

- PBI-CCP-QA-0001 QA Welding Consumable Control ProcedureDocument15 pagesPBI-CCP-QA-0001 QA Welding Consumable Control ProcedureTadaya KasaharaNo ratings yet

- Welding Duplex Stainless SteelDocument44 pagesWelding Duplex Stainless SteelInoCastilloNo ratings yet

- Hydrogen Induced Cracking PDFDocument254 pagesHydrogen Induced Cracking PDFAnas PratamaNo ratings yet

- EpriDocument21 pagesEprihubert_veltenNo ratings yet

- Past Present and Future of The Duplex Stainless SteelsDocument10 pagesPast Present and Future of The Duplex Stainless SteelsbayumahardikaNo ratings yet

- Centerline Segregation in Continuous Casting BilletsDocument5 pagesCenterline Segregation in Continuous Casting BilletsAnonymous MAJuDkNo ratings yet

- Corrosion Test PiecesDocument23 pagesCorrosion Test PiecesGijoNo ratings yet

- Test PackDocument17 pagesTest PackMuhammad Bilal Arif100% (4)

- High Performance Age-Hardenable Nickel Alloys Solve Problems in Sour Oil & Gas ServiceDocument8 pagesHigh Performance Age-Hardenable Nickel Alloys Solve Problems in Sour Oil & Gas ServiceArdy PrasetyoNo ratings yet

- Residual Stress and Its Role in FailureDocument55 pagesResidual Stress and Its Role in FailureEagle SpiritNo ratings yet

- Assessment of Creep Damage in Fe-Ni-Cr Alloys: Frans SorshDocument67 pagesAssessment of Creep Damage in Fe-Ni-Cr Alloys: Frans SorshAicepyrre MetGod MortelNo ratings yet

- 109.8181.MPI - Pre.Unit.730395.Cover RadiatorDocument2 pages109.8181.MPI - Pre.Unit.730395.Cover RadiatorHerr Ddiman100% (1)

- 254smo (Uns 31254)Document8 pages254smo (Uns 31254)Yang Gul LeeNo ratings yet

- Mat Spec, Astm A 694 F65 Low Alloy Steel Forgings: SubseaDocument14 pagesMat Spec, Astm A 694 F65 Low Alloy Steel Forgings: SubseaJones Pereira Neto100% (1)

- CMT Welding Research PaperDocument23 pagesCMT Welding Research PaperUpendra93No ratings yet

- Decomposition of Austenite in Austenitic Stainless SteelsDocument13 pagesDecomposition of Austenite in Austenitic Stainless SteelsregistrosegNo ratings yet

- Diagramas TT de Ferro e Aço - Aço de Alta ResistênciaDocument111 pagesDiagramas TT de Ferro e Aço - Aço de Alta ResistênciaFernando VenceslauNo ratings yet

- Alloy 625 Spec SheetDocument3 pagesAlloy 625 Spec SheetJSH100No ratings yet

- Heat Treatment RequirementsDocument7 pagesHeat Treatment RequirementsarunradNo ratings yet

- Longtermoxidationbehaviour PDFDocument10 pagesLongtermoxidationbehaviour PDFAnonymous lmCR3SkPrKNo ratings yet

- WeldDecayTesting TechSheet Sfs PDFDocument0 pagesWeldDecayTesting TechSheet Sfs PDFNooruddin SheikNo ratings yet

- Alloying ElementsDocument51 pagesAlloying Elements庄查理No ratings yet

- Failure Analysis and Remaining Life Assessment of Service Exposed Primary Reformer Heater TubesDocument21 pagesFailure Analysis and Remaining Life Assessment of Service Exposed Primary Reformer Heater TubesOwais MalikNo ratings yet

- The Effect of Large Heat Input On The Microstructure and Corrosion Behaviour of Simulated Heat Affected Zone in 2205 Duplex Stainless SteelDocument8 pagesThe Effect of Large Heat Input On The Microstructure and Corrosion Behaviour of Simulated Heat Affected Zone in 2205 Duplex Stainless SteelAnonymous Qha8B2No ratings yet

- Shallow Crack Fracture Mechanics Toughness Tests and Applications: First International ConferenceFrom EverandShallow Crack Fracture Mechanics Toughness Tests and Applications: First International ConferenceNo ratings yet

- Microstructural FeaturesDocument27 pagesMicrostructural FeaturesHagen_of_TronjeNo ratings yet

- Oto 99022Document157 pagesOto 99022jobinhoeljovenNo ratings yet

- Copying and Distributing Are Prohibited Without Permission of The PublisherDocument16 pagesCopying and Distributing Are Prohibited Without Permission of The PublisherMatthew PhillipsNo ratings yet

- Welding Metallurgy of Stainless Steels During Resistance Spot Welding Part I - Fusion Zone PDFDocument11 pagesWelding Metallurgy of Stainless Steels During Resistance Spot Welding Part I - Fusion Zone PDFKhalid HafezNo ratings yet

- SWI Procedure PaintingDocument6 pagesSWI Procedure PaintingRamy EidNo ratings yet

- Delta FerriteDocument9 pagesDelta FerritealadinsaneNo ratings yet

- Effect of Tempering Temperature On Microstructure and Mechanical Properties of AISI 6150 SteelDocument5 pagesEffect of Tempering Temperature On Microstructure and Mechanical Properties of AISI 6150 SteelCường BéoNo ratings yet

- ML 1015998765Document42 pagesML 1015998765ডঃ শুভম চ্যাটার্জীNo ratings yet

- Materials Challenges in Nuclear EnergyDocument24 pagesMaterials Challenges in Nuclear EnergyW.t. HanNo ratings yet

- Corrosion Resistant Materials 04Document197 pagesCorrosion Resistant Materials 04Anonymous NxpnI6jCNo ratings yet

- Recovery and Recrystallization Kinetics in AA1050 and AA3003 Aluminium AlloysDocument196 pagesRecovery and Recrystallization Kinetics in AA1050 and AA3003 Aluminium AlloysRavjManjunathNo ratings yet

- Intergranular CorrosionDocument4 pagesIntergranular CorrosionMecha EngrNo ratings yet

- GMAW of Creep Resistant SteelsDocument5 pagesGMAW of Creep Resistant SteelsJustin Morse100% (1)

- A New Role For Microalloyed SteelsDocument11 pagesA New Role For Microalloyed SteelsMuhammed SulfeekNo ratings yet

- Mil IndexDocument57 pagesMil IndexFranco SwanepoelNo ratings yet

- Midrex DFM 4Qtr2023 FinalDocument17 pagesMidrex DFM 4Qtr2023 Finalsunil.seepanaNo ratings yet

- Pu Dead Matt White DatasheetDocument1 pagePu Dead Matt White DatasheetKhushal JangidNo ratings yet

- Cylinder Reboring Machine and Surface GrinderDocument1 pageCylinder Reboring Machine and Surface Grinderdaya shanker shuklaNo ratings yet

- Granules AssignmentDocument15 pagesGranules AssignmentKarnati PraveenaNo ratings yet

- Metal Identification Tests GuideDocument24 pagesMetal Identification Tests GuideAnonymous dh6DITNo ratings yet

- Misc - ABC-Tile-Adhesive PDFDocument1 pageMisc - ABC-Tile-Adhesive PDFPol Patrick TolentinoNo ratings yet

- Caltex Aquatex 3180-0805Document3 pagesCaltex Aquatex 3180-0805faisiiNo ratings yet

- 2.1.3 METHOD/ Metode PelaksanaanDocument12 pages2.1.3 METHOD/ Metode PelaksanaanrovanNo ratings yet

- Full Download Book Handbook of Silicon Based Mems Materials and Technologies PDFDocument28 pagesFull Download Book Handbook of Silicon Based Mems Materials and Technologies PDFdonald.everhart573100% (27)

- Continuous Grain Flow Forged Carbon and Alloy Steel Crankshafts For Medium Speed Diesel EnginesDocument5 pagesContinuous Grain Flow Forged Carbon and Alloy Steel Crankshafts For Medium Speed Diesel EnginesAli Saleh Saad AL-isawiNo ratings yet

- Hochglanz Lack Küche ReinigenDocument4 pagesHochglanz Lack Küche ReinigenUmme RubabNo ratings yet

- Workshop Technology (JJ104) ExerciseDocument4 pagesWorkshop Technology (JJ104) Exerciseadib1991No ratings yet

- Diager Catalogue English 2019Document26 pagesDiager Catalogue English 2019api-513440808No ratings yet

- Flexible Precision For High-Quality Plate MountingDocument5 pagesFlexible Precision For High-Quality Plate MountingM & F PACK c.a.No ratings yet

- Know Before - Erection of em Parts (Francis) : SN. Components Questions 1 Generator (Stator)Document2 pagesKnow Before - Erection of em Parts (Francis) : SN. Components Questions 1 Generator (Stator)santoshNo ratings yet

- Precidur S355JR / J0 / J2: Structural SteelDocument2 pagesPrecidur S355JR / J0 / J2: Structural Steelsorin robertNo ratings yet

- John King ChainsDocument16 pagesJohn King ChainsElkin ValbuenaNo ratings yet

- 10-75 Casing Hanger Data SheetDocument3 pages10-75 Casing Hanger Data Sheetyehia sayedNo ratings yet

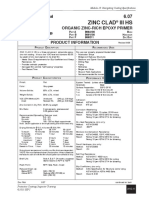

- Zinc Clad Iii HS: Organic Zinc-Rich Epoxy Primer Industrial & Marine Coatings Product InformationDocument8 pagesZinc Clad Iii HS: Organic Zinc-Rich Epoxy Primer Industrial & Marine Coatings Product InformationThennarasu VelloreNo ratings yet

- Aluminium Profiles CatalogueDocument156 pagesAluminium Profiles Cataloguefebri antoNo ratings yet

- Shoe FinishingDocument13 pagesShoe Finishing17044 AZMAIN IKTIDER AKASHNo ratings yet

- Sheet Metal FormingDocument13 pagesSheet Metal FormingjotikaNo ratings yet

- Stylish Serving TrayDocument7 pagesStylish Serving TrayAdnan HasanovicNo ratings yet

- DI-EDC-PTP-553-004 REV. A - SUPPORT C1-A, C1-B & C1-C - ApprDocument2 pagesDI-EDC-PTP-553-004 REV. A - SUPPORT C1-A, C1-B & C1-C - ApprMc Dowell CampangNo ratings yet