Professional Documents

Culture Documents

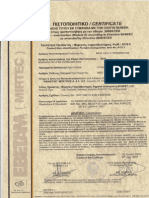

Standard ELOT EN 3.07+A1 Portable Fire Extinguishers Part 7

Uploaded by

EdésioMenesesCavalcanti0 ratings0% found this document useful (0 votes)

108 views54 pagesEuropean standard for Portable fire extinguishers.

Original Title

Standard ELOT EN 3.07+A1 Portable fire extinguishers Part 7

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentEuropean standard for Portable fire extinguishers.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

108 views54 pagesStandard ELOT EN 3.07+A1 Portable Fire Extinguishers Part 7

Uploaded by

EdésioMenesesCavalcantiEuropean standard for Portable fire extinguishers.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 54

2007-11-02 1CS:13.220.10

EAOT EN 3.07 + A1

—

TAM

OGHKH

om

Sa!

{8

EAAHNIKO NPOTYNO

®opnroi TupoaBeoripEs - Mépos 7: XapaxrnpiotiKa, arrarTAGEIs aTréBooNs Kat YéBoSo1

Boxwpnis

Portable fire extinguishers - Part 7: Characteristics, performance requirements and test

methods

Kadon Tipohoynans: 18

©EAOT — EAAHNIKOE OPTANIEMOS TYNONOIHSHE AE ‘Axopvay 313 «11145 ABnva.

ee:

EAOT EN 3.07+ Al

Eovixds Mpé20y0s

Avré sivan to O20 EmKipoons

tov eyxexpipévoo Evpomaixoi

Mporixov

EN 3-7:2004+ A

007

os Ex2qvKod Mporizon.

To xpétvxo avré dratiOerat otyy

Ayyhansi, Paz20K9 1 Peppaversy

pérsaa and tov Exec

Opyavien6 Toromoinays Ab

Na

nal Foreword

This Endorsement Sheet ratifies

the approval of European

EN 3-7:2004 = AL : 2007

a Hellenic Standard,

This standard iy

English, French or ¢

the Hellenic 01

Standardization SX.

sailable in

‘man from

on for

EUROPEAN STANDARD EN 3-7:2004+A1

NORME EUROPEENNE

EUROPAISCHE NORM August 2007

Ics 13,220.10 ‘Supersedes EN 3-7:200

English Version

Portable fire extinguishers - Part 7: Characteristics, performance

requirements and test methods.

Exincteurs dincendie portals - Parte 7 Caracténstques, Tragbare Feverioscher Tall. Eigonschatten

Performances et metnodes dessa Lestungsantocderungen und Prutungen

Tins European Standart was approved by CEN on § Maveh 2003 ane! scales Amendment 1 approved hy CEN on 39 June 2007

CCEN members are bout to comply wath the CENICENELEC intemal Regulalons which stipulate the consis forging ths Eerie

Standard the stats of nabonal standard vathout any alteration. Up-to-date sts and tniogeaphical telersizes concen sc halal

Sanats may be obtanes on application t6 the CEN Managemen! Gente aro any GEN memiver

Ths €

n Stanardwxsts mn tvee ofa versions (Engksh, French Guemian) A version in any other

ponsbally ofa CEN member nto is cas Lag sd nok! tothe: CEN Rlanagenet Gen

1h Republe, Dennurk, Eons Flat

mls Nowy Poa Pht

CEN mentors an the national stariaeds boibes oF Austna, Bryan, Buiiana Cypas: C

France: Germany. Grose, Hungary lela lead aly Lata Cater. Lepxcrtwuny Mata, Neth

Remarws Skank Slowrenn Spat Swen Sastan! Urals! Kimo

a!

COMITE FURDPPES BE SORM TIS S10

Management Centre: rue de Stassart, 368-1050 Brussels,

© 2007 CEN. Allnghts of explsation in any form and by any means reserved Rot No EN 3-7 200u%A\

wore for CEN nabonal Members

EN 3-7:2004+A1:2007 (E)

Contents

Foreword,

1 Scope...

2 Normative references...

3. Terms and definitions

4 General

44 Description of a portable fire extinguisher

42 Control of discharge

43 Operating position...

44 Hose assembly

45 — Propellants

48 Stored pressure extinguishers.

5 Testing of portable fire extinguishers

6 Nominal charges, filling tolerances and minimum fire performance

6.1 Nominal charges

62 Filling tolerances

63 B) Design of the filling opening, excluding carbon dioxide fire extinguishers

6.4 Minimum fire ratings

7 Duration of operation, residual charge and operating temperatures.

TA Duration of operation

72 Residual charge

73 Commencement of discharge

74 Effective range of operating temperature

8 Retention of propellant

8.1 Verification

82 Acceptance levels

83 Production leak tests

9 Dielectric test for water based extinguishers

91 General

92 Required performance

10 Requirements for components.

401 General

402 Operation and emission control mechanismsidevices

103 Safety devices.

104 Filter for water based portable fire extinguishers.

105 Hose and coupling systems

10.6 Controt valve

11 Means of pressure indication

111 Pressure gauge.

112 Pressure indicator ..

12 Horns for carbon dioxide portable fire extinguishers.

13 Portable fire extinguisher mounting bracket

14 Resistance to corrosion.

141 Resistance to external corrosion... . 2

142 _ Resistance to extinguishing medium of extinguishers using water based media..

18 Fire performance..

154 Generale

452 Class A ire rating

453 Class B fire rating

154 Class F fire rating

16 Portable fire extinguisher identification.

184 Colour nnn

162 Marking.

17 Maintenance

Annex A (normative) Duration of operation, residual charge tests

Annex B (normative) Range of operating temperature.

Annex C (normative) Dielectric test

‘Annex D (normative) Operation and emission control mechanismsidevices

Annex & (normative) Test for performance of the hose.

Annex F (normative) Control valve test

Annex G (normative) Tests on the horn

Annex H (normative) Resistance to corrosion.

‘Annex (normative) Fire tests,

‘Annex J (normative) Measurement of moisture content of wood

‘Annex K (normative) Compaction procedure

Annex L (normative) f Specific requirements for Class F fire extinguisher

Annex M (normative) [*) Polar solvents

Bibliography

EN 3-7:2004+A1:2007 (E)

Foreword

‘This document (EN 3-7:2004+A1:2007) has been prepared by Technical Committee CENITC 70 "Manual means of

firefighting equipment’, the secretariat of which is held by AFNOR.

This document shall be glven the status of a national standard, either by publication of an identical text or by

endorsement, at the latest by February 2008 and conficting nationat stancards shall be withdrawn at the latest by

February 2008.

This document includes Amendment 1, approved by CEN on 2007-06-30,

This document supersedes EN 3-7:2004

The start and finish of text introduced or altered by amendment is indicated in the text by tags fs)

EN 3 consists of the following parts. under the general title “Portable fire extinguishers

b) deleted text

EN part

Part 6" Provisions for the attestation of conformity of portable fre extinguishers in accordance wat

To part 5

Part 7 Characteristics, performance requirements and test metho\

Part & Additional requirements to EN 3-7 for the construction, resistance to pressure and mechanical tests

extinguishers with 3 maximum allowable pressure equal or lower than 30 har

Part 9 Additional requiements to EN 3-7 for pressure resistance of CO,.extnauusher

Part 10° Provisions valuating the confornty of a portable fire extinguishes to EN 3X part 7

According to the CENICENELEC intemal Regulations, the national standaras organizations of the follosung

‘countries are bound to implement this European Standard: Austria. Belgium. Bulgana, Cyprus. Czech Republic

Denmark, Estonia, Finland. France. Germany, Greece, Hungary, Iceland. Ireland, aly, Latvia. Lthusni

Luxembourg, Matta, Netherlands, Norway. Poland, Portugal, Romania. Slovakia, Slovenia. Spain, Sweden,

Switzerland and United Kingdom.

*) EN 3-6 wil be superseded by EN 3-10

2) EN 3:10 mill update and amend EN 36. EN 3-10 wil supersede EN 3-6

EN 3-7:2004+A1:2007 (E)

14 Scope

‘This standard specifies the characteristics, performance requirements and test methods for portable fre

extinguishers,

Reference to the suitability of an extinguisher for use on gaseous fires (class C fires) are at the manufacturer’

discretion. but are applied only to powder type extinguishers which have gained a class B or class A and class B

rating.

Suitability of extinguishers for use on class 0 fires (fires involving flammable metals) is outside the scope of this

standard in respect of test fires. However, extinguishers claiming class D sultabilty are covered in all other respects

by the requirements in this standard for powder extinguishers,

F) it is considered hazardous for powder and carbon dioxide fire extinguishers to be used on Class F fires. For

this reason powder and carbon dioxide fire extinguishers are excluded for conformance with regard to Class F in

this European Standard. (

OIE the extinction of a metal re prasents a situabon so spectic (in terms of ie meta’ Kself M8 form the confit of

the fire etc thats not passibie to deline a representative standard fre for the purposes of testing Ihe eicmncy of

fextngasshers on clase D tes needs to be eslabisher on a eae by case basis

This European Standard incorporates by dated of undated reference, provisions from other publications, These

normative references are cited at the appropriate places in the text and the publications are listed hereafter For

ales! references, subsequent amendments to oF revisions of any of these publications apply to this European

‘Standard only when incorporated in it by amendment or revision, For unstated references the Intest edtiton of the

publication referred to applies (including amendments)

EN 2. Classification of fires

{80 9227. Comosion tests in artticial atmospheres — Salt spray tests

(SO 657-1, Hot-olled stee! sections — Part 1 Equal-leg angles — Dimensions

'S0 4470, Sawn umber — Determination of tn

average morstute content of a fot

Forbregister RAL-841-Gi

3. Terms and definitions

For the purposes of this European Standard, the following terms and definitions apply.

34

Tire extinguisher

appliance containing an extinguishing medium which can be expelled by the action of intemal pressure and be

directed on toa fre

NOTE Ths pressure can be stored pressure or pressure prosuced by the release of an auxilary gas from a carhidge

EN 3-7:2004+A1:2007 (E)

32

portable fire extinguisher

Fre extinguisher which is designed to be carried and operated by hand and which in working order has @ mass of

rot more than 20 kg

NOTE Throughout ths standard ts referrd to as an “extinguisher

33

clean agent

Slectrically non-conducting, volatile, or gaseous fire extinguishing medium that does not leave a residue upon

evaporation

NOTE Examples are fuorocartons (FCs), pertuorocarbons (PFCs) and fluxorocartans (FICS)

34

halon

agent that contains as primary components one or more organic compounds containing one oF more of the

flements fluonne, chlorine, bromine, or iodine

35

body

shell of the extinguisher not fited with its a

ssories but fitted with all its welded/brazed parts

36

extinguishing medium

ubstance contained in the extinguisher which causes extinction ofa fire

37

charge

veneer volume of the extinguishing medium contained in the extinguisher. expressed as

viater based extinguishers and as a mass (in kilograms) for other extinguishers

a volume (in hires) for

38

water based extinguisher

T vextinguisher contaming water. water with additive or wet chemical

NOTE this also mendes for A

39

powder extinguisher

txtinguisher containing fire extinguishing powder

3.10

carbon dioxide extinguisher

extinguisher containing carbon dioxide

3a

halon extinguisher

extinguisher containing halon

3.12

clean agent extinguisher

extinguisher containing a clean agent

313

‘duration of operation

time dering which the extinguishing medium is discharged, without any interruption in the di

valve fully opened rot including aischarge of the residual propellant gas

charge and with the

1004+A1:2007 (E)

3.14

residual charge

mass of medium remaining after continuous complete discharge including all propellant gas

as

‘maximum pressure at maximum operating temperature, Tay) (Pressure experimentally measured)

pressure measured in the extinguisher after stabisation during atleast 24 h at maximum operating temperature

{whichis > 60°C) ané for cartdge operated extinguishers, the maximum prossute ts the maximum pressure

Tecorded for 0.5 during a period of three minutes, excluding the est second after release of the propelan gas,

3.16

Towa

‘maximum operating temperature declared by the manufacturer (see 7.4.1)

3a7

1,

minimum operating temperature declared by the manulacturer (see 74.1)

4 General

4.1 Description of a portable fire extinguisher

4.1.4 A portable fee

tinguisher is descnbed by the type of extinguishing mediuny it contains At present, there

4, including foams [+ and wet chemical Gl extinguishers (sete Note 1)

powder type extinguishers:

carbon dioxide type extinguishers:

halon type extinguishers (see Note 2)

clean agent extinguishers

NOTE 1 Water based eungusshers can be pronase wth on witout ahs eee

Water based extinguishers. including foam. containing different proportions of low freeze depressant shall be:

treated as separate and distinct models for the purposes of testing the range of operating temperatures isee 74.2)

and electrical conductivity (see clause 9), and fre rating tests. All other requirements relating to the design an

onstruction of water based extinguishers are applicable to all models nrespective of content

NOE 2 Attention ss drawn to European Counc Reyiéahon 2037/2000 concern the use of halons

4.1.2 Aportable re extinguisher consists ofthe following components

a) body see 35):

b)_ body ftings, which are fied to or screwed onto the body. and include at least he folowing

contral device(s) (see 4.2. 4.3 and 10.1

— hose assembly (see 4.4) andior horns andlor nozzles:

— head assembly. This also constitutes the main closure (see 6 3)

:2004+A1:2007 (E)

— operating device (see 4.3).

NOTE The head assembly, operating device and control devices) can be separate or may be incorporated in a single unit.

©) media (see 4.1.1)

4.2 Control of discharge

Portable fire extinguishers shall be fited with a self-closing control valve to enable the discharge to be interrupted

temporarily (see 10.6)

4.3 Operating position

Extinguishers shall operate without being tured over to an inverted position. The operating device of an

tentinguisher shall be located on the top of the extinguisher. A control device at the end of the hose shall be

permitted. Hand wheel controls of the valve on external propellant cartridges shall be located on the top 60 % of the

‘extinguisher body,

4.4 Hose assembly

eat

Extinguishers having a mass of extinguishing medium greater than 3 kg. oF a volume of extmguis

greater than 3 shall be provided with a discharge hose.

The length of the flexible section of the hose assembly shall be 400 mm or greater

When an extinguisher having a mass of extinguishing medium less than or equal to kg. oF a volume of

extinguishing medium less than or equal to 3115 ftled with a discharge hose. the hose assembly shall have a

‘minimum overall length of 250 mm

4.5 Propellants

in Table 1 or mixtures thereof, shall be used The maximum water content shal bres

Only propeliants lst

specifedin Table 1. except when sex! in stored prassure water based wxtingurshers, Tracers may bie dled to the

propellant to facilitate leakage detuction, but the tracer need not be indicated w the: making

Table 1 — Permitted propellants

Propeliant Maximum water content

mass fraction. %

- > 1

air 008 1]

‘Argon Ti

Carton doe 015) I

Haku 0.006

[Rog 0.006

4.6 Stored pressure extinguishers

Stored pressure extinguishers. except carbon dioxide, shall nave a means of checking the presence of pressure.

see clause 8 and clause 11

EN 3-7:2004+A1:2007 (E)

5 Testing of portable fire extinguishers

Extinguishers for testing shall be stored for at least 24 h at a temperature of (20 + 5) °C before the tests are carried

‘out and shall be maintained within this temperature range until tested. Tests shall be camied out within 5 min ofits

removal from storage,

Powder extinguishers shall be subjected to the compaction procedure given in Annex K before the storage period

preceding the duration of operation test and the control valve test, and before the fire performance test. Water

based extinguishers shall be subjected to the compaction procedure according to Annex K only before the storage

period preceding the duration of operation test.

6 Nominal charges, filling tolerances and minimum fire performance

6.1 Nominal charges

Nominal charges of portable fre extinguishers shall be equal to one of the values given in Tables 3 to 8 according

to the nature of the extinguishing medium

6.2 Filling tolerances

The actual charge of the extinguisher shall be equat tothe nominal charge within the tolerances given in Table 2

Table 2 — Filling tolerances

Extinguishing medium Relative tolerance

%

Pender

1g

‘Al oer mea

6.3 L) Design of the filling opening, excluding carbon dioxide fire extinguishers,

The filing opening shall have a minimum diometer of

20.mm for extinguishers with a charge of less than o equal to 3 kg oF 3

25 mm for extinguishers witha charge of more than ‘kg oe 34

The main closure ofthe filing opening, intended to be removed during service oF maintenance. shall be provided

with an automatic means of venting any resicval pressure from the extinguisher. The inital venting of any residual

pressure shall occur when the means of secunng the closure, or pressure retaining par, is disengaged by not more

than one thid of full engagement. (

6.4 Minimum fire ratings

6.4.1 General

Fire classes are defined in EN 2

EN 3-7:2004+A1:2007 (E)

‘The minimum fire ratings are specified in E) Tables 3 to 8 and L.2 GI, according to the type of extinguishing

medium and the charge.

Fire performance shall be tested in accordance with clause 15, and the extinguisher shall attain a class A rating, a

Gass rating or both as specified in the relevant table, in accordance with the rating claimed by the

Sanufacturer’ BD Class F extinguishers shall attain a class F rating and may optionally have a class A and/or class

B rating.

EXAMPLE powder extinguisher for which the manufacturer wishes to claim class A and class B ratings achieves, for the

Sze with a 9 kg charge. a minimum fre rating of 27A and 1448.

Clean agent extinguishers shall have a minimum fie rating of 58 andor 216 for extinguishers with charges in the

range 1 kg. 2kg, 3kg, 4 kg, 6kg, kg and 12 kg

6.4.2 Ratings for class A fires

Fire ratings of extinguishers for class A fires are given in Tables 3 and 4.

NOLE The mumbers i the frst column of each tabi refer tothe size ofthe test fie (sit Anne

Table 3 — Fire ratings, minimum duration of operation and nominal charges

for powder extinguishers

Fire rating | Minimum ‘Nominal permitted charges

duration of

‘operation

s ko

5A 6 -

2A 6 2 -

1A 9 1244

A ° Tegan

A T2nany

Ba 5 zaaeon |

5A 5 tesa eye

‘Table 4 — Fire ratings, minimum duration of operation and nominal charges for water,

based extinguishers, including foam extinguishers,

Fire rating | Minimum ‘Nominal permitted charges

duration of

operation

5 1

5a 6 23

aa 2 236

aA 2 2369

21a 3 23.69

TA 2 2368 |

HA 8 2369

3A 5 23.69

5A, 15 23.69

10

EN 3-7:2004+A1:2007 (E)

6.4.3 Ratings for class 8 fires

Minimum fire ratings of extinguishers for class 8 fires are given in Tables 5, 6, 7 and 8.

Water based fire extinguishers claiming suitability for use on polar soWent shall additionally pass the tests

specified in Annex M and shall be marked accordingly. @

NOTE The numbers in the frst column of each table refer tothe size ofthe test fie (see Annex |).

Table § — Fire ratings, minimum duration of operation and nominal charges

for powder extinguishers,

Fire rating | _ Minimum Nominal permitted charges

duration of

‘operation

5 ko

28 6 7

a @ te

te a 12a

708 "

oe o

a) paca i _

sa L2aaeg

a 15 12 a4eu

28 6 L2a4 oo 12

Table 6 — Fire ratings. minimum duration of operation and nominal charges for water based

extinguishers. including foam extinguishers

Fire rating | Minimum ‘Nominal permitted charges

duration of

operation,

5 '

a8 @

550 3 meets

78 e 2 |

[ae . 23

18 2 236 -|

1a 1s 238

1858 18 2369

2338) 15 2369

"

EN 3-7:2004+1:2007 (E)

‘Table 7 — Fire ratings, minimum duration of operation and nominal charges for CO; extinguishers

Fire rating] Minimum ‘Nominal permitted charges

duration of

‘operation

kg

218 6 2

8 2

588 3 25

708 3 28

298 9 28

Tae 28

[wan 5 25

18 15 25 _|

ae. 15

Table 8 — Fire ratings, minimum duration of operation and nominal charges for halon extinguishers

Fire rating | Minimum ‘Nominal permitted charges

duration of

operation,

5 kg

7 Duration of operation, residual charge and operating temperatures

7.4 Duration of operation

7.4.4. Minimum duration

The duration of operation shall be greater than or equal to the appropriate value given in {+) Tables 3 to 8 and

LZ Gl when the portable fire extinguisher is tested according to Annex A after being subjected to the compaction

procedure in accordance with Annex K (see clause 5).

TA2_ Spread of measurements

When three extinguishers are tested in accordance with Annex A. after being subjected to the compaction

procedure in accordance with Annex K (see clause 5). the duration of operation of each extinguisher shal be within

415 Ye of the average valve.

2

EN 3-7:2004+A1:2007 (E)

7.2 Residual charge

‘The residual charge (see 3.14) of extinguishing medium shall not be more than 10 % of the nominal charge when

the extinguisher is tested in accordance with Annex A after being subjected to the compaction procedure Ih

accordance with Annex K (see clause 5).

7.3 Commencement of discharge

When tested in accordance with Annex A. after being subjected to the compaction procedure in accordance with

Annex Kall extinguishers shall operate within 4 s of the control valve being opened. When testing extinguishers

Pressurised by a separate action, the control valve shall be operated within 6 $ alter activation,

7.4 Effective range of operating temperature

7441 Ly, 30 Typ Claimed by the manufacturer shall be used for the tests in 7.4.2 and Annex B.

7.4.2 Extinguishers shall be able to operate benween I, ANG Ip

Jin forall extinguishers shall be 60 °C or higher

In excluding water based extinguisher shall he - 20 C.. 30 Cor lower:

Fn for water based extinguishers shall be #.5°C.0C. 66-10-18 206-286

30 C oF lower, For water based extinguishers without any protection against treezing al

bers c

When tested at yyy,

following requirements:

NG Fyn feMperature: ns, wn accontancee with ANNEX B. extinguishers shall confon ta the

the discharge shall commence within 1s of the opening of thee control valve.

except for CO, extinguishers. the: durian of operation shall: nat more than twice thee value stabhishedt at

temperature of 20 C CO, extinguishes shall pontornn to 74

the duration of operation shall be not hess than 6

the residual charge shall be not more than 15 %s of the nominal charge for extinguishers containng 8C type

Powder. and not more than 10°. of the namwnal charge: tor extinguishers contaming other meres

7.4.3 The duration of operation of CO. extinguishers: shall he as follows

A Igy, the duration of operation shall be tot more than

he value established at a temperature of 20 °C.

At the minimum operating temperature. lia. the duration of operation shall he not more than 2

established at 20 °C.

times the value

13

EN 3-7:2004+A1:2007 (E)

8 Retention of propellant

8.4 Verification

8.4.4 General

{Al extinguishers and propellant cartridges shall be designed in such a way as to permit their retention of propellant

to be checked at regular intervals.

8.41.2 Weighing

The following shall be capable of being checked by weight.

— propellant cartridges.

fe measuring methods

8.1.3.4 It shall be possible to check the retention of pressure of a stored pressure extinguisher. with the

‘exception of carbon dioxide extinguishers, as specified in 8.1.3.2, 8.1.3.3 or 8.1.3.4

8.1.3.2 The extinguisher shall be fites with a connection to enable the internal pressure to be checked directly

by an independent apparatus. Such a connection shall be fitted with a pressure retaining cap (see 8.1.3.1) and

shall communicate directly to the contents under pressure. Such a pressure retaining cap can be a cap, pressure

{gauge or pressure indicator

8.1.3.3. Alternatively. the extinguisher shall be fited with a pressure gauge conforming t0 11.1

8.1.3.4 —Atternatwely the extinguisher shall be fited with a pressure indicator which ot 2 In

Addition to this device the extinguisher shall also be filled with a connection which conforms to 8.1.3.2 in order that

the pressure indicator can be checkes:

8.2 Acceptance levels

Leakage from an extinguisher, oF propellant cartridge, shall not exceed the following

of the expanded gas at 20 C per year

1) for stored pressure extinguishers a rate less than or equal t0

NOTE The volume ofthe expanded gas isthe free volume of the gas at 20

b)_ for extinguishers and propellant cartadges tested by weighing, a rate of §°s of the nominal charge per year:

tor extinguishers. pressurised only al the moment of operation. ater pressurisation a leak exceeding 5 cm? of

gas pet minute, per kilogram or lite of charge ofthe extinguisher

8.3 Production leak tests

To test for conformity to &.2a) and 8.2b). all extinguishers and propellant cartridges shall be tested A rate of

leakage greater than the limit specified in 8.2a) or 8.2b) shall result in the rejection of the extinguisher

To test for conformity to 8.2c). samples shall be tested to an appropriate sampling plan. A rate of leakage greater

than the limit specified in 8 2c) shall result in the rejection of the batch of extinguishers

14

EN 3-7:2004+A1:2007 (E)

9 Dielectric test for water based extinguishers

9.1 General

‘The dielectric test is designed to establish the suitablity of water based extinguishers for use on live electncal

equipment by measurement ofthe electrical conductivity of the discharge stream.

In order to be usable on lve electrical equipment, water based extinguishers shall conform to 92.

NOTE For the marking requrement see clause 16.

9.2 Required performance

When the extinguisher is in operation and the metalic plate is live, the current between the handle and earth, and

between the nozzle and earth, shall be not more than 0,5 mA at any time during the complete discharge of the

portable fre extinguisher The test shall be carried out in accordance with Annex C.

10 Requirements for components

10.1 General

With the exception of the safety device specified in 10.3 no component of the fire extinguisher shall require t0 b

‘mounted. removed or modified before or dunng use.

10.2 Operation and emission control mechanismsidevices

The: activation of the extinguisher shall not depen! upon the repetition of a given action an the same device. For

extinguishers other than CO, extinguishers, the force or the energy required 0 activate the operating device(s}

Shall be no greater than those given in Table 9 for temperatures UP 10 Iyyy-

For CO, extinguishers, this force

{00 N at the maximun temperatere (7,

hall be: no greater than 200 N at temperatures up to 40°C

»

und no greater than

Acwvation means the totally of actions required for pressurisation (if the extinguisher 18 not permanently under

pressure) and the initial release of the extinguishing agent. Ifa single device can activate the unt without repetition

fol movement. itis permissible for the same deuice to be re-used in order to control the output (see Annex D)

Table 9 — Force or energy required to activate the operating device

Type of device Maximum force or energy 1]

Force Energy |

N 4

Finger tagger co)

“Sauseze gui lever 200

‘Screw down hand whee! *? 100 —

Stnke knoe ~ 2

* Th ore shall moaned at the outst edge ofthe whee

The anna oa

10 wheel o.be 380" actrove ual pera postion

15

EN 3-7:2004+A1:2007 (E)

10.3 Safety devices

‘The operating mechanism of the extinguisher shall be provided with a safety device to prevent inadvertent

operation. The release of the safety device shall involve an operation cistinct from that ofthe operating mechanism

‘hd shall require a force between the limits of 20 N and 100 N.

B deleted text

‘The safety device shall be so constructed that any unaided manual attempt. using a force or impact equal to twice

the relevant value given in Table 9 to initiate discharge. without first operating this device. does not deform or break

any part of the mechanism in such 2 way as to prevent the subsequent discharge of the extinguisher.

The extinguisher shall be fited with a safety element. The safety element shall be provided with means to show

vihether the extinguisher may have been operated. This may be in the form of a wire and seal or a mechanism

Ninich prevents re-inserion of the safely element. It shall be possible to see if the safety element has been

removed.

10.4 Filter for water based portable fire extinguishers

‘the discharge from water based portable fire extinguishers shall be through a filer, in order to retain forergn matter

This fiter shall be placed upstream of the smallest section of the discharge passage Each onfice of the titer shalt

fave an area smaller than that of the smallest cross-section of the discharge passage The total area of the

avined liter onfices shall be at least equal to 6 limes the smallest cross-section of the discharge passage. This

fier shall be accessible to facihtate maintenance operations on the portable fre extinguisher

10.5 Hose and coupling systems

‘The hose and coupling system shall function throughout the operating lempecature range. ant coupling 3)

Shall be designed and fitted n such a way that they cannot damage the hose

When tested in accordance Annex E, the performance ofthe hose shall conforns to a) orb ts appropriate

4). Foralltypes except CO, portable fre extinguishers

twee tes 11d? the test being carried out at (20 - 5) C,

twice Fa) the test being cartied out at (quye* 2) CAN AL yyy 21

by for CO, extinguishers

45 times Pay the test being caried out at (20 » 51°C

4.25 times gay) the test being carried Out at (Say * 2) °C and atthe minoum clawed temperature

10.6 Control valve

40.6.4 Extinguishers shall be fited with a self dosing control valve allowing the discharge of the extinguishing

Inesia to be ciscontnued. furthermore, the valve shall be resistant to leakage following the cessation of the

Cmission as specified in 10.6.2, 10.6.3 or 10.64. as applicable, Testing shall be carried Out in accordance with

Annex F

40.6.2 For extinguishers other than 1 kg and 2kg powder extinguishers and all CO, extinguishers the second

value of pressure shall be ether. not less than 80% of the first measured value or not less than 50 % of the

pressure measured before opening the contol valve.

16

f

EN 3-7:2004+A1:2007 (E)

40.6.3 For 1kg and 2kg powder extinguishers the second pressure value shall be not less than 80 % of the

first measured value.

40.6.4 For CO) extinguishers the second value of the mass shall be not less than 80 % of the frst measures

value

11 Means of pressure indication

41.1 Pressure gauge

41.4.1 The pressure gauge shall be capable of being checked to ensure that itis in good working order by an

independent apparatus which uses the application of an extemal pressure for checking the pressure.

11.1.2 The scale of the pressure gauge (see Figure 1) shall have:

‘4 zero zone {to indicate zero pressure), If there is an end stop for the moving pointer. this shall be on the

hogative pressure side of the zero zone The pointer shall not contact the end stop at zero pressure

atures tse 74) with

‘a green zone {working zone), corresponding to the pressures between operating te

the following tolerances

mp

15% A Si

#6 Seat |

{The derived pressures anu; Founded off to the: nearest fll oF hall bar

The zones either side of the green zone shall be ved

The permitted etfors in indication ace

{bar max at the low pressure en yreen zone,

6 Se at the high pressure end of the queen: zone

the (P"* 20. C} point shall be maicated and the maximum perrtted error ts + 0.5 bar

To ensure thal the pressure indication is visible, the pressure gauge shall conform to the following

gially ante the adirating green zone with a length

the gauge shall have a moving pointer extending «

tol the green zone hexght

bpetween 50% ane

the position of the pointer at both ends of the green zone and at J*(# 20°C) shall be such that itis clearly

visible,

the gauge shall have a total scale length equal to or greater than 1.5 times the length from zero to the high

pressure end of the green zone

7

&

EN 3-7:2004+A1:2007 (E)

P (aor

Key

1 Rounded to te nearest 05 bar

2 Green

1 Re

Figure 1 — Scale on pressure gauge

114.3. When tested at a temperature of (20-51 C. the pressure gauge shall operate within the range ol eeror

permitted by 14.1.2 after having been subjected to 1 000 pressure cycles from ze

O10 Flug) A BACK 40 ZOHO a

an average rate of pressure change of (20 ' 5) bar/min

11.14 The materials of construction of the pressure gauge which may be in contact with the extinguishing

medium and propellant gas shall he compatible with these or protected from them

14.4.5 _Alltests shall he earned out at 20 + §)°C.

11.2 Pressure indicator

124

pressure indicator shall indicate whether the extinguisher is inn operable: condition,

o

11.2.2. The change in indication between an operable and an inoperable condition shall occur at a pressure

corresponding to the pressure at the minimum operating temperature, The error in this indication shall not exceed

bar,

12 Horns for carbon dioxide portable fire extinguishers

12.1. If the horn is not incorporated in the extinguisher (e.g. when its connected by a hose) it shall be fitted with a

handle to protect the hand of the operator against cooling during use

12.2. Ate being subjected to the test described in G. 1. the hom shall show no damage, and no deformation which

alters the diameter of the end of the hom by more than 10 %,

12.3 All connections between the valve and the horn and nozzle shall be such as to prevent loosening or

detachment. Where this is provided by mechanical means such as lock-nuts, lock-washers, or spring washers, the

torque required to loosen the assembly shall be equal to or greater than 20m. When adhesives. or other

methods of assembly. are used the torque required to loosen the assembly shall be equal to or greater than 10 Nim

18

Ue

EN 3-7:2004+A1:2007 (E)

12.4 After being subjected to the test described in G.2 the hom shall show no damage, and no deformation which

alters the diameter of the end of the horn by more than 10 %.

43 Portable fire ex:

\guisher mounting bracket

‘The testis carried out on one specimen

if a mounting bracket is provided withthe extinguisher it shall conform to the following requirements:

removal of the extinguisher trom the bracket shall be easy and its method of removal shall be obvious:

— the bracket. when mounted on a wall in accordance with the manufacturers instructions shall be capable of

supporting without permanent deformation 2 load of at least twice the total mass of the portable fire

extinguisher

NOTE Special brackets to ne used for extngushers in vetucies. on vessel

internauional eeyul

and on aircraft ean be subject 0 national oF

14 Resistance to corrosion

14.1. Resistance to external corrosion

Alter having been subjected to the test procedure described in H.1 the two extinguishers both shall conform ta the

following requirements

the forre, oF energy. as applicable, required to activate the extinguisher shall be as specified in 10.2

the force required to release the safely devics

hall be as specited in 10.3,

lested in accordance with Annex A the duration of operation at (20 + 10) C shall be

age vakie given ay 7.1.2

when the extinguisher

within 25 % ofthe ave

aiter operation the pressures gauge oF pressure indicator, Hone #5 flted, shall eturn a6 she indwation of 1

pressure

when tested in accordance with Annex E, the performance of the hose shall be as specified

bbeing cams out at (20 + 5) °C:

there shall be no corrasion of the metal of the extinguisher likely to impair ts operation oF satety

14.2 Resistance to extinguishing medium of extinguishers using water based media

Alter having been subjected to the test procedure described in H.2 the two extinguishers both shall conform to the

following requirements

There shall be no visible signs of corrosion of the metal, nor detachment. cracking or bubbling of any protective

coating of the body. There shall be no visible change in the colour of the extinguishing medium other than that

resulting fram the thermal cycling

NOTE Allowance should be made for the change of colour hat occurs naturally due fo the temperature changes. Its

recommended that two samples of the extinguishing medium are stored in closed glass conlaners for reference purposes

lanereby one of the samies ss exposed to the same temperature cycing as the extingulsher an compares tothe medium in

the eatingusher afer ne test

19

:2004+A1:2007 (E)

45 Fire performance

15.1 General

45.1.1 Fire performance shall be tested in accordance with Annex | 3), Annex L and Annex M (il. Before testing,

powder extinguishers shall be subjected to the compaction procedure described in Annex K.

15.1.2 A portable fire extinguisher shall be deemed to satisfy the relevant fire performance requirements when

two test fires of a series of three are extinguished, A test series is complete after three fires. or when the

first two fires have both been extinguished or have both not been extinguished. Each test series shall be completed

belore the next is commenced. There is no restriction on the number of series that may be carried out on the same

type of portable fire extinguisher without modifications, but a series shall consist of consecutive fires and results

shall not be ignored,

15.1.3 Ifonly one test fire from a series of 3 is extinguished, this successful resul! may be used once only as the

intial result ip the next set of fire tests on this extinguisher model at a lower fire test rating

15.2 Class A fire rating

The class A fie rating shall be determined in accordance with |2

15.3 Class B fire rating

The class B fire rating shall be determined in accordance with .3 [4) and sustabilty for polar solvents, if applrable

in accordance with Annex MD

15.4 |i) Class F fire rating

The Class F fire rating shall be determined in accordance with LS. OH

16 Portable fire extinguisher identification

16.1 Colour

The colour of the body shall be rext RAL 300 veiled in Farteenyster RAL KAT Gi

National regulations may requite @ zone of colour with an area of up to 10° of the surface arwa of the extinguisher

body to be used to identify the extinguishing agent

16.2 Marking

‘The marking on the extinguisher shall be in contrasting colour's) to the background Tw marking shall be divided

Into five parts as shown in Figure 2

The marking required for Parts 1. 2, 3 and 5 shall be contained on the same label of m the same frame

(or frame} shall be in such a position that it can be clearly read when the extinguisher is an ts mounting be

‘The marking required for Part 4 may be placed elsewhere on the extinguisher

The value of 11. for calculating the height of the lettering (which shall be determined by reference to an upper case

letter E), except when the marking is in more than one language. shaill be not less than,

— 3mm for extinguishers having a charge = 3 kg or 3

— 5mm for extinguishers having a charge > 3 kg or 31

20

|

|

EN 3-7:2004+A1:2007 (E)

Ifthe marking is in more than one language, the minimum value of 1/ shall be 2 mm.

‘The height of the lettering in Parts 1, 2, 3 and 4 shall be as follows subject to a tolerance of # 10 %.

— Partt 1.5 + [Hor the words ‘fire extinguisher

= 0.75 « I for the other information:

— Part 2: ett

— Pan ett

~ Part osm,

The height of the frame containing Part 5 shall not exceed 1/3 of the total height of Parts 1, 2 and 3

NOTE ——Ihearcau numbers mcate the parts of the marking ad he NURDAES fo The Agh of wach pa Cate the Ne

De lettering a8 a proportion of 1 (sme 162),

a

EN 3-7:2004+A1:2007 (E)

FIRE EXTINGUISHER 15

@ 12 KG ABC POWDER 075

5A 2338 c 075

| @ 1, REMOVE SAFETY CLIP |

I

‘By 2. STRIKE KNOB

| =

3. SQUEEZE NOZZLE LEVER

A IE

+

© Caution 1

REFILL AFTER ANY USE CHECK PERIOUIALLY

HECK CARTRIDGE WEIGHT ANNUALLY

mo

“ay USL UNLY PROUUGIS AND SPAKE PAKS IN GUNFORMIY

@) HY AGHFED MODE 05

EXTINGUISHING MEDIUM 12g ABC” APPROVAL No J1°A

PROPELLANT 225 4 C TYPE Xx2511

teepe

MANUFACTURER |

ATURE RANGE

NOTE The cried numbers indicate the parts of the marking and the numbers 19 the ight of @ach pat nse the Mean

of tne lettering as a proportion of # (see 16.21

Figure 2 — Example of marking of an extinguisher

22

EN 3-7:2004+A1:2007 (E)

Part 1 shall contain the following information in sequence:

— the words "FIRE EXTINGUISHER’; or ‘EXTINGUISHER’ plus medium, or ‘FIRE EXTINGUISHER’ plus

medium:

— the type of extinguishing medium and the nominal charge:

— the fie rating or ratings of the extinguisher [BD (see 6.4, Clause 15, Annex | and Annex L) @

Part 2. shall contain the following information:

— the instructions for use, which shall include one or more pictograms each with an explanation:

‘The text of the instructions for use shail be n the language or languages of the country where the extinguisher isto

be used, the different actions to be carried out being shown one after another vertically trom top to bottom,

The pictograms shall all be located in the same position with regard to the relevant

movements to be carried out shall be indicated by arrows.

texts and the direction of the

pictograms representing the type of fires are shown in 4) Figure 3 and Figure L.1. Class A, Class B and

Class F pictograms (if shail only br used where the corresponding fire rating 1s shown on the marking, Class

C pictogram shall only be shown on powder extinguishers where Class C sultabiliy i shown on the marking

These pictograms shall be arranges! Nonizontally on one line under the instructions for use:

Fi) for extinguishers having additionally passed the requirements of Annex M_ the words

also suitable for use on polar Solvers" smemedately under the pictagtams representing the types of fire,

The pictograms representing the types of fre shall appear in square boxes of side 20 mm minimum for portable fre

extinguishers with a charge of less than ot equal 10 3 kg or 31 and 25 mm minimum for portable fire extinguishers

with a charge of more than 3kg or 31 A square contanimy a code letter shall appear al the comer of each

pictogram as shown in Figure 3

Extinguishers claiming class O suitability shall not be nuked for suitability of any other fire class,

Part 3. shall contain information relating 10 any restactions oF dangers of Use. IN particular in relation to toxiy

NOTE Attention is dr te national estat

Portable fire extinguishers using water of foam and not tested to, of not meeting the requirements of, clause 9 shall

be marked with the following waming: “WARNING Do niot use on live electrical equipment

Portable fire extinguishers using other agents anc water based extinguishers meeting the requirements of clause 9

shall be marked to indicate that they ate sutlabl for use on hve electrical equipment e.g, “suitable for use on

electrical equipment up to 1.000 V ata distance of tm

NOTE Attention s dra to national regulations a

Part 4 shall contain at least the following

{an instruction to refi after any operation

an instruction to check periodically and to use only products and spare parts in conformity with the agreed

model for refiling and maintenance.

the identification of the extinguishing meaium and, in particular, identification and percentage of additives for

water based media

23

od

EN 3-7:2004+A1:2007 (E)

— if applicable, the identification of the propellant gas

— the number(s) orreference(s) relating to the approval ofthe extinguisher:

— the manufacturer's model designation:

— the operating temperature range

‘a waming against the risk of freezing for water based extinguishers:

— areference to the European Standard EN 3.

Part § shall contain

the name and address of the portable fre extinguisher manufacturer andior supplier

in addition, the year of manulacture shall be marked somewhere on the portable fire extinguisher

1b &

| ita

Figure 3— Pictograms

17 Maintenance

It shallbe possible to perform perintic maintenance on each portable fire extinguisher

n the making gern Bart (see 16.21,

NOTE 2 Allenton s rain to national regulations

24

EN 3-7:2004+A1:2007 (E)

Annex A

(normative)

Duration of operation, residual charge tests

NOTE See7.1, 72and 7.3.

The test shall be carried out on 3 specimens.

Weigh the extinguisher.

Hold the extinguisher in its normal working position (i.e, hand-held) and keep it immobile for the duration of the test,

For those extinguishers supplied with a final control valve and an independent actwation system, (see 7.3)

pressunse when the final control valve is closed, Open this control valve 6s after the commencement of

pressunsation of the extinguisher

wvated by a single operation of the conti value (se# 7), open the control valve

e test.

For extinguishers which are a

‘and leave open for the duration of

Measure and record the time between the opening of the control valve and the commencement of discharge.

Measure and record the duration of operation

For gaseous extinguishers: reweigh, calculate and record the residual charge

For all other extinguishers’ reweigh, empty the residual extinguishant, remeigh or measure and record

25

EN 3-7:2004+A1:2007 (E)

Annex B

(normative)

Range of operating temperature

NOTE See74

B.1 Carry out testing on four extinguishers. Before testing, weigh each extinguisher, then subject

two extinguishers to temperature cycle A as given in 8.2 and subject the other two extinguishers to temperature

cycle B as given in 8.3, Storage at the temperatures given in B.2 and 8.3 shall be carried out in conditioning

chambers. Liquid baths shall nat be used. Extinguishers shall remain upnight during temperature cycling

B.2 Temperature cycle A. Store the extinguisher, at each of the following temperatures in succession for

aay

(yn + 21°C. a8 specified in 7.4.2;

(+2055) C.

(on $ 20°C.

8.3 Temperature cycle 8 Store the extinguisher. at rach of the following temperatures succession for

Doha th

Uae! 20°C:

(+ 20+ 8)°C:

Uy 1 20°C. 8 specified in 7.4.2

8.4 Operate the extinguisher within min of is removal from the conditioning chamber The: extinguisher shall be

operated in accordance wth 7.3, except for cartige [ype extinguishers where activation sty stnghe ction

this case the cartridge shall be opened anc the control valve closed ummedately fora period of 6 s after which the

control valve shall be reopenest

B.S Measure and record the time between the opening of the final contiol valve ant the commencement of

Gischarge. Measure and recora the duration of operation

B.6 For gaseous extinguishers: reweigh, caleulate and record the residual charge For all other extinguishers:

reweigh, empty the residual extinguishant, reweigh or measure and record

26

we

EN 3-7:2004+A1:2007 (E)

Annex C

(normative)

Dielectric test

NOTE See couse 9.

C.1 Apparatus

1.1. A metallic plate. the target. (1 - 1)m, hung vertically by insulators and with no object or structure closer

than:

‘mi below the bottom ofthe plate

‘meither side of the edges of the plate

py fom eather face of the plate

(0.5 my above thes top ofthe plate

C.A.2 A trough oF other container, arranged helow the target plate to collect any liqux! run off from the plate

and insulated tron eat

4.3 A high voltage transformer. enabling sn alternating voltage of IS KY to be established! benveeer thee

metallic plate and earth

The impedance of the circuit shall be such that. when the Seconelary is short circuited and the pawnary suppl

voltage equal 10 10 %s of is normal supply voltage, the secondary current is not less than 0.1 mA,

sd bya

€.1.4 An insulating support, for fixed nozcke extinguishers

1.5 An insulating tray. Hor extinguishers hie! wih a hose)

€.2 Test procedure

The apparatus shall be set up according to the arrangemer

shown in Figure C.1

A fixed nozzle type extinguisher shall be fixed onto the insulating support and so arranged that the discharge outlet

Situated at 11m fom the metalic plate. the target, rs directed towards its centre

{An extinguisher with a hose shall be placed on the insulating tay and so arranged that the discharge outlet is 1 m

from the target plate and directed towards its centre

The current shall be measured by an ammeter connected in turn between the handle of the extinguisher and earth

and between the nozzle ang earth. Ifno complete metallic path exists between the extinguishing media ang at least

‘one of the above connection points to the measunng device, such a path shall be created for the purpose of the

test

Discharge the extinguisher. ensuring that the discharged medium contacts the target, and measure and record the

current

27

EN 3-7:2004+A1:2007 (E)

Dimensions in meters.

Key

lest transtoxmer

Low vottage supply

1

2

3 Metatic plate

5 Exvngusher under test

6 Collecting trough insulate

tear

Figure C1 — Schematic arrangement of apparatus for dielectric test

28

E 7

EN 3-7:2004+A1:2007 (E)

Annex D

(normative)

Operation and emission control mechanisms/devices

NOTE See ciause 10.

D.1 Measurement of the forces

The forces. which shall be measured with the use of a dynameter, shall be applied statically and perpendicularly at

the normal point where force is used to render the extinguisher operable.

D.2 Measurement of energy

[The energy of 2 J is obtained by allowing a 4

shall be applied in the direction of the operating mode.

eight (see 0.3) to fall from a Height of $0 mm, The impact

NOTE Tre maxim fons raga! fo oper tne extn

wed

D.3 F) Apparatus

The weight (see 0.2) shall consist of a cylindrical steel weight with tat surtaces measuring 75 mm in diameter ana

wexghing 4 kg. The weight shall be capable of falling freely (

29

EN 3-7:2004+A1:2007 (E)

Annex E

(normative)

Test for performance of the hose

NOTE See 105,

Where testing is to be carried out at a temperature other than 20 °C. condition the hose and attached components

at the relevant temperature for a period of between 12 h and 24 h:

— test at (202 5)°C. 1 specimen

9St at (Tinae * 20°C. 2 specimens,

6SE AL [yy * 2)°C. 2 specimens.

The hose shal be fitted to @ means of providing the required pressure and the open end blanked off by surtable:

increase the pressure in the hose to the minimum applicable value as specified in

30's and maintain the pressure for a further 30.5, Ifthe hose does not burst. increase: thes pressure until the: Hose

ssuire at which this occurs,

‘does burst and record the p

NOIE ——Allochet components mnekase pists

30

:2004+A1:2007 (E)

Annex F

(normative)

Control valve test

NOTE See 108

F.1. General

‘This test shall be carried out at (20 + 10) °C (see 10.6).

‘The testis carried out on 2 specimens

F.2 All extinguishers excluding 1 kg and 2 kg powder extinguishers

Operate the extinguisher and allow the medium to discharge for between 5% and 19 % of the average discharge

duration given in 71-2

For extinguishers with a (propellant) gas cartneige. open the control valve in accordance with a) orb as applicable

A) the extinguisher i fitted with a pressun

‘operate the pressurization device ancl 3 mw fater open the control valve to initiate discharge

ion device ndepenient of ths device which opens the canteol vale

by ia Single action pressurizes the exunguisher and releases the fist emission of gas. pressurize the

fextinguisher initially and 7 myn later open the contrat valves again to permit discharge of the extinguishing

medium

then close the contral valve

Measure thee internal pressure, oF

having been closed and again after § min, the contol valve: having remained ch

ist of CO, the mas, of thee exturqutsher yethin 10/s of thee conte

«forthe duration ofthis perio

F.3 1kg and 2 kg powder extinguishers

Operate the extinguisher and allow the rveciuns to deschange for between T's and 16 s

Then close the control valve.

Measure the internal pressure within 10 s of the control valve having been closed ana again after 2 min; the control

valve having remained closed far the duration of this period,

”

EN 3-7:2004+A1:2007 (E)

Annex G

(normative)

Tests on the horn

NOTE See clause 12

G.1 Static load test

‘The testis carried out on one specimen,

Place the horn on its side on a right Surface. Measure the diameter of the wide end of the horn in the vertical plane:

Apply a static load of 25 kg to the wide end of the hom in the vertical plane, using a exrular contact surface of

Soanm diameter Apply the load for 5 min. (48 + 2)h after removal of the toad re-meaoure: the dam

tend of the horn in the vertical plang and examine the horn for damage

ter of the wit

G.2 Temperature test

The test s catried out on two specimen

2) © and as

Measure the diameter of the wide end of the horn, Bring the hor to a teniprerature of aw

the extinguisher, Re-measure the diameter of the wide end of the horn in the same plane as the Hest mensurenn

‘and examine the hor for damage.

32

Annex H

(normative)

Resistance to corrosion

NOTE See 14

H.1 External corrosion

Complete sample extinguishers shall be subjected to a salt spray test in accordance with ISO 9227 type NSS for a

period of 480 h, and then shall immediately be washed carefully 1o remove any salt deposits. Two extinguishers

shall be tested, either two of the same size or one extinguisher each of two different sizes from the same family

which use the same material and method! af constuction.

H.2 Resistance to water based extinguishing medium

Two extinguishers charged m arcorcance with the manufacturers filing instructions. shall he subjected 8 times 10

ihe temperature cycle given mn Table H 1. Storage at the temperatures speciied in Table H 1 shall be carried out in

Conditioning chambers. Liquid baths shall not be used. The duration of any ene complete cycle shall nat exceed

20h

Table H.1 — Temperature cycle

Sage Duan Temperate

8 “<

| :

| es

On completon of the eight temperat

‘nlour change, and each extinguisher be

‘examination Detachment of any protective coat

cycles. the extinguishing medium shall be drained off and examined tor

shall be cul into two sections in a manner which petits internal

Ing local to the plane of section shall he disregarded

33

EN 3-7:2004+A1:2007 (E)

Annex |

(normative)

Fire tests

NOTE See clause 15,

1.1 General

To cary out these tests the operator shall be dressed in clothing suitable for the purpose. The use of a helmet

gloves and approved non-reflective visor shall be permitted. The operator shall not wear an aluminium-faced sutt

Cartage type extinguishers shall be pressurised prior fo the end of the pre-combustion period.

1e compaction procedure descrined in Annex K shall be carried out on each powder

before submission to the fire test

extinguisher immediately

12 Class A fire test

NOE Sow 182

1.2.1 Characteristics of test fires

Class A test fires shall consist of a crib of wooden sticks supported on a metal frame 250 mm high, 900 mm wide

and of a length equal to that of the test fire (see Figure 1.1), The metal frame shall be constructed from angie

sections (L « W) (50 - 50) mm as spectfied in ISO 657-1

2 the fire size) followed! by tte letter A Flys dresignating

Each test fire ts designated by a number (which indi

Table L1

umber of the test fre represents the following two parameters as shown in T

the length of the test fire in decimetres, ‘¢., the length of the wooden slicks arranged n the longtucinal

direction of the test fire

test fre

the number of 500 mim wooden sticks for each layer arranged in the transverse direction of th

NOTE ach test fires designate by a number m a series in which each lenny 1s aca to the sun of the two preceding

Terms 1e ths senes ws aquvalent fon geometral progressing havin a'common rate of about M2 He kiana es 27a

nd 138 represent the product ofthe preceding term and. fL62

y

34

EN 3-7:2004+A1:2007 (E)

Table I.1 — Characteristics of class A test fires

Designation oftative | _ Number of 500 mm wooden Length of test tre

stl in each travers layer =

m= 5 05

an a os

18 2 13

28 a a

2A n a7

ua “ aa

4 2 aa

550 | ss 58

Test fires greater than 27A shall be constructed using fes of smaller siz

The ends of the longtudinal sticks shall touch

5 (fires, frames and trays) see Table 1.2.

Table 12 — Construction of class A test fires

aa ma 1

& a

i va |

2A

ass |

S60 A 1a A

To provide adequate support tor the woouen sticks for fines larger than KSA, metal cross members shall be added

tothe frame pasitioned as for 8A andl 13A tres,

For example a 218 frame shall have cross members postioned 800 mm from each end

The wooden sticks shall be of Pinus silvesins containing 10 %w to 15 % of moisture by mass when determned! in

accordance with Annex J. They shall be sawn and! of square section of side (39 + 21mm. The density of the woo.

shall be 0.40 giany’ 10 0,65 kia

The wooden sticks shall be stacked in fourteen lavers on the metal frame. as shown in Figures It and 2

35,

&

EN 3-7:2004+A1:2007 (E)

Dimensions in millimetres

500,

440 :

100 |

| Pe

Figure 11 — Example of class A fire (13 A fire) - Front view (identical for all fires)

36

EN 3-7:2004+A1:2007 (E)

Dimensions in mitimetres

XK xX Xt Kx Kx OX OX KX

Or Sd

XX xX XX XO XT OT OX

XM kX MX Mh XX XT OX KT XX

|

KX Xt Ix kx XX XT XT

C7

XK XX Xd XX OX OT XK

0 el

LK x kx xX XX

Figure 1.2 — Example of class A fire (13 A fire) - Side view (variable according to size of fire)

The sticks m each Inyer shall be spaced at reqular intervals with gaps ol ficm between the sticks

The sticks lad transversely (layers 2.4, 6, 8,10, 12 and 1A} shall ave a fixed Heng of (500 ° 109m

The sticks lax! longtudinally (layers 1. 3, 5. 7.9, 11 and 13) shall have fixed lengths which vary according to the

test fre as given in Table 11, with tolerance of - 10 nm

NOTE When the test res consituced using smaller fires the tlerane apis othe lath ofthe ensued sticks

A tie size beyond 55A shall not he used (see Table I

12.2. Test conditions

The test fre shall be located indoors 1m a test chamber and shall be sheltered from draughts. The ambient

temperature shail be between 0 °C and 30 °C.

‘The test chamber shall have the following characterstics

— minimum height of the house (internals 8 m:

— area. Around the class A frame there shall be a minimum distance of 3 m to the test house wal. (For example:

Inthe case of a 55A, the room shall have a minimum length of 11.5 m and a minimum breadth of 6.5 m)

air and surrounding conditions: a) Minimum 0, concentration throughout the test at a height of between 0.8 m

and 1.$ m shall be 19 %. The measuring device shall be attached to the operator,

7

EN 3-7:2004+A1:2007 (E)

— the maximum air speed before ignition shall be 0,2 m/s measured above the centre of the frame at a height of

0.2 m for horizontal airspeed and at a height of i'm above the uppermost stick in the crib. The measurement

has to be taken before the crib is ignited. During the test and for 3 min after the test no characteristics of

ventilation or airflow are allowed to change. The test starts by measurement of the ar speed.

‘A metal lighting tray with a width of 600 mm and a depth of 100 mm shall be used. The length of the tray shall be

100 mm greater than the fire size.

In the case of multiple frames being used to construct the fire, it shall be permissible for the overall length to be

increased by 200 mm to 300 mm.

‘The lighting tray shall be placed symmetrically beneath the crib forming the test fre

Water shall be added to the tray to a depth of 30 mm, Heptane of a quality identical to that used for the Class 8

fires (in accordance with 13.2) shall then be added, the quantity being sufficient to give a burning time of 2 rnin 30

1.2.3 Test procedure

The heptane shall be ignited

After the fire has burnt for 2 min, the ray shall be wethdrawn from beneath the ent

The cri shall then be permittad t0 burn for a further 6 min, making a folal pre-test time: of 8 min. al which pont te

test fre can be considered to be established and extinction shall be commenced

The operator shall then bring the extinguisher into use, and direct the jet onto the: test fire while mowing) found

his own discretion in order to obtain the best result. The entire contents af the extngurshier may be lischarge

ether continuously oF in successive bursts

The maximum extinguishing time shall not exceed § min for tes up to and including 214 and 7 mun for tres of a

greater size. The operator shall indicate when the extinguisher is fully discharged oF when the fre 1s extinguishes!

within the permitted time

in both cases the fire shall be observed for “mun from that point A new pene! ofS arm starts av the ease of a

re-operation wathin the permed tine,

For the test to be deemed successful, al lames shall be extinguistved amt there shall be mn recurrence of Hames

during the 3 min observation period

13. Class B fire tests

13.1 Characteristics of test fires

Class B test fres shall be made in a range of welded sheet steel circular trays. the dimensions of which are gwen

Table 13. The base shall be the same nominal thickness as the walls and the thickness tolerance of the base nt!

wall materat shall conform to the relevant national standard. Stifening bars or sections may be welded to the

Underside of the base with a minvmum distance of 200 mm between substantially parallel stiffeners. All tolerances

specified relate to the tray at its time of manufacture

The trays shall contain water. overlaid with a layer of fuel (see 13.2) m the following proportion: 1/3 water 2/3 fuel

The total volume of liquid in the tray shall be as spectied in Table 1.3. which wil give a depth of water of

approximately 10 mm. and a depth of fuel approximately 20 mm

The test fires are designated by a number (which indicates the fre size) followed by the letter 8. The number

represents the volume of liquid, in Itres, contained in the tray

38

hear

NOTE Each test res designated by a number in a series in which term is equal to the sum of the two preceding terms, ie

this 1s equvaent oa geometcal progression having a common rato of about 1.62. The additonal fires 708, 1138, and 1836

represen he product ofthe preceding term and

‘The surface area of the tray in square decimetres is equal to the product of the test fire size and x.

‘A fre size beyond 2338 shall not be used (see Table I.3).

Table 1.3 — Construction of class B test fires.

Designation | Volume of Dimensions of ray

oftesttie | quid

(usdaters | lateral Depth Thickness | Approximate | Minimum

Wate) | lomoter at ‘ofwalls | “area of fre | duration of

vm ‘peraon

' a sm wn mt 5

78 7 wow |e 20 068 6

7 z ar i 7 ®

3 Ta 16 [ais 7

7 taro 15 | a0 2 5

© tae [200s 7

otal + 20 zs | cy ahh we

zano-25 | aww 2 ae i

2a | ao a ae 1

te Sorta | zon Ta Ta im

The minimum height fron the surface of the fuel to the rin of the tray shall be 100 mm for fires up and wschucin

708 and 140 mm for tres of lager sizes

The veh front the around to the nin of the tray shall not exceed 350 mim The construction af thee ray sb

prevent the flow of aw under the tay. oF sand oF earth shall be bunt aroun the tay up to but not above the level of

the base

After each test, a minimum of § mm of fuel shail remain

For powder extinguishers, at leas! one fire i each sens shail be successfully extinguished on a fresh waterifuel

filing for tne rating to be accepted

For successive tests with CO. type extinguishers only, fuel may be added to the existing test fi

For wat

based extinguishers, fresh fuel and water shall be used for each test

1.3.2 Test conditions

‘The ambient temperature shall be between 0 °C and 30°C.

Class B Fite tests can be caried out indoors or outdoors

39

EN 3-7:2004+A1:2007 (E)

For indoor fre tests the conditions shall be:

— the height of the test chamber (internal) shall be equal to or greater than 5 times the diameter of the test fire

tray,

— the area of the test chamber in square metres (m2) shall be equal to or greater that the test fre designation:

— each side of the test chamber shall be equal to or greater than 4 times the diameter of the test tray with a

minimum length of 7.5 m (see Table |.4):

— air and surrounding conditions shall be as defined for Class A fires,

Table 1.4 — Minimum dimensions of test chambers

Minimum height | Minimum side length

(tray x 5) (tray x4) and7.5m |

Fire test 8 whichever is the

i ‘greatest

(m)

For outdoor te tests the wind speed shall not be greater than Sms

The fuel for the class 8 test fires shall be idustnal heptane which shall nave the followang charactensties

distilation curve 84 Cio 108 ©.

ference between inital ana final points of distilation, 10

aromatic content (11 ier

density at 18°C 0.680 to 0.720

13.3 Test procedure

The heptane shall be ignited and then be permitted to burn for 1 min, at which point the test fre can be consitered

ta be established and extinction shall commence within 10 s

The operator shall nen bring the extinguisher into use, and direct the jet onto the test fre while moving round at h

own discretion in order to obtain the best resull. The entre contents of the extinguisher may be discharged either

continuously or in successive bursts.

40

EN 3-7:2004+A1:2007 (E)

‘The operator shall indicate when the extinguisher is fully discharged or when the fire is extinguished,

For the test to be deemed successful, all lames shall be extinguished.

a

S.

EN 3-7:2004+A1:2007 (E)

Annex J

(normative)

Measurement of moisture content of wood

NOTE Seel.21

The moisture content of wood shall be determined in accordance with ISO 4470, The measurements shall be made

fon at least § samples each (500 + 10) mm long.

42

Row

EN 3-7:2004+A1:2007 (E)

Annex K

(normative)

Compaction procedure

NOTE See clause .

K.1 Apparatus

The compaction machine shall be designed to accept only one extinguisher at a time. which shall be raised by 2

fod and guided by castors, The plate supporting the extinguisher shall be steel, (300+ 5) mm square and

{60 + 1) mm thick

‘The compaction machine shall conform to the following

the ro shall be adjustable to adjust tothe extinguisher base

the rod salle able to move freely

the extinguisher shall he guided without constramt inthe quate castors

the impact shall take place on the steet plate and not on the rout

the cam to be used ss shown in Figure K 1

K.2 Procedure

The extinguisher, © the condition in winch i 1s put ao service, 142 filled and charged according ta the

uanufaciurer's instructions with the extinguishing agent speciied by the manufacturer for use in that extisgursher,

© shall be subjected te thy compatction actin:

sid condditiones etl 1

The extinguisher shall be held in the vertical postion mn the compaction machine and dropped vertically $00 tines,

from a height of 15 om, ata frequency of 1 Hz, onto a ngid horizontal steel plate.

43

EN 3-7:2004+A1:2007 (E)

B Dimensions in milimetres

Koy

1 centee of rtation

Figure K.1 — Cam design for compaction machine

44

EN 3-7:2004+A1:2007 (E)

Annex L

(normative)

E) Specific requirements for Class F fire extinguisher

L.1 General

Portable fre extinguishers for use on cooking oil fires shall have a class F test fre rating,

Powder and carton dioxide fire extinguishers should not be used on Class F fires as their use on this type offre is

considered nazardous. For this reason powder and carbon dioxide fire extinguishers shall nettner be teste

according fo this annex or marked withthe "F™ pictogram.

NIE Extinguishers may also nave els: A anor hne cans

L.2 Class F test fire ratings

L.2.1 Class F fire rating

Exonquishers shall nave a class F fue rating wv accordase with Table (1 when tested n agcordance with L

Table L.1 — Fire rating minimum duration of operation and nominal charges for class F extinguishers

Rating | Volume of cooking Nominal Minimum |

olin test fire permitted duration of

charges, ‘operations,

0 run a s

cg Beta pS Figure aes eae i

[28 Bt Dae a

OF WRT oF 2aes Tw

| I

T5F Tet or

45

:2004+A1:2007 (E)

L.3 Dielectric test

All extinguishers usable on class F purposes shall conform to the requirements of the dielectric test in Clause 9

L4 Pictogram

See Figure L.1.

L5 Class F fire test

L.5.1 General

To camry out these tests, the operator shall be dressed in clothing suttable for the purpose. The use of a neimet

gloves and approved non rellective visor shall be permitted. The operator shall not wear an akiminum-faced suit

The ambient temperature of the test tAcilly prior to gaibon shall be between QC ane 30°C

Carthage type extinguishers shall be pressurized pror to the end ot the pres combustion period

L.5.2 Class F test fire

L521 General

Method of fre fighting

The operator shall discharge the entire contents without interruption front a manimum distance as recommended by

the manufacturer on the label after the sre-buen time.

hie atiack shall take place tron only one direction or side of the te

L522 Apparatus

15221 General

The cooking oil test fires shall be conducted using a steel tray to simulate a wenn fa ever

1522.2 SFr

tray

SF fire test tray, constructed of steel sheet, (2.0 + 0.25) mm thick and (170 + 10) mm deep and mountes an a

support structure (see Figure U2)

52.2.3 25F, 40F and 75° fire test tray

25F, 40F and 75F fire test tray. constructed of steel sheet (2.0 + 0.25) mm thick and {250 + 10) mm deen (see

Figure L.3 and Table L.2), The tray shall have liquid-tight joints, and the reinforcing angle shall be conunuous

around the perimeter of the tray to produce a tumed-out edge level with the top of the tray The width of the top

‘edge shall be 45 mm. The tray shall be mounted on a supporting structure which raises the top of the tray 10 a

height of (1 000 12) mm above the floor.

182.24 Thermocouple

In order to monitor the oil temperature. a thermocouple shall be located (25 = §) mm below the oll surface (belore

heating), but not closer than 75 mm to the test fire tray's walls

46

EN 3-7:2004+A1:2007 (E)

L.5.3 Combustible oil

Pure edible vegetable ol, with an auto-ignition temperature range of between 330 °C and 380 °C.

L.5.4 Procedure

The test chamber shall have the following characteristic:

= minimum height of the house (internal): 8 m

— area: Around the tray there shall be a minimum distance of 3m to the test house wall. (For example: in the

case of a 75F. the room shall have a minimum length of 4.5 m and a minimum breadth of 3.5 m)

Heat the oll in the fre test tray using a sutable heating arrangement until non-piloted autovignition occurs,

‘Auto-ignition shall occur in a maximum time of 3.5 h from the start of heating of the apparatus.

When auto ignition occurs,

“urn off tye neat source anit allow to burn freely fe (120,15 bare commencement offre fighting

[After each test. clean the apparatus thoroughly and renew wth fresh oll priae to subsequent fire testing

NOTE Cae shew te taken tao thet capes eng agra y the ha SourE bale At Agnte

L.5.5 Fire test requirements/measurements

5 shall conform to tne folowing ren

Portabe tee extingus

A} Burning matenal shall not be ejected

1b) The fae shall be extinguished sand there shall be no te-agnition of the test fer, or any overtiow of he dtunrur

20 mam peniod fllowang the complete visctarge of the extingurstver

Ol shal remany the fay at the end ol the test to prove thot extinguishment has accursed by ayiphettian of sh

extnguistant and not by ol starvation

)_ The ol temperature shall be monitored at auto-igntion

2) Application of the media shal not cause enlargement of the flames

NOTE Hames ove 2 2a ination ative &

sacoaptaie

aight const enangerment Sho ten

festabliss compliance with this requirement