Professional Documents

Culture Documents

Technical Specifications

Uploaded by

jothipriyadCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Technical Specifications

Uploaded by

jothipriyadCopyright:

Available Formats

Technical Specifications

TECHNICAL

SPECIFICATIONS

-1-

Technical Specifications

GENERAL CONSTRUCTION PRACTICES

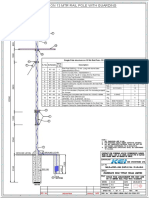

CONSTRUCTION PRACTICES FOR 11 KV SUB-TRANSMISSION LINES

1. SURVEY AND MARKING: The preliminary survey of the line will be done jointly by CSEB and Contractors

authorised representative. The survey done should be plotted on the map and submitted to CSEB Engineer-InCharge of the work.

During preliminary survey crossings/proximity to buildings and to all categories of power lines as well as

telecom lines under P&T Deptt. should be clearly indicated in the route map.

The detailed survey should be under taken only after the route alignment submitted is approved. The pit

marking is then done at the locations. Any likely discrepancy in respect of ground/building clearance is sorted out

first then the work shall be started. In case of erection to be carried out across power line, telegraph, telephone

lines and public roads, the engineer in charge shall however furnish the required drawings of the crossings for

the purpose. All necessary care should be taken by the contractor to avoid damage to crops and trees and

properties while executing the work.

2. EXCAVATING PITS FOR ERECTION OF POLES: After the pit locations are located & peg marked on the

ground, the pole pit of size 600x900x1500mm be dug. The base padding of 200mm thick with 1:3:6 cement

concrete be done before erection of pole. The earthing coil should also be grounded 800mm below ground level

by digging a separate pit & filling the pit with soil. The earthing coil is jointed with the earth wire provided in the

base of the PCC pole and metallic fittings should be earthed with the embedded wire in the PCC pole at the top.

The pole in the pole pit be erected in truly vertical position and the pit should be filled with boulders for line poles

and PCC poles of DPS be concreted 0.3 Cmt. per pole. The pit is filled with 1:3:6 cement concrete mixture for

size 450x600x1500mm. The poles should be erected with maximum span of 100 meters.

In case of Rail Pole/H Beam the earthing coil is bolted with the same. . The pole in the pole pit be

erected in truly vertical position and the Rail Pole/H Beam and poles for DPs and tangent locations should be

concreted 0.5 Cmt. per pole with 1:3:6 cement concrete mixture for size 450x600x1500mm. The poles should be

erected with maximum span of 100 meters.

3. FIXING OF V CROSS ARM, TOP CLAMPS, DC CHANNELS etc. ON THE POLES:

The fitting such as V cross arm, top clamps, D.C. channel etc. should be fixed on poles as per standard

practice adopted in CSEB. The fabrication of above fittings should also be got done as per standard drawing

available in the CSEB. The general specification of steel sections are given below:

i. V Cross arm should be made out of M.S. Angle of size 65x65x6mm. The weight of one V cross arm is

approximately 10.45 Kg/Cross Arm.

ii. Top clamp should be made of M.S. Angle of size 65x65x6mm. The weight of clamp should be

approximate 3.48 Kg/Top clamp.

iii. D.C. cross arm 4 centre should be made out of the M.S. channel of size 100x50x6 mm. The weight of

one DC cross arm comes out 46.00 Kg D.C. and length 2370 mm.

iv. Other special fittings if required may be got fabricated as per the standard drawings of CSEB. The

clamps for holdings the fittings should be fabricated out of M.S. flat 65x8 mm size as per the

standard drawings of CSEB weight 3.5 Kg/Pair clamp.

All nuts & bolts used shall be of M.S. with combination of plain and spring washer and machine made.

4. FIXATION OF INSULATORS AND HARDWARE OF PINS: Insulator shall be handled carefully in all stages of

loading and the individually checked for cracks, damages, loss of glaze etc. before assembling and erection of at

site.

a) The 11KV galvanized steel pins made by process of forging suitable for 11KV pin insulators having

maximum failing load of 5 K.N. with small steel head as per fig IB of IS 2486 (ii)/1974 shall be used. The

dimension of pin shall conform to ref L-306N fig 69IS-2486 (ii)/1974. The pin shall be provided with nut

(hot dip galvanized) one plain washer and one spring washer (electro galvanized).

b) The disc insulators should be fitted with 11KV Hardware for tensioning the conductor 11KV hardware

should be fixed in the disc insulators as per the standard practice and in the correct position to bear the

-2-

Technical Specifications

tension of conductor. The 11KV strain hardware fitting of aluminium alloy suitable for required size of

Conductor (ACSR) should be used conforming to IS-2486 (Part-II) 1989.

The 4 feet centre DP are to be erected at the pre-decided location and six stays should be provided on

the DP. The location of pit for embedding the anchor plate and stay rod shall carefully be determined either in

true alignment. The overhead line or at angle locations as per the requirement of the case. The pit 0.4x0.6x1.6

mtr. shall be excavated and anchor plate with stay rod shall be suitably aligned in such a manner that the stay

wire when binded with anchor rod & stay clamp at pole, the same should make an angle of 30 degree to 45

degree from the pole in the tightened position. Cement concrete mix 1:3:6 shall be poured 0.2 cmt. in the pit, well

packed with ramming adequately & cured properly. The stay clamp shall be located near and below the DC

Cross arm to counter balance the tensile load of the line conductor. Stay wire shall be bound at both ends i.e. at

the box and the stay rod. Fly guy/storm guy, as per the site conditions should be used after getting approval from

CSEB. The stay set consisting of Anchor Rod, Anchor plate, turn buckle bow, thimble should be used at the

tension locations.

The conductor shall be laid out in such a way that there is no damage to conductor. Reels of conductor

should be handled carefully so that no damage to conductor strands occur.

5. STRINGING OF CONDUCTOR: Conductor should be laid out from a rotating wheel supported on jacks for

easy unwinding of the conductor snatch blocks shall be used for stringing the conductor and shall have groves of

a shape and size to allow early flow of conductor and ensure damage free operation. Come along clamps should

be used to grip the conductor at the time of stringing.

6. SAGGING OF CONDUCTOR: All conductors sagging shall be preferred in accordance with the sag and

tension tables. After the conductors have been pulled to the required sag, intermediate spans shall be checked to

determine the correct sag. The conductor shall be installed on insulators secured to it by means of 6 SWG

aluminium binding wire. The jumpers at the tension locations should also be bound by 6 SWG aluminium binding

wire. Before fixing the conductor on insulator and strain hardware, aluminium tape should be wrapped on the

conductor.

7. GUARDING: The 11KV guarding cross arm is to be fitted on the pole as per the drawing available in the

CSEB for guarding the line with 8 SWG GI wire as guard wire and 10 SWG GI wire for lacing. Guarding cross

arm made of 75x40x6 mm angle 5 feet long should be clamped at 300mm below the bottom arm of V cross arm.

8. ANTI-CLIMBING DEVICE: Barbed wire weighing 3.5 Kg per pole should be wrapped at a height of 3000 mm

above ground level stretching in 900 mm length. Both ends of barbed should be clamped suitably to avoid

coming down from its location.

9. DANGER BOARD: Danger Board for 11KV voltage and danger mark conforming to IS:2551-1963 should be

fixed on each location.

SPECIFICATION FOR LT LINE ON 140 Kg. 8 METER LONG PCC POLE

1. SCOPE: Planning, supply, installation, testing and commissioning of 415 Volt over-head low tension line on

140 Kg. 8 meter long PCC Pole and necessary iron fitting etc. complete. All relevant supports fittings and

fixtures, conductors shall conform to their respective IS specifications. The physical layout of the work has to be

got approved by the concerned competent office of CSEB before start of work.

2. POLE: The overhead LT line shall be supported on 140 Kg. 8 meter long PCC pole as specified in the

schedule of item conforming to ISS. Normally one sixth of the pole length shall be buried in the ground. The

supports shall suitable be spaced depending on the number and size of the conductors, number of in between

plots, road crossings etc. in general, the spacing of supports shall be approximately 50-60 meters depending

upon road crossing, telephone crossing etc, and in no case the inter-distance between two consecutive support

shall exceed 65 meters as per rule 85 of the Indian Electricity Rules, 1956.

For erection of pole, a pit size of 600x900x1500 mm should be done and base padding of 200mm thick

should provided and back filling of pole pit with boulders. Suitable time of atleast seven days shall be allowed for

-3-

Technical Specifications

setting the base concrete with proper curing etc. Then the pole shall be laid in the center of the pit and tied with

ropes of adequate strength on four sides of the poles by means of suitable clamps each fixed at right angle to its

other two adjacent side clamps. Loose ends of two sides of ropes forming a straight line shall be tied firmly with

deep driver iron pigs located equi-distance from the corner of the pole pit. One of the two ends of remaining

ropes shall be connected to turner and the opposite rope shall be kept loose and ready to be tied on deep driver

iron pig when the pole attains vertical position. To avoid any chance of injury or damage to labours and

technicians working at site the remaining portion of earth pit shall then be refilled with excavated soil and well

consolidated.

3. CROSS ARMS AND BRACKETS: The LT cross arm shall be made up of M.S. Angle as follows:

i)

LT 3 Pin Cross Arm:

50x50x6 mm size 4.5 Kg/meter, 680 mm long

ii)

LT 4 Pin Cross Arm:

50x50x6 mm size 4.5 Kg/meter, 980 mm long

The minimum clearance between holes for U clamps shall be 300mm. A minimum space of 40mm along

the length of the bracket shall be kept spare from top hole and bottom hole of the bracket the length of cross arm

and bracket shall be suitable for spacing of conductors earth wire and guarding in accordance with the minimum

spacing specified in relevant ISS and in accordance to Indian Electricity Rules. The width of the bracket shall be

not less than 50 Cms.

4. INSULATORS: L.T. Porcelain shackle insulators of size 90x75mm conforming to IS: 1445-1977 shall be

provided and fixed in U clamps for holding the conductors. LT shackle hardware galvanizing shall conform to

ISL 2633-1964 for 4 dip tests.

For holding neutral conductor Aluminium bobbin insulators of size 60x50mm size with nuts bolts shall be

provided.

5. CONDUCTORS: For single phase three wire line ACSR 20 Sqmm Cu.Eq. (Weasel) conductor will be used

for phase and 13 Sqmm Cu.Eq. Squirrel for neutral. Similarly for three phase four wire line ACSR 20 Sqmm

Cu.Eq. (Weasel) conductor will be used for phase and 13 Sqmm Cu.Eq. Squirrel for neutral. Also for three phase

four wire line ACSR 30 Sqmm Cu.Eq. (Rabbitl) conductor will be used for phase and 20 Sqmm Cu.Eq Weasel for

neutral in some of the locations. The conductors shall be laid out in such a manner that there is no damage to the

conductors in any form. While stringing overhead conductors, there should not be any kinking. Reels of

conductor should be handled carefully, so that there is no cutting, nicking or fraying of the conductor strands.

Conductor should be laid out from a rotating wheel supported on jacks for easy unwinding of the conductor. The

conductor shall be binded to its respective shackle insulator by means of binding wire at one of the terminal end

of span. The nuts shall be unscrewed in such a manner that top of nut gets flushed with bolts surface, so as to

enable the U clamp to be at maximum distance from the brackets. Aluminium sheaves fitted with ball bearing

should be used at all points of conductor support for easy pulling and to ensure uniform tension throughout the

conductor length. The conductor should be pulled with a proper come along clamps. Conductor shall be pulled

upto a proper sag in span at or near the dead end section of the line and then binds with the shackle insulator by

means of adequate size of binding wire. The tension should then be adjusted threading of nut of MS U clamp

until correct sages chained in spacing near the pulling end. The conductor shall then be binded with the shackle

insulators of mid span poles maintaining proper sag and tension. The overhead line shall be correctly aligned.

Where there is any deviation more than 30-Degree from straight line the overhead conductor shall be shackled of

at the support. Similarly terminal and function poles shall also be provided with shackle insulators.

D loops shall be provided on each conductor on both sides of each LT pole and all jumpers of LT line

and service line shall be done on these loops only. The size of D loop shall generally be 200mm wide, 100mm

high with 150mm additional length on both sides for binding. The cross sectional area of conductor of D loop

shall be the same as that of conductor to which it is being binded.

Aluminium tape shall be used for each contact/jumpers on lines. Binding at all places shall be done

neatly by Aluminium binding wire of size 8 SWG.

6. CLAMPS: Back clamps and stay clamps for LT line should be made up of 50x6mm MS flats.

7. GUARDING: Suitable guarding shall be provided as per provision of Rules 88 of Indian Electricity Rules. The

spacing between the outermost conductor and the guard wires shall not be less than 30 Cm. both vertically and

horizontally. Diamond guarding shall be provided at a distance of 4 feet min. from the pole on its each side.

-4-

Technical Specifications

Any other type of guardings shall be done with the permission of the Engineer-In-Charge. The guard

wire shall be GI and shall in no case be less than 8 SWG in size and shall have a breaking strength of not less

than 635 Kg.

8. EARTHING OF PCC POLE:

i)

11KV Every pole should be earthed by earthing coil at the bottom and fittings at the top.

ii)

LT Every third pole should be earthed by earthing coil at the bottom and fittings at the top.

CONSTRUCTION PRACTICE OF ADDITIONAL BAY AT 33/11 KV

SUB-STATION

1. GANTRY:

a. A gantry shall mean a group of two RS joists /or H Beam of required equal sections and equal lengths

joined together along their toe of both flanges, with webs of both joints facing each other, shim welded

throughout the length on both sides of flange and re strengthening of joints by MS flats of 50 mm x 6

mm thick as desired and directed by Engineer-in-Charge. The RS joists shall be 175 mm x 85 mm

corresponding to ISMB 175 of required length.and H Beam shall be 152x152 mm ,37.1 Kg /meter

b. Installation: The physical layout of entire sub-station with positions of equipment, bus bar structures

and outgoing feeders shall be marked at site and has to be got approved by the concerned competent

officer of CSEB before start of works, support required to be erected shall be painted on 1/6th of its

length with approved type of anticorrosive paint. For erection of bus bar structure supports, normally

one sixth of the support shall be buried in ground. A pit of size 0.6 Mtr. x 0.9 Mtr. of required 1.5 Mtr.

depth shall be excavated. A layer of 20 cm thick of 1:3:6 cement concrete poured for base pad

concreting of post is to be done by 1:3:6 ratio cement concrete of size 0.45 M x 0.60 M x 1.5 M. Suitable

time shall be allowed for setting the cement concrete before removal of holding ropes. Proper curing of

cement concrete by means of wet gunny bag for at least seven days shall be done. All precautions

shall be taken to avoid any chance of injury or damage to labors working at site.

c.

Erection of structure & Equipments: After the columns/supporting structures are erected respective

equipments of 33/11 KV are to be erected carefully by suitable crane. The breaker and isolators are to

be erected as 3 phase unit basis and other item like 11 KV CT, PT, LA PI etc. are to be erected on Iphase unit basis and rigidly mounted on the supporting structures.

Control relay panels are to be mounted inside the control room in the same order as in the

switchyard.

After the earth mat design is finalized, the earth mat with 50x6 mm GI flat are to be put for

each equipment. Then flats are to be interconnected with each other.

The bus bars are to be strung after all the columns and beams are fitted. Both the bus shall be

of single bus type with suitable tension insulators and 11 KV Auxiliary bus are also to be strung.

Control and power cables should be laid in consultation with Engineer-in-Charge for safe and

easy maintenance. All the equipments of each 33/11 KV bays are to be connected by suitable jumpers

and clamps.

d. Muffing: A layer of 1:3:6 mix cement concrete 45 cm x 45 cm on all sides of the pole upto a height of

45 cm and tapered on top shall be coasted and adequately cured for seven days. One finishing coat of

cement paste shall be applied on outer surfaces of the muffing.

e. MS Iron Fittings: All channels used shall not be less than 100x50x 6 mm. All angle used shall not be

less than 65 x 65 x 8 mm corresponding to ISI 6565. MS flats used shall be of sections as directed by

Engineer-in-Charge.All nut-bolts used shall be MS with a combination of plain and spring washer.

Wherever required use of lock nuts shall be made without any extra cost.

2.

CONDUCTORS:

Aluminum conductor steel reinforced of size 100 Sqmm having approximate ultimate tensile strength of

3299 Kg. and 0.27450 Ohm/Km resistance at 20 deg. C. conforming to IS: 398-1961 as specified in

the schedule of item and directed by Engineer-in-Charge shall be used for 3 phase 3 wire 33 KV or 11

KV over head bus bars. The conductors shall be laid down in such a manner that there is no damage to

-5-

Technical Specifications

the conductor in any form. While stringing of conductors there should not be any kinking. Conductor

should be pulled upto a proper sag as directed by Engineer-in-Charge. Tension should then be adjusted

until correct sag is obtained in spacing near the pulling end. Stringing chart should be used for proper

stretching of conductor. The sag shall then be checked either by sighting method or by stopwatch

reflected method. The conductor shall be installed on insulators secured to it by means of 6 SWG

aluminium binding wire and aluminum tape on it maintaining proper tension and sag.

3.

PAINTING OF POLE: - All steel poles, brackets, cross arms and all steel fittings shall be first painted with

two coat of red oxide paint. The portion of the pole to be buried inside the ground shall be painted with

two coats of bitumen tar. After erection of pole, the external surface of pole and all steel items shall be

painted with two coats of aluminium paint in an approved manner.

4.

GUYS AND STRUTS:

a. GUYS: The guys shall consist of anchor plate, stay rod with bow and ratchet assembly, thimbles stay

wires, stay grips and stay clamps. All iron fittings of stay shall be painted with Red Oxide paint. The

minimum size of stay wire shall be 7/4.0 mm with and ultimate breaking strength of 6450 Kg. The stay

rod shall be 20 mm dia 2 meters long fitted with bow and ratchets assembly having ultimate tensile

strength of 8000 Kg. The anchor plate shall not be less than 300 x 300 x 6 mm size made up of mild

steel. Turnbuckles with 20 mm dia. screw shall have ultimate breaking strength of 8000 kg.

b. CHAIN LINK FENCING: The outdoor switchyard shall be enclosed by GI wire mesh chain link fencing.

The fencing shall be supported by adequate angle iron frame work of minimum size 50 x 50 x 6 mm

and shall have iron bracings of the angle iron frames. The upper parts shall be bent to the required

degree and shall have four lines GI barbed wires. Framework of gates of the switchyard shall be made

up of M.S. flate and (n.b) M.S. bars. The gates shall have a locking arrangement with providing 7 layers

"Godrej" make lock. The gate is to be fabricated as per drawing & design provided by the Engineer-inCharge. The minimum height of fencing post is 2.4 meters above level and 0.5 meter below ground

level. The distance between angle iron supports is minimum 2.0 meter and one angle iron should be

provided on top of chain link fencing around the switchyard and one angle iron (50x50x6mm) just

touching the ground level around the switchyard. The complete chain link fencing work shall be painted

with two coats of primer and two coats of suitable weatherproof paint.

5. CABLE AND EARTHING:

a. Cables: The cables shall be supplied, inspected, laid tested and commissioned in accordance with

drawings, specifications relevant standard specifications and cable manufacturer's instructions. The MV

cable shall be PVC insulated PVC sheathed alluminium conductor armoured cable of 1100 volts grade.

All cable shall be inspected upon receipt at site and checked for any damage during transit by the

Engineer-in-Charge before it laid down to trenches, walls etc.

b. Laying of Cables: Cables shall be laid by skilled and experienced workman using adequate rollers to

minimise stretching of the cable. Great care shall be exercised in laying cables to avoid forming kinks.

The relative position of cables shall be first marked to avoid the cables crossing each other. At all points

of changes in direction in horizontal as well as in and vertical planes, the cables shall be bent smooth

with a radius of bend not less than 12 times the diameter of the cables. For laying cables under-ground

a trench of atleast 750 mm deep of required width shall be excavated for entire length of cable route.

The trench shall be brick masonry made. A bed of fine sand of 100mm thickness shall be dressed and

well dressed. The cable shall be laid on the bed of sand with full precautions to avoid any kinking,

twisting and damage of cable. Fine sand shall be spread over the cable and shall be flushed with top

surface RCC Slab are to be placed at suitable size to cover cable trenches.

For cables to run along the wall proper and accurate verticality shall be maintained. Before

fixing the cables on walls vertical plumbed arcing shall first be made. Parallel cables shall be spaced

atleast 50 mm apart maintaining their relative position over the entire length. Saddles for gripping the

-6-

Technical Specifications

cables shall be spaced not more than 1 meter apart in order to avoid undue stress on the cables due to

its own weight.

c.

Earthing:

All the non-current carrying metal parts of electrical installation shall be earthed

properly. All metal conduits trucking, cable sheaths, switch gear, distribution fuse boards, light fittings

and all other parts made of metal shall be banded together and connected by means of specified

earthing conductors to an efficient earthing system. All earthing shall be in conformity with the Indian

Electricity Rules and in accordance to IS: 3043-1987.

d. Earthing Conductors: All earthing conductors shall be of GI plate, GI pipe or earthing coil of specified

size and shall be protected against mechanical injury or corrosion.

e. Sizing of Earthing Conductor: Under no circumstances the cross sectional area of earthing conductor

shall be less than half of the largest current carrying conductor subject to an upper limit of 80 Sqmm. If

the area of the largest current carrying conductor or bus bar exceeds 160 Sqmm. then two or more

earthing conductor shall be used in parallel to provide at least half one cross sectional area of the

largest current carrying conductor.

6. TYPE OF EARTH ELECTRODE:

a. Plate Electrode: Plate electrode forming a grid shall be used for earthing stations around substations.

Required numbers of earth electrodes directed by Engineer-in-Charge should be provided for substation

earthing. All electrodes shall be inter connected to form a grid. The substation equipments the

structures shall be earthed in manner as approved and directed by Engineer-in-Charge.

b. Connections to Earth: All sub station equipment shall be earthed on a grid system. The grid around the

substation connecting earthing stations shall be of bare GI conductor of size not less than 7/3.15mm.

The transformer neutral shall be connected. To the grid with two separate and independent bare GI

conductor. All other sub station equipment shall be earthed with separate and independent GI strip of

required section or bare GI conductor of size 6 SWG connected to grid. The earthing conductors inside

the buildings shall be properly supported with clamps and brass screws. GI strips outside the building

shall be laid atleast 450 mm below the finished ground level.

7.

Over lapping in strips at joints where required shall be minimum 75 mm. The joints shall be reverted

with rivets and brazed in approved manner. Sheathed lugs of adequate capacity and size shall be used

for all termination of connection. Lugs shall be fitted to the equipment body to be earthed after the

metal is cleaned of paint and other oily substance and properly tinned.

SITE TESTING AND PRE-COMMISSIONING CHECKS:

A.

B.

An indicative list of tests is given below. Contractor shall perform any additional test based on specialties of

the items as per the Field Quality Plan / instructions of the equipments manufacturer or owner without any

extra cost to the Owner. The Contractor shall arrange all instruments required for conducting these tests

alongwith calibration certificates and shall furnish the list of instruments to the Owner for approval. Detailed

test certificates duly signed by CSEB representative & agency representative of tests jointly carried out at

site before putting the equipments in use, shall be submitted by the contractor in three copies as per

following distribution:

o/o the Executive Engineer,

Officer in Charge

8.

GENERAL CHECKS:

Check for physical damages.

Visual examination of zinc coating/ painting.

Check from name plate that all items are as per order/ specification.

Check tightness of all bolts, clamps and connecting terminals using toque wrenches.

For oil filled equipments check for oil leakage, if any. Also check oil level and top up.

Check ground connections for quality of weld and application of zinc rich paint over welded joints of galvanized

surfaces.

Check cleanliness of insulator and bushings.

-7-

Technical Specifications

All checks and tests specified by the manufacturers in their drawings and manuals as well as tests specified in

the relevant code of erection.

SPECIFICATION FOR 11/0.4KV 63/100 KVA TRANSFORMER DP

STRUCTURE

1. SCOPE: Design, planning, supply, installation, testing for commissioning of double pole structure (D.P.

structure) for pole mounting transformer Sub-station with all allied equipments etc. complete. The Sub-station

plan shall be got approved by the concerned competent office of Chief Engineer (Electrical Safety) cum Chief

Electrical Advisor to Government of C.G. and concerned competent office of C.G. Electricity Board prior to

erection work.

2. SUPPORTS: The D.P. structure shall have two numbers 140 Kg. 8 meter long PCC Pole for 63 & 100 KVA

Sub-station as specified in the schedule of items. Normally one sixth of the pole shall be buried in the ground.

The support shall be placed at a distance of 2400 mm. For erection of pole, a pit digging of size 600x900x1500

mm should be done and base padding of 200 mm thick should be provided and concreting with 0.3 Cmt per pole

with 1:3:6 cement concrete mixture for size 450x600x1500 mm.

Suitable time for atleast seven days shall be allowed for setting the base concrete with proper curing

etc. the pole shall than be laid in the center of the pit and tied with ropes of adequate strength of four side of the

pole by means of suitable clamps fixed at right angles to each other. Loose ends of two sides of ropes forming a

straight line shall be tied firmly with deep driven iron pigs located equidistant from the center of the pole pit. One

of the remaining two ends of remaining ropes shall be connected to turfer and the end of opposite rope shall be

kept loose and ready to be tied with deep driven iron pigs shall be manned by skilled worker to control the

unwanted deflection of pole while pulling it by turfer. The pole shall then be pulled by turfer and correctly aligned

to its truly vertical position and then set in 1:3:6 cement concrete poured upto ground level. Suitable time shall be

allowed for setting the cement concrete before removing the ropes. Proper curing of cement concrete for atleast

seven days shall be done. All precautions shall be taken to avoid any chance of injury or damage to labour and

technicians working at site.

3. FITTINGS:

11KV V cross arms shall be made up of MS Channel 65x65x6 mm size having phase to phase

clearance of 1070 mm.

11KV top clamps shall be made up of MS angle 65x65x6 mm size 405 mm long.

DC cross arms, single pole cut point DC, transformer mounting DC, AB Switch mounting DC, DO and

LA mounting channel shall be made up of MS Channel 100x50x6 mm size of required length.

Back clamps and stay clamps shall be made up of 65x8 mm size.

MS Nut and Bolts conforming to IS: 1363-1902 shall be used of 5/8 (16mm) for fitting works and for

earthing arrangements GI nut-bolts must be used.

4.

AB Switch :

AB switches and DO Fuses should be supplied with base steel structure, terminal bi-metallic connectors / PG

clamps / earth connector. They should be checked for proper alignment and free & smooth operation. The

insulators should be cleaned before commissioning. The linkage of contacts should be checked for free and

adequate grip. The AB switch should be checked for fully OPEN/CLOSED positions. Contact between two

movable points should be checked and recorded. The contacts should be adequately lubricated before

commissioning. Connection of terminal connectors shall be checked for proper tightness. Operating handle

should be separately grounded. Equipments should be supplied with detail technical specifications enclosed. The

associated mounting / connection accessories items shall not be considered for measurement under any head of

Price Schedule even if they happen to be appearing in Price Schedule.

-8-

Technical Specifications

4. LIGHTENING ARRESTOR: The 11KV lightening arrestor shall be valve type arrestor consisting of an outer

ceramic body containing 9 Set of resistance (Valves) and spark gaps in series. The resistance shall be made of

special silicon carbide ceramic, which offer high resistance to power frequency voltages and low resistance to

surge voltages. Arrestor should be installed as close as possible, to the HT line. The arrestor should be solidly

earthed. The lightening arrestor shall be mounted on 100x50x6 mm MS Channel fixed approximately 1500mm

below the 11KV tapping point.

5. D.O. FUSE UNIT: The 11KV drop out fuse unit shall have current carrying capacity of 200 Amps having 2

Nos 11KV post insulators fitted on bakelite base with fuse barrel as per BSS-1314. The DO fuse should be got

checked and test certificate from CPRI Bangalore/Bhopal as per IS: 5792-1970 should be obtained and

produced.

6. TRANSFORMERS: The 11/0.4KVstep-down distribution transformer shall be supplied and installed as per

the specifications mentioned in the Transformer Section.

7. DISTRIBUTION BOX: The distribution box suitable for 63/100 KVA transformer with isolator on incoming

side and SPMCCB on out going side will be used.

All sheet steel work shall undergo a process of digressing, pickling in acid, cold rinsing, phosphating,

possivating and then sprayed with a high corrosive resistant primer and then backed in oven. The finishing

treatment shall be by application of two coats of synthetic enamel gray paint in an approved manner.

8. DANGER CAUTION BOARDS: The danger of caution boards shall have to be displayed on pole,

Transformer and LT distribution panel. The danger signboards should conform to IS: 2551-1963.

9. ANTI-CLIMBING DEVICE: Anti-climbing device consisting of barbed wire extending to a minimum length of

900mm shall be provided on poles. Both ends of the barbed wire shall be secured to poles by means of suitable

iron clamps as per the direction of Engineer-In-Charge.

10. PAINTING OF DP STRUCTURES: All metallic parts except transformer and LT distribution box of D.P.

structure and PCC Pole shall be painted in an approved manner.

11. EARTHING OF SUB-STATION: Three numbers pipe earthing with 2.5 meter long GI Pipe 40mm dia used

connecting pipe earthing with 4mm GI wire with LA transformer neutral, transformer body, DO earthing, Channel

earthing. Pole pit is filled with soil.

EQUIPMENT ERECTION NOTES

All support insulators; circuit breaker and other fragile equipment shall preferably be handled with cranes with

suitable booms and handling capacity.

The slings shall be of sufficient length to avoid any damage to insulator due to excessive swing, scratching by

sling ropes etc.

For cleaning the inside and outside of Hollow insulators only muslin of leather cloth shall be used.

Handling equipment, sling ropes etc. Should be tested before erection and periodically for strength.

Bending of compressed air piping should be done by a bending machine and through clod bending only. Bending

shall be such that inner diameter of pipe is not reduced.

Cutting of the pipes wherever required shall be such as-to avoid flaring of the ends, and only a proper pipecutting tool shall be used. Hacksaw shall be used. Hacksaw shall not be used.

The Contractor shall arrange at site all the equipments, instruments and auxiliaries required for testing and

commissioning of equipment.

-9-

Technical Specifications

STORAGE OF EQUIPMENTS

The Contractor shall provide and construct adequate storage shed for proper storage of equipments. Weather

sensitive equipment shall be stored indoor. All equipments during storage shall be protected against damage due

to acts of nature of accidents. The storage instruction of the equipment manufacturer/Owner shall be strictly

adhered to.

HELICALLY FORMED FITTINGS:

Pin insulator ties:

Helically formed insulator ties shall be suitable for specified conductor size, Helically formed ties used for

holding the conductor on the pin insulator shall be made of aluminum allow or aluminized steel or aluminumclad steel wire and shall conform to the requirement of IS: 12048-1987.

The ties shall be suitably for pin insulator dimensions and conductor sizes to be specified by specified by the

owner. Elastomer pad for insulator shall be used with the ties to avoid abrasion of the conductor coming into

direct contact with the insulator.

Test : The ties shall be subjected to the tests specified in IS: 12048-1987.

Fittings for Strain Insulators:

The Fittings shall consist of the following components:

. Cross arm strap conforming to IS:2486(Part-II)-1989.

. Aluminum alloy die cast thimble-clevis for attaching to the tongue of Strain insulator on one end for

accommodating the loop of the helically formed dead-end fitting at the other end in its smooth internal

contour. The thimble shall be suitable for all sizes of conduct ors ranging from 7/2. 11mm to 7/3.35 mm

AAAC. The thimble clevis shall be attached to the insulator by a steel cutter pin used with a non-ferrous

split pin of brass or stainless steel. The thimble shall have clevis dimensions as per IS:2486(Part-II)1989.

.Helically formed dead-end grip having a prefabricated loop to fir into the grooved contour of the thimble

on one end for application over the conductor at the other end. The formed fitting shall conform to the

requirement of IS:12048-1987.

Tests: The helically formed fittings for strain insulators shall be subjected to tests as per IS:12048-1987.

The other hardware fittings shall be tested as per IS: 2486(Part-I).

The scope of work is as under:Erection and commissioning of following :(I) single circuit 11 KV line on PCC poles 140 Kg/8.0 meter long with maximum span 100 mtr. using

Rabbit/Weasel ACSR conductor,

(II) 11KV line on 60 Kg / meter 9 meter long Rail Pole or 37.1 Kg / meter 9 meter long H Beam with Rabbit

conductor,

(III) LT line single phase three wire & 3 phase 4 wire using weasel & squirrel ACSR conductor for phase &

neutral respectively on 140 Kg. 8.0 meter long PCC pole,

(IV) LT line single phase three wire & 3 phase 4 wire using Rabbit and weasel ACSR conductor for phase &

neutral respectively on 140 Kg. 8.0 meter long PCC pole,

(V) 11/0.4 KV pole mounted Sub-station on 140 Kg 8.0 meter long PCC pole alongwith steel structure with

Transformer/without Transformer including supplying, installation & commissioning of 11 KV line/LT line and pole

mounted Sub-station in the Rural area anywhere in Chhattisgarh State on turnkey basis.

a)

DPs on PCC poles 140 Kg/8.0 meter long shall be erected with every 1.6 Km of line in the rural area of

Chhattisgarh State.

b)

Survey & approach clearance.

- 10 -

Technical Specifications

c)

Pits digging for supports and stays & supply and erection of PCC poles /Rail Pole/ H Beam and grouting

of stays.

d) i. Supply and fixing of top clamp, V Cross Arms, D.C. channels, Disc & Hardware, Pin & Pin Insulator.

ii. Supply & fixing of LT 3 Pin cross arm, LT hardware nut bolt shackle insulator &

earth knob.

iii. Supply & fixing of LT 4 Pin cross arm, LT hardware nut bolt shackle insulator & earth knob.

iv. Supply & fixing of DC cross arm, transformer mounting channel, DO and LA mounting

channel, DO set, lightening arrestor, distribution box, cable & transformer.

e)

i. Supply and stringing of 11 KV lines with Rabbit/Weasel ACSR conductor.

ii) Supply and stringing of LT line single phase three wire using weasel (20 Sqmm Cu Eq)

(13 Sqmm Cu Eq) ACSR conductor for phase and neutral.

& Squirrel

iv).

Supply and stringing of LT line three phase four wire using weasel (20 Sqmm Cu Eq) & Squirrel

(13 Sqmm Cu Eq) ACSR conductor for phase and neutral.

v).

Supply and stringing of LT line three phase four wire using Rabbit (30 Sqmm Cu Eq) & Weasel

(20 Sqmm Cu Eq) ACSR conductor for phase and neutral

f)

Supply and providing guarding on the line.

g)

i.

ii.

iii.

Testing & energisation of single circuit 11 KV line.

Testing & energisation of single circuit LT line.

Testing & energisation of pole mounted Sub-station.

h)

The minimum length of 11 KV line, which will be given for execution on contract or turnkey basis shall

be about 1.0 Km combine together 11KV and LT line as one job. However, if the contractor agrees, the smaller

work may also be awarded.

i)

There are some works where PCC poles are erected. If contractors agrees, these incomplete works

may also be awarded for completion of balance works.

Detailed drawing of fabricated materials may be seen at the office, if required.

SPECIFICATION FOR CONSTRUCTION OF 33 KV LINE

1. SURVEY AND MARKING: The preliminary survey of the line should be done and plotted on the map and

submitted to CSEB Engineer in charge of the work.

During preliminary survey crossings/proximity to buildings and to all categories of power lines as well as

telecom lines under P&T Deptt. Should be clearly indicated in the route map.

The detailed survey should be under taken only after the route alignment submitted is approved. The pit

marking is then done at the locations. Any likely discrepancy in respect of ground/building clearance is sorted out

first then the work shall be started. In case of erection to be carried out across power line, telegraph, telephone

lines and public roads, the engineer in charge shall however furnish the required drawings of the crossings for

the purpose. All necessary care should be taken by the contractor to avoid damage to crops and trees and

properties while executing the work.

2. EXCAVATING PITS FOR ERECTION OF POLES: After the pit locations are located & peg marked on the

ground, the pole pit of size 600x900x1500mm be dug. The base padding of 200mm thick with 1:3:6 cement

concrete be done before erection of pole. The earthing coil should also be grounded 800mm below ground level

by digging a separate pit & filling the pit with soil. The earthing coil is jointed with the earth wire provided in the

base of the PCC pole and metallic fittings should be earthed with the embedded wire in the PCC pole at the top.

In case of Rail Pole/H Beam the earthing coil is bolted with the same. The pole in the pole pit be erected in truly

- 11 -

Technical Specifications

vertical position and the PCC pole should be filled with boulders and PCC poles of DPS be concreted 0.5 Cmt.

per pole. The pit is filled with 1:3:6 cement concrete mixture for size 450x600x1500mm. The poles should be

erected with maximum span of 100 meters.

3. FIXING OF V CROSS ARM, TOP CLAMPS, DC CHANNELS etc. ON THE POLES:

The fitting such as V cross arm, top clamps, D.C. channel etc. should be fixed on poles as per standard

practice adopted in CSEB. The fabrication of above fittings should also be got done as per standard drawing

available in the CSEB. The general specification of steel sections is given below:

v. V Cross arm should be made out 9 M.S. Angle of size 75x75x6mm. The weight of one V cross arm is

approximately 25.70 Kg/Cross Arm.

vi. Top clamp should be made of M.S. Angle of size 75x75x6mm. The weight of clamp should be

approximate 4.08 Kg/Top clamp.

vii. D.C. cross arm 5 centre should be made out of the M.S. channel of size 100x50x6.0 mm. The weight of

one DC cross arm comes out 62.3 Kg D.C. and length 3245 mm.

viii. Other special fittings if required may be got fabricated as per the standard drawings of CSEB. The

clamps for holdings the fittings should be fabricated out of M.S. flat 65x8 mm size as per the standard

drawings of CSEB weight 3.5 Kg/Pair clamp.

All nuts & bolts used shall be of M.S. with combination of plain and spring washer and machine made.

4. FIXATION OF INSULATORS AND HARDWARE OF PINS: Insulator shall be handled carefully in all stages of

loading and the individually checked for cracks, damages, loss of glaze etc. before assembling and erection of at

site.

c) The 33KV galvanized steel pins made by process of forging suitable for 33KV pin insulators having

maximum failing load of 10 K.N. with small steel head as per fig IB of IS 2486 (ii)/1974 shall be used.

The dimension of pin shall conform to ref L-306N fig 69IS-2486 (ii)/1974. The pin shall be provided with

nut (hot dip galvanized) one plain washer and one spring washer (electro galvanized).

d) The disc insulators should be fitted with 33KV Hardware for tensioning the conductor 33KV hardware

should be fixed in the disc insulators as per the standard practice and in the correct position to bear the

tension of conductor. The 33KV strain hardware fitting of aluminium alloy suitable for Dog Conductor

(ACSR) should be used conforming to IS-2486 (Part-II) 1989.

The 5 feet centre DP are to be erected at the pre-decided location and six stays should be provided on

the DP. The location of pit for embedding the anchor plate and stay rod shall carefully be determined either in

true alignment. The overhead line or at angle locations as per the requirement of the case. The pit 0.4x0.6x1.6

mtr. shall be excavated and anchor plate with stay rod shall be suitably aligned in such a manner that the stay

wire when binded with anchor rod & stay clamp at pole, the same should make an angle of 30 degree to 45

degree from the pole in the tightened position. Cement concrete mix 1:3:6 shall be poured 0.3 cmt. in the pit, well

packed with ramming adequately & cured properly. The stay clamp shall be located near and below the DC

Cross arm to counter balance the tensile load of the line conductor. Stay wire shall be bound at both ends i.e. at

the box and the stay rod. Fly guy/storm guy, as per the site conditions should be used after getting approval from

CSEB. The stay set consisting of Anchor Rod, Anchor plate, turn buckle bow, thimble should be used at the

tension locations.

The conductor shall be laid out in such a way that there is no damage to conductor. Reels of conductor

should be handled carefully so that no damage to conductor strands occur.

5. STRINGING OF CONDUCTOR: Conductor should be laid out from a rotating wheel supported on jacks for

easy unwinding of the conductor snatch blocks shall be used for stringing the conductor and shall have groves of

a shape and size to allow early flow of conductor and ensure damage free operation. Come along clamps should

be used to grip the conductor at the time of stringing.

6. SAGGING OF CONDUCTOR: All conductors sagging shall be preferred in accordance with the sag and

tension tables. After the conductors have been pulled to the required sag, intermediate spans shall be checked to

determine the correct sag. The conductor shall be installed on insulators secured to it by means of 6 SWG

aluminium binding wire. The jumpers at the tension locations should also be bound by 6 SWG aluminium binding

wire. Before fixing the conductor on insulator and strain hardware, aluminium tape should be wrapped on the

conductor.

- 12 -

Technical Specifications

7. GUARDING: The 33KV guarding cross arm is to be fitted on the pole as per the drawing available in the

CSEB for guarding the line with 6 SWG GI wire as guard wire and 8 SWG GI wire for lacing. Guarding cross arm

made of 75x75x6 mm angle 8 feet long should be clamped at 300mm below the bottom arm of V cross arm.

8. ANTI-CLIMBING DEVICE: Barbed wire weighing 35 Kg per pole should be wrapped at a height of 3000 mm

above ground level stretching in 900 mm length. Both ends of barbed should be clamped suitably to avoid

coming down from its location.

9. DANGER BOARD: Danger Board for 33KV voltage and danger mark conforming to IS: 2551-1963 should be

fixed on each location.

IMPORTANT INSTRUCTIONS BEFORE FILLING UP THE PRICE BID

Rates entered against each items shall deemed to have included the following works:

1. All nuts, bolts and screw etc. of required size. Measurement and payment of nut bolts screw etc.

shall not be made with the items of iron/steel hardware. Nuts and bolts should be machine made

only of renamed makes.

2. All mechanical works e.g. fabrication, cutting, drilling, welding, grinding, painting and blacksmith

works etc.

3. Cable and overhead conductors terminations, crimping of lugs with crimping tools and cost of

appropriate size of lugs, cable glands etc.

4. Providing and applying sealing compounds, insulating toughness compound wherever required and

directed.

5. Touching up all damaged paint with one coat of red oxide primer and two finishing coats of

approved synthetic enamel paint.

6. All fixing accessories such as saddles, brass screws, lug plugs etc.

7. Cutting chases, holes and making good the same wherever required.

8. All lead and lift, transportation of materials at site, loading unloading and all labour required

completing the job.

9. The items are complete in itself and any allied work or equipments not mentioned in the

nomenclature of item but forming part of the system shall in all respect deemed to be included

within the meaning of the execution of the said item and shall not be paid extra than the tendered

rates until and unless specified. The tenderer are therefore advised to have clear under-standing of

the 33 KV sub station and 33 & 11 KV & LT KV line work before filling in the rates.

10. Each and every item shall be reading continuation with its respective specification for work and

specific requirements of relevant Indian Standard Specification and local Electricity Authority before

filling up the rates.

11. Drilling and cutting holes in brick/RCC walls for clamping cables, earth leads, earth strips, GI pipes

or whatever it may be including cost of clamping device.

- 13 -

Technical Specifications

Technical

Specification

of Items

TECHNICAL SPECIFICATION OF 11 & 33 KV PIN INSULATOR

- 14 -

Technical Specifications

1.

SCOPE:This specification covers the design, manufacture, testing, supply and delivery of 11 KV and 33

KV Porcelain Pin Insulators for use on 11 KV and 33 KV overhead Power Lines.

2.

STANDAND:Except where they conflict with specific requirement in the specification, the Pin Insulators shall

comply with the Indian Standard Specification IS:731-1971 and its amendments from time to time.

The insulator conforming to any other internationally accepted standard which ensures equal

or better quality than the standard mentioned above would also be acceptable.

Where the material is offered according to the international standards, an English version of

the specifications shall be attached with the tender.

3.

ATMOSPHERIC CONDITIONS:3.1

The material offered shall be suitable for operation under the climatic conditions indicated in

Clause 31 of Annexure II General Terms and Conditions of purchase appended with this Tender

Specification.

3.2

Reference atmospheric conditions at which insulators characteristics shall be expressed for the

purpose of comparison shall:Ambient Temperature

Barometric Pressure

Absolute Humidity

-20 Degree Centigrade

- 1013 Milli bars

-11 gms of water per cubic meter corresponding to 63 percent

relative humidity at 20 Degree Centrigrade

Note:- A pressure of 1013 millibars is equivalent to a pressure of 750 mm of Mercury at 0 degree

centigrade.

3.3

Tests for the purpose of this standard shall preferably be carried out under conditions of

temperature and humidity specified in IS:196-1966(i.e. at a temperature of 27+ 2 degree centigrade and

relative humidity of 66+2 percent) and at the prevailing atmospheric pressure. When this is not

possible, test may be carried out under conditions naturally obtained at the time of the test. The

barometric pressure, air temperature and humidity shall be recorded for the purpose of correction.

Corrections of test voltage for atmospheric conditions is given in Appendix A of IS:731-1971.

4.

The Thimble for 11 KV Pin Insulator should be suitable for use with Galvanised Steel Pins

conforming to reference S-165 of IS:2486 (Part-II) of 1974 with shank length 150 mm which is provided

with a small steel head. Similarly, the thimble of 33 KVPin Insulator should be suitable for use with 33

KV Galvanised steel Pins conforming to reference I-300-N of fig. 6 with shank length of 150 mm and

with large head of ISS-2486 (Part-II) of 1974.

5.

INSULATOR CHARACTERISTICS:The insulator shall have the electrical and mechanical characteristics which are given below:The test voltage of insulator shall be as under:11KV PIN

INSULATOR

1.

2.

3.

4.

5.

33KV PIN

INSULATOR

Highest system voltage 12KV (rms)

36 KV (rms)

Wet Power frequency

35 KV (rms)

75 KV(rms)

withstand voltage test

for one minute

Visible discharge voltage 9 KV (rms)

27 KV (rms)

Power frequency puncture 105 KV (rms)

180 KV (rms)

withstand voltage

Impulse withstand voltage

75 KV(peak)

170 KV (peak)

- 15 -

Technical Specifications

(In the above standards, power frequency voltage is expressed as peak values divided by 2

and impulse voltage is expressed as peak value)

6.

The withstand and flash over voltage are referred to the reference atmospheric conditions.

7.

Mechanical Loads

Minimum Failing Loads

i.

11 KV Pin Insulator

5 KN

ii.

33 KV Pin Insulator

10 KN

8.

DIMENSIONS AND CREEPAGE DISTANCE:The insulators shall have the following dimensions and minimum creepage distance for a

moderately polluted atmosphere:Particulars

11 KV Pin Insulator

33 KV Pin Insulator

(A)

Dimensions

i.

Height

130 MM

210 MM

ii.

Diameter

125 MM

275 MM

(B) Creepage Distance 230 MM

580 MM

9.

TESTS:- The insulator shall comply with the following tests as per IS-731-1971.

9.1

TYPE TESTS:The following constitute the type tests :a.

Visual examination

b.

Verification of dimensions

c.

Visible discharge test

d.

Impulse withstand voltage test

e.

Wet power frequency withstand voltage test

f.

Temperature cycle test

g.

Mechanical failing load test

h.

Puncture test

i.

Porosity test

j.

Galvanising test.

Type test certificate from recognized Govt. lab for the tests carried out on prototype of same

specifications shall be enclosed with the tender. The type test certificates shall not be more then 5

years old from the date of opening of tender.

9.2

ROUTINE TESTS:The following shall be carried out as the routine tests:a. Visual examination

b. Electrical Routine tests

c. Mechanical Routine tests

9.3

ACCEPTANCE TESTS:The test samples after having withstood the routine tests shall be subjected to the following

acceptance tests in the order indicated below:a.

Verification of dimensions

b.

Temperature cycle test

c.

Mechanical failing load test

d.

Puncture test

e.

Porosity test

f.

Galvanising test

9.4

Tolerance in insulator dimensions shall be as per the relevant Indian Standard i.e.

(0.04d+1.5) mm when d 300 mm and where d is the dimension in mm.

10.

MARKING:Each insulator shall be legibly and indelibly marked to show the followings:a.

Name and trade mark of manufacturer

b.

Month and year of manufacture

c.

Minimum failing load in newtons

d.

Country of manufacture

- 16 -

Technical Specifications

Marking on porcelain shall be printed/engraved and shall be applied before firing.

11.

PACKING:All insulators shall be packed in wooden crates suitable for easy but rough handling and

acceptable for rail and road transport.

12.

STANDARDISATION OF DIMENSIONS OF TOP AND NECK OF 11 KV PIN INSULATOR

Please note that now-a-days Board is using preformed ties for binding conductor with the Pin

Insulator instead of conventional method of binding by aluminium binding wire and tape. The

design of the preformed ties depends upon the dimensions of top and neck of 11 KV Pin

Insulator. For proper gripping of the conductor with the help of preformed fittings it has

become necessary to standardise the dimensions of the insulator top and neck. Accordingly, a

drawing 051-32/CSEB/1 dt.1.9.2001, which indicates the standardised dimensions of top and

neck of 11 KV Pin Insulator is enclosed with Tender Specification. This drawing has been

approved by REC, New Delhi, therefore, the tenderers are advised to offer material based on

this drawing.

TECHNICAL PARTICULARS FOR 11KV PIN INSULATORS

--------------------------------------------------------------------------------------------------------------.

Sno.

Particulars

11KV Pin

Insulator

--------------------------------------------------------------------------------------------------------------.

1.

Makers name & Country

2.

Electrical Characteristics

a.

Nominal system voltage

b.

Highest system voltage

c.

Visible discharge voltage

d.

Dry one minute power frequency

withstand voltage

e.

Wet one minute power frequency

withstand voltage

f.

Power frequency puncture

g.

Impulse (1/50 micro second

wave) Voltage

h.

Impulse flashover (1/50 micro

second wave) voltage negative

i.

Impulse flashover (1/50 micro

second wave) voltage negative

j.

Dry flashover voltage

k.

Wet flashover voltage

3.

11 KV (rms)

12 KV (rms)

9 KV (rms)

55 KV (rms)

35 KV (rms)

105 KV (rms)

75 KVP

108 KVP

124 KVP

60 KV

40 KV

Mechanical characteristics:

a. Minimum falling load

b. Minimum creepage distance

5 KN

230 mm

4.

Colour of glaze

Brown

5.

Size of insulators:

a. Height

b. Diameter

130 mm

125 mm

6.

Standard according to which

As per IS:

- 17 -

Technical Specifications

7.

porcelain insulator shall be

manufactured and tested

731/1971

Tolerance in dimensions if any

As per ISS

8.

Weight per unit of

a. Porcelain Part

To be indicated

b. Thimble

To be indicated

----------------------------------------------------------------------------------------------------------------.

TECHNICAL SPECIFICATION OF 33 KV GS PINS

1.

SCOPE : The specification provides for manufacture & testing of 33 KV GS Pins suitable for Pin

Insulators, complying with Indian Standard Specification No.IS:2486 (Part-I) 1971, IS:2486 (Part-II & III) 1974

and the latest version thereof.

2.

GENERAL REQUIREMENTS FOR 33 KV GS PINS :-

2.1

The Pins shall be a single piece obtained by the process of forging. They shall not be made by jointing /

welding / Shrink fitting of any other process from more than one piece of materials. They shall be of good finish

free from flaws and other defects. The finish of the collar shall be such that a sharp angle / edges between the

collar and the shank is avoided and the collar or the seating surface shall be down correctly on to the cross arm

when fixed to that through a hole the diameter of which is 2 mm greater than the diameter of the shank.

2.2

All ferrous pins & nuts shall be galvanized by the hot dip process. Other fittings i.e. flat washers and

spring washers may be electro galvanized as per Clause.5.2.3 of IS: 2486 (Part-I) & subsequent amendments, if

any, and should satisfy the tests as per IS: 1573 of 1986 and subsequent amendments (if any). The threads of

nuts and taped holes when cut after galvanizing shall be well oiled or greased.

2.3

The Pins shall be as per relevant figure indicated in IS: 2486 (Part-II) with small / large steel heads and

shall match with the Pin type insulators with cemented zinc thimble having similar threads.

3.

MARKING :

Each and every material shall be legibly and indelibly and marked with NAME OR TRADE MARK of the

manufacturer and suitable identification mark like property marking CSEB should be engraved / embossed.

4.

TEST & TEST CERTIFICATES:

TYPE TEST CERTIFICATE: Notarized type test certificate giving the results of samples tested for the

tests, as per Clause-4.3.1 of IS:2486 (Part-I) 1971 for the item quoted, shall compulsorily be enclosed by the

tenderer alongwith their offer in support of evidence of compliance of the specifications and guaranteed

particulars.

TYPE TEST :

a) Freedom from defects,

b) Verification of dimensions,

c) Galvanising test (both uniformity of Zn.coating and Wt.of Zn.coating).

d) Mechanical tests,

e) Chemical composition test,

Type test shall be made and certified by any Govt. recognized authority.

5.

ROUTINE TEST:

The test certificate of the lot giving the results of routine tests as per requirement of Clause4.3.3 of IS:2486 (Part-I) 1971 shall have to be submitted invariably by the firms alongwith the offers of

materials being made by them for pre-despatch inspection of the materials.

- 18 -

Technical Specifications

6.

ACCEPTANCE TEST:

(Test to be carried-out during pre-dispatch inspection)

(i)

The dimensional requirement of 33 KV GS Pins offered for pre-despatch inspection shall be

checked and verified as per IS:2486 (Part-II)/1974 and the following tests shall be carried-out and

witnessed by the Inspecting Officer during inspection of the material as per requirement of the IS:2486

(Part-I) 1974.

(ii)

Checking of threads on heads: The dimensions of the threads on the heads of Pins shall be

checked and verified by means of gauges (Ref.IS:2486 (Part-II)/1974.

(iii)

Galvanizing Test: The uniformity of Zinc coating and Wt. of Zinc coating for Pins and Nuts shall

be verified as per requirements of IS:2633/1972.

(iv)

Mechanical test: This test shall be conducted in accordance with the Clause-4.6 of IS:2486

(Part-I) 1971.

(v)

Visual Examination Test:- All the pins shall be checked visually for its good workmanship and

finishing.

All the relevant Indian Standard Specifications (ISS) shall be made available by the firms

invariably to the inspecting officer for reference while carrying out the pre-despatch inspection of the lot.

The Technical Particulars of 33 KV GS Pins are indicated in the Schedule-I B enclosed and

these shall be required to be met out on inspection of the material.

7.

LOT :All the GS Pins of same type and design manufactured under similar conditions of production

offered for acceptance, a lot may consist of whole or part of the quantity offered.

A lot shall consist of only one type of fittings manufactured essentially from the same raw

material and under identical conditions.

8.

PACKING :

The materials are to be packed in gunny bags, each bag containing 25 nos. of 33 KV Pins.

9.

DRAWING :Two sets of detailed drawing (s) of the products(s) shall have to be submitted along with offer

and again two sets along with acceptance letter on issue of LOI for approval before issue of detailed

order.

10.

TOLERANCE:

All applicable as per latest edition / amendments of IS:2486 (Part-I).

TECHNICAL REQUIREMENTS

S.N.

1. I

PARTICULARS

Dimensions

II

Pins & Studs

III

Nuts

REQUIREMENT OF 33 KV GS PINS

Shall conform strictly to reference L-300-N of Figure-6 of

IS:2486 (Part-II) 1974.

The forged pins & studs shall be of steel complying with

class:2 of IS:2004/1962.

The nuts shall be made of material conforming to property

class 4.8 of IS:1367/1983(Part-xiii) with regard to its

mechanical properties.

- 19 -

Technical Specifications

IV

Steel Head

Nuts, Flat & spring washers

VI

VII

Failing load

Drawing ref.of IS:2486 (Part-II)

2

I

II.

III

IV

V.

VI

VII

VIII

IX

X

Dimensional Requirements

Length of stalk

Bottom diameter of stalk

Top diameter of stalk

Length of shank

Diameter of shank

Length of threaded portion in

the shank

Length of threaded portion of

stalk

Thickness of collar

Diameter of collar

Tolerance

Method of Galvanizing

TESTS

Dip test

Mass of zinc coating

I

ii.

Applicable specifications:

(with latest amendments, if

any)

This shall be as per Fig.1-B (large steel head) of IS:2486

(Part-II/1974 suitable for use with indigenous 33 KV Pin

Insulators

a) Nuts shall be hot dip galvanized,

b) One flat washer & spring washer shall be provided with

each pin. Both these washers shall be electro galv. as per

Clause- 5.2.3 of IS:2486 (Part-I).

Minimum 1080 kg.(10 KN)

i) Fig.No.6,

ref. No. L-300N

ii) Fig.No.1 (B)

33 KV GS Pins

300 mm

44 mm

27 mm

150 mm

24 mm

100 mm

47 mm

6.00 mm

67 mm

i. No negative tolerance is permissible for Dip test & Mass

of Zinc coating,

ii. +/- 5% (Plus Minus five percent) shall be allowed in all the

dimensions except in thickness of collar and threaded

portion of stalk.

As per IS:2633/1972 (Hot dip for both 11 KV & 33 KV

Galvanizing GS Pins)

FOR GS PINS

FOR GI NUTS

4 dips of 1 minute each 4 dips of 1 minute each

300 gms/m2 (Minimum) 300 gms/m2 (minimum)

The mass of zinc coating on Pins shall be as per Clause-4

of IS:4759-1979 and in case of Nuts shall be as per Clause

No.4 of IS:1367 (Part-XIII)-1983. The above tests shall

invariably be conducted during all routine inspection of

material (S.No.I,II & III).

IS:2486 (Part-II) of 1974.

IS:2486 (Part-I) of 1971,

IS:4759-1979 and IS:1367 (Part-XIII)-1983

IS:2633-1972

IS:2004-1962

TECHNICAL PARTICULARS FOR GS PINS

Sno.

1.

Particulars

Dimensions

2.

Pins & Studs

3.

Nuts

4.

Steel Head

Requirement of 11 KV GS Pins

Shall conform strictly to reference S-165-P of Figure-5 of IS: 2486

(Part-II) of 1974.

The forged pins and studs shall be of steel complying with clause: 2

of IS: 2004/1962.

The nuts shall be made of material conforming to property clause

4.8 of IS: 1367/1983 (Part-xiii) with regard to its mechanical

properties.

This shall be as per Figure 1-A (small steel head) of IS: 2486 (Part- 20 -

Technical Specifications

5.

II) 1974 suitable for use with indigenous 11KV pin insulator.

a) Nuts shall be not dip galvanised.

b) One flat washer & spring washer shall be provided with each pin.

Both these washers shall be electro galvanised as per clause-5.2.3

of IS: 2486(Part-I)

Mounting arrangements

Shall be suitable for mounting on 75x100mm M.S.Channel

Falling load

Minimum 540 Kg. (5 KN)

Dimensional Requirements

11 KV GS Pins

Length of stalk

165 mm

Bottom diameter of stalk

25 mm

Top diameter of stalk

24 mm

Length of shank

150 mm

Diameter of shank

20 mm

Length of threaded portion in 100 mm

the shank

Length of threaded portion of 44 mm

stalk

Thickness of collar

5.00 mm

Diameter of collar

40 mm

67 mm

Tolerance

i) No negative tolerance is permissible for Dip test & Mass of Zinc

coating.

ii) 5% (Plus minus five percent) shall be allowed in all the

dimensions except in thickness of collar and threaded portion of

stalk.

Method of Galvanising

As per IS: 2633/1972 (Hot dip for both 11KV Galvanising GS Pins)

TESTS

FOR GS PINS

FOR GI NUTS

Dip Test

4 dips of 1 minute each

4 dips of 1 minute each

Mass of zinc coating

300 gms/m2 (Minimum)

300 gms/m2 (Minimum)

The mass of zinc coating on Pins shall be as per Clause-4 of

IS:4759-1979 and in case of Nuts shall be as per Clause No. 4 of

IS: 1367 (Part-XIII)-1983. The above tests shall invariably be

conducted during all routine inspection of material (S.No. I, II & III).

Applicable specifications: (with IS: 2486 (Part-II) of 1974

latest amendments, if any).

IS: 2486 (Part-I) of 1971,

IS: 4759 1979 and IS: 1367 (Part-XIII) 1983.

IS: 2633 1972

IS: 2004 - 1962

Nuts, Flat & Spring Washers

6

7.

8.

I.

II.

III.

IV.

V.

VI.

VII.

VIII.

IX.

X.

9.

I.

II.

10.

TECHICAL SPECIFICATION OF11KV DISC INSULATOR

1.

SCOPE:This specification covers the design, manufacture, testing, supply and delivery of porcelain Disc

Insulator for use on 11 KV and 33 KV overhead power lines.

2.

STANDARD:Except where they conflict with specific requirement in the specification, the Disc Insulator shall comply

with the Indian Standard Specification IS:731/1971 and its amendment from time to time.

The insulator conforming to any other internationally accepted standard which ensures equal or better

quality than the above standard would also be acceptable.

Where the material is offered according to the international standards, an English version of the

specification shall be attached with the tender.

3.

ATMOSPHERIC CONDITIONS:3.1

The material offered shall be suitable for operation under the climatic conditions indicated in Clause 31

of Annexure-II General Terms and Conditions of purchase appended with this tender specification.

- 21 -

Technical Specifications

3.2

Reference atmospheric conditions at which insulator characteristics shall be expressed for the purpose

of comparison shall be:Ambient Temperature

Barometric Pressure

Absolute Humidity

Note:-

20 Degree Centigrade

1013 millibars

11 gms of water per cubic

Meter corresponding to 63%

Relative humidity at 20 Degree

Centigrade

A pressure of 1013 millibars is equivalent to a pressure of 750 mm of Mercury at 0 degree centigrade.

3.3

Tests for the purpose of this standard shall preferably be carried out under conditions of temperature

and humidity specified in IS:196-1966 (i.e. at a temperature of 27+2 degree centigrade and relative humidity of

66+2 percent) and at the prevailing atmospheric pressure. When this is not possible, test may be carried out

under conditions naturally obtained at the time of the test. The barometric pressure, air temperature and

humidity shall be recorded for the purpose of correction.

Corrections of test voltage for atmospheric conditions is given in Appendix A of IS:731-1971.

4.

GENERAL REQUIREMENTS:The porcelain shall be sound free from defects, thoroughly vitrified and smoothly glazed.

4.1

Unless otherwise specified, the glaze shall be brown in colour. The glaze shall cover all the porcelain

parts of the insulator except those areas which serve as supports during firing or are left unglazed for the

purpose of assembly.

4.2

The design of insulator shall be such that stresses due to expansion and contraction in any part of the

insulator shall not lead to deterioration. The porcelain shall not engage directly with hard metal.

4.3

Cement used in the construction of the insulator shall not cause fracture by expansion or lossening by

contraction and proper care shall be taken to locate the individual parts correctly during cementing. The cement

shall not give rise to chemical reaction with metal fittings and its thickness shall be as unifom as possible.

5.

TYPE OF INSULATOR:The insulator shall be of type B according to its construction which is defined hereunder:Type B:-An insulator or an insulator unit in which the length of the shortest puncture path through solid

insulating material is less than half the length of the shortest flash over path through air outside the insulator.

6.

6.1

INSULATOR CHARACTERISTICS:The insulator shall have the electrical and mechanical characteristics which are given below:The test voltage of insulator shall be as under:-

1.

2.

3.

4.

5.

6.2

Disc Insulator

Highest system voltage

12 KV (rms)

Wet power frequency withstand

35 KV (rms)

voltage for one minute

Visible discharge voltage

9 KV(rms)

Power frequency puncture withstand voltage

105 KV (rms)

Impulse withstand voltage

75 KV(peak)

In this standard, power frequency voltage are expressed as peak values divided by 2 and impulse

voltage are expressed as peak value.

6.3

6.4

The withstand and flash over voltage are referred to the reference atmospheric conditions.

Minimum Failing Load

45 KN

7.

7.1

DIMENSIONS:The insulator shall have the following dimensions:Diameter - 254 mm

Height -146 mm (Hole to Hole)

- 22 -

Technical Specifications

7.2

CREEPAGE DISTANCE:The insulator shall have minimum 320 mm creepage distance for a heavily polluted atmosphere.

8.

TESTS:The insulators shall comply with the following tests as per IS:731-1971 with its latest amendments.

8.1

TYPE TESTS:- The following constitute the type tests :

a.

Visual examination

b.

Verification of dimensions

c.

Visible discharge test

d.

Impulse voltage withstand test

e.

Wet power frequency withstand voltage test

f.

Temperature cycle test

g.

Electro-Mechanical failing load test

h.

Puncture test

i.

Porosity test

j.

Galvanizing test.

Type test certificate from recognized Govt. lab for the tests carried out on prototype of same

specifications shall be enclosed with the tender for each type test failing which the tenders are liable for

rejection. The type test certificates shall not be more than 5 years old from the date of opening of

tender.

8.2

ROUTINE TESTS:The following shall be carried out as the routine tests:a.

Visual examination

b.

Electrical Routine tests

c.

Mechanical Routine tests

8.3

ACCEPTANCE TESTS:Acceptance of samples after having withstood the routine tests shall be subjected to the following

acceptance tests in the order indicated below:a.

b.

c.

d.

e.

f.

Verification of dimensions

Temperature cycle test

Electro Mechanical failing load test

Puncture test

Porosity test

Galvanizing test

8.4

Tolerance in insulator dimensions shall be as per the relevant Indian Standard, i.e. (o.04d+1.5)mm

when d300 mm and where d is the dimension in mm.

9.

MARKING:Each insulator shall be legibly and indelibly marked to show the followings:a.

b.

c.

d.

Name and trade mark of manufacturer

Month and year of manufacture

Minimum failing load in new tons

Country of manufacture

Marking of porcelain shall be printed/engraved and shall be applied before firing.

10.

PACKING:All insulator shall be packed in wooden crates suitable for easy but rough handling and acceptable for

rail and road transport.

TECHNICAL PARTICULARS OF 11 KV DISC INSULATORS

- 23 -

Technical Specifications

1. Makers name & country

2. Type of Insulator

:

:

3. Electrical Characteristics:

a.

b.

c.

d.

e.

f.

g.

h.

i.

j.

k.

l.

Nominal system voltage

Highest system voltage

Visible discharge voltage

Dry one minute power frequency

withstand voltage

Wet one minute power frequency

withstand voltage

Power frequency juncture

withstand voltage

Impulse withstand (1.2/50

microsecond wave) voltage positive

Impulse withstand (1.2/50

microsecond wave)voltage negative

Impulse flash over (1.2/50

microsecond wave)voltage positive

Impulse flash over (1.2/50

microsecond wave)voltage negative

Dry flash over voltage

Wet flash over voltage

4. a. Minimum creepage distance

b. Minimum failing load

: 11 KV (RMS)

: 12 KV (RMS)

: 9 KV (RMS)

: 70 KV (RMS)

: 40 KV (RMS)

: 110 KV (RMS)

: 100 KVP

: 100 KVP

: 105 KVP

: 110 KVP