Professional Documents

Culture Documents

Whitworth Pipe Threads: ISO 7/1 DIN 2999 BS 21 DIN ISO 228 Part 1

Whitworth Pipe Threads: ISO 7/1 DIN 2999 BS 21 DIN ISO 228 Part 1

Uploaded by

Gaurav GargOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Whitworth Pipe Threads: ISO 7/1 DIN 2999 BS 21 DIN ISO 228 Part 1

Whitworth Pipe Threads: ISO 7/1 DIN 2999 BS 21 DIN ISO 228 Part 1

Uploaded by

Gaurav GargCopyright:

Available Formats

Pipe Threads

Whitworth Pipe Threads

Using Whitworth pipe threads it has to be distinguished between those threads which are thought to be sealing on the

thread and those which produce a mechanical connection without sealing function.

Those threads which are sealing on the thread are specified in various national and international standards. Basic

thread dimensions are common for all threads mentioned below. ISO 7/1 and BS 21 do not only specify the connection

of cylindrical internal and taper external thread as DIN 2999 does, but in addition define a taper internal thread (taper

1 : 16). Gauging systems for all three threads differ and may lead to different results and decisions.

The thread connection given in DIN ISO 228 is not

meant to be sealing on the thread. Basic thread dimen1 standard

4 internal-/external thread

sions and pitch is common to the sealing threads.

2 title of standard

5 short sign for thread

3 kind of connection

ISO 7/1

1

2

3

4

5

6

1.

2.

DIN 2999

Pipe threads where pressure tight

joints are made on the

threads

Whitworth pipe threads for threaded

pipes and fittings

sealing on the thread

internal thread

cylind.

taper

Rp

Rc

taper limit plug

gauge ISO 7/2 1)

external thread

taper

R

taper limit ring

gauge ISO 7/2 1)

BS 21

DIN ISO 228 part 1 2)

Pipe threads for tubes and fittings

where pressure tight joints are made

on the threads

Pipe threads where pressure-tight

joints are not made on the threads

sealing on the thread

internal thread

cylindrical

external thread

taper

Rp

taper limit plug

gauge DIN 2999-4

R

cylindrical limit

ring gauge DIN 2999-5

6 kind of gauges

sealing on the thread

internal thread

cylind.

taper

Rp

external thread

taper

Rc

taper limit plug

gauge BS 21

R

taper limit ring

gauge BS 21

not sealing on the thread

internal and external thread

cylindrical

G

cylindrical Go / No Go plug gauge

cyl. Go ring gauge tolerance A or B

DIN ISO 228 part 2

Standard ISO 7/2 specifying the appropriate gauges is subject to general revision.

DIN ISO 228 has replaced DIN 259 (Whitworth pipe threads - cylindrical internal and external threads). For the cylindrical internal and external

thread short sign R has been applied, which could have led to confusion, because the same short sign is used for the taper external thread

of DIN 2999 or ISO 7/1. Compared to DIN ISO 228 there are no differences between the threads but some minor differences between the

gauges.

P

p

Out.- Pitch- Minor-

[TPI] [mm] d = D d2 = D2 d1 = D1

G

1/16

1/8

1/4

3/8

1/2

5/8

3/4

7/8

1

1.1/8

1.1/4

1.1/2

1.3/4

2

2.1/4

2.1/2

2.3/4

3

3.1/2

4

28

28

19

19

14

14

14

14

11

11

11

11

11

11

11

11

11

11

11

11

0,907

7,723

7,142

0,907

9,728

9,147

1,337 13,157 12,301

1,337 16,662 15,806

1,814 20,955 19,793

1,814 22,911 21,749

1,814 26,441 25,279

1,814 30,201 29,039

2,309 33,249 31,770

2,309 37,897 36,418

2,309 41,910 40,431

2,309 47,803 46,324

2,309 53,746 52,267

2,309 59,614 58,135

2,309 65,710 64,231

2,309 75,184 73,705

2,309 81,534 80,055

2,309 87,884 86,405

2,309 100,330 98,851

2,309 113,030 111,551

6,561

8,566

11,445

14,950

18,631

20,587

24,117

27,877

30,291

34,939

38,952

44,845

50,788

56,656

62,752

72,226

78,576

84,926

97,372

110,072

a

Rp / Rc

R

1/16

1/8

1/4

3/8

1/2

3/4

4

4

6

6,4

8,2

Tolerances of

internal thread

pitch- turns

[mm]

0,071 1.1/4

0,071 1.1/4

0,104 1.1/4

0,104 1.1/4

0,142 1.1/4

9,5 0,142 1.1/4

Toleran. of

external thr.

turns

mm

1

1

1

1

1

0,9

0,9

1,3

1,3

1,8

1,8

10,4

0,18 1.1/4

2,3

1.1/4

1.1/2

12,7

12,7

0,18 1.1/4

0,18 1.1/4

1

1

2,3

2,3

15,9

0,18 1.1/4

2,3

2.1/2

17,5 0,217 1.1/2 1.1/2

3,5

20,6 0,217 1.1/2 1.1/2

3,5

25,4 0,217 1.1/2 1.1/2

3,5

Tolerances for internal Whitworth pipe threads

and taps.

1) Hahnreiter taps are being produced with

closer tolerance band

Pipe Threads

American Pipe Threads

pipe thread

general purpose

dry sealing

general purpose

fastening thread

dry sealing

dry sealing

external thread

internal thread

remarks

taper

taper

taper

taper

taper (NPT)

cylindrical

profile as NPT

cylindrical

cylindrical

UN-thread profile

taper (NPTF)

cylindrical

profile as NPTF

taper (NPT-SAE / cylindrical

thread diameter slightly increased with,

NPTF)

same width of tolerance field

NPSL L=Locknut

cylindrical

cylindrical

NPT-, NPSC-, NPSM- and NPSL-thread are defined in ANSI/ASME B1.20.1, NPTF, NPSF and NPSI-thread are given in ANSI B1.20.3

NPT

NPTF

NPSC C=coupling

NPSM M=mechanical

NPSF

NPSI

NPT

E1

[TPI]

[mm]

-pitch

L1

[mm]

L1

L2

[Gg]

[mm]

L3

L5

(3Turns)

[mm]

[mm]

1/16

7,938

27

0,941

7,142

4,064 4,32

6,632

2,822

4,750

1/8

10,287

27

0,941

9,489

4,102 4,36

6,703

2,822

4,821

1/4

13,716

18

1,411

12,487

5,786 4,10

10,206

4,234

7,384

3/8

17,145

18

1,411

15,926

6,096 4,32

10,358

4,234

7,536

1/2

21,336

14

1,814

19,772

8,128 4,48

13,556

5,443

9,929

3/4

26,670

14

1,814

25,117

4,75

13,861

5,443

10,234

33,401

11,5

2,209

31,461

10,16

4,60

17,343

6,627

12,924

1.1/4

42,164

11,5

2,209

40,218

10,668 4,83

17,953

6,627

13,536

1.1/2

48,260

11,5

2,209

46,287

10,668 4,83

18,377

6,627

13,960

60,325

11,5

2,209

58,325

11,074 5,01

19,215

6,627

14,798

2.1/2

73,025

3,175

70,159

17,323 5,46

28,892

6,350

22,542

portrayal of NPT-thread

D

[mm]

8,611

88,900

3,175

86,068

19,456 6,13

30,480

6,350

24,130

3.1/2

101,600

3,175

98,776

20,853 6,57

31,750

6,350

25,400

114,300

3,175

111,433

21,438 6,75

33,020

6,350

26,670

D outside- of pipe

E1 pitch- at length L1

L1 position of handtight engagement

L3

L4

L5

L2 useful external thread

wrenching allowance

length of external thread

external thread with complete thread profile

(on the length of 2 P beyond L5 external thread profile is incomplete at the top

of the threads because the cone of thread profile meets the cylindrical outside

diameter of the pipe)

incomplete thread produced by the chamfer of thread cutting tool

The difference between thread profile of NPT and NPTF threads is the width of flat of profile on the outside and minor

diameter. NPTF thread has got an overlap of profiles of internal and external thread. By this method, drysealing

property is achieved. Compared to the NPT, NPTF is one thread longer on L1 + L3 and L2.

P

[TPI]

NPT

width of flat of profile

27

18

14

11 1/2

8

min.

0,036

0,053

0,069

0,084

0,122

max.

0,104

0,145

0,163

0,185

0,229

NPTF

width of flat of profile

height of profile

min.

0,634

0,974

1,288

1,590

2,356

max.

0,753

1,129

1,451

1,767

2,540

ground

min.

0,102

0,127

0,127

0,152

0,203

top

max.

0,152

0,178

0,178

0,229

0,279

min.

0,051

0,076

0,076

0,102

0,152

max.

0,102

0,127

0,127

0,152

0,203

You might also like

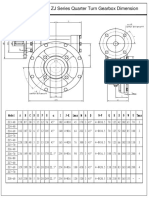

- Greatork-ZJ Series Gearbox DimensionDocument3 pagesGreatork-ZJ Series Gearbox DimensionCan PoonsawatNo ratings yet

- Din en Iso 9013Document8 pagesDin en Iso 9013Cemal NergizNo ratings yet

- Torque Data ChartDocument2 pagesTorque Data CharttnchsgNo ratings yet

- Minimum Thread Engagement With Respect To Material StrengthDocument10 pagesMinimum Thread Engagement With Respect To Material StrengthDarío CostasNo ratings yet

- KtuDocument3 pagesKtuBharat PremNo ratings yet

- Data Chart For Threads by MARYLANDDocument71 pagesData Chart For Threads by MARYLANDN.Palaniappan100% (6)

- DinDocument1 pageDinMelissa SmithNo ratings yet

- Misumi Technical Data PDFDocument1 pageMisumi Technical Data PDFtnchsg100% (1)

- Metric Tolerances ChartDocument6 pagesMetric Tolerances ChartjoleolNo ratings yet

- Limit and Fit - ISO Hole Chart - ToleranceDocument2 pagesLimit and Fit - ISO Hole Chart - Toleranceagniva datta100% (2)

- 6885 1Document1 page6885 1ajeshNo ratings yet

- Nps - NPSM - NPSC TapsDocument1 pageNps - NPSM - NPSC TapsCarlos Murguia PerezNo ratings yet

- Drill-Ø For Threads and Minor-Ø of Nut Threads: Gewinde - Kernloch-Ø Und Kern-Ø MuttergewindeDocument6 pagesDrill-Ø For Threads and Minor-Ø of Nut Threads: Gewinde - Kernloch-Ø Und Kern-Ø Muttergewindeleonbone100% (1)

- Standard Machining ToleranceDocument1 pageStandard Machining ToleranceDenny Ilyas AttamimiNo ratings yet

- VTI Ball Valve IOM PDFDocument16 pagesVTI Ball Valve IOM PDFSandra Viviana Esquivel BenavidesNo ratings yet

- ISO 228 - Pipe Threads Where Pressure-Tight Joints Are Not Made On The ThreadsDocument4 pagesISO 228 - Pipe Threads Where Pressure-Tight Joints Are Not Made On The ThreadsjesusNo ratings yet

- Handbook H-28 1957 Part-IIDocument126 pagesHandbook H-28 1957 Part-IIMisaelNo ratings yet

- Asme Section II A-2 Sa-453 Sa-453mDocument10 pagesAsme Section II A-2 Sa-453 Sa-453mAnonymous GhPzn1xNo ratings yet

- BS 970Document5 pagesBS 970aezeadNo ratings yet

- Iso 9974-2 Metric Port PDFDocument3 pagesIso 9974-2 Metric Port PDFJai Bhandari50% (2)

- The Manual of Fastening EN 8100 PDFDocument106 pagesThe Manual of Fastening EN 8100 PDFOleh SmolovyiNo ratings yet

- Design and Mechanisn of Internal Gear PumpDocument13 pagesDesign and Mechanisn of Internal Gear PumpabhairulzNo ratings yet

- ASME B16.5 - List of Material SpecificationDocument3 pagesASME B16.5 - List of Material Specificationjr_satish6965No ratings yet

- Thread Tolerances For Screws and NutsDocument2 pagesThread Tolerances For Screws and NutsBill WhiteNo ratings yet

- Metric Tolerances and Thread PitchDocument2 pagesMetric Tolerances and Thread PitchEnDjo Ech RahardjoNo ratings yet

- NS-1-150. Impact TestingDocument2 pagesNS-1-150. Impact TestingWHWENNo ratings yet

- NPT Thread EngagementDocument1 pageNPT Thread Engagementmdambros1No ratings yet

- Q7 Gear&Geartools 2007Document45 pagesQ7 Gear&Geartools 2007M.NatarajanNo ratings yet

- Maryland Metrics - Thread Data ChartsDocument2 pagesMaryland Metrics - Thread Data ChartsNicusor BuleteanuNo ratings yet

- Is - 919-Part 2Document46 pagesIs - 919-Part 2mmkattaNo ratings yet

- BS 21 - Pressure Tight Pipe Thread JointsDocument8 pagesBS 21 - Pressure Tight Pipe Thread JointsHARSHANo ratings yet

- British Standard Pipe ThreadDocument3 pagesBritish Standard Pipe ThreaduttampokharkarNo ratings yet

- 35Document10 pages35phankhoa83No ratings yet

- Teknopoli: North American ConnectionsDocument39 pagesTeknopoli: North American ConnectionsKishor JadhavNo ratings yet

- 20a Torque CalculationDocument11 pages20a Torque CalculationRiyan EsapermanaNo ratings yet

- BSP ThreadsDocument3 pagesBSP ThreadssatphoenixNo ratings yet

- 2019 Pipes Connection Standards 20190228Document5 pages2019 Pipes Connection Standards 20190228Osama sayedNo ratings yet

- Din2440 PDFDocument3 pagesDin2440 PDFIndra HazamiNo ratings yet

- Selecting and Measuring Pipe & Fittings: Thread Type CompatibilityDocument1 pageSelecting and Measuring Pipe & Fittings: Thread Type CompatibilityITLHAPNNo ratings yet

- Thread Chart: Horizon Industrial 1190 S.E. Century Dr. Lees Summit, Mo 64063 888-866-2501 816-554-6167 (FAX) 1Document4 pagesThread Chart: Horizon Industrial 1190 S.E. Century Dr. Lees Summit, Mo 64063 888-866-2501 816-554-6167 (FAX) 1jkhgvdj mnhsnjkhgNo ratings yet

- Din 8140-3-1993Document5 pagesDin 8140-3-1993ashkansoheyl50% (2)

- 13.-En NT Bolts UtilcellDocument3 pages13.-En NT Bolts Utilcellnu.arabiaNo ratings yet

- ISO 7 - Pipe Threads Where Pressure-Tight Joints Are Made On The ThreadsDocument3 pagesISO 7 - Pipe Threads Where Pressure-Tight Joints Are Made On The ThreadsSoumava Mukherjee100% (1)

- Thread Connector IdentificationDocument11 pagesThread Connector IdentificationbearNo ratings yet

- Orifice Plate - Monobloc: DatasheetDocument8 pagesOrifice Plate - Monobloc: Datasheetbiomed systechNo ratings yet

- 2 Drilling PipesDocument82 pages2 Drilling Pipesdf_campos3353No ratings yet

- O-Rings and SealsDocument10 pagesO-Rings and SealsManuel CarvalloNo ratings yet

- 37° Tube Fittings: Instrumentation SolutionsDocument9 pages37° Tube Fittings: Instrumentation SolutionsNilesh MistryNo ratings yet

- Mall Pipe ThreadsDocument14 pagesMall Pipe Threadsanac_mathNo ratings yet

- Whitworth Tapered Pipe Thread DIN EN 10226-1, DIN EN 10226-2 Formerly Known As DIN 2999 BSPT (British Standard Tapered Pipe)Document1 pageWhitworth Tapered Pipe Thread DIN EN 10226-1, DIN EN 10226-2 Formerly Known As DIN 2999 BSPT (British Standard Tapered Pipe)LucianNechiforNo ratings yet

- Drill StemDocument28 pagesDrill Stemchonubobby100% (1)

- BSPT Whitworth Tapered Pipe Thread DIN EN 10226-1 and DIN EN 10226-2Document2 pagesBSPT Whitworth Tapered Pipe Thread DIN EN 10226-1 and DIN EN 10226-2Ingenieria APANo ratings yet

- ภาพถ่ายหน้าจอ 2567-01-06 เวลา 12.21.58Document122 pagesภาพถ่ายหน้าจอ 2567-01-06 เวลา 12.21.58จีรพจน์ ไทรทองคำNo ratings yet

- Diameter / Decimal / Metric Chart For Small DiametersDocument2 pagesDiameter / Decimal / Metric Chart For Small DiametershansNo ratings yet

- PDMSDocument39 pagesPDMSprathikNo ratings yet

- BIG Daishowa Drill TapperDocument4 pagesBIG Daishowa Drill TapperNursapta nugrohoNo ratings yet

- The Essential Guide To Spring Technology: WWW - Springs.co - UkDocument32 pagesThe Essential Guide To Spring Technology: WWW - Springs.co - UkFurqan ShabbirNo ratings yet

- Threads in Pneumatics - FestoWiki - EnglishDocument3 pagesThreads in Pneumatics - FestoWiki - EnglishSaeed QahremaniNo ratings yet

- Surface Vehicle Standard: InternationalDocument45 pagesSurface Vehicle Standard: InternationalshivendrakumarNo ratings yet

- Pre-Feasibility Report 1. Project Name of Company / Mine Owner LocationDocument10 pagesPre-Feasibility Report 1. Project Name of Company / Mine Owner Locationvarun2860No ratings yet

- Chapter Five: Is Everything Suffering?Document2 pagesChapter Five: Is Everything Suffering?Lauren DiMartinoNo ratings yet

- Eas 2Document16 pagesEas 2aamichoNo ratings yet

- Hypolipidemic Drugs PharmdDocument38 pagesHypolipidemic Drugs Pharmddarlington D. y ayimNo ratings yet

- C Lab ProgrammingDocument47 pagesC Lab ProgrammingSandhya KandikatlaNo ratings yet

- History of Indian AdvertisingDocument13 pagesHistory of Indian AdvertisingdheepaNo ratings yet

- Using Flyback Diodes in Relays Prevents Electrical Noise in Your CircuitsDocument12 pagesUsing Flyback Diodes in Relays Prevents Electrical Noise in Your CircuitsjackNo ratings yet

- Nano MedicineDocument14 pagesNano Medicineargie dayotNo ratings yet

- Sika® Waterbar®: Product Data SheetDocument3 pagesSika® Waterbar®: Product Data SheetSarwan ArifinNo ratings yet

- D M E DME: Istance Easuring QuipmentDocument21 pagesD M E DME: Istance Easuring QuipmentzesleyNo ratings yet

- Gowler David - 2000 - Parables and Their Social ContextsDocument12 pagesGowler David - 2000 - Parables and Their Social Contextsnachos_51No ratings yet

- EciDocument299 pagesEcisarsan makinaNo ratings yet

- D155ax 8Document16 pagesD155ax 8eliasNo ratings yet

- Fa Aug 2020Document4 pagesFa Aug 2020Ieymarh Fatimah100% (1)

- WybieDocument11 pagesWybieSilvia Marini CaveneciaNo ratings yet

- San Mateo Daily Journal 03-04-19 EditionDocument28 pagesSan Mateo Daily Journal 03-04-19 EditionSan Mateo Daily JournalNo ratings yet

- Commercialization of New Technology-Based Product: Unit 8Document35 pagesCommercialization of New Technology-Based Product: Unit 8terlojitanNo ratings yet

- 1301 RDH 102 75 3 RevEDocument71 pages1301 RDH 102 75 3 RevEds temporalNo ratings yet

- Bahasa Inggris 50 Soal 2Document24 pagesBahasa Inggris 50 Soal 2poro poroNo ratings yet

- NUR 242 CH 19 Bleeding Crossword Answer Key-1Document1 pageNUR 242 CH 19 Bleeding Crossword Answer Key-1Krystal BlantonNo ratings yet

- Zener Diode and Diode ApplicationDocument51 pagesZener Diode and Diode Applicationnibar dyllanNo ratings yet

- Counting Number of Subspaces-2Document10 pagesCounting Number of Subspaces-2Adi SubbuNo ratings yet

- 2020 Catalogue Diesel GeneratorDocument25 pages2020 Catalogue Diesel GeneratorRavikant SainiNo ratings yet

- Recent VendorsDocument4 pagesRecent VendorsVaishali JaiswalNo ratings yet

- Unit 1-5 NEP (UNDERSTANDING POLITICAL THEORY)Document78 pagesUnit 1-5 NEP (UNDERSTANDING POLITICAL THEORY)GAGAN ANAND100% (1)

- BRIA 26 2 The Potato Famine and Irish Immigration To AmericaDocument4 pagesBRIA 26 2 The Potato Famine and Irish Immigration To AmericaMatty WhittakerNo ratings yet

- Reading - Practice 04Document3 pagesReading - Practice 04Phương NgNo ratings yet

- Chilling and FreezingDocument20 pagesChilling and FreezingLingaraj KumarNo ratings yet