Professional Documents

Culture Documents

Capping Cylindrical Concrete Specimens With Sulfur or Capping Compound ASTM Designation: ASTM C617 Purpose

Uploaded by

Elias Antonio Tapia Cuevas0 ratings0% found this document useful (0 votes)

13 views1 pageThis document provides instructions for capping cylindrical concrete specimens with sulfur or capping compound to prepare them for compressive strength testing. The procedure involves heating the capping material to 130°C and using an alignment device and melting pot to apply a thin, uniform layer to create a smooth, perpendicular surface on both ends of the specimen. Proper preparation and quick work are needed to apply the cap before the material solidifies.

Original Description:

apuntes refrentado con azufre

Original Title

Capping Cylindrical Concrete Specimens With Sulfur or Capping Compound

Copyright

© © All Rights Reserved

Available Formats

DOC, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document provides instructions for capping cylindrical concrete specimens with sulfur or capping compound to prepare them for compressive strength testing. The procedure involves heating the capping material to 130°C and using an alignment device and melting pot to apply a thin, uniform layer to create a smooth, perpendicular surface on both ends of the specimen. Proper preparation and quick work are needed to apply the cap before the material solidifies.

Copyright:

© All Rights Reserved

Available Formats

Download as DOC, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

13 views1 pageCapping Cylindrical Concrete Specimens With Sulfur or Capping Compound ASTM Designation: ASTM C617 Purpose

Uploaded by

Elias Antonio Tapia CuevasThis document provides instructions for capping cylindrical concrete specimens with sulfur or capping compound to prepare them for compressive strength testing. The procedure involves heating the capping material to 130°C and using an alignment device and melting pot to apply a thin, uniform layer to create a smooth, perpendicular surface on both ends of the specimen. Proper preparation and quick work are needed to apply the cap before the material solidifies.

Copyright:

© All Rights Reserved

Available Formats

Download as DOC, PDF, TXT or read online from Scribd

You are on page 1of 1

Capping Cylindrical Concrete Specimens with Sulfur or Capping Compound

ASTM Designation: ASTM C617

Purpose:

To cap hardened Portland cement concrete cylinders and drilled concrete

cores with sulfur mortar or other capping compounds to prepare the specimen for

compressive strength testing

Significance and Use:

this procedure provides plane surfaces perpendicular to the

specimen axis on the ends of concrete cylinders before performing the compression test.

Equipment:

1.

Alignment device consisting of a frame with guide bars and a cup. The size of the

alignment device should match the specimen size.

2.

Melting pot, used for melting sulfur mortars or capping compound, equipped with

automatic temperature control. The melting pot should be used either outdoors or

under an exhaust hood. Heating over an open flame is dangerous, because the

mixture may ignite if overheated.

Capping Procedure

1.

Prepare the sulfur mortar or capping compound by heating to about 130 oC. Use a

metal thermometer to check the temperature. Make sure to empty any old mortar

and to use fresh mortar to avoid the loss of strength due to successive heating. The

fresh sulfur mortar must be dry when it is placed in the pot, because dampness

may cause foaming.

2.

Warm the capping cup or device slightly before use to slow the rate of hardening

and to permit the production of thin caps.

3.

Oil the capping cup lightly and stir the molten sulfur mortar or the capping

compound immediately prior to pouring into the cup. Make sure the ends of

moist-cured specimens are dry enough at the time of capping, so there will be no

steam or foam pockets.

4.

Hold the concrete cylinder with two hands and push it against the guide bars of

the capping device. Carefully lower the specimen until it rests in the cup. this

step must be completed quickly before the sulfur or capping compound solidifies.

The thickness of the cap should be about 3-mm (1/8 inch) and not more than 8mm (5/16 inch) in any part.

5.

Before the cylinder is tested for compressive strength, the cap should be cured in

order to have strength comparable to that of the concrete.

You might also like

- Making CruciblesDocument3 pagesMaking Cruciblesborakas2011No ratings yet

- Laboratory Manual of Glass-BlowingFrom EverandLaboratory Manual of Glass-BlowingRating: 5 out of 5 stars5/5 (1)

- Kiln Operation ManualDocument25 pagesKiln Operation ManualLeulNo ratings yet

- Insulating Refractory Concrete Installation GuideDocument28 pagesInsulating Refractory Concrete Installation Guidesaju varghese100% (1)

- Capping Cylindrical Concrete Specimens With Sulfur or Capping CompoundDocument1 pageCapping Cylindrical Concrete Specimens With Sulfur or Capping CompoundElias Antonio Tapia CuevasNo ratings yet

- DownloadDocument7 pagesDownloadpilopoNo ratings yet

- Furnace MaintenanceDocument3 pagesFurnace MaintenanceTravis WoodNo ratings yet

- 4 Ways To Cap Concrete Cylinder SpecimenDocument3 pages4 Ways To Cap Concrete Cylinder SpecimenHafiz FizuNo ratings yet

- 4 Ways To Cap Concrete Cylinder SpecimenDocument3 pages4 Ways To Cap Concrete Cylinder SpecimensuryakantameNo ratings yet

- Installation and Removal of Interference Compressor Drive Coupling Hubs, Edit BMDocument3 pagesInstallation and Removal of Interference Compressor Drive Coupling Hubs, Edit BMjose luis rattiaNo ratings yet

- Ductility Test of BitumenDocument8 pagesDuctility Test of BitumenMuhammad Arslan AfzalNo ratings yet

- Casting Procedure-December 15th, 2016Document5 pagesCasting Procedure-December 15th, 2016Николай СидоренкоNo ratings yet

- Department of Transportation: California Test 521 June 2012Document4 pagesDepartment of Transportation: California Test 521 June 2012germanNo ratings yet

- Initial and Final Setting Time of CementDocument4 pagesInitial and Final Setting Time of CementHamza MughalNo ratings yet

- CT Lab ManualDocument26 pagesCT Lab ManualJagathChandraNo ratings yet

- Method Statement For Concrete CompressionDocument5 pagesMethod Statement For Concrete CompressionResearcherNo ratings yet

- DownloadDocument2 pagesDownloadpilopoNo ratings yet

- Concrete Test Cubes WIDocument2 pagesConcrete Test Cubes WIEE007CANo ratings yet

- Bitumen Tests PDFDocument8 pagesBitumen Tests PDFnouman khattakNo ratings yet

- Melt Flow Index Test (MFI: DefinitionDocument6 pagesMelt Flow Index Test (MFI: Definitionashas waseemNo ratings yet

- Department of Transportation: California Test 551 August 2012Document21 pagesDepartment of Transportation: California Test 551 August 2012Mohsen TennichNo ratings yet

- Lok Set Resin CapsuleDocument4 pagesLok Set Resin CapsuleDaniel Alcides Arias RafaelNo ratings yet

- Flow Lines Description: Flow Lines Are Streaks, Patterns, or Lines - Commonly Off-TonedDocument5 pagesFlow Lines Description: Flow Lines Are Streaks, Patterns, or Lines - Commonly Off-TonedMadhab BeraNo ratings yet

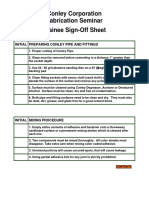

- Conley Corporation Fabrication Seminar Trainee Sign-Off SheetDocument3 pagesConley Corporation Fabrication Seminar Trainee Sign-Off SheetDieguitoOmarMoralesNo ratings yet

- Solvent Cementing Literature As On WebsiteDocument5 pagesSolvent Cementing Literature As On WebsiteNaeemSiddiquiNo ratings yet

- .Archivetemptest 3 - Ductility of Bituminous MaterialsDocument7 pages.Archivetemptest 3 - Ductility of Bituminous MaterialsSadon B AsyNo ratings yet

- Materials Testing Laboratory Laboratory Exercise No. 4 Testing of Portland CementDocument14 pagesMaterials Testing Laboratory Laboratory Exercise No. 4 Testing of Portland CementRejoice SamboNo ratings yet

- Copaltite Complete Usage Guide PDFDocument4 pagesCopaltite Complete Usage Guide PDFAnonymous nw5AXJqjdNo ratings yet

- Metal Ceramic Crown Lab ManualDocument25 pagesMetal Ceramic Crown Lab ManualchusbNo ratings yet

- WI 15 Cement TestingDocument6 pagesWI 15 Cement TestingRaja Varshney100% (1)

- Concrete Technology: Sem (Iii) Scheme - I Cha - 1. CementDocument30 pagesConcrete Technology: Sem (Iii) Scheme - I Cha - 1. CementKanishka roll28No ratings yet

- Pipe ForgeDocument6 pagesPipe ForgePierre799esNo ratings yet

- Instruction: Created By: CREP Approved By: GRC Approved Date: 22. December 2015Document12 pagesInstruction: Created By: CREP Approved By: GRC Approved Date: 22. December 2015supendra phuyalNo ratings yet

- Curing InstructionsDocument16 pagesCuring InstructionsDildeep PallipadNo ratings yet

- To Measure The Ductility of A Given Sample of Bitumen 2. To Determine The Suitability of Bitumen For Its Use in Road ConstructionDocument2 pagesTo Measure The Ductility of A Given Sample of Bitumen 2. To Determine The Suitability of Bitumen For Its Use in Road ConstructionKinley PelzangNo ratings yet

- Troubleshooting GuideDocument25 pagesTroubleshooting GuideIjabiNo ratings yet

- Installation Instruction For Conventional Castables PDFDocument2 pagesInstallation Instruction For Conventional Castables PDFakv_bhelNo ratings yet

- .Archivetemptest 2 - Softening Point of BitumenDocument6 pages.Archivetemptest 2 - Softening Point of BitumenSadon B AsyNo ratings yet

- CongretetestingDocument11 pagesCongretetestingBatepola BacNo ratings yet

- Laboratory Manual: Name: Roll No.: Semester: Academic YearDocument58 pagesLaboratory Manual: Name: Roll No.: Semester: Academic YearDipankar NathNo ratings yet

- Closed Moulds Waiting For PouringDocument1 pageClosed Moulds Waiting For PouringvasanthiNo ratings yet

- Carbon Residue - TestDocument2 pagesCarbon Residue - TestSHERWIN MOSOMOSNo ratings yet

- Making Test Cubes From Fresh ConcreteDocument4 pagesMaking Test Cubes From Fresh Concretesjpaul197367% (6)

- Compressive Strength of Cement Mortars Using 50 MM Cube Specimens T 106 & C109Document4 pagesCompressive Strength of Cement Mortars Using 50 MM Cube Specimens T 106 & C109YasirNo ratings yet

- CIP 34 - Making Concrete Cylinders in The FieldDocument2 pagesCIP 34 - Making Concrete Cylinders in The FieldGreg YeeNo ratings yet

- Unit-V Investment Casting of SuperalloysDocument36 pagesUnit-V Investment Casting of SuperalloysJ JhansibaiNo ratings yet

- Standard UnitsDocument10 pagesStandard UnitsysilangitNo ratings yet

- Test Method BitDocument24 pagesTest Method Bitdstv2005No ratings yet

- Standard Practice For Recovering Residue From Emulsified Asphalt Using Low-Temperature Evaporative TechniquesDocument4 pagesStandard Practice For Recovering Residue From Emulsified Asphalt Using Low-Temperature Evaporative Techniquesjun floresNo ratings yet

- Cement ManualDocument10 pagesCement ManualyowmaNo ratings yet

- Civil Material (Concrete) - Steel Reinforcement PreparationDocument5 pagesCivil Material (Concrete) - Steel Reinforcement PreparationDini NoordinNo ratings yet

- Transportation Engineering Lab ManualDocument21 pagesTransportation Engineering Lab ManualMuhammad IrfanNo ratings yet

- Histologic Plant Tissue Preparation Techniques. 5 - Embedding StepDocument4 pagesHistologic Plant Tissue Preparation Techniques. 5 - Embedding StepFrancis ValdezNo ratings yet

- Lab Report - Copy EditedDocument24 pagesLab Report - Copy EditedSaksham ShekhawatNo ratings yet

- Highway 2Document10 pagesHighway 2Ahmad OmarNo ratings yet

- Determination of DuctilityDocument2 pagesDetermination of DuctilityResul EskerovNo ratings yet

- Making and Curing Concrete Test Specimens in The Laboratory: Experiment No. 6Document4 pagesMaking and Curing Concrete Test Specimens in The Laboratory: Experiment No. 6Mark Anthony Estoque Dusal0% (1)

- Sect 6 Injection Mold Design TipsDocument17 pagesSect 6 Injection Mold Design TipsRanataNo ratings yet

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet