Professional Documents

Culture Documents

Comparison Tabulation Between Specification and Actual Approved Execution

Comparison Tabulation Between Specification and Actual Approved Execution

Uploaded by

hvduylinhOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Comparison Tabulation Between Specification and Actual Approved Execution

Comparison Tabulation Between Specification and Actual Approved Execution

Uploaded by

hvduylinhCopyright:

Available Formats

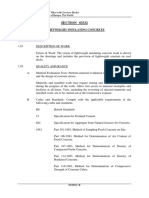

COMPARISON TABULATION BETWEEN SPECIFICATION AND ACTUAL APPROVED EXECUTION

Item: Topping-Up Concrete of Tower 1 & Tower 2

Items

Ref. Spec

A. MATERIAL

Cement

2.2.1

Cement content

3.2.1

Water/cement ratio

Nominal size of coarse

aggregate

Compresive strength

3.2.1

3.2.1

Air content

16.1

B. MEASURES TO AVOID CRACKING

Fresh concrete temperrature

The differenc concrete

temperature (inside mass

poured concrete)

Others

Description

385 kg/m3

0.452

5-13mm & 5-23mm

ditto

ditto

7 days = 24MPa

28 days = 35MPa

The average air content by volume of the fresh concrete at the time of placing shall

not exceed 5%.

32.5MPa

44.0MPa

< 5%

ditto

ditto

Refer concrete record

5.3

max 37oC

< 30oC

Refer concrete record

5.3

max 6oC above ambient temp (shade)

max 25oC

< 6oC

< 25oC.

ditto

Refer temperature monitoring log

- Keeping all mix constituents shaded where possible to reduce their temperatures in

the stockpile.

- Cooling of mixing water and/or replacing part or whole of the added water with ice.

Yes

5.5

- Reducing the cement content by the use of admixtures (but not below that

required

for durability)

- Using a cement with a lower heat of hydration.

- Restricting the time between mixing and placing of the concrete to not more

than 2 hours

- Providing approved surface insulation continuously over all exposed surfaces to

prevent draughts and to maintain uniform temperature through the concrete mass

Holcim Mass Pour PCB40-LH

Remark

Complied with TCVN 7712 : 2013 & BS

146

Refer to mix design

3.2.1

The cement used shall be Portland cement complying with SS 26 or Portland blast

furnace cement complying with BS 146 : Part 2

min 350 kg/m3

max 550 kg/m3

max 0.55

max 20mm

Actual

Yes. A part of water replaced by ice

Yes. Actual 385 kg/m3

Refer trial mix design

Yes (Holcim Mass Pour was used)

Yes

Refer trial mix design

Refer concrete record

Yes. Exposed concrete surfaces was

covered by insulation & PVC sheet

Refer method statement

- Providing shade to the concrete surface to prevent heat gain from direct radiation

Yes. By Insulation material

ditto

For large pours or for elements with section dimensions exceeding 600 mm, an

approved

surface insulation system shall be provided

Yes. Curring by insulation method at

least 5 days after concrete casting

ditto

C. CURING

11.7.3

You might also like

- Mass Concrete Method StatementDocument11 pagesMass Concrete Method StatementAnte Dabo100% (1)

- Thermal Control in Mass ConcreteDocument2 pagesThermal Control in Mass ConcreteHandy Ham DannyNo ratings yet

- Curing Concrete - Concrete Technology - Portland Cement Association (PCA)Document6 pagesCuring Concrete - Concrete Technology - Portland Cement Association (PCA)Jay PatelNo ratings yet

- The Fabrication of Materials: Materials TechnologyFrom EverandThe Fabrication of Materials: Materials TechnologyRating: 5 out of 5 stars5/5 (1)

- Zamil Steel ManualDocument469 pagesZamil Steel ManualDhanu Padhu80% (5)

- MASS CONCRETE METHOD STATEMENT - FinalDocument89 pagesMASS CONCRETE METHOD STATEMENT - FinalMichael Assefa100% (1)

- Design and Control of Concrete Mixtures P 251-360Document110 pagesDesign and Control of Concrete Mixtures P 251-360Narcisa RudnicNo ratings yet

- Temperature of Mass ConcreteDocument41 pagesTemperature of Mass Concreterahmat amaik0% (1)

- Cold Weather ConcretingDocument2 pagesCold Weather ConcretingBoris DikovNo ratings yet

- Controlling Temperatures in Mass ConcreteDocument4 pagesControlling Temperatures in Mass ConcreteBatepola Bac100% (1)

- Temperature and Effect On ConcreteDocument59 pagesTemperature and Effect On ConcreteBart KwanNo ratings yet

- Hot and Cold Weather ConcretingDocument7 pagesHot and Cold Weather ConcretingFaisal Gulzar100% (1)

- Hot Weather ConcretingDocument74 pagesHot Weather ConcretingTonyBuiNo ratings yet

- 1 Hot Weather Concreting - PDFDocument51 pages1 Hot Weather Concreting - PDFYoumna ShatilaNo ratings yet

- Thermal Insulation Handbook for the Oil, Gas, and Petrochemical IndustriesFrom EverandThermal Insulation Handbook for the Oil, Gas, and Petrochemical IndustriesRating: 3.5 out of 5 stars3.5/5 (3)

- The Institute of Energy's Second International Conference on COMBUSTION & EMISSIONS CONTROL: Proceedings of The Institute of Energy Conference Held in London, UK, on 4-5 December 1995From EverandThe Institute of Energy's Second International Conference on COMBUSTION & EMISSIONS CONTROL: Proceedings of The Institute of Energy Conference Held in London, UK, on 4-5 December 1995Rating: 5 out of 5 stars5/5 (1)

- Steam Curing (REPORT)Document1 pageSteam Curing (REPORT)Vanny Gimotea BaluyutNo ratings yet

- Temperature Problems in Concreting: Main ReferenceDocument4 pagesTemperature Problems in Concreting: Main ReferenceMirosha NavaratnaNo ratings yet

- Hot - Weather Creaton 2Document7 pagesHot - Weather Creaton 2Pankaj PriyadarshiNo ratings yet

- Concrete in Hot Weather Conditions-Challanges - Precautions: Dr. S. Vijaya Mohan RaoDocument6 pagesConcrete in Hot Weather Conditions-Challanges - Precautions: Dr. S. Vijaya Mohan RaoHussain ElarabiNo ratings yet

- Setting and Hardening of ConcreteDocument30 pagesSetting and Hardening of ConcreteManjer123No ratings yet

- Bs 1881 - 112 (1983) PDFDocument11 pagesBs 1881 - 112 (1983) PDFAdesina AlabiNo ratings yet

- Hot Weather Concreting-1Document37 pagesHot Weather Concreting-1ephNo ratings yet

- Cold Weather Concrete PDFDocument4 pagesCold Weather Concrete PDFyanickdouce1206No ratings yet

- Setting and Hardening ConcreteDocument24 pagesSetting and Hardening Concreteabdulwahab1175% (4)

- PCA-Cold Weather Concreting Heating MaterialDocument18 pagesPCA-Cold Weather Concreting Heating MaterialMian M KhurramNo ratings yet

- Hot Weather ConcretingDocument10 pagesHot Weather ConcretingAgramovic PetarNo ratings yet

- 3CC SpecDocument3 pages3CC SpecKS LeeNo ratings yet

- Thermal Control in ConcreteDocument14 pagesThermal Control in ConcreteDeshapriyaNo ratings yet

- CIP Cold WeatherDocument2 pagesCIP Cold WeatherGrou RiakNo ratings yet

- Hot Weather Concreting Cold Weather ConcretingDocument46 pagesHot Weather Concreting Cold Weather ConcretingIRFAN SHARNo ratings yet

- Tablas ACI 306RDocument2 pagesTablas ACI 306RCjmiguel MiguelNo ratings yet

- Proposal For Batching Plant For Temperature Controlled ConcreteDocument13 pagesProposal For Batching Plant For Temperature Controlled ConcretearuanNo ratings yet

- Maximum Fresh Concrete Temperature Requirements (MMSP Project)Document3 pagesMaximum Fresh Concrete Temperature Requirements (MMSP Project)Tin ZawNo ratings yet

- 12 - Hot Weather ConcretingDocument2 pages12 - Hot Weather ConcretingHakan Kuruoğlu0% (1)

- Conc - Tech Lec-5Document17 pagesConc - Tech Lec-5kassawNo ratings yet

- New Admixtures For Eliminating Steam Curing and Its Negative Effects On DurabilityDocument21 pagesNew Admixtures For Eliminating Steam Curing and Its Negative Effects On Durabilityअभिषेक महर्षिNo ratings yet

- QC and Mix Design DataDocument39 pagesQC and Mix Design Dataइंजि कौस्तुभ पवारNo ratings yet

- Emerging Lecture 2 & 3Document48 pagesEmerging Lecture 2 & 3izim izimNo ratings yet

- Hot Weather ConcretingDocument10 pagesHot Weather ConcretingIm ChinithNo ratings yet

- SECTION 03332: Lightweight Insulating ConcreteDocument4 pagesSECTION 03332: Lightweight Insulating ConcreteStraus WaseemNo ratings yet

- Temperature - 1Document2 pagesTemperature - 1ksshashidharNo ratings yet

- CE 308 Lec 13 Special Weather ConcretingDocument12 pagesCE 308 Lec 13 Special Weather ConcretingwasimkhaliqNo ratings yet

- A Review of Hot Climate Concreting, and The Appropriate Procedures For Ordinary Jobsites in Developing CountriesDocument16 pagesA Review of Hot Climate Concreting, and The Appropriate Procedures For Ordinary Jobsites in Developing CountriesbellaNo ratings yet

- Guideline On Use of Ready Mix ConcreteDocument2 pagesGuideline On Use of Ready Mix Concretebill_lee_242No ratings yet

- Ncma Tek 3-1CDocument4 pagesNcma Tek 3-1CB0B_PNo ratings yet

- Chapter 8 ConcreteDocument140 pagesChapter 8 ConcreteJulius MuhimboNo ratings yet

- Laborario # 3 Carretera IiDocument6 pagesLaborario # 3 Carretera IiCAMPOS TORRICO CAINNo ratings yet

- Low Heat Development in Self-Compacting Concretes For Massive StructuresDocument11 pagesLow Heat Development in Self-Compacting Concretes For Massive StructuresDarius StanciuNo ratings yet

- Construction Updates: Extreme Weather ConcretingDocument8 pagesConstruction Updates: Extreme Weather Concretingzacharia MshandeteNo ratings yet

- Semana 07 O - Hot Weather Concreting - PCA Chapter 16Document12 pagesSemana 07 O - Hot Weather Concreting - PCA Chapter 16Ernesto Morán OrtizNo ratings yet

- CIP 12 - Hot Weather ConcretingDocument2 pagesCIP 12 - Hot Weather ConcretingSatt PaingNo ratings yet

- Procedure For REINFORCED MASS CONCRETE 01Document4 pagesProcedure For REINFORCED MASS CONCRETE 01Adnan ArshidNo ratings yet

- Aci Mix Design Example 1Document39 pagesAci Mix Design Example 1aberaNo ratings yet

- Encyclopaedia Britannica, 11th Edition, Volume 8, Slice 3 "Destructors" to "Diameter"From EverandEncyclopaedia Britannica, 11th Edition, Volume 8, Slice 3 "Destructors" to "Diameter"No ratings yet

- Heat Transfer in Polymer Composite Materials: Forming ProcessesFrom EverandHeat Transfer in Polymer Composite Materials: Forming ProcessesNicolas BoyardNo ratings yet

- Clean Ironmaking and Steelmaking Processes: Efficient Technologies for Greenhouse Emissions AbatementFrom EverandClean Ironmaking and Steelmaking Processes: Efficient Technologies for Greenhouse Emissions AbatementNo ratings yet

- So Tay An Toan Va Ve Sinh Lao Dong (Jica)Document52 pagesSo Tay An Toan Va Ve Sinh Lao Dong (Jica)hvduylinhNo ratings yet

- Vandex ProductDocument5 pagesVandex ProducthvduylinhNo ratings yet

- Dramix Advantages Over Rebar/meshDocument10 pagesDramix Advantages Over Rebar/meshhvduylinhNo ratings yet

- Sikafloor - 161: 2-Part Epoxy Primer, Levelling Mortar, Intermediate Layer and Mortar ScreedDocument6 pagesSikafloor - 161: 2-Part Epoxy Primer, Levelling Mortar, Intermediate Layer and Mortar ScreedhvduylinhNo ratings yet