Professional Documents

Culture Documents

Wood Base

Uploaded by

antonioCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Wood Base

Uploaded by

antonioCopyright:

Available Formats

Assembly instructions for wood base

Copyright 2004, Bottlehead Corp.

rabbet on inner

edge locates

chassis plate

Each base is composed of two long and two short pieces 1x4 alder, miter cut and rabbeted for support

of the aluminum chassis plate.

Additionally, you will need wood glue, masking tape, 220 grit sandpaper, stain and the finish of your

choice.

We strongly urge you to do a dry run of the assembly instructions, following all directions excepting the

application of glue, before attempting the final, glued assembly

Begin assembly by laying the four pieces in a line, with their inner (mitered) faces down,

alternating a short piece, then a long piece:

all rabbeted

edges

oriented to

this side

be sure to butt each end evenly against the next, and be sure all the rabbeted edges are

oriented the same way. Now place a three to four inch piece of masking tape across each joint:

Now carefully flip the entire assembly over. When ready for final asssembly apply a small amount of

wood glue evenly to each mitered surface, including the two end miters. For the first dry run, leave the

glue out until you are sure all pieces are properly oriented and aligned.

Next, set the assembly on edge, with the rabbeted face up, and form the four pieces into a box:

Place one more 3-4 piece of tape on the one corner that is untaped. The box will have pulled into a

squared shaped. Place a chassis plate into the rabbeted inner edge to assure that it fits properly, and let

the glue dry for a few hours. Remove the tape from each corner, lift away the chassis plate, and sand,

stain, and finish to taste.

You may secure the assembled chassis to the base with polyurethane glue or epoxy for a permanent

mounting or use silicone sealer or adhesive foam strips for a removable mounting. Most builders leave

the chassis plate unattached for ease in modification of the circuit.

You might also like

- Caravela 1.7: Free Plans: How To Build TheDocument31 pagesCaravela 1.7: Free Plans: How To Build TheKeith WilliamsNo ratings yet

- Caravela1 7-IngDocument19 pagesCaravela1 7-IngFernando Siveris XavierNo ratings yet

- Rust Repair Patches Made EasyDocument8 pagesRust Repair Patches Made EasyeduardowilkNo ratings yet

- Flagcase ConstructionDocument2 pagesFlagcase ConstructionajaxleonNo ratings yet

- Sabot 8 FT Pram DinghyDocument6 pagesSabot 8 FT Pram DinghyFrenchwolf420100% (2)

- F-15 Park Jet Construction Guide Rev ADocument21 pagesF-15 Park Jet Construction Guide Rev AAkas AsriNo ratings yet

- Bensen b8 PDFDocument8 pagesBensen b8 PDFmaxNo ratings yet

- Building ShelvesDocument14 pagesBuilding ShelvesZoran MladenovicNo ratings yet

- Jewelry Box: Woodworks: Beginner Project 2009-2010Document7 pagesJewelry Box: Woodworks: Beginner Project 2009-2010Sal GNo ratings yet

- F-14 Park Jet Construction Guide 2Document23 pagesF-14 Park Jet Construction Guide 2John MondoNo ratings yet

- T-38 Park Jet Construction GuideDocument16 pagesT-38 Park Jet Construction Guidemam73No ratings yet

- Build This Boat Shaped BarDocument6 pagesBuild This Boat Shaped BarMark MihalkoNo ratings yet

- Arbor - Making An Easy ArborDocument5 pagesArbor - Making An Easy ArbordaniellourencoNo ratings yet

- Build A Boat!: Step 1: Materials SelectionDocument9 pagesBuild A Boat!: Step 1: Materials SelectionDan0% (1)

- Family Handyman Ultimate 1 Day ProjectsFrom EverandFamily Handyman Ultimate 1 Day ProjectsRating: 5 out of 5 stars5/5 (1)

- Build Your Own Humidor PDFDocument9 pagesBuild Your Own Humidor PDFmcvelli40100% (1)

- Station Wagon SkiffDocument8 pagesStation Wagon SkiffJim100% (3)

- Best Speakers EVARDocument4 pagesBest Speakers EVARAccording To HondaNo ratings yet

- Build A Cremation CaskDocument7 pagesBuild A Cremation CaskJeffrey Michael Atencio100% (1)

- Aquarail JetskiDocument6 pagesAquarail Jetskitony_williams_4No ratings yet

- Build Your Own French Doors - Popular Woodworking MagazineDocument34 pagesBuild Your Own French Doors - Popular Woodworking Magazinekostas1977No ratings yet

- Miniature Marble Machine For WEB 259013455Document2 pagesMiniature Marble Machine For WEB 259013455Squinkle78% (9)

- Bait Boat Plans 3Document1 pageBait Boat Plans 3sebi270No ratings yet

- PRO ROC Gypsum Board Installation GuideDocument12 pagesPRO ROC Gypsum Board Installation Guidejohnnyboy12345100% (1)

- Altar InstructionsDocument12 pagesAltar InstructionsSimonida Mona VulićNo ratings yet

- 005 - Fairing CompoundDocument9 pages005 - Fairing CompoundVishnuNo ratings yet

- F-18 Park Jet Construction Guide Rev ADocument20 pagesF-18 Park Jet Construction Guide Rev ASzymon WójcikNo ratings yet

- Install Rubber Flooring: The Quick Way ToDocument4 pagesInstall Rubber Flooring: The Quick Way Tormc_sheevakumarNo ratings yet

- Redwood Canoe PDFDocument6 pagesRedwood Canoe PDFpaulo_enpjNo ratings yet

- F-14 Park Jet Construction GuideDocument23 pagesF-14 Park Jet Construction Guidemam73100% (1)

- Butcher BlockDocument32 pagesButcher BlockMark DingleNo ratings yet

- 36 String Gothic Harp: Musicmaker's KitsDocument29 pages36 String Gothic Harp: Musicmaker's KitsConrad Reyes100% (1)

- JAS 39 Park Jet Construction ManualDocument17 pagesJAS 39 Park Jet Construction Manualmam73No ratings yet

- 1/10 Scale Sport Hydro 1969 Notre DameDocument2 pages1/10 Scale Sport Hydro 1969 Notre Damewidian rienandaNo ratings yet

- TV/VCR Cabinet With Swivel Tray: Tools & MaterialsDocument6 pagesTV/VCR Cabinet With Swivel Tray: Tools & Materials- yAy3e -No ratings yet

- Sportster Bipe 40 ManualDocument32 pagesSportster Bipe 40 ManualMolocromNo ratings yet

- Envisionlabs Wood ClocksDocument22 pagesEnvisionlabs Wood ClocksAlfonso100% (1)

- Pirogue PlansDocument6 pagesPirogue Plansnative11247250% (2)

- Dolls House 1Document13 pagesDolls House 1ZRomulus73No ratings yet

- Krenov Style Hand PlaneDocument8 pagesKrenov Style Hand PlanerhinorodNo ratings yet

- Fabricación de ArpasDocument15 pagesFabricación de ArpasJesús RamírezNo ratings yet

- Durock Cement Board Installation Guide en CB237 PDFDocument11 pagesDurock Cement Board Installation Guide en CB237 PDFRonald KahoraNo ratings yet

- Irish Bouzouki (Octave Mandolin) Kit: Musicmaker'S KitsDocument20 pagesIrish Bouzouki (Octave Mandolin) Kit: Musicmaker'S KitsnhandutiNo ratings yet

- Combination Lock Instructions v1dDocument20 pagesCombination Lock Instructions v1demreNo ratings yet

- Hourglass Mountain Dulcimer: Musicmaker's KitsDocument12 pagesHourglass Mountain Dulcimer: Musicmaker's KitsKen WilkmanNo ratings yet

- Woodworking TipsDocument13 pagesWoodworking TipsjahemscbdNo ratings yet

- Better BoxesDocument6 pagesBetter Boxes71valiant100% (1)

- Bench - Langcrest - LoveseatDocument5 pagesBench - Langcrest - LoveseatvdbrogerNo ratings yet

- RodSmith Build-It! KitsDocument1 pageRodSmith Build-It! KitsCamil BwoyNo ratings yet

- Bending ShapesDocument4 pagesBending ShapesramjoceNo ratings yet

- Traditional Bookcase: Woodworks: Intermediate ProjectDocument6 pagesTraditional Bookcase: Woodworks: Intermediate ProjectDúctil De La Gran Raza de YithNo ratings yet

- Čamac Od KedraDocument58 pagesČamac Od KedraБ. А.No ratings yet

- Three Piece Kayak With Images PDFDocument5 pagesThree Piece Kayak With Images PDFSylvia GoiburuNo ratings yet

- Dollhouse - Planta de ConstruçãpDocument12 pagesDollhouse - Planta de Construçãpfranneto100% (1)

- How To Build A Bookcase: Intro: Tools and MaterialsDocument7 pagesHow To Build A Bookcase: Intro: Tools and Materialssaric_terrill4785100% (1)

- How to Build a Global Model Earthship Operation I: Tire WorkFrom EverandHow to Build a Global Model Earthship Operation I: Tire WorkNo ratings yet

- Building A Garden Shed Step By Step Instructions and PlansFrom EverandBuilding A Garden Shed Step By Step Instructions and PlansRating: 2 out of 5 stars2/5 (1)

- Resep KoreaDocument37 pagesResep KoreapineNo ratings yet

- 6th Central Pay Commission Salary CalculatorDocument15 pages6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- Salad Dressing RecipesDocument10 pagesSalad Dressing Recipesmaverick_navigateur89No ratings yet

- Granny Whites Bread RecipesDocument483 pagesGranny Whites Bread RecipesDavy ForceNo ratings yet

- The Versatile EggDocument109 pagesThe Versatile EggJessie FariasNo ratings yet

- The Very Best ofDocument704 pagesThe Very Best ofchefyousefNo ratings yet

- Vegetarianismo - Vegan Cookbook Recipes (Ingles)Document84 pagesVegetarianismo - Vegan Cookbook Recipes (Ingles)Kadek AmikNo ratings yet

- Know Your SpicesDocument32 pagesKnow Your SpicesrivahcatNo ratings yet

- Salad MasterDocument157 pagesSalad MasterVicky GutuiNo ratings yet

- BBQ The Ultimate Grilling Guide PDFDocument13 pagesBBQ The Ultimate Grilling Guide PDFGeorge PetrakosNo ratings yet

- The Geezer CookbookDocument83 pagesThe Geezer CookbookDarren WhiteleyNo ratings yet

- Recipes Tried and TrueDocument103 pagesRecipes Tried and Truelokikg100% (2)

- Sri Lanka CookingDocument51 pagesSri Lanka Cookingchamithanu100% (1)

- Utensiless MealsDocument10 pagesUtensiless Mealsaboonader00No ratings yet

- Loss Weight Forever - 50 Habits of Naturally Thin PeopleDocument8 pagesLoss Weight Forever - 50 Habits of Naturally Thin PeopleSedeenaNo ratings yet

- MarinadesDocument8 pagesMarinadesGjuro14No ratings yet

- Generations of RecipesDocument180 pagesGenerations of Recipesjhony52100% (1)

- Hotdog RecipesDocument12 pagesHotdog RecipesmefjakNo ratings yet

- Healthy, Thrifty MealsDocument78 pagesHealthy, Thrifty MealsIulia VilauNo ratings yet

- Recipes To Spice Up Your SummerDocument11 pagesRecipes To Spice Up Your SummerjoanNo ratings yet

- Healthy Gourmet RecipesDocument26 pagesHealthy Gourmet RecipesDare SpartuNo ratings yet

- Cooking - Pies & Pizzas RecipesDocument105 pagesCooking - Pies & Pizzas Recipesagape_1st7100% (4)

- The Pacific Islands CookbookDocument84 pagesThe Pacific Islands CookbookFernando FeitoNo ratings yet

- (E-Book) Cooking & Recipes - How To Prepare Delicious Meals On A BudgetDocument114 pages(E-Book) Cooking & Recipes - How To Prepare Delicious Meals On A BudgetDaz MasonNo ratings yet

- 6th Central Pay Commission Salary CalculatorDocument15 pages6th Central Pay Commission Salary Calculatorrakhonde100% (436)

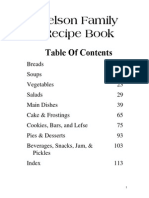

- Nelson Family Recipe BookDocument120 pagesNelson Family Recipe BookabuzarshazliNo ratings yet

- Heavenly Cookies PDFDocument43 pagesHeavenly Cookies PDFrick4dNo ratings yet

- Hillbilly Hanks Roadkill RecipesDocument13 pagesHillbilly Hanks Roadkill Recipesmefjak0% (1)

- FondueDocument81 pagesFondueundieselNo ratings yet

- (Ebook) - Cookbook - Native American Health Recipes PDFDocument134 pages(Ebook) - Cookbook - Native American Health Recipes PDFMonica CiucuNo ratings yet