Professional Documents

Culture Documents

Rexroth Formulas

Uploaded by

subashgsubashCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Rexroth Formulas

Uploaded by

subashgsubashCopyright:

Available Formats

Sales Industry Sector Metallurgy

Formulary Hydraulics

Hydraulic Formulary

Author: Houman Hatami

Tel.: +49-9352-18-1225

Fax: +49-9352-18-1293

houman.hatami@boschrexroth.de

10.01.2013

Sales Industry Sector Metallurgy

Formulary Hydraulics

CONTENTS

RELATIONS BETWEEN UNITS ............................................................................................................. 4

IMPORTANT CHARACTERISTIC VALUES OF HYDRAULIC FLUIDS ................................................ 6

GENERAL HYDRAULIC RELATIONS ................................................................................................... 7

PISTON PRESSURE FORCE ...................................................................................................................... 7

PISTON FORCES ..................................................................................................................................... 7

HYDRAULIC PRESS ................................................................................................................................. 7

CONTINUITY EQUATION ........................................................................................................................... 8

PISTION SPEED....................................................................................................................................... 8

PRESSURE INTENSIFIER .......................................................................................................................... 8

HYDRAULIC SYSTEM COMPONENT ................................................................................................... 9

HYDRO PUMP ......................................................................................................................................... 9

HYDRO MOTOR ....................................................................................................................................... 9

Hydro motor variable ...................................................................................................................... 10

Hydro motor fixed ........................................................................................................................... 11

Hydro motor intrinsic frequency ..................................................................................................... 12

HYDRO PISTON ..................................................................................................................................... 13

Differential piston ............................................................................................................................ 14

Double acting cylinder .................................................................................................................... 15

Cylinder in differential control ......................................................................................................... 16

Cylinder intrinsic frequency at differential cylinder ......................................................................... 17

Cylinder intrinsic frequency at double acting cylinder .................................................................... 18

Cylinder intrinsic frequency at plunger cylinder.............................................................................. 19

PIPING................................................................................................................................................... 20

APPLICATION EXAMPLES FOR SPECIFICATION OF THE CYLINDER PRESSURES AND

VOLUME FLOWS UNDER POSITIVE AND NEGATIVE LOADS ........................................................ 21

DIFFERENTIAL CYLINDER EXTENDING WITH POSITIVE LOAD ..................................................................... 22

DIFFERENTIAL CYLINDER RETRACTING WITH POSITIVE LOAD ................................................................... 23

DIFFERENTIAL CYLINDER EXTENDING WITH NETAGIVE LOAD.................................................................... 24

DIFFERENTIAL CYLINDER RETRACTING WITH NEGATIVE LOAD .................................................................. 25

DIFFERENTIAL CYLINDER EXTENDING AT AN INCLINED PLANE WITH POSITIVE LOAD .................................. 26

DIFFERENTIAL CYLINDER RETRACTING AT AN INCLINED PLANE WITH POSITIVE LOAD................................. 27

DIFFERENTIAL CYLINDER EXTENDING AT AN INCLINED PLANE WITH NEGATIVE LOAD ................................ 28

DIFFERENTIAL CYLINDER RETRACTING AT AN LINCLINED PBLANE WITH NEGATIVE LOAD ............................ 29

HYDRAULIC MOTOR WITH POSITIVE LOAD ............................................................................................... 30

HYDRAULIC MOTOR WITH NEGATIVE LOAD.............................................................................................. 31

IDENTIFICATION OF THE REDUCED MASSES OF DIFFERENT SYSTEMS ................................... 32

LINEARE DRIVES .................................................................................................................................. 33

Primary applications (Energy method) ........................................................................................... 33

Concentrated mass at linear movements....................................................................................... 35

Distributed mass at linear movements ........................................................................................... 36

ROTATION ............................................................................................................................................ 37

COMBINATION OF LINEAR AND ROTATIONAL MOVEMENT .......................................................................... 38

HYDRAULIC RESISTANCES...39

ORIFICE EQUATION ............................................................................................................................... 39

TROTTLE EQUATION .............................................................................................................................. 39

10.01.2013

Sales Industry Sector Metallurgy

Formulary Hydraulics

HYDRO ACCUMULATOR .................................................................................................................... 40

HEAT EXCHANGER (OIL- WATER) .................................................................................................... 41

LAYOUT OF A VALVE ......................................................................................................................... 43

10.01.2013

Sales Industry Sector Metallurgy

Formulary Hydraulics

Relation between Units

Size

Lengths

Surfaces

Volume

Density

Unit

Symbol

Relation

Micrometer

1m = 0,001mm

Millimeter

mm

1mm = 0,1cm = 0,01dm = 0,001m

Centimeter

cm

1cm = 10mm = 10.000m

Decimeter

dm

1dm = 10cm = 100mm = 100.000m

Meter

1m = 10dm = 100cm = 1.000mm = 1.000.000m

Kilometer

km

1km = 1.000m = 100.000cm = 1.000.000mm

Square centimeter

cm2

1cm2 = 100mm2

Square decimeter

dm2

1dm2 = 100cm2 = 10.000mm2

Square meter

m2

1m2 = 100dm2 = 10.000cm2 = 1.000.000mm2

Are

1a = 100m2

Hectare

ha

1ha = 100a = 10.000m2

Square kilometer

km2

1km2 = 100ha = 10.000a = 1.000.000m2

Cubic centimeter

cm3

1cm3 = 1.000mm3 = 1ml = 0,001l

Cubic decimeter

dm3

1dm3 = 1.000cm3 = 1.000.000mm3

Cubic meter

m3

1m3 = 1.000dm3 = 1.000.000cm3

Milliliter

ml

1ml = 0,001l = 1cm3

Liter

1l = 1.000 ml = 1dm3

Hectoliter

hl

1hl = 100l = 100dm3

Gram/

g

cm3

g

kg

t

g

=1 3 =1 3 =1

cm3

dm

m

ml

Cubic centimeter

Force

Newton

1N = 1

Weight

kg m

J

=1

s2

m

1daN = 10N

Torque

Newton meter

Nm

1Nm = 1J

Pressure

Pascal

Pa

Bar

Bar

1Pa = 1N/m2 = 0,01mbar = 1kg

m s2

psi =

pound

inch 2

1bar = 10

Psi

1psi = 0,06895 bar

kp

cm 2

10.01.2013

N

N

= 100.000 2 = 10 5 Pa

2

cm

m

kp

= 0,981bar

cm 2

Sales Industry Sector Metallurgy

Formulary Hydraulics

Mass

Acceleration

Milligram

mg

1mg = 0,001g

Gram

1g = 1.000mg

Kilogram

kg

1kg = 1000g = 1.000.000 mg

Ton

1t = 1000kg = 1.000.000g

Mega gram

Mg

1Mg = 1t

Meter/

m

s2

per square second

Angular speed

One/ Second

Radiant/ Second

Power

m

N

=1

s2

kg

1g = 9,81 m/s2

= 2n

1

s

n in 1/s

rad

s

Nm

J

kg m m

=1 =1 2

s

s

s

s

Watt

Newton meter/ second

Nm/s

Joule/ second

J/s

Work/ Energy

Watt second

Ws

Heat volume

Newton meter

Nm

Joule

Kilowatt hour

kWh

1kWh = 1.000 Wh = 10003600Ws = 3,6106Ws

Kilo joule

kJ

= 3,6103kJ = 3600kJ = 3,6MJ

Mega joule

MJ

Mechanic

Newton/ square

N

mm2

tension

millimeter

Plane angle

Second

1 = 1/60

Minute

1 = 60

Degree

Radiant

rad

1 = 60 = 3600 = rad

180

1W = 1

1Ws = 1Nm = 1

kg m

m = 1J

s2

N

= 10bar = 1MPa

mm2

1rad = 1m/m = 57,2957

1rad = 180/

Speed

One/second

1/s

One/minute

1/min

1 1

= s = 60 min 1

s

1

1

= min 1 =

60s

min

10.01.2013

Sales Industry Sector Metallurgy

Formulary Hydraulics

Important Characteristic Values of Hydraulic Fluids

HLP

HFC

HFA

(3%)

HFD

880

1085

1000

925

10-100

36-50

0,7

15-70

12000-14000

20400-23800

1500017500

1800021000

[Bar]

Specific Heat at 20C

2,1

3,3

4,2

1,3-1,5

[kJ/kgK]

Thermal Conductivity at 20C

0,14

0,4

0,6

0,11

[W/mK]

Optimal Temperatures

40-50

35-50

35-50

35-50

[C]

Water Content

40-50

80-97

[%]

Cavitation Tendency

low

high

very high

low

Density at 20C

3

[kg/m ]

Kinematic Viscosity

at 40C

2

[mm /s]

Compressions Module E

at 50C

10.01.2013

Sales Industry Sector Metallurgy

Formulary Hydraulics

General Hydraulic Relations

Piston Pressure Force

Figure

Equation / Equation Variations

Symbols / Units

F = 10 p A

F = p A 10

A=

d=

F = piston pressure force[N]

d2

4

p = fluid pressure[bar]

A = piston surface[cm2]

d = piston diameter[cm]

= efficiency cylinder

4 F 0,1

p

p = 0,1

4 F

d2

Piston Forces

Figure

Equation / Equation Variations

Symbols / Units

F = pe A 10

F = pe A 10

A=

F = piston pressure force[N]

pe = excess pressure on the piston[bar]

d2

4

A = effective piston surface[cm2]

d = piston diameter[cm]

= efficiency cylinder

A For annulus surface:

A=

(D2 d 2 )

4

Hydraulic Press

Figure

Equation / Equation Variations

Symbols / Units

F1 = Force at the pump piston[N]

F1

F

= 2

A1 A 2

F2 = Force at the operating piston[N]

A1 = Surface of the pump piston [cm2]

F1 s1 = F2 s2

A2 = Surface of the operating piston [cm2]

s1 = Stroke of the pump piston [cm]

s2 = Stroke of the operating piston [cm]

10.01.2013

F1 A1 s 2

=

=

F2 A2 s1

= Gear ratio

Sales Industry Sector Metallurgy

Formulary Hydraulics

Continuity Equation

Figure

Equation / Equation Variations

Q1 = Q 2

Symbols / Units

Q1,2 = Volume flows [cm3/s, dm3/s, m3/s]

Q1 = A 1 v 1

A1,2 = Area surfaces [cm2, dm2, m2]

v1,2 = Velocities

Q2 = A 2 v2

[cm/s, dm/s, m/s]

A 1 v1 = A 2 v 2

Piston Speed

Figure

Equation / Equation Variations

v1 =

Q1

A1

v1,2 = Piston speed [cm/s]

Q1,2 = Volume flow [cm3/s]

Q

v2 = 2

A2

A1 =

Symbols / Units

A1 = Effective piston surface (circle) [cm2]

A2 = Effective piston surface (ring) [cm2]

d2

4

(D2 d 2 )

A2 =

4

Pressure Intensifier

Figure

Equation / Equation Variations

Symbols / Units

p1 = Pressure in the small cylinder [bar]

p1 A 1 = p 2 A 2

A1 = Piston surface [cm2]

p2 = Pressure at the large cylinder [bar]

A2 = Piston surface [cm2]

10.01.2013

Sales Industry Sector Metallurgy

Formulary Hydraulics

Hydraulic System Components

Hydro Pump

Q=

V n vol

1000

pQ

Pan =

600 ges

Q = Volume flow [l/min]

[l/min]

V = Nominal volume [cm3]

n = Drive speed of the pump [min-1]

[kW]

Pan = Drive power [kW]

p = Service pressure [bar]

1,59 V p

[Nm]

M=

100 mh

M = Drive torque [Nm]

ges = Total efficiency (0,8-0,85)

ges = vol mh

vol = Volumetric efficiency (0,9-0,95)

mh = Hydro-mechanic efficiency(0,9-0,95)

Hydro Motor

Q = Volume flow [l/min]

V = Nominal volume [cm3]

Q=

V n

1000 vol

n = Drive speed of the pump [min-1]

ges = Total efficiency (0,8-0,85)

vol = Volumetric efficiency (0,9-0,95)

Q vol 1000

n=

V

M ab

mh = Hydro-mechanic efficiency

(0,9-0,95)

p V mh

=

= 1,59 V p mh 10 2

20

Pab =

p = Pressure difference between motor inlet and

outlet (bar)

p Q ges

10.01.2013

Pab = Output power of the motor [kW]

Mab = Output torque [Nm]

600

Sales Industry Sector Metallurgy

Formulary Hydraulics

Hydro Motor Variable

Md =

P=

n=

Md = Torque [Nm]

n = Speed [min-1]

Md n

30000

30000

Md =

n=

30000 P

Md

M d max

i Getr

i = Gear ratio

Getr = Gear efficiency

mh = Mech./hydraulic efficiency

vol = Vol. efficiency

Vg = Flow volume [cm3]

Md

Vg mh

Vg n

1000 vol

QP =

P=

Mdmax = Max torque [Nm]

n max

i

p = 20

Q=

P = Power [kW]

Vg n vol

1000

Q p

600 ges

10.01.2013

10

Sales Industry Sector Metallurgy

Formulary Hydraulics

Hydro Motor Fixed

Md =

P=

n=

Md = Torque [Nm]

n = Speed [min-1]

Md n

30000

30000

Md =

n=

30000 P

Md

M d max

i Getr

i = Gear ratio

Getr = Gear efficiency

mh = Mech./hydraulic efficiency

vol = Vol. efficiency

Vg = Flow volume [cm3]

Md

Vg mh

Vg n

1000 vol

QP =

P=

Mdmax = Max torque [Nm]

n max

i

p = 20

Q=

P = Power [kW]

Vg n vol

1000

Q p

600 ges

10.01.2013

11

Sales Industry Sector Metallurgy

Formulary Hydraulics

Hydro Motor Intrinsic Frequency

V

( G )2

2 E

2

0 =

VG

J red

+ VR )

(

2

f0 = 0

2

10.01.2013

VG = Displacement [cm3]

0 = Intrinsic angular frequency [1/s]

f0 = Intrinsic frequency [Hz]

Jred = Moment of inertia red. [kgm2]

El = 1400 N/mm2

VR = Volume of the line [cm3]

12

Sales Industry Sector Metallurgy

Formulary Hydraulics

Hydro Cylinder

d d 1 0,785 2

[cm ]

A= 1

=

400

100

2

d1 = Piston diameter [mm]

d2 = Piston rod diameter [mm]

p = Service pressure [bar]

d 2 0,785 2

[cm ]

100

2

A st =

v = Stroke speed [m/s]

V = Stroke volume [l]

(d d 2 ) 0,785 2

[cm ]

AR = 1

100

2

Q = Volume flow, considering the leakages

(l/min)

p d1 0,785

[kN]

FD =

10000

Qth = Volume flow, without considering the

p (d 1 d 2 ) 0,785

[kN]

Fz =

10000

vol = Volumetric efficiency (approx. 0,95)

h

Q

[m/s]

v=

=

t 1000 A 6

t = Stroke time [s]

Qth = 6 A v =

Q=

V=

t=

leakages (l/min)

V

60

t

h = Stroke [mm]

FD

[l/min]

FZ

Q th

vol.

FS

Ah

[l]

10000

A h6

Q 1000

10.01.2013

[s]

13

Sales Industry Sector Metallurgy

Formulary Hydraulics

Differential Cylinder

dK = Piston diameter [mm]

4 FD

pK

d K = 100

dst = Rod diameter [mm]

FD = Pressure force [kN]

pK =

4 10 FD

d K2

p St =

4 104 FZ

(d K 2 d St 2 )

Fz = Traction force [kN]

pK = Pressure at the piston side [bar]

= Aspect ratio

QK = Volume flow piston side [l/min]

QSt = Volume flow rod side [l/min]

va = Extending speed [m/s]

dK

2

2

(d K d St )

ve = Retracting speed [m/s]

Volp = Working volume [l]

6

2

va d K

QK =

400

QSt =

ve =

va =

VolF = Fill-up volume [l]

h = Stroke [mm]

6

2

2

v e (d K d St )

400

QSt

6

2

2

(d K d St )

400

QK

6

2

dK

400

Vol p =

Vol F =

4 10

d St h

h (d K d St )

4 10

10.01.2013

14

Sales Industry Sector Metallurgy

Formulary Hydraulics

Double Acting Cylinder

pA =

pB =

QA =

4 104

4 104

dK = Piston diameter [mm]

FA

2

2

(d K d StA )

dstA = Rod diameter A-side [mm]

dstB = Rod diameter B-side [mm]

FB

2

2

(d K d StB )

FA = Force A [kN]

FB = Force B [kN]

6

2

2

v a (d K d StA )

400

pA = Pressure at the A-side [bar]

pB = Pressure at the B-side [bar]

QA = Volume flow A-side [l/min]

6

2

2

QB =

v b (d K d StB )

400

ve =

va =

QB = Volume flow B-side [l/min]

va = Speed a [m/s]

QSt

vb = Speed b [m/s]

6

2

2

(d K d St )

400

Volp = Compensating volume [l]

VolFA = Fill-up volume A [l]

QK

VolFB = Fill-up volume B [l]

6

2

dK

400

Vol p =

4 10

Vol FA =

Vol FB =

d St h

2

h (d K d StA )

h (d K d StB )

4 10

4 10

10.01.2013

15

Sales Industry Sector Metallurgy

Formulary Hydraulics

Cylinder in Differential Control

dK = Piston diameter [mm]

4 FD

d st = 100

p St

dst = Rod diameter [mm]

FD = Pressure force [kN]

4 10 FD

d St 2

4

pK =

Fz = Traction force [kN]

pK = Pressure at the piston side [bar]

pSt = Pressure at the rod side [bar]

4 104 FZ

p St =

(d K 2 d St 2 )

Q=

h = Stroke [mm]

QK = Volume flow piston side [l/min]

6

2

v a d St

400

QSt = Volume flow rod side [l/min]

Extension:

va =

QP = Pump flow [l/min]

va = Extending speed [m/s]

QP

6

2

d St

400

Q d

QK = P 2 K

d St

ve = Retracting speed [m/s]

Volp = Working volume [l]

VolF = Fill-up volume [l]

Q P (d K d St )

2

d St

2

QSt =

Retraction:

ve =

QP

6

2

2

(d K d St )

400

QSt=QP

QP d K

QK =

2

2

(d K d St )

2

Vol p =

Vol F =

4 10

d St h

h (d K d St )

4 10

10.01.2013

16

Sales Industry Sector Metallurgy

Formulary Hydraulics

Cylinder Intrinsic Frequency at Differential Cylinders

AK = Piston surface [cm2]

d

AK = K

4

100

2

AR = Piston ring surface [cm2]

dK = Piston diameter [mm]

dSt = Piston rod diameter [mm]

(d d St )

AR = K

4

100

2

dRK = NW- piston side [mm]

LK = Length of piston side [mm]

dRSt = NW-rod side [mm]

d L

= RK K

4

1000

2

VRK

LSt = Length of rod side [mm]

h = Stroke [cm]

d L

= RSt St

4

1000

VRK = Volume of the line piston side [cm3]

VRSt

mRK =

VRSt = Volume of the line rod side [cm3]

mRK = Mass of the oil in the line piston side [kg]

VRK l

1000

mRSt = Mass of the oil in the line rod side [kg]

hK = Position at min intrinsic frequency [cm]

V l

= RSt

1000

mRSt

f0 = Intrinsic frequency [Hz]

A h V

V

R

+ RSt RK

3

3

A3

AR

AK

R

hk =

1

1

(

)

+

AR

AK

01 = 0

f 01 =

A EL

AR El

1

( K

+

)

A

h

A

(

h hK )

m

K

R

K

+ VRK

+ VRSt

10

10

2

0 =

f0 =

0 = Angular frequency

0

2

4

mlred

1

d

= mRK K + mRSt

d RK

d RSt

10.01.2013

400 A R

17

01

2

mred

mlred + mred

Sales Industry Sector Metallurgy

Formulary Hydraulics

Cylinder Intrinsic Frequency at Double Acting Cylinders

AR = Piston ring surface [cm2]

(d d St )

AR = K

4

100

2

dK = Piston diameter [mm]

dSt = Piston rod diameter [mm]

dR = NW [mm]

d L

VR = RK K

4

1000

LK = Length of the piston side [mm]

V l

mR = R

1000

VR = Volume of the line [cm3]

h = Stroke [mm]

mR = Mass of the oil in the line [kg]

f0 = Intrinsic frequency

2 E l

AR

0 = 100

(

)

AR h

m red

+ VRSt

10

2

0 = Angular frequency

Equation applies only to the middle position of the

double rod cylinder

Natural frequency of any position can be calculated

using the equation for the differential cylinder (as shown

on page 17, however AK = AR)

f0 =

0

2

mlred

1

= 2 mRK

dR

01 = 0

f 01 =

400 A R

mred

mlred + mred

01

2

10.01.2013

18

Sales Industry Sector Metallurgy

Formulary Hydraulics

Cylinder Intrinsic Frequency for Plunger Cylinders

AK = Piston surface [cm2]

d

AK = K

4

100

2

dK = Piston diameter [mm]

dR = Diameter of the piping [mm]

LK = Length piston side [mm]

d L

VR = K K

4

1000

2

LR = Length of the line [mm]

h = Stroke [mm]

V l

mR = R

1000

VR = Volume of the line [cm3]

MR = Mass of the oil in the line [kg]

2

E

AK

0 = 100 l (

)

mred AK h + VRSt

f0 =

0 = Angular frequency

0

2

m lred

d

= 2 mR K

dR

01 = 0

f 01 =

f0 = Intrinsic frequency

mred

mlred + mred

01

2

10.01.2013

19

Sales Industry Sector Metallurgy

Formulary Hydraulics

Piping

p =

l v 2 10

d2

lam.

turb.

0,316

= 4

Re

vd

turb. = Pipe friction coefficient for turbulent flow

l = Length of the line [m]

v = Velocity in the line [m/s]

103

6 d2

d =

lam. = Pipe friction coefficient for laminar flow

v=

= Density [kg/dm ] (0,89)

= Pipe friction coefficient

64

=

Re

Re =

p = Pressure loss at direct piping [bar]

102

d = Internal diameter of the piping [mm]

= Kinematic viscosity [mm /s]

2

Q = Volume flow in the piping [l/min]

400 Q

6 v

10.01.2013

20

Sales Industry Sector Metallurgy

Formulary Hydraulics

Application Examples for Specification of the Cylinder Pressures

and Volume Flows under Positive and Negative Load

Nomenclature

Parameters

Symbols

Units

Acceleration / deceleration

m/s2

Cylinder surface

A1

cm2

Ring surface

A2

cm2

Aspect ratio

=A1/A2

FT

daN

Fa=0,1ma

daN

External forces

FE

daN

Friction forces (coulomb friction)

FC

daN

Sealing friction force

FR

daN

Weight force

daN

Total force

Acceleration force

Mass

G

+ mK

g

kg

Piston mass

mK

kg

Volume flow

Q=0,06 Avmax

l/min

vmax

cm/s

T=J+ TL

Nm

m=

Torque

Load torque

TL

Nm

Angular acceleration

rad/s2

Inertia moment

kgm2

10.01.2013

21

Sales Industry Sector Metallurgy

Formulary Hydraulics

Differential Cylinder Extending with Positive Load

Calculation:

Layout:

FT = Fa+FR+FC+FE

p1 =

[daN]

Given Parameters

p 2 = 5,25 +

FT = 4450 daN

PS = 210 bar

PT = 5,25 bar

A1 = 53,50 cm2

A2 = 38,10 cm2

= 1,40

vmax = 30,00 cm/s

==> p1 und p2

Q N = 96

p S A2 + R [ FT + ( pT A2 )]

bar

A2 (1 + 3 )

p p

p2 = pT + S 2 1 bar

Verification of the cylinder dimensioning and

calculation of the nominal volume flow QN,

depending on the load pressure p1.

Q= 0,06A1vmax

QN = Q

l/min

35

p S p1

l/min

Selection of a Servo valve 10% larger than the

calculated nominal volume flow.

10.01.2013

210 120

= 52bar

1,4 2

Q= 0,0653,530=96 l/min

p1 =

210 38,1 + 1,4 2 [4450 + (5,25 38,1)]

= 120bar

38,1(1 + 1,4 3 )

22

35

= 60l / min

210 120

Sales Industry Sector Metallurgy

Formulary Hydraulics

Differential Cylinder Retracting with Positive Load

Layout:

Calculation:

FT = Fa+FR+FC+FE

[daN]

p2 =

Given Parameters

p 1 = 5,25 + [(210 187)1,4 2 ] = 52bar

FT = 4450 daN

PS = 210 bar

PT = 5,25 bar

A1 = 53,50 cm2

A2 = 38,10 cm2

= 1,40

vmax = 30,00 cm/s

==> p1 und p2

Q= 0,0638,130=69 l/min

( p A 3 ) + FT + ( pT A2 )]

bar

p2 = S 2

A2 (1 + 3 )

Q N = 96

p1 = pT + [( p S p2 ) 2 ] bar

Verification of the cylinder dimensioning and

calculation of the nominal volume flow QN,

depending on the load pressure p1.

Q= 0,06A2vmax

l/min

35

pS p 2

l/min

QN = Q

Selection of a Servo valve 10% larger than the

calculated nominal volume flow.

10.01.2013

(210 38,1 1,42 ) + 4450 + (5,25 38,1 1,4)]

= 187bar

38,1(1 + 1,43 )

23

35

= 84l / min

210 187

Sales Industry Sector Metallurgy

Formulary Hydraulics

Differential Cylinder Extending with Negative Load

Calculation:

Layout:

FT = Fa+FR-G

p1 =

[daN]

Given Parameters

p2 = 0 +

FT = -2225 daN

PS = 175 bar

PT = 0 bar

2

A1 = 81,3 cm

2

A2 = 61,3 cm

= 1,3

vmax = 12,7 cm/s

==> p1 und p2

p S A2 + 2 [ FT + ( pT A2 )]

bar

A2 (1 + 3 )

p p

p2 = pT + S 2 1 bar

Q N = 62

Verification of the cylinder dimensioning and

calculation of the nominal volume flow QN,

depending on the load pressure p1.

Q= 0,06A1vmax

l/min

35

p S p1

l/min

Selection of a Servo valve 10% larger than the

calculated nominal volume flow.

10.01.2013

175 36

= 82bar

1,32

Q= 0,0681,312,7=62 l/min

p1 =

QN = Q

175 61,3 + 1,32 [2225 + (0 61,3)]

= 36bar

61,3(1 + 1,33 )

24

35

= 31l / min

175 36

Sales Industry Sector Metallurgy

Formulary Hydraulics

Differential Cylinder Retracting with Negative Load

Calculation:

Layout:

FT = Fa+FR-G

p2 =

[daN]

(210 61,3 + 1,32 ) 4450 + (0 61,3 1,3)]

= 122bar

61,3(1 + 1,33 )

Given Parameters

p 1 = 0 + [(210 122)] = 149 bar

FT = -4450 daN

PS = 210 bar

PT = 0 bar

2

A1 = 81,3 cm

2

A2 = 61,3 cm

= 1,3

vmax = 25,4 cm/s

==> p1 und p2

Q= 0,0661,325,4=93 l/min

p2 =

Q N = 93

( p S A2 ) + FT + ( pT A2 )]

bar

A2 (1 + 3 )

3

p1 = pT + [( p S p2 ) 2 ] bar

Verification of the cylinder dimensioning and

calculation of the nominal volume flow QN,

depending on the load pressure p1.

Q= 0,06A2vmax

l/min

35

pS p 2

l/min

QN = Q

Selection of a Servo valve 10% larger than the

calculated nominal volume flow.

10.01.2013

25

35

= 59l / min

210 122

Sales Industry Sector Metallurgy

Formulary Hydraulics

Differential Cylinder Retracting at an Inclined Plane with Positive Load

Calculation:

Layout:

(140 19,9) + 1,62 [2225 + (3,5 19,9)]

= 85bar

19,9(1 + 1,63 )

FT = Fa+FE+FS+[G(cos+sin)] daN

p1 =

Given Parameters

p 2 = 35 +

FT = 2225 daN

PS = 140 bar

PT = 3,5 bar

2

A1 = 31,6 cm

2

A2 = 19,9 cm

= 1,6

vmax = 12,7 cm/s

==> p1 and p2

p1 =

Q= 0,0631,612,7=24 l/min

Q N = 24

p S A2 + 2 [ F + ( pT A2 )]

p2 = pT +

A2 (1 + 3 )

p S p1

bar

bar

Verification of the cylinder dimensioning and

calculation of the nominal volume flow QN,

depending on the load pressure p1.

Q= 0,06A1vmax

l/min

35

p S p1

l/min

QN = Q

Selection of a Servo valve 10% larger than the

calculated nominal volume flow.

10.01.2013

140 85

= 25bar

1,6 2

26

35

= 19 l/min

140 85

Sales Industry Sector Metallurgy

Formulary Hydraulics

Differential Cylinder Retracting at an Inclined Plane with Positive Load

Calculation:

Layout:

(140 19,9 1,63 ) + 1780 + [3,5 19,9 1,6)]

= 131bar

19,9(1 + 1,63 )

FT =Fa+FE+FS+[G(cos+sin)] daN

p2 =

Given Parameters

p 1 = 3,5 + [(140 131) 1,6 2 = 26bar

FT = 1780 daN

PS = 140 bar

PT = 3,5 bar

2

A1 = 31,6 cm

2

A2 = 19,9 cm

= 1,6

vmax = 12,7 cm/s

==> p1 and p2

p2 =

Q= 0,0619,912,7=15 l/min

Q N = 15

( p S A2 3 ) + F + ( pT A2 )]

A2 (1 + 3 )

bar

p1 = pT + [( p S p2 ) 2 ] bar

Verification of the cylinder dimensioning and

calculation of the nominal volume flow QN,

depending on the load pressure p1.

Q= 0,06A2vmax

QN = Q

l/min

35

pS p 2

l/min

Selection of a Servo valve 10% larger than the

calculated nominal volume flow.

10.01.2013

27

35

= 30 l/min

140 131

Sales Industry Sector Metallurgy

Formulary Hydraulics

Differential Cylinder Extending at an Inclined Plane with Negative Load

Calculation:

Layout:

FT = Fa+FE+FR+[G(cos-sin)] daN

p1 =

(210 106) + 1,22 [6675 + (0 106)]

= 131bar

106(1 + 1,43 )

Given Parameters

FT = -6675 daN

PS = 210 bar

PT = 0 bar

2

A1 = 53,5 cm

2

A2 = 38,1 cm

= 1,4

vmax = 25,4 cm/s

==> p1 und p2

p1 =

Caution!!!

Negative load is leading to cylinder cavitation.

Specified parameters to be changed by means of

using a larger cylinder size, increasing the system

pressure or reducing the necessary total force.

A1 = 126 cm

p S A2 + 2 [ F + ( pT A2 )]

p2 = pT +

A2 (1 + 3 )

p S p1

bar

bar

Verification of the cylinder dimensioning and

calculation of the nominal volume flow QN,

depending on the load pressure p1.

Q= 0,06A1vmax

QN = Q

p2 =

l/min

Selection of a Servo valve 10% larger than the

calculated nominal volume flow.

10.01.2013

A2 = 106 cm

210 44

= 116bar

1,2 2

Q= 0,0612625,4=192 l/min

35

Q N = 192

= 88 l/min

210 44

l/min

35

p S p1

28

R=1,2

Sales Industry Sector Metallurgy

Formulary Hydraulics

Differential Cylinder Retracting at an Inclined Plane with Negative Load

Calculation:

Layout:

(210 38,1 1,43 ) + [ 6675 + (0 38,1 1,4)]

= 107 bar

38,1(1 + 1,43 )

F = Fa+FE+FR+[G(cos-sin)] daN

p2 =

Given Parameters

p 1 = 0 + [(210 107) 1,4 2 ] = 202 bar

F = -6675 daN

PS = 210 bar

PT = 0 bar

2

A1 = 53,5 cm

2

A2 = 38,1 cm

= 1,4

vmax = 25,4 cm/s

==> p1 and p2

Q= 0,0638,125,4=58 l/min

Q N = 58

( p S A2 3 ) + F + ( pT A2 )]

bar

p2 =

A2 (1 + 3 )

p1 = pT + [( p S p2 ) 2 ] bar

Verification of the cylinder dimensioning and

calculation of the nominal volume flow QN,

depending on the load pressure p2.

Q= 0,06A2vmax

QN = Q

l/min

35

pS p 2

l/min

Selection of a Servo valve 10% larger than the

calculated nominal volume flow.

10.01.2013

29

35

= 34 l/min

210 107

Sales Industry Sector Metallurgy

Formulary Hydraulics

Hydraulic Motor with a Positive Load

Calculation:

Layout:

T = J+TL

p1 =

[Nm]

p 2 = 210 127 + 0 = 83bar

Given Parameters

T = 56,5 Nm

PS = 210 bar

PT = 0 bar

3

DM = 82 cm /rad

M = 10 rad/s

QM= 0,011082=8,2 l/min

Q N = 8,2

==> p1 and p2

p S + p T 10T

bar

+

2

DM

p 2 = p S p1 + p T bar

p1 =

Verification of the cylinder dimensioning and

calculation of the nominal volume flow QN,

depending on the load pressure p1.

QM= 0,01MDM

QN = QM

l/min

35

p S p1

l/min

Selection of a Servo valve 10% larger than the

calculated nominal volume flow.

10.01.2013

210 + 0 10 56,5

+

= 127bar

2

82

30

35

= 5,3 l/min

210 127

Sales Industry Sector Metallurgy

Formulary Hydraulics

Hydraulic Motor with a Negative Load

Calculation:

Layout:

T = J-TL

p1 =

[Nm]

p 2 = 210 40 + 0 = 170bar

Given Parameters

T = -170 Nm

PS = 210 bar

PT = 0 bar

3

DM = 82 cm /rad

M = 10 rad/s

QM= 0,011082=8,2 l/min

Q N = 8,2

==> p1 and p2

p S + p T 10T

bar

+

2

DM

p 2 = p S p1 + p T bar

p1 =

Verification of the cylinder dimensioning and

calculation of the nominal volume flow QN,

depending on the load pressure p1.

QM= 0,01MDM

QN = QM

l/min

35

p S p1

l/min

Selection of a Servo valve 10% larger than the

calculated nominal volume flow.

10.01.2013

210 + 0 10 ( 170)

+

= 40bar

2

82

31

35

= 3,6 l/min

210 40

Sales Industry Sector Metallurgy

Formulary Hydraulics

Identification of the Reduced Masses of Different Systems

The different components (cylinder / motors ) have to be dimensioned for the layout of the

necessary forces of a hydraulic system, so that the acceleration and the deceleration of a mass is

correct and targeted.

The mechanics of the system are defining the stroke of the cylinders and motors.

Speed- and force calculations have to be carried out.

Statements with view to acceleration and its effects on the system can be made by fixing the reduced

mass of a system.

The reduced mass (M) is a concentrated mass, exerting the same force and acceleration

components as the regular mass at the correct system.

The reduced moment of inertia (Ie) has to be considered for rotational systems.

The reduced mass has to be fixed in a first step for considerations with stroke measuring systems or

for applications with deceleration of a mass!

Newtons second axiom is used for the specification of the acceleration forces.

F = m a

F= force [N]

m= mass [kg]

a= acceleration [m/s2]

The following equation is applied for rotational movements:

= I

= torque [Nm]

= moment of inertia [kgm2]

= angular acceleration [rad/s2]

10.01.2013

32

Sales Industry Sector Metallurgy

Formulary Hydraulics

Linear Drives

Primary Applications (Energy Method)

The mass is a concentrated mass and the rod l is weightless. The cylinder axis is positioned

rectangular to the rod l.

Relation between cylinder and rod:

vc v m

=

r

l

ac am

=

r

l

Needed torque for acceleration of the mass:

= IX = F r

= m l 2 X

= m l2 X

I = m l2

am

l

am

l

= m lXa m

==>

F=

m l am

= m i am

r

i=

l

r

mi can be considered as mass movement m.

F = m i am = m i

l ac

= m i2 a c = M a c

r

mit

ac am

=

r

l

F= cylinder force

M= reduced mass

ac= acceleration of the cylinder rod

General validity:

M = mi

The same result can be obtained by the aid of the energy method (kinetic energy of the mass m). The

dependence of the mass movement with the cylinder movement can be specified with the help of the

geometry of the system.

2

Energy of the mass:

1

1

KE = I 2 = m l 2 2

2

2

10.01.2013

(I=mi2)

33

Sales Industry Sector Metallurgy

Formulary Hydraulics

1

v

= m l2 c

r

2

=

=

(vc=r )

1

l2

2

m 2 vc

2

r

1

2

M vc

2

10.01.2013

M=mi

34

and i=l/r

Sales Industry Sector Metallurgy

Formulary Hydraulics

Concentrated Mass with Linear Movements

v is the horizontal component of v. v is positioned rectangular to rod l.

Energy method:

1

1

KE = I 2 = m l 2 2

2

2

v

1

= m l2

2

r

( =v/r)

l2

1

2

= m 2 v

r

2

1

2

= m i2 v

2

with v=vcos

==> KE =

1

m i2 v 2

2

1 m i2

1

v2 = M v2

2

2 (cos )

2

with M = m

If:

i2

==> M is position-depending

(cos ) 2

= 0 then, =1

and M=mi2

=90 then, cos=0

and M=

=30 then, cos=0,866

and M = m

i2

0,75

If a cylinder is moving a mass, as shown in the preceding figure, and the movement is situated between -30 and

+30, the acceleration- and deceleration forces have to be calculated in the center of motion with a reduced mass,

twice as large as the one in the neutral center.

10.01.2013

35

Sales Industry Sector Metallurgy

Formulary Hydraulics

Distributed Mass at Linear Movements

When considering the same rod l with the mass m, you can here also calculate the reduced mass of

the rod.

1

1

1

KE = I 2 = X m l 2 2

2

2

3

v

1

1

= X m l2

2

3

r

1

m l2

3

( =v/r)

l2

1

1

2

= X m 2 v

r

2

3

1

1

2

= X m i2 v

2

3

with v=vcos

M=

1

1 m i2

1

X

v2 = M v2

2

2

3 (cos a )

3

1 m i2

2 (cos a ) 2

10.01.2013

36

Sales Industry Sector Metallurgy

Formulary Hydraulics

Rotation

If considering now a rotating mass with a moment of inertia I, driven by a motor (ratio D/d).

1

1

d

KE = I 2 m = I ( ) 2

2

2

D

I= moment of inertia [kgm2]

1 d

= I 2

2 D

= angular acceleration [rad/s2]

1

= I i2 2

2

1

= Ie 2

2

Ie= Ii2

i=d/D

If a gearbox has to be used, i has to be considered.

2

If i=D/d, then Ie=I/i

10.01.2013

37

Sales Industry Sector Metallurgy

Formulary Hydraulics

Combination of Linear and Rotational Movement

A mass m is here moved by a wheel with radius r. The wheel is weightless.

KE =

=

1

2

m ( r )

2

=

1

m v2

2

v=r

1

m r 2 2

2

1

Ie 2

2

10.01.2013

Ie= mr

38

Sales Industry Sector Metallurgy

Formulary Hydraulics

Hydraulic Resistances

The resistance of an area reduction is the change of the applied pressure difference

corresponding volume flow change.

R=

p to the

d (p)

dQ

Orifice Equation

QBlende = 0,6 K

dB

2 p

4

2

K = flow coefficient (0,6-0,8)

= 0,88 [kg/dm3]

dB = orifice diameter [mm]

p = pressure difference [bar]

Qorifice= [l/min]

Throttle Equation

Q Drossel

r4

( p1 p 2 )

=

8 l

Qthrottle= [m3/s]

= dynamic viscosity [kg/ms]

l = throttle length [m]

r = radius [m]

= kinematic viscosity [m2/s]

= 880 [kg/m3]

10.01.2013

39

Sales Industry Sector Metallurgy

Formulary Hydraulics

Hydro Accumulator

1

1

p 0 p1

V = V0 1

p1 p 2

p2 =

V0 =

p1

V

1

1

p0

V0

p

V

1

1

p 0 p1

1

p2

p1

10.01.2013

= 1,4 (adiabatic compression)

V = effective volume [l]

V0 = accumulator size [l]

p0 = gas filling pressure [bar]

p1 = service pressure min [bar] (pressure loss at the

valve)

p2 = service pressure max [bar]

p0 = <0,9*P1

Provide an accumulator in the pressure circuit for

pressure-controlled pumps!

Swivel time of pump tSA of the pump catalog.

V = Q t SA

40

Sales Industry Sector Metallurgy

Formulary Hydraulics

Heat Exchanger (Oil - Water)

ETD = t l t K

Vl = oil flow [l/min]

PV = dissipation power [kW]

P

p 01 = V

ETD

tl = inlet temperature oil [C]

14 PV

t K =

VK

tK = inlet temperature cooling water [C]

tl = cooling of the oil [K]

tK = heating of the cooling water [K]

VK = cooling water flow [l/min]

Calculation of tl is different, depending on the

ETD = inlet temperature difference [K]

respective hydraulic fluid.

p01 = spec. cooling capacity [kW/h]

HFA

t l =

HLP/HFD

14,7 PV

Vl

t l =

HFC

36 PV

Vl

t l =

17,2 PV

Vl

The size of the heat exchangers can be defined by the calculated value p01 of the diagrams of the

different manufacturers.

10.01.2013

41

Sales Industry Sector Metallurgy

Formulary Hydraulics

Example AB-Standards:

10.01.2013

42

Sales Industry Sector Metallurgy

Formulary Hydraulics

Layout of a Valve

The necessary volume flow can be calculated

based on the cylinder data as well as on the

extending and retracting speeds.

Q= 0,06A2vmax

l/min

X

pS p2

l/min

QN = Q

P= PS system pr.-PLload pr.-P Treturn pressure

(Load pressure

2

*System pressure)

3

X= 35 (Servo valve) pressure loss via a leading edge

X= 35 (Prop valve) pressure loss via a leading edge

(Prop valve with shell)

At optimal efficiency

FT = load force [daN]

PS = system pressure [bar]

PT = return pressure [bar]

A1 = piston surface cm2

A2 = ring surface cm2

= aspect ratio cylinder

vmax = extending speed of the cylinder cm/s

X= 5 (Prop valve) pressure loss via a leading edge

(Prop valve without shell)

Selection of a valve 10% larger than the

calculated nominal volume flow

p1 and p2

p2 =

( p S A2 3 ) + FT + ( pT A2 )]

bar

A2 (1 + 3 )

p1 = pT + [( p S p2 ) 2 ] bar

Verification of the cylinder dimensioning and

calculation of the nominal volume flow QN,

depending on the load pressure p1.

Translation: Harm/March 16, 2011

10.01.2013

43

You might also like

- DBM Gmec (Ing) MerloDocument87 pagesDBM Gmec (Ing) MerloNicoleta Costea83% (6)

- Softener CalculationDocument4 pagesSoftener Calculationkmsiddharthan95% (19)

- How To Review PV Elite Design Report PDFDocument9 pagesHow To Review PV Elite Design Report PDFprocess process100% (1)

- Hydrostatic Transmission Circuit "Rexroth" System On: DBM2000 XS DBM2000 EV DBM2500 EV DBM3500 EVDocument39 pagesHydrostatic Transmission Circuit "Rexroth" System On: DBM2000 XS DBM2000 EV DBM2500 EV DBM3500 EVNicoleta Costea100% (1)

- 1 Operation ManualDocument31 pages1 Operation ManualNazar KhanNo ratings yet

- Rexroth Hidr - Formule PDFDocument43 pagesRexroth Hidr - Formule PDFZoran Tanja JarakovićNo ratings yet

- Hyd Formelsammlung enDocument43 pagesHyd Formelsammlung enLidijaSpaseskaNo ratings yet

- Rexroth Hydraulic FormulaeDocument43 pagesRexroth Hydraulic FormulaePremangshu SahaNo ratings yet

- Slewing Gantry Crane With Double-Link SystemDocument11 pagesSlewing Gantry Crane With Double-Link Systemduyhp231296No ratings yet

- How To Review PV Elite Report: (Specific To Forbes Marshall)Document9 pagesHow To Review PV Elite Report: (Specific To Forbes Marshall)thomas_v501925No ratings yet

- اخر تعديل ع النوتهDocument24 pagesاخر تعديل ع النوتهAhmed AldeepNo ratings yet

- Rules of ThumbDocument25 pagesRules of ThumbCaroline MacVeyNo ratings yet

- Marine Bearing Installation Manual PDFDocument64 pagesMarine Bearing Installation Manual PDFJuniorJavier Olivo Farrera100% (1)

- DBM 2000 XS, DBM 2000 EV and DBM 2500 EV: Engine Removal FromDocument28 pagesDBM 2000 XS, DBM 2000 EV and DBM 2500 EV: Engine Removal FromNicoleta CosteaNo ratings yet

- PHB 5 PDFDocument22 pagesPHB 5 PDFestephan82No ratings yet

- User Guide PDFDocument27 pagesUser Guide PDFbulentbulut100% (1)

- Densitometer Non-Radioactive NRD Op & Maint TOCDocument31 pagesDensitometer Non-Radioactive NRD Op & Maint TOCOctavian SarbuNo ratings yet

- Section H9: DealkalizersDocument10 pagesSection H9: DealkalizersDxtr MedinaNo ratings yet

- Nifty HR17n Service ManualDocument79 pagesNifty HR17n Service ManualQussai BitarNo ratings yet

- Ime PDFDocument44 pagesIme PDFnp27031990No ratings yet

- Design of SlabDocument36 pagesDesign of SlabDuaa SalehNo ratings yet

- TD 302 Cemp EEx-d Technische Catalogus ATEX 63-315Document87 pagesTD 302 Cemp EEx-d Technische Catalogus ATEX 63-315TrePcaNo ratings yet

- Hydro-Cyclone Separation Unit: Cost EstimationsDocument20 pagesHydro-Cyclone Separation Unit: Cost EstimationsMuhammad Hussain BilalNo ratings yet

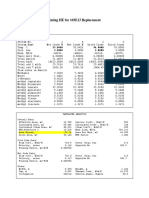

- Rating HE For 103E13 Replacement - v1005Document7 pagesRating HE For 103E13 Replacement - v1005Farras WibisonoNo ratings yet

- The Investigation of Appropriate Control Algorithms For The Speed Control of Wind Turbine Hydrostatic SystemsDocument79 pagesThe Investigation of Appropriate Control Algorithms For The Speed Control of Wind Turbine Hydrostatic SystemsHarika RaaviNo ratings yet

- Technical Product Manual: 2021 EDITIONDocument26 pagesTechnical Product Manual: 2021 EDITIONadacostNo ratings yet

- Juki ddl9000bDocument29 pagesJuki ddl9000bMathieu BouchardNo ratings yet

- Siemens Switchboard and Protection ManualDocument472 pagesSiemens Switchboard and Protection Manual1wocker1100% (1)

- 3 ShaftDocument16 pages3 ShaftSuresh CNo ratings yet

- Conversion FactorsDocument1 pageConversion FactorsWasantha JayarathnaNo ratings yet

- Technical Information PSVDocument30 pagesTechnical Information PSVVinicius De Holanda PasoliniNo ratings yet

- DBM2000 XS - DBM2000 EV DBM2500 EV - DBM3500 EV: Removal of Both Loader and Drum FromDocument33 pagesDBM2000 XS - DBM2000 EV DBM2500 EV - DBM3500 EV: Removal of Both Loader and Drum FromNicoleta CosteaNo ratings yet

- Ariel Compressor Calculation MethodDocument9 pagesAriel Compressor Calculation MethodSulagna RoyNo ratings yet

- Balcony Design AnsysDocument30 pagesBalcony Design Ansysmuhammad1970maqsoodNo ratings yet

- Pocket Formula GuideDocument68 pagesPocket Formula GuideMike StevensonNo ratings yet

- Chronos Richardson Bag PaletiserDocument38 pagesChronos Richardson Bag Paletisernmarkov80No ratings yet

- Conversion FactorsDocument1 pageConversion FactorsRamachandran VenkateshNo ratings yet

- En Manual GT-500Document56 pagesEn Manual GT-500Adrian Petre100% (1)

- MLX91209CA Datasheet PDFDocument15 pagesMLX91209CA Datasheet PDFJavierPariNo ratings yet

- Service Manual: HeightriderDocument112 pagesService Manual: Heightridermiquel villarNo ratings yet

- Service Manual - M50606 - 001Document64 pagesService Manual - M50606 - 001Folkwin LapNo ratings yet

- MAMCING-01 CingoDocument130 pagesMAMCING-01 CingoNicoleta CosteaNo ratings yet

- Air Pollution Control - Wet ScrubbersDocument77 pagesAir Pollution Control - Wet ScrubbersDAISYLIN ANBU SUJITHA SNo ratings yet

- Pressure Conversion ChartDocument1 pagePressure Conversion Chartamarkore3486No ratings yet

- Cp1650 Manual de PartesDocument28 pagesCp1650 Manual de PartesJuan Alfredo ValdésNo ratings yet

- Hydrometer Test: IntroductionDocument4 pagesHydrometer Test: Introductionsatyam agarwalNo ratings yet

- 24 Mi 1743Document24 pages24 Mi 1743Kamyar KhaksarNo ratings yet

- 2011 Cost Models SectionDocument56 pages2011 Cost Models Sectionoduk odbayarNo ratings yet

- Fluid PowerDocument88 pagesFluid PowerGabriel Ak100% (3)

- Power Electronics Design: A Practitioner's GuideFrom EverandPower Electronics Design: A Practitioner's GuideRating: 4.5 out of 5 stars4.5/5 (3)

- Variable Speed Pumping: A Guide to Successful ApplicationsFrom EverandVariable Speed Pumping: A Guide to Successful ApplicationsRating: 3 out of 5 stars3/5 (2)

- Nuclear Magnetic Resonance: Petrophysical and Logging ApplicationsFrom EverandNuclear Magnetic Resonance: Petrophysical and Logging ApplicationsRating: 5 out of 5 stars5/5 (1)

- Incompressible Flow Turbomachines: Design, Selection, Applications, and TheoryFrom EverandIncompressible Flow Turbomachines: Design, Selection, Applications, and TheoryNo ratings yet

- Application of Optimal Control Theory to Enhanced Oil RecoveryFrom EverandApplication of Optimal Control Theory to Enhanced Oil RecoveryRating: 4.5 out of 5 stars4.5/5 (3)