Professional Documents

Culture Documents

Sulphate Attack and Alkali-Silica

Sulphate Attack and Alkali-Silica

Uploaded by

Umar SabaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Sulphate Attack and Alkali-Silica

Sulphate Attack and Alkali-Silica

Uploaded by

Umar SabaCopyright:

Available Formats

Proceedings of Second International Symposium on Concrete Tecnology for

Sustainable February - Development with Emphasis on Infrastructure,

Hyderabad, India, 27 February - 3 March (2005) pp. 55-67.

SULPHATE ATTACK AND ALKALI-SILICA

EXPANSION

M. Collepardi, ENCO, Engineering Concrete, Ponzano Veneto

(TV) Italy

ABSTRACT : A holistic approach was adopted to examine

concrete durability problems by taking into account physical

aspects (such as capillary porosity, micro-cracking, macrovoids) and chemical reactions. A ternary representation of the

complex damage process in reinforced concrete structures was

used by examining the coexistence of the main three elements

effecting the concrete durability: a) interconnected porosity, b)

exposure to aggressive agents, and c) presence of water.

This model was adopted to examine two specific examples of

the concrete damage dealing with the cement matrix, the

embedded aggregates:

-sulfate attack of the cement matrix;

-alkali-aggregate reaction.

Keywords:

alkali-silica reaction, durability, sulfate attack

Mario Collepardi is President of ENCO, Engineering Concrete,

Ponzano Veneto (Italy). He is author or co-author of numerous

papers on concrete technology and cement chemistry. He is also

the recipient of several awards for his contributions to the

knowledge of superplasticizers and their use in concrete.

Proceedings of Second International Symposium on Concrete Tecnology for

Sustainable February - Development with Emphasis on Infrastructure,

Hyderabad, India, 27 February - 3 March (2005) pp. 55-67.

INTRODUCTION

According to the holistic model proposed by Mehta (1, 2), a

well-constituted, properly consolidated, and cured concrete

continues to be substantially watertight and durable as long as

capillary pores and microcracks in the interior do not become

interconnected pathways leading to the surface of concrete.

Loading effects as well as heating/cooling or wetting/drying

cycles in service are responsible for the propagation of

microcracks that normally exist in reinforced concrete structures

(RCS) at the transition zone between the cement matrix and

aggregates or at the interface between the cement mortar and

reinforcing bars. This mechanism (Fig. 1) that happens in RCS

in service, but not necessarily in laboratory concrete specimens,

causes a gradual loss of watertightness (Stage 1). Then initiation

and propagation of damage of RCS can occur due to the

penetration of environmental aggressive agents (water, air, and

ions such as Cl-, SO4=, Na+) through the interconnected porosity.

Due to the expansive character of all the interactions between

the concrete components (cement matrix, aggregate, reinforcing

steel) on the one hand, and the aggressive agents on the other,

damaging effects such as cracking, spalling, loss of mass, and

strength reduction can occur and then increase more and more

the permeability (Stage 2).

According to this model, no apparent damage will be

observed during Stage 1 corresponding to the gradual loss of

watertightness, whereas in Stage 2 the damage occurs slowly at

first, then at an increasingly rate (Fig. 2).

AN OTHER VIEW OF THE HOLISTIC MODELTERNARY REPRESENTATION

According to the above description of the holistic model, preexisting micro-cracks and their interaction with the

environmental action play a dominant role in determining the

long-term durability behavior of well constituted, properly

consolidated and cured concrete.

Proceedings of Second International Symposium on Concrete Tecnology for

Sustainable February - Development with Emphasis on Infrastructure,

Hyderabad, India, 27 February - 3 March (2005) pp. 55-67.

However, this material refers to RCS characterized by a low

capillary porosity of the cement matrix (related with a low

water-cement ratio and moist curing), and the absence of macrovoids caused by an un-proper consolidation of the fresh mixture

related with its inadequate workability.

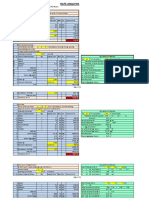

An other view of the holistic model will be presented in this

paper in order to put more emphasis in the important role played

by the water-cement ratio (w/c) and concrete workability - both

affected by the use of superplasticizers - in determining the

durability behavior of RCS. This presentation is based on the

selection of the most important elements affecting the damage

process. For instance Fig. 3 offers an other view of the holistic

model through a ternary representation of the damage process

determined by the co-existence of the following three principal

elements.

i)

Interconnected porosity. It is related not only to microcracks caused by the environmental action (weathering and

loading effects) but even to the capillary porosity of the

cement matrix (caused by high w/c and inadequate curing)

and un-proper consolidation producing macro-voids

particularly when stiff concrete mixtures are placed.

ii) Exposure to aggressive agents. It is related to the main

three chemical mechanisms of degradation of RCS:

a) sulfate attack

b) corrosion of reinforcing bars

c) alkali-silica reaction (ASR)

iii) Presence of water. It is related to the intermittent or

continuous penetration of the environmental water

determining the durability behavior of RCS. Water acts as

aggressive agent by itself (freezing-thawing) or concurrently

with other aggressive agents (CO2, O2, Cl-, SO4=, alkali) in

the three mentioned degradation mechanisms. Moreover, it

also acts as liquid carrier for reactant ions diffusing through

the interconnected pores of the cement matrix.

A synthetic representation of the holistic approach for the

damage of RCS can be examined through the help of Fig. 3

Proceedings of Second International Symposium on Concrete Tecnology for

Sustainable February - Development with Emphasis on Infrastructure,

Hyderabad, India, 27 February - 3 March (2005) pp. 55-67.

where each element corresponds to a circle. Each area of the

circle corresponds to a system in which only one of the three

elements of the system is present, and this situation does not

present any risk at all for the damage of RCS. The area in the

middle, where the three circles overlap, corresponds to

situations of serious risk for the damage since all the three

needed elements are present: interconnected porosity,

environmental water, and exposure to aggressive agents.

In the absence of one of these elements the damage of RCS

cannot occur. For instance, in porous and/or micro-cracked

concrete not exposed to water the damage does dot happen even

if there is a potential presence of environmental aggressive

agents such as SO4= and Cl-: in the absence of water, these ions

cannot migrate through the interconnected pores and neither the

sulfate attack of the cement matrix nor the corrosion of the

metallic reinforcement can occur. The following examples will

illustrate this point.

Sulfate attack

This attack is related to the expansive character of the

ettringite formation by reaction of internal (into the concrete) or

external (from the environment) sulfate with the hydrated

calcium aluminate of the hardened cement matrix.

Not necessarily the ettringite formation produces a damaging

effect. When it occurs homogeneously and immediately (within

hours or days) in a mixture or in a deformable concrete - early

ettringite formation (EEF) - the related expansion does not

cause any significant localized disruptive action (Table 1). This

happens when ground gypsum reacts with anhydrous calcium

aluminates within some hours (set regulation) or when a calcium

aluminate sulfate (C4A3S) hydrates within few days producing a

relatively small, homogeneous, harmless and rather useful stress

(expansive cements for shrinkage compensating concretes).

On the other hand, when ettringite forms heterogeneously and

later (after months or years) - delayed ettringite formation

(DEF) - the localized related expansion in a rigid hardened

concrete produces cracking, spalling, and strength loss.

Proceedings of Second International Symposium on Concrete Tecnology for

Sustainable February - Development with Emphasis on Infrastructure,

Hyderabad, India, 27 February - 3 March (2005) pp. 55-67.

Therefore only DEF - and not EEF - is associated with a

damaging sulfate attack (Table 1).

There are two different types of DEF-related damage

depending on the sulfate source (Table 2): external or internal

sulfate attack. External sulfate attack (ESA) occurs when

environmental sulfate (from water or soil) penetrates concrete

structures. Internal sulfate attack (ISA) occurs in a sulfate-free

environment for the late sulfate release from either gypsumcontaminated aggregates or thermal decomposition of ettringite

(3).

Figures 4 and 5 give a view of the holistic model through a

ternary representation of the ESA- and ISA-related damage

respectively. In particular the ESA induced damage is

determined by the co-existence of the following three elements:

Permeability

Sulfate-rich environment

Presence of water

On the other hand, the ISA-induced damage is related to the

co-existence of the following three elements:

Micro-cracking

Late sulfate release

Presence of water

The positive role played by superplasticizers, in reducing the

w/c and then the permeability of the cement matrix, is very

important in the ESA since this effect significantly retards the

penetration of SO4= ions from the environment into the concrete

and consequently reduce the corresponding DEF-related

damage. On the other hand, the ISA may occur even in

superplasticized concretes with very low w/c since sulfate is

According to the terminology currently used "DEF" is related to the internal

sulfate attack only in a sulfate-free environment (3). However, more

correctly delayed ettringite formation means that ettringite forms later

independently of the sulfate source.

Proceedings of Second International Symposium on Concrete Tecnology for

Sustainable February - Development with Emphasis on Infrastructure,

Hyderabad, India, 27 February - 3 March (2005) pp. 55-67.

already available into the concrete (Fig. 5) feed the delayed

deposition of ettringite.

Alkali-silica reaction

Due to interaction between certain aggregates (containing

amorphous silica or strained quartz) and the highly alkaline

solution of the pore aqueous phase, concrete can deteriorate and

this reaction is known as "alkali-silica reaction" (ASR). The

alkali content of the pore aqueous phase depends primarily on

the alkali content of the clinker phase and even on the exposure

to environmental sodium salts (sea water and deicing agents).

The three elements needed for the ASR (Fig. 6) are:

Alkali content

Alkali-reactive silica

Presence of water

Superplasticizers can mitigate the damaging effect of ASR by

reducing the concrete permeability and then the penetration of

water as well as of environmental sodium salts. On the other

hand, superplasticizers appear to be less effective in preventing

ASR-related damage when alkalis come from the clinker phase,

then when they are initially into the concrete. In such a case, the

best way of preventing ASR-related damage is the use of

pozzolanic materials in combination with a water-reducing

admixture, if any.

CONCLUSIONS

A synthetic view of the holistic approach for the deterioration

of reinforced concrete structures was proposed through a ternary

representation of the damage process determined by the coexistence of the following three principal elements:

interconnected porosity

exposure to aggressive agents

Proceedings of Second International Symposium on Concrete Tecnology for

Sustainable February - Development with Emphasis on Infrastructure,

Hyderabad, India, 27 February - 3 March (2005) pp. 55-67.

presence of water

The following examples of concrete deterioration were

examined by using this ternary representation:

external sulfate attack;

internal sulfate attack;

corrosion of reinforcing bars;

alkali-silica reaction.

External sulfate attack, corrosion of reinforcing bars, and

alkali-silica reaction promoted by the alkali penetration from the

environment (sea water, deicing salts) can be significantly

mitigated by using superplasticizers due to the reduction in

concrete permeability and then in the penetration of aggressive

agents (SO4=, Cl-, CO2, O2, Na+) from the environment into the

concrete.

On the other hand, superplasticizers play a less important role

in damaging processes, such as internal sulfate attack or alkalisilica reaction promoted by high alkali cement content, where

the aggressive agents (SO4= and alkali ions) are already

available into the concrete.

REFERENCES

(1) Mehta, P.K., "Concrete Technology at the Crossroads Problems and Opportunities", Concrete Technology:

Past, Present and Future, SP-144, American Concrete

Institute, Detroit, 1994, pp 1-31.

(2) Mehta, P.K., "Durability-Critical Issues for the Future",

Concrete International, V. 19, No. 7, July, 1997, pp 2733.

(3) Collepardi, M., "A State-of-the-Art Review on Delayed

Ettringite Formation", Cement and Concrete Composites,

25 ,2003, pp 401-407.

Proceedings of Second International Symposium on Concrete Tecnology for

Sustainable February - Development with Emphasis on Infrastructure,

Hyderabad, India, 27 February - 3 March (2005) pp. 55-67.

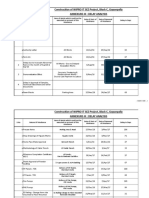

Table 1 - Early and delayed ettringite formation

ETTRINGITE FORMATION

EARLY ETTRINGITE

FORMATION (EEF):

DELAYED ETTRINGITE

FORMATION (DEF):

It occurs homogeneusly and

immediately (within hrs or days).

It occurs heterogeneously and

later (after months or years)

The related expansion does not

cause a localized and disruptive

action since it occurs in a fresh

mixture or in a deformable concrete.

The related expansion produces

cracking, spalling, and strength

loss since it occurs in a rigid,

stiff, hardened concrete.

It is due to ground gypsum which

reacts with calcium alluminates

of the portland clinker phase (set

regulation) or to sulfate-based

expansive agents in shrinkage

compensating concretes.

Its damaging effect is related to

environmental or internal sulfate

source (sulfate attack).

Table 2 - Delayed ettringite formation by external and

internal sulfate attack

DELAYED ETTRINGITE FORMATION (DEF)

EXTERNAL SULFATE

ATTACK

INTERNAL SULFATE

ATTACK

It occurs when ennvironmental

sulfate (from water or soil)

penetrates concrete structures

in service.

It occurs in a sulfate-free environment

for the late sulfate release from

gypsum-contaminated aggregates or

sulfur-rich clinker phase.

It occurs in a permeable concrete.

It needs preliminary microcracks

where deposition of ettringite crystals

can occur.

It occurs in a moist environment

favoring diffusion of SO4= through

the aqueous phase of the capillary

pores.

It occurs in a moist environment

=

favoring diffusion of SO4 and other

++

reacting ions (Ca and alluminate)

through water-saturated capillary

pores.

Proceedings of Second International Symposium on Concrete Tecnology for

Sustainable February - Development with Emphasis on Infrastructure,

Hyderabad, India, 27 February - 3 March (2005) pp. 55-67.

WATERTIGHT RCS WITH DISCONTINUOS

MICROCRACKS & CAPILLARY PORES

STAGE 1

WEATHERING & LOADING

EFFECTS

INTERCONNECTED POROSITY &

WATERTIGHTNESS LOSS

STAGE 2

ENVIRONMENTAL

AGGRESSION DUE TO

PENETRATION OF:

EXPANSION CAUSED BY:

steel corrosion

sulfate sttack on cement matrix

alkali attack on aggregates

freezing of water

water

air (O2 & CO2)

ions (Cl-, SO4=, Na+, K+)

CRACKING, SPALLING, MASS LOSS &

STRENGTH REDUCTION

Figure 1. A holistic model of concrete deterioration from

environmental effects. Adapted from Mehta (1, 2).

DAMAGE

PROPAGATION

DEMAGE OF RCS

DAMAGE

INITIATION

NO VISIBLE

DAMAGE

0

0

10

12

STAGE 2

STAGE 1

TIME

Figure 2. A two-stage damage model for reinforced

concrete structures (RCS). Adapted from Mehta (1,

2).

Proceedings of Second International Symposium on Concrete Tecnology for

Sustainable February - Development with Emphasis on Infrastructure,

Hyderabad, India, 27 February - 3 March (2005) pp. 55-67.

DAMAGE OF REINFORCED

CONCRETE STRUCTURES (RCS)

INTERCONNECTED

POROSITY

(PERMEABILITY)

PRESENCE OF

WATER

DAMAGE

OF RCS

capillary pores (high w/c and poor

curing)

macroroids (unproper compaction

of fresh concrete related to its

inadequate workability)

microcracks (loadings in service

and cyclic heating/cooling or

wetting/drying)

EXPOSURE TO

AGRESSIVE

AGENTS

moist environment

air (O2, CO2)

SO4=, Cl- and alkali ions

Figure 3. Ternary representation of the damage of RCS.

DEF RELATED TO EXTERNAL SULFATE ATTACK (ESA)

PERMEABILITY

high-capillary porosity

microcracking

moist environment

ESA

PRESENCE OF

WATER

SULFATE-RICH

ENVIRONMENT

water

soil

Figure 4. Ternary representation of the DEF related to

ESA in RCS.

Proceedings of Second International Symposium on Concrete Tecnology for

Sustainable February - Development with Emphasis on Infrastructure,

Hyderabad, India, 27 February - 3 March (2005) pp. 55-67.

DEF RELATED TO INTERNAL SULFATE

ATTACK (ISA)

MICROCRACKING

moist environment

restrained thermal & drying shrinkage

high temperature steam curing

alkali-silica reaction

loading in service

excessive and non-uniform stress

distribution in prestressed RCS

ISA

PRESENCE OF

WATER

LATE SULFATE

thermal decomposition of

RELEASE

ettringite

gypsum-contaminated aggregates

Figure 5. Ternary representation of the DEF related to

ISA in RCS.

ALKALI-SILICA REACTION (ASR)

ALKALI CONTENT

alkali-rich portland cement

environmental alkali salts (sea water

and de-icing agents)

moist environment

ASR

PRESENCE OF

WATER

ALKALI

REACTIVE

SILICA

amorphous silica or strained

quartzs in aggregate particles

Figure 6. Ternary representation of the ASR concrete

damage.

Proceedings of Second International Symposium on Concrete Tecnology for

Sustainable February - Development with Emphasis on Infrastructure,

Hyderabad, India, 27 February - 3 March (2005) pp. 55-67.

You might also like

- NPS Transaction Statement For Tier I Account: Current Scheme PreferenceDocument2 pagesNPS Transaction Statement For Tier I Account: Current Scheme PreferenceRaj Bharath33% (3)

- Operating Manual FX-7102 PDFDocument140 pagesOperating Manual FX-7102 PDFBoyke Winterberg67% (3)

- NDP Girder DocsDocument11 pagesNDP Girder DocswindsorstarNo ratings yet

- Hindrance RegisterDocument14 pagesHindrance RegisterRaj Bharath88% (8)

- Cpwd-6 For E-Tendering 1Document8 pagesCpwd-6 For E-Tendering 1Raj BharathNo ratings yet

- Potential Client (20200306)Document286 pagesPotential Client (20200306)shalu0% (1)

- Enzymatic and Non-Enzymatic BrowningDocument2 pagesEnzymatic and Non-Enzymatic BrowningChristian Ramos NievesNo ratings yet

- New Formula For Creep of Concrete in Fib Model Code 2010Document8 pagesNew Formula For Creep of Concrete in Fib Model Code 2010RamchandraNo ratings yet

- Floor Openings in Two-Way SlabsDocument7 pagesFloor Openings in Two-Way Slabsgulilero_yoNo ratings yet

- ACI Concrete International Floor Openings in Two-Way Slabs PDFDocument7 pagesACI Concrete International Floor Openings in Two-Way Slabs PDFgulilero_yoNo ratings yet

- Creep Design PDFDocument4 pagesCreep Design PDFSugumar SNo ratings yet

- 5) Design of Beams Using WSDDocument6 pages5) Design of Beams Using WSDVanessa Rosal PalerNo ratings yet

- ASCE Serviceability RequirementsDocument3 pagesASCE Serviceability RequirementsSyed AbuthahirNo ratings yet

- Numerical Analysis of Temperature Development in Concrete at An Early AgeDocument191 pagesNumerical Analysis of Temperature Development in Concrete at An Early AgeatankasalaNo ratings yet

- Reinstatement of Utility CutsDocument13 pagesReinstatement of Utility CutsArif AznurNo ratings yet

- Simplified Procedures For Calculation of Instantaneous and Long-Term Deflections of Reinforced Concrete BeamsDocument12 pagesSimplified Procedures For Calculation of Instantaneous and Long-Term Deflections of Reinforced Concrete BeamssukolikNo ratings yet

- Particular Specification For Reinforced Massive Concrete StructuresDocument4 pagesParticular Specification For Reinforced Massive Concrete StructuresMengthuyNo ratings yet

- Behaviour of Laterally Loaded Piles in Layered Soil DepositsDocument4 pagesBehaviour of Laterally Loaded Piles in Layered Soil DepositsSudharsananPRSNo ratings yet

- Table 60001 Concrete DurabilityDocument1 pageTable 60001 Concrete DurabilityZaid JamilNo ratings yet

- Shrinkage & CreepDocument6 pagesShrinkage & Creepbadr amNo ratings yet

- Reduction of Overturning Effects at Soil-Foundation InterfaceDocument2 pagesReduction of Overturning Effects at Soil-Foundation InterfaceClaudio ColettaNo ratings yet

- UNIT-2 Serviceability and Durability of ConcreteDocument16 pagesUNIT-2 Serviceability and Durability of Concreteapi-297121029No ratings yet

- Strut and Tie Models Recommended ReadingDocument2 pagesStrut and Tie Models Recommended ReadingBadr AmmarNo ratings yet

- Shallow FoundationsDocument101 pagesShallow FoundationsTanaka ChiripashiNo ratings yet

- Pile - Chapter 6Document16 pagesPile - Chapter 6SudharsananPRSNo ratings yet

- CHAPTER 6 Serviceability CriteriaDocument9 pagesCHAPTER 6 Serviceability CriteriaLittleRedNo ratings yet

- Cement Replacement Materials LectureDocument36 pagesCement Replacement Materials LectureCyrus HongNo ratings yet

- The Water Permeability of Concrete and Its Relationship With StrengthDocument9 pagesThe Water Permeability of Concrete and Its Relationship With StrengthReny AkmaliaNo ratings yet

- Water TanksDocument59 pagesWater TanksSheikh_MutaharNo ratings yet

- Evaluating Structural Buildup at Rest of Self-Consolidating Concrete Using Workability TestsDocument10 pagesEvaluating Structural Buildup at Rest of Self-Consolidating Concrete Using Workability TestsHuaman Chavez Jesus AngelNo ratings yet

- Semi-Empirical Procedures For Evaluating Liquefaction Potential, Idriss & Boulanger, 2004Document26 pagesSemi-Empirical Procedures For Evaluating Liquefaction Potential, Idriss & Boulanger, 2004hugojameswoodNo ratings yet

- Lec01 Introduction v03Document28 pagesLec01 Introduction v03new2trackNo ratings yet

- Safety Factor Pile AASHTO 1997, CBC 1992Document36 pagesSafety Factor Pile AASHTO 1997, CBC 1992Rahmaddian Nanda PerdanaNo ratings yet

- Guide To Compressive Membrane Action: Prepared For The Concrete Brldge Development GroupDocument46 pagesGuide To Compressive Membrane Action: Prepared For The Concrete Brldge Development GroupChhandak BiswasNo ratings yet

- (1963) Housner - The Bevavior of Inverted Pendulum Strtuctures During EarthquakesDocument15 pages(1963) Housner - The Bevavior of Inverted Pendulum Strtuctures During EarthquakesEdison GuzmanNo ratings yet

- Autogenous Self-Healing of ConcreteDocument23 pagesAutogenous Self-Healing of Concreteanon_650335530No ratings yet

- Time Effects On Bearing Capacity of Driven PilesDocument4 pagesTime Effects On Bearing Capacity of Driven Pilessmw100% (1)

- Chapter One IntrodutionDocument30 pagesChapter One Introdution123No ratings yet

- Modified Proposed Provisions For Aseismic Design of Liquid Storage Tanks: Part II - Commentary and ExamplesDocument14 pagesModified Proposed Provisions For Aseismic Design of Liquid Storage Tanks: Part II - Commentary and Examplesafzal taiNo ratings yet

- Shear Design of Beams PDFDocument7 pagesShear Design of Beams PDFBlend DlerNo ratings yet

- Use of Expanded Polystyrene in Road EmbankmentsDocument6 pagesUse of Expanded Polystyrene in Road EmbankmentsmikadituNo ratings yet

- Spread Footing FlexibilityDocument11 pagesSpread Footing FlexibilitypciemakNo ratings yet

- 2 PDFDocument41 pages2 PDF123No ratings yet

- Shukla Sivakugan Das IJGE Jan 2009-89-108Document21 pagesShukla Sivakugan Das IJGE Jan 2009-89-108Enrique BarragánNo ratings yet

- Creep, Shrinkage & ElasticityDocument33 pagesCreep, Shrinkage & ElasticityMia HussainNo ratings yet

- Delayed Ettringite Formation in ConcreteDocument1 pageDelayed Ettringite Formation in ConcretemakhsmyNo ratings yet

- Salgado and Yoon., Dynamic Cone Penetration Test For SubgradDocument109 pagesSalgado and Yoon., Dynamic Cone Penetration Test For SubgradokiNo ratings yet

- GEO2019 Emad Farouz CBIS Drilled ShaftsDocument24 pagesGEO2019 Emad Farouz CBIS Drilled ShaftsOanh PhanNo ratings yet

- Flo-Grout BP800Document26 pagesFlo-Grout BP800qasim078100% (1)

- Duracrete - Probabilistic Performance Based Durability Design of Concrete StructuresDocument10 pagesDuracrete - Probabilistic Performance Based Durability Design of Concrete StructuresPablo BenitezNo ratings yet

- Concrete ShrinkageDocument14 pagesConcrete ShrinkageTroy MinavesNo ratings yet

- Evaluation of Shear Resistance of High Strength Concrete Beams Without Web Reinforcement Using AnsysDocument7 pagesEvaluation of Shear Resistance of High Strength Concrete Beams Without Web Reinforcement Using AnsysHuda JawadNo ratings yet

- Civil Engineering (PILING) - Ground Heave Around Driven Piles in ClayDocument225 pagesCivil Engineering (PILING) - Ground Heave Around Driven Piles in Clayfhsn84No ratings yet

- Technical Advisory T 5040Document13 pagesTechnical Advisory T 5040Tim_C100% (1)

- Sika UK Concrete Handbook 2013Document131 pagesSika UK Concrete Handbook 2013Ahmed TahaNo ratings yet

- 1 Extraction of Strut and Tie ModelDocument39 pages1 Extraction of Strut and Tie ModelRam100% (1)

- Ubc-1997-Volume 2 (Wind Seismic Considerations) PDFDocument32 pagesUbc-1997-Volume 2 (Wind Seismic Considerations) PDFMakhzumi Muhammad UmarNo ratings yet

- State - of - The - Art - Review - Piles - in - Clay - (Revised - 17th December)Document56 pagesState - of - The - Art - Review - Piles - in - Clay - (Revised - 17th December)ALANG CANDRA MARSUDIANTONo ratings yet

- Advanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionFrom EverandAdvanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionNo ratings yet

- Design of Piles Under Cyclic Loading: SOLCYP RecommendationsFrom EverandDesign of Piles Under Cyclic Loading: SOLCYP RecommendationsAlain PuechNo ratings yet

- Plates and Shells for Smart Structures: Classical and Advanced Theories for Modeling and AnalysisFrom EverandPlates and Shells for Smart Structures: Classical and Advanced Theories for Modeling and AnalysisRating: 5 out of 5 stars5/5 (1)

- Durability of ConcreteDocument3 pagesDurability of ConcreteSujay SadashivappaNo ratings yet

- Stress Management: Unit-IV Pranayama and StressDocument16 pagesStress Management: Unit-IV Pranayama and StressRaj BharathNo ratings yet

- Monthly DDO Reconciliation For Receipts For June, 2021 Ifmis Government of TelanganaDocument1 pageMonthly DDO Reconciliation For Receipts For June, 2021 Ifmis Government of TelanganaRaj BharathNo ratings yet

- AsanSM IIIDocument18 pagesAsanSM IIIRaj BharathNo ratings yet

- Stress Management: Unit - V Dhyana and StressDocument31 pagesStress Management: Unit - V Dhyana and StressRaj BharathNo ratings yet

- Ac Exam PDF 2019 - Jan To MayDocument99 pagesAc Exam PDF 2019 - Jan To MayRaj Bharath100% (1)

- Stress Management: Ashtanga YogaDocument29 pagesStress Management: Ashtanga YogaRaj BharathNo ratings yet

- Block C: Concrete Abstract UOMDocument8 pagesBlock C: Concrete Abstract UOMRaj BharathNo ratings yet

- Cpwd-6 For E-Tendering 2Document7 pagesCpwd-6 For E-Tendering 2Raj BharathNo ratings yet

- Basic Finance - Day1Document72 pagesBasic Finance - Day1Raj BharathNo ratings yet

- Fuel Safety PDFDocument12 pagesFuel Safety PDFRaj BharathNo ratings yet

- Rate AnalysisDocument6 pagesRate AnalysisRaj BharathNo ratings yet

- Railconstruction0714 PDFDocument1 pageRailconstruction0714 PDFRaj BharathNo ratings yet

- Irc SP 38 1992 PDFDocument25 pagesIrc SP 38 1992 PDFRaj BharathNo ratings yet

- Argon Pure GasDocument2 pagesArgon Pure GasRaghu Pathy100% (1)

- Intl Dubai 2008 February TradeShowDocument57 pagesIntl Dubai 2008 February TradeShowAkil KaziNo ratings yet

- Final Paper For PublicationDocument14 pagesFinal Paper For PublicationAyush Dutt TripathiNo ratings yet

- (2022) Bahamondes Et Al (JLS) Dyadic IH On SSDocument19 pages(2022) Bahamondes Et Al (JLS) Dyadic IH On SSEDUARDONo ratings yet

- Marketing 5.0 Putting Up Blockt TogatherDocument139 pagesMarketing 5.0 Putting Up Blockt TogatherPreetiKhatriNo ratings yet

- Ab Arogyadaan SchemeDocument11 pagesAb Arogyadaan SchemeSrinivas Kumar KNo ratings yet

- Mix Sectors' CompaniesDocument5 pagesMix Sectors' CompaniesAnna LaClair100% (1)

- FFRTC LogDocument1,074 pagesFFRTC LogSukmawati ikut dongNo ratings yet

- ZXDocument13 pagesZXRv RamanNo ratings yet

- Clinical Ocular Toxicology - FraunfelderDocument371 pagesClinical Ocular Toxicology - Fraunfelderelias misael montero ramirez100% (1)

- Brady BMP21 PLUS KIT1 DatasheetDocument1 pageBrady BMP21 PLUS KIT1 DatasheetmkNo ratings yet

- Snafu1000 - Friends With (Maternity) BenefitsDocument50 pagesSnafu1000 - Friends With (Maternity) BenefitsschulmaerrNo ratings yet

- Unit 1 - Manufacturing Practices - WWW - Rgpvnotes.inDocument33 pagesUnit 1 - Manufacturing Practices - WWW - Rgpvnotes.inASHOKA KUMARNo ratings yet

- CN - 12th (2018C) - EDocument57 pagesCN - 12th (2018C) - Enext billionaireNo ratings yet

- Mangaban, Jonalyn M. Seat # B1 September 6, 2017: Key Steps in Dna IsolationDocument3 pagesMangaban, Jonalyn M. Seat # B1 September 6, 2017: Key Steps in Dna IsolationJona MangabanNo ratings yet

- WeltyDocument24 pagesWeltyFelipeNo ratings yet

- Comparative and SuperlativeDocument3 pagesComparative and SuperlativeMon Martinez DiezNo ratings yet

- The Life Cycle of GalaxiesDocument10 pagesThe Life Cycle of GalaxiesJessica RodriguesNo ratings yet

- 44 - 1004 - SDS10062Document15 pages44 - 1004 - SDS10062kokoNo ratings yet

- HW 1 Essay 1Document6 pagesHW 1 Essay 1api-610554438No ratings yet

- The Geranium by Patricia GraceDocument9 pagesThe Geranium by Patricia GracemingNo ratings yet

- GATRONOVA Internship ReportDocument34 pagesGATRONOVA Internship ReportAbdulmunaf SheikhNo ratings yet

- Spoolmatic Pro: Air-Cooled Pistol-Grip Spool GunDocument8 pagesSpoolmatic Pro: Air-Cooled Pistol-Grip Spool GunLesther Coloch GonzálezNo ratings yet

- How To Wire An Arduino Based 3 Axis CNC MachineDocument11 pagesHow To Wire An Arduino Based 3 Axis CNC MachineSetyo WidodoNo ratings yet

- WMA Regulations 2012Document68 pagesWMA Regulations 2012nyambunagahenti20No ratings yet

- Nemo Arms 2019 Winter CatalogDocument36 pagesNemo Arms 2019 Winter CatalogJan MoszczukNo ratings yet