Professional Documents

Culture Documents

Chem Tech Series 100 150 Specifications en

Chem Tech Series 100 150 Specifications en

Uploaded by

dghgvfgvvbOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Chem Tech Series 100 150 Specifications en

Chem Tech Series 100 150 Specifications en

Uploaded by

dghgvfgvvbCopyright:

Available Formats

The Chem-Tech Series 100 is the standard by which all

other dosing pumps are judged, Chem-Tech Series

100/150 pumps with motorized-diaphragm technology

deliver dependable performance and extended longevity.

The Series 100/150 provides quiet, consistent metering

over long periods of time in a compact form.

A tried-and-true electric motor transfers power via a

sealed gearbox and eccentric cam for smooth, reliable

dosing.

Operating Benefits

Reliable metering performance.

Sealed gear train.

Easy tube change-out.

Self priming.

Chemical resistant materials.

Simple installation.

Simple, adjustable system with knob and locking lever

provide easy flow rate control and turndown.

The compact, injection-molded housing and clear pump

head offer both affordability and chemical resistance.

The industrial grade, low-stress diaphragm provides long

life, even in harsh conditions and continuous duty cycles.

Series 100 Models - The preferred metering pump for

water conditioning professionals around the world.

Perfect for applications where economical, consistent

performance is required. Capable of a wide range of

flows, from less than 3 USGPD (0.47 lph) up to 30

USGPD (4.72 lph) and pressures up to 100 PSIG (7

BAR).

Series 150 Models - Built upon the same solid platform

as the 100 Models, these units are capable of higher flow

rates. With a range offering up to 100 USGPD (15.76

lph), the Series 150 can meet the demands of larger

applications. Maximum pressure is 60 PSIG (4.2 BAR).

Features

Guided Quad Check Valve System.

Bleed Valve Assembly Standard.

Feed Rate Control.

Duplex Models. Both Series are configurable for

dosing two chemicals at different rates.

Controls

Aftermarket

KOPkits

Gauges

Dampeners

Pressure Relief Valves

Tanks

Pre-Engineered Systems

Process Controllers

(PULSAblue, MicroVision)

Feed Rate Control

Adjustable Feed Rate.

Series 100/150

Mechanical Metering Pumps

Series 100, 150

Specifications and Model Selection

Engineering Data

Pump Head Materials Available:

Diaphragm:

Engineering Data

Clear PVC

PVC

PP

316SS

CSPE

Viton

PTFE-faced CSPE backed

Viscosity Max CPS:

Power Input:

Temperature Limitations:

Shipping Weight:

300 CPS

115 VAC/60 HZ,

230 VAC/50 HZ

230 VAC/60 HZ

125F / 51C max.

8 lbs. / 3.63kg.

Specifications subject to change without notice.

Check Valves Materials Available:

Seats/O-Rings:

PTFE

CSPE

Viton

Balls:

Ceramic

PTFE

316 SS

Fittings Materials Available:

GFPPL

PVC

PVDF

Bleed Valve:

Same as fitting and check valve selected,

except 316SS

Injection Valve & Foot Valve Assy:

Same as fitting and check valve selected

Tubing:

Clear PVC

White PE

Black PE

Important: Material Code - GFPPL=Glass-filled Polypropylene, PVC=Polyvinyl Chloride,

PE=Polyethylene, CSPE=Generic formulation of Hypalon, a registered trademark of E.I.

DuPont Company. Viton is a registered trademark of E.I. DuPont Company. PVC wetted

end recommended for sodium hypochlorite.

Integrated Tank Systems

Integrated Tank Systems

Pulsafeeders ITS System is a completely

integrated tank system constructed of high

density UV resistant polyethylene (PE) with a 15

gallon capacity. This tank system is translucent

with 5 gallon increments and the tanks low level

indicator allows visual monitoring of chemicals

without opening the tank. The tight fitting child

proof lid keeps the chemical free of

contaminants and protects the surrounding area

from chemical fumes.

The ITS System also allows for easy access to

the liquid end and control panel of the mounted

pump.

A system consists of a chemical tank with lid

and bulkhead fittings: a liquid level indicator float

assemble and feeder mounting hardware.

Dimensions All dimensions expressed as inches (mm)

1.00 in.

CTI001 K11

You might also like

- BF610Document4 pagesBF610Prasad KulkarniNo ratings yet

- BOLT Manufacturing Process PDFDocument37 pagesBOLT Manufacturing Process PDFshreyasi_mahanty60% (10)

- BF3000Document6 pagesBF3000Jokanoe LertNo ratings yet

- Westfalia Separator Visco Booster Unit en 9997 0787 030Document16 pagesWestfalia Separator Visco Booster Unit en 9997 0787 030etchegarayfNo ratings yet

- Installation, Operation and Maintenance Manual: Safety TroubleshootingDocument42 pagesInstallation, Operation and Maintenance Manual: Safety TroubleshootingMohamed Abdel Samie100% (3)

- J1 FormDocument17 pagesJ1 FormBS.BOHICA1757No ratings yet

- Pulsatron Series C PDFDocument2 pagesPulsatron Series C PDFnico samsonNo ratings yet

- Pulsatron Plus Series CL Specifications enDocument2 pagesPulsatron Plus Series CL Specifications enHiroito MartinezNo ratings yet

- GPCBASIXDocument7 pagesGPCBASIXAzj SonyNo ratings yet

- CalColumns BrochureDocument2 pagesCalColumns BrochureRaya SNo ratings yet

- Ventil HC100 19BDocument6 pagesVentil HC100 19BLeandro HerreraNo ratings yet

- Pulsatron Series C Plus Tech SheetDocument2 pagesPulsatron Series C Plus Tech SheetHugo ParedesNo ratings yet

- طلمبات القياس الكهربائية فئة MDocument4 pagesطلمبات القياس الكهربائية فئة MRheoserve Industrial SolutionsNo ratings yet

- Bleed Off Valve: Safe and Controlled Bleed Off of The Annulus PressureDocument2 pagesBleed Off Valve: Safe and Controlled Bleed Off of The Annulus PressurekNdashNo ratings yet

- Walchem Pump EH-HV Series Brochure, EWN, EHE35E1, EHE35E2Document2 pagesWalchem Pump EH-HV Series Brochure, EWN, EHE35E1, EHE35E2PromagEnviro.comNo ratings yet

- AquaFuse PolyBaSS CatalogueDocument11 pagesAquaFuse PolyBaSS Catalogueani_datNo ratings yet

- Walchem Pump EK Series Brochure, EKB, EKCDocument4 pagesWalchem Pump EK Series Brochure, EKB, EKCPromagEnviro.comNo ratings yet

- CROWN Esd Brochure Usa 3 2Document4 pagesCROWN Esd Brochure Usa 3 2Ahmed Ayman Yassin100% (1)

- طلمبات حقن قياسية -دليل إختيارDocument2 pagesطلمبات حقن قياسية -دليل إختيارRheoserve Industrial SolutionsNo ratings yet

- BioChem Pinch Valve User ManualDocument33 pagesBioChem Pinch Valve User ManualthynameisraymondNo ratings yet

- PULSATRON A Plus طلمبات حقن الكيماويات الكهربائيةDocument8 pagesPULSATRON A Plus طلمبات حقن الكيماويات الكهربائيةRheoserve Industrial SolutionsNo ratings yet

- Lewa Process - Membranpumpar PDFDocument16 pagesLewa Process - Membranpumpar PDFes9857No ratings yet

- Doseuro CatologueDocument16 pagesDoseuro CatologueGb vinhhungNo ratings yet

- PULSAFEEDER 5 Function Valve Sell SheetDocument2 pagesPULSAFEEDER 5 Function Valve Sell SheetJackeline MateosNo ratings yet

- Protech Filling LinesDocument41 pagesProtech Filling Linesapi-270111516No ratings yet

- Data Sheet Lyonomic en 0Document4 pagesData Sheet Lyonomic en 0Matias RivarolaNo ratings yet

- WT.025.055.000.IE - ps.0714 Evoqua ChlorinatorDocument8 pagesWT.025.055.000.IE - ps.0714 Evoqua ChlorinatorNguyễn Đăng QuýNo ratings yet

- ProductsDocument8 pagesProductsLe ChauveNo ratings yet

- SCMS 7035Document5 pagesSCMS 7035Jose Manuel CastroNo ratings yet

- Aktapurifierinstructionalmaterial PDFDocument27 pagesAktapurifierinstructionalmaterial PDFjvreddiNo ratings yet

- Maximum Adaptability: Electromagnetic Dosing PumpsDocument6 pagesMaximum Adaptability: Electromagnetic Dosing PumpsÁrpád VassNo ratings yet

- 8-1 3750 Pressurisation Unit BrochureDocument8 pages8-1 3750 Pressurisation Unit BrochureAmeet Gupte0% (1)

- Total Product CatalogueDocument37 pagesTotal Product CatalogueFARIDNo ratings yet

- Metering Pumps: (Gear Driven & Direct Drive)Document20 pagesMetering Pumps: (Gear Driven & Direct Drive)melihozdoganNo ratings yet

- Ste/Surfacetest Tree: HalliburtonDocument2 pagesSte/Surfacetest Tree: Halliburtonsaeed65No ratings yet

- Turbine Bypass ValveDocument12 pagesTurbine Bypass ValveRam MohanNo ratings yet

- Kammer Control ValvesDocument2 pagesKammer Control ValvesJl Do SantosNo ratings yet

- Instrumentation Advance Course Part 2Document69 pagesInstrumentation Advance Course Part 2FACE BOOKNo ratings yet

- Walchem Pump EHE Series Brochure, EHE31, EHE36, EHE46, EHE56Document4 pagesWalchem Pump EHE Series Brochure, EHE31, EHE36, EHE46, EHE56PromagEnviro.comNo ratings yet

- Functionality Dim. of The Pipe Connections (Acc. To DIN 11866)Document1 pageFunctionality Dim. of The Pipe Connections (Acc. To DIN 11866)lalala3581No ratings yet

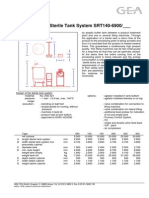

- Technical Data: Sterile Tank System SRT140-6900Document2 pagesTechnical Data: Sterile Tank System SRT140-6900Luis Guillermo Echeverri LopezNo ratings yet

- Catálogo Master FloDocument12 pagesCatálogo Master FloclaudioandrevalverdeNo ratings yet

- High Pure Water Machine Producing Water Specialized For LaboratoryDocument30 pagesHigh Pure Water Machine Producing Water Specialized For LaboratoryFaizNo ratings yet

- Accessories HydraulicsDocument47 pagesAccessories HydraulicsawfahaddadinNo ratings yet

- BR Valves Test Benches en Co 61985 PDFDocument12 pagesBR Valves Test Benches en Co 61985 PDFcafe negroNo ratings yet

- Foamproport Bladder TankDocument6 pagesFoamproport Bladder Tankgpskumar22No ratings yet

- Electric Submersible Sewage PumpsDocument8 pagesElectric Submersible Sewage PumpsMiroslavCrnogoracNo ratings yet

- Fisher SUB 250Document6 pagesFisher SUB 250shuyuanz6595No ratings yet

- Hose Test Unit SpecsDocument4 pagesHose Test Unit Specsศุภกฤต รักในหลวงNo ratings yet

- NBS 2010 Online Catalog Fermentors BioreactorsDocument46 pagesNBS 2010 Online Catalog Fermentors Bioreactorsjonas1227No ratings yet

- Pneumatic VVDocument20 pagesPneumatic VVsaashadanNo ratings yet

- Hi Flow Control Valves.iDocument3 pagesHi Flow Control Valves.iGilberto Meneses NavarroNo ratings yet

- 1-1-6 en Frese Optima Aug 10Document12 pages1-1-6 en Frese Optima Aug 10mymikeymikesNo ratings yet

- Capital Controls® Series Nxt3000: Modular Design Gas Feed System With Self Contained Automatic Switchover CapabilityDocument8 pagesCapital Controls® Series Nxt3000: Modular Design Gas Feed System With Self Contained Automatic Switchover CapabilityLoan NguyênNo ratings yet

- ProMinent Alpha Motor Driven Diaphragm Metering PumpsDocument4 pagesProMinent Alpha Motor Driven Diaphragm Metering PumpsdsakprominentbdgNo ratings yet

- LPG System AccessoriesDocument4 pagesLPG System AccessoriesPatel KalingaNo ratings yet

- Tech Sheet Series CDocument2 pagesTech Sheet Series CLalu Adam Akmal IsnenNo ratings yet

- Apco Air Release Valves Arv Arv Air Release Valves Sales 600Document4 pagesApco Air Release Valves Arv Arv Air Release Valves Sales 600RashedNo ratings yet

- Lit SepacfiiDocument4 pagesLit SepacfiiOctavianus HarahapNo ratings yet

- Frese CatalogueDocument15 pagesFrese CatalogueSyed Kamal FareedeeNo ratings yet

- Fire Fighting BOQDocument5 pagesFire Fighting BOQRamadan Rashad0% (1)

- Marth 1800 PrestressingDocument17 pagesMarth 1800 PrestressingRamesh100% (4)

- G9 CSS Q1 Lesson 2 Common Tools and Equipment For Computer Systems ServicingDocument10 pagesG9 CSS Q1 Lesson 2 Common Tools and Equipment For Computer Systems Servicingeddieson vasquezNo ratings yet

- E-Waste List - 24.03.2023Document2 pagesE-Waste List - 24.03.2023KinkiniNo ratings yet

- Colegio de San Gabriel Arcangel of Caloocan Escuela San Gabriel de Arcangel Foundation, IncDocument3 pagesColegio de San Gabriel Arcangel of Caloocan Escuela San Gabriel de Arcangel Foundation, IncJasmine BalbinNo ratings yet

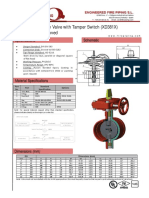

- Grooved Butterfly Valve With Tamper Switch (Xd381X) Ul/Fm/Vds ApprovedDocument1 pageGrooved Butterfly Valve With Tamper Switch (Xd381X) Ul/Fm/Vds ApprovedMohamed KhaldiNo ratings yet

- 1 PPT - Pavement of Bricks and TilesDocument11 pages1 PPT - Pavement of Bricks and TilesBHANUSAIJAYASRINo ratings yet

- Panther: A Range of Robust, IP65 Rated, Surface Mounted Luminaires With Opal or Prismatic DiffusersDocument2 pagesPanther: A Range of Robust, IP65 Rated, Surface Mounted Luminaires With Opal or Prismatic DiffusersArnel DodongNo ratings yet

- Fastener Spacing and Margin DataDocument13 pagesFastener Spacing and Margin DataLONG VUNo ratings yet

- E - Pfaudler Glass Linings 614 4EDocument18 pagesE - Pfaudler Glass Linings 614 4Edevang asherNo ratings yet

- Technical Spects GNX-PP GeneralDocument1 pageTechnical Spects GNX-PP GeneralRehanNo ratings yet

- Prediction of HardenabilityDocument5 pagesPrediction of Hardenabilitysivajirao70No ratings yet

- Safety Data Sheet R407CDocument11 pagesSafety Data Sheet R407CAndres MartinezNo ratings yet

- Dion FR 7721-00Document3 pagesDion FR 7721-00Vasu DevanNo ratings yet

- ACEDGE Compressor CatalogueDocument48 pagesACEDGE Compressor CatalogueNuttee BulbonNo ratings yet

- 60NSDocument2 pages60NSLawrence LeeNo ratings yet

- B1e 004 PDFDocument40 pagesB1e 004 PDFNguyễn Xuân ĐiệpNo ratings yet

- Pipe Flow Friction Factor Calculations With Excel Spreadsheets 3 June 15 Final PDFDocument29 pagesPipe Flow Friction Factor Calculations With Excel Spreadsheets 3 June 15 Final PDFlyguyenquocduyNo ratings yet

- Case 1: Soil: Project Title: Prince Majed Palace Design of Underground Water TankDocument5 pagesCase 1: Soil: Project Title: Prince Majed Palace Design of Underground Water Tanktantq-1No ratings yet

- Ansi Asabe S278.7 Jul2003 (Iso 11001-1-1993) (R2009)Document8 pagesAnsi Asabe S278.7 Jul2003 (Iso 11001-1-1993) (R2009)StephanNo ratings yet

- LPDC Flow SimulationDocument5 pagesLPDC Flow SimulationDavid JendraNo ratings yet

- Chapter 3. Separation Techniques in MixturesDocument12 pagesChapter 3. Separation Techniques in MixturesOctavio II OdejarNo ratings yet

- Vakum Distilation SystemDocument16 pagesVakum Distilation SystemAbdusselam AkgulNo ratings yet

- Astha: Main Plant Operation Dept. Captive Power Plant-Ii 540MwDocument25 pagesAstha: Main Plant Operation Dept. Captive Power Plant-Ii 540MwRohith KumarNo ratings yet

- Additives Improve Scratch Resistance in Automotive Applications PDFDocument5 pagesAdditives Improve Scratch Resistance in Automotive Applications PDFsonchemenNo ratings yet

- 2015 KABAR CatalogDocument19 pages2015 KABAR CatalogCarolDiasNo ratings yet

- CC100 ListDocument3 pagesCC100 ListlewoodwardNo ratings yet