Professional Documents

Culture Documents

1521 Uso

Uploaded by

Witchfinder GeneralCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

1521 Uso

Uploaded by

Witchfinder GeneralCopyright:

Available Formats

Belzona 1521

(HTS1)

INSTRUCTIONS FOR USE

1. TO ENSURE AN EFFECTIVE MOLECULAR

WELD

METALLIC SURFACES APPLY ONLY AFTER BLAST

CLEANING

a)

b)

c)

d)

Brush away any loose contamination and remove dirt, oil,

grease etc., with Belzona 9111 (Cleaner/Degreaser), or

any other effective cleaner which does not leave a residue

e.g. methyl ethyl ketone (MEK).

Select an abrasive to give the necessary standard of

cleanliness and a minimum depth of profile of 3 mils (75

microns).

Use only an angular abrasive.

Blast clean the metal surface to achieve the following

standard of cleanliness:ISO 8501-1 SA 2 very thorough blast cleaning

American Standard Near White Finish SSPC SP10

Swedish Standard SA2 SIS 05 5900

After blasting, metal surfaces should be coated before any

contamination of the surface takes place.

NOTE: SALT CONTAMINATED SURFACES

The soluble salt contamination of the prepared substrate,

immediately prior to application, shall be less than 20mg/m

(2g/cm).

Metal surfaces that have been immersed for any periods in salt

solutions e.g. sea water, should be blasted to the required

standard, left for 24 hours to allow the ingrained salts to sweat to

the surface, then washed prior to a further brush blast to remove

these. This process may need to be repeated several times to

ensure complete removal of the salts. Salt removal aids are

commercially available that will assist and speed salt removal.

Contact Belzona for best recommendation.

2. PIT FILLING & STRIPE COATING

All welds should be prepared to NACE RP0178 Grade C or

better. Deep pitting and rough welds should be smoothed out

with Belzona 1511. Before application of Belzona 1521 allow

to harden in accordance with the relevant Instructions For Use

before grit blasting to create a frosted surface free from any

gloss with a target profile of 40 microns.

All detail areas such as welds, brackets, baffles, deflectors etc.

that cannot be effectively sprayed should be coated with

Belzona 1591. See relevant Instructions For Use for details.

3. COMBINING THE REACTIVE

COMPONENTS FOR HEATED AIRLESS

SPRAY

Only commence mixing once the spray equipment has been

assembled and thoroughly tested - see Instructions for

spraying Belzona solvent free coatings.

www.belzona.com

Mix ratio 9.5:1 by volume

WORKING LIFE

From the commencement of mixing, Belzona 1521 must be

used within the times shown:

Temperature

Use all

material within

68F(20C)

86F(30C)

104F(40C)

65 mins.

35 mins.

20 mins.

4. APPLYING BELZONA 1521

FOR BEST RESULTS

Do not apply when:i) The substrate temperature is below 41F (5C), above

104F (40C) or the relative humidity is above 85%.

ii) The substrate temperature is less than 5F (3C) above

dewpoint.

iii) Rain, snow, fog or mist is present.

iv) There is moisture on the metal surface or is likely to be

deposited by subsequent condensation.

v) The working environment is likely to be contaminated by oil

or grease from adjacent equipment or from smoke from

kerosene heaters.

4.1 EQUIPMENT REQUIRED

Belzona 1521 must be sprayed using heated airless

equipment. Either a single airless pump or plural equipment,

capable of metering accurately and mixing the two components,

can be used. See Instructions for spraying Belzona solvent

free coatings.

Tip Temperature

104-122F (40-50C)

Tip pressure (minimum) 2500 psi (172 bars)

Tip size

17-23 thou (0.43-0.58mm)

DO NOT THIN

Cleaning solvent

Belzona 9121, MEK or Acetone

4.2 COVERAGE RATE

The Belzona 1521 shall be applied to achieve a minimum

thickness of 20 mils (500 microns).

The maximum thickness shall be 48 mils (1000 microns).

The theoretical coverage rate at 20 mils (500 microns) is

21.5sq.ft. (2m)/litre.

A. Where it is not possible to achieve a uniform coating at the

required thickness, the material should be applied as a two coat

system. Apply the first coat of Belzona 1521 at a target

thickness of 18 mils (450 microns). A practical coverage rate of

21.5sq.ft.(2 m)/litre should be aimed for. Allow to harden for at

least 16 hours.

Before applying a second coat, wash the surface of the

Belzona 1521 with a warm detergent solution to remove any

amine bloom that has formed. Rinse with clean water and allow

Publication No. 31-01-10

to completely dry. Carefully grit blast to create a frosted surface

free from any gloss with a target profile of 40 microns.

Apply a second coat of Belzona 1521 at a target thickness of

14 mils (350 microns). A practical coverage rate of

28sq.ft.(2.6m)/litre should be aimed for.

B. Where application conditions permit, Belzona 1521 may be

applied as a single coat at a target thickness of 30 mils (750

microns). To achieve the recommended film thickness a

practical coverage rate of 12.9sq.ft. (1.2 m)/litre should be

aimed for.

5. COMPLETION OF THE MOLECULAR

REACTION

5.1 IN SERVICE CURE

If the service temperature is above 140F (60C) then no post

cure is necessary and the coating should be allowed to cure as

detailed below.

Temperature

Hard for

inspection or

dry heat post

curing

20 hours

15 hours

10 hours

7 hours

5 hours

3 hours

Machining

and/or light

loading

Actual coverage rates obtained will vary according to equipment

choice, application technique, component size and application

environment. Interruption to application will significantly increase

wastage.

50F/10C

59F/15C

68F/20C

77F/25C

86F/30C

104F/40C

4.3 INSPECTION

a) Immediately after application of each unit, visually inspect

for pinholes and misses. Where detected, these should be

immediately brushed out.

b) Once the application is complete and the coating has

hardened, carry out a thorough visual inspection to confirm

freedom from pinholes and misses, and to identify any

possible mechanical damage.

c) Spark testing can be carried out to confirm coating

continuity. A DC voltage of 2,400 volts is recommended to

confirm that a minimum coating thickness of 20 mil (500

microns) has been achieved.

5.2 POST CURE

The coating should be allowed to cure as above then post cured

as below only if

a) The service temperature is below 140F (60C).

b) The service temperature is achieved at a faster rate

than 55F (30C) per hour.

c) if immediate exposure to aggressive media will occur.

d) If coated equipment is to be transported.

e) If coated equipment is not to be returned to service

within 7 days.

4.4 REPAIRS

Any misses, pinholes or mechanical damage found in the

coating should be repaired as follows. Wash the surface of the

Belzona 1521 with a warm detergent solution to remove any

amine bloom that has formed. Rinse with clean water and allow

to completely dry. Carefully grit blast or abrade to create a

frosted surface free from any gloss with a target profile of 1.5

mils (40 microns) before applying further product. Belzona

1591 may be used for localized repairs.

Post cure temperature

140F (60C)

158F (70C)

176F (80C)

194F (90C)

212F (100C)

32 hours

24 hours

16 hours

12 hours

8 hours

6 hours

Full mechanical,

loading, immersion or

pre-steam post

curing

4 days

3 days

2 days

1 days

24 hours

18 hours

Cure time

16 hours

8 hours

4 hours

2 hours

1 hour

The post cure temperature should not exceed 212F (100C).

Temperature should not be increased at more than 55F (30C)

per hour.

4.5 CLEANING

Mixing tools should be cleaned immediately after use with

Belzona 9111 or any other effective solvent e.g. MEK or

Acetone. Brushes spray equipment and other application tools

should be cleaned using a suitable solvent such as MEK or

Acetone.

HEALTH & SAFETY INFORMATION

Please read and make sure you understand the relevant Material Safety Data Sheets.

The technical data contained herein is based on the results of long term tests carried out in our laboratories and to the best of our knowledge is true and accurate on the date of publication. It is however

subject to change without prior notice and the user should contact Belzona to verify the technical data is correct before specifying or ordering. No guarantee of accuracy is given or implied. We assume no

responsibility for rates of coverage, performance or injury resulting from use. Liability, if any, is limited to the replacement of products. No other warranty or guarantee of any kind is made by Belzona, express

or implied, whether statutory, by operation of law or otherwise, including merchantability or fitness for a particular purpose.

Nothing in the foregoing statement shall exclude or limit any liability of Belzona to the extent such liability cannot by law be excluded or limited.

Copyright 2010 by Belzona International Limited. All rights reserved. Certain portions of this work copyright 1980-2009 by Belzona International Limited. No part of this work covered by the copyrights

hereon may be reproduced or used in any form or by any means - graphic, electronic or mechanical including photocopying, recording, taping or information storage and retrieval systems - without written

permission of the publisher.

Belzona is a registered trademark

ISO 9001:2008

Q 09335

ISO 14001:2004

EMS 509612

Europe & Africa

Belzona Polymerics Ltd.

Harrogate, UK

t: +44 (0) 1423 567641

f: +44 (0) 1423 505967

e: belzona@belzona.co.uk

Belzona 1521 - Instructions for Use - (2)

The Americas

Belzona Inc.,

Miami, FL USA

t: +1 (305) 594 4994

f: +1 (305) 599 1140

e: belzona@belzona.com

Asia & Oceana

Belzona Asia Pacific

Chonburi, Thailand

t: +66 38 491031

f: +66 38 491102

e: belzona@belzona.cn

China

Belzona Hong Kong

Hong Kong, China

t: +852 3101 7461

f: +852 3101 7530

e: belzona@belzona.hk

Printed in England Publication No. 31-01-10

You might also like

- Vol XI No. 4 Manguera FlotanteDocument1 pageVol XI No. 4 Manguera FlotanteWitchfinder GeneralNo ratings yet

- Torre de FraccionamientoDocument1 pageTorre de FraccionamientoWitchfinder GeneralNo ratings yet

- Books Habilidades GenteDocument3 pagesBooks Habilidades GenteWitchfinder GeneralNo ratings yet

- Potential Failure Mode and Effects AnalysisDocument1 pagePotential Failure Mode and Effects AnalysisNatarajan GopalaswamyNo ratings yet

- Oil & Gas OffshoreDocument16 pagesOil & Gas OffshoreWitchfinder GeneralNo ratings yet

- 1521 UsoDocument2 pages1521 UsoWitchfinder GeneralNo ratings yet

- Recubrimiento ProtectorDocument62 pagesRecubrimiento ProtectorWitchfinder GeneralNo ratings yet

- Filt RosDocument4 pagesFilt RosWitchfinder GeneralNo ratings yet

- Wire Rope Condition Monitoring & Inspection SystemDocument2 pagesWire Rope Condition Monitoring & Inspection SystemWitchfinder GeneralNo ratings yet

- IIMM ISO 55001 Supplement v1-2014-734Document36 pagesIIMM ISO 55001 Supplement v1-2014-734ilmu286% (7)

- Proposed New ASMEB31P Standard On Preheat & PWHT PDFDocument34 pagesProposed New ASMEB31P Standard On Preheat & PWHT PDFWitchfinder General100% (1)

- LinksDocument2 pagesLinksWitchfinder GeneralNo ratings yet

- Advisory Circular: U.S. Department of TransportationDocument176 pagesAdvisory Circular: U.S. Department of TransportationSakthi MuruganNo ratings yet

- Centurion XPG Series: InstrumentsDocument3 pagesCenturion XPG Series: InstrumentsWitchfinder GeneralNo ratings yet

- Centurion XPG Series: InstrumentsDocument3 pagesCenturion XPG Series: InstrumentsWitchfinder GeneralNo ratings yet

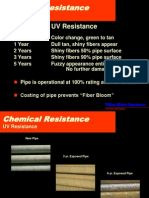

- Chemical ResistanceDocument2 pagesChemical ResistanceWitchfinder GeneralNo ratings yet

- Astm F714Document9 pagesAstm F714Witchfinder General100% (1)

- Centurion XPG Series: InstrumentsDocument3 pagesCenturion XPG Series: InstrumentsWitchfinder GeneralNo ratings yet

- Safety To Cost RFFDocument158 pagesSafety To Cost RFFbebis2009No ratings yet

- Pipeline Risk ManagementDocument2 pagesPipeline Risk ManagementWitchfinder GeneralNo ratings yet

- Risk Based DecisionsDocument12 pagesRisk Based DecisionsWitchfinder GeneralNo ratings yet

- 1104 Errata 2 December 2008Document1 page1104 Errata 2 December 2008Witchfinder GeneralNo ratings yet

- ASTM A6 - ASME SA6 Thickness Tolerances of Steel PlatesDocument1 pageASTM A6 - ASME SA6 Thickness Tolerances of Steel PlatesWitchfinder General60% (5)

- Information To Be Supplied by The PurchaserDocument4 pagesInformation To Be Supplied by The Purchasernikidragon4uNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)