Professional Documents

Culture Documents

Submerged Mons Cus

Uploaded by

Condeescu NicoletaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Submerged Mons Cus

Uploaded by

Condeescu NicoletaCopyright:

Available Formats

Bioprocess Engineering 17 (1997) 7579 Springer-Verlag 1997

A new process for red pigment production by submerged culture

of Monascus purpureus

M. Hamdi, P.J. Blanc, M.O. Loret, G. Goma

75

Abstract Formation of red pigment by Monascus purpureus via diauxic growth on glucose and ethanol in

submerged culture was optimized based on inoculum

preparation and culture medium. A vegetative inoculum

was prepared from spores grown on ethanol. The optimized culture medium was low in phosphates, and had an

initial pH of 5.5. The characteristics of Monascus purpureus grown on glucose and on ethanol were compared: the

specific consumption rate of glucose (qG) was higher than

the specific consumption rate of ethanol (qE), whereas the

specific growth rate was greatest with ethanol. The specific

production rate of red pigment (pOD) and pigment yield

(YOD/s) with glucose was twice that with ethanol. A novel

fermentation process was developed with M. purpureus

initially grown with controlled ethanol formation, and

consumption of the latter during pigment formation.

List of symbols

DO

qG

qE

l

pE

pOD

Yx/s

YOD/s

(%)

Dissolved oxygen

(g/g.h)

Specific consumption of glucose

(g/g.h)

Specific consumption of ethanol

(h1)

Maximum specific growth rate

(g/g.h)

Specific production rate of ethanol

(ODU/g.h) Maximum specific production rate of

red pigment

(g/g)

Yield of biomass on substrate

(ODU/g) Yield of red pigment on ethanol

1

Introduction

Study of the natural red food colorants has intensified and

the objective being to replace certain synthetic ones.

Monascus sp. red pigment has been recently utilized in the

orient for making red rice wine, red soybean cheese, and

red chinese rice [1]. The production of Monascus pigment

as food coloring agent by both submerged and agar surface

cultures have been studied extensively in the past 10 years

[1, 2, 3, 4]. Yields in submerged culture are affected by

medium composition, pH and agitation [2, 3]. A chemically-defined medium supporting rapid and intensive red

pigment production, using glutamate as nitrogen source

was developed, and shifted the site of pigment from being

predominantly cell-bound to being mainly extra cellular

[4]. We focus on red pigment production by Monascus

purpureus (this work) and M. ruber [5] grown in a

submerged culture in both defined and complex media.

2

Material and methods

2.1

Microorganism and inoculum preparation

Monascus purpureus CBS 10907 was maintained on potato

dextrose agar (PDA) (Difco, Detroit, MI.). Spores were

prepared by growth on PDA in an Erlenmeyer flask for 6

days at 30 C. Spores were washed from the agar with

sterile water and glass beads. Cultures were inoculated

with a spore suspension (0.5 ml) in 250-ml Erlenmeyer

flasks (40/250 ml) of optimized medium (see below,

Table 1) and incubated on a rotary shaker (150 rpm) at

30 C.

2.2

Growth conditions

Batch cultures were performed in 2 l fermentors (S.G.I.,

Toulouse, France) containing 1.5 l optimized medium

(Table 1) at 30 C. The agitation system was a Rushton-like

turbine. The dissolved oxygen concentration was kept

constant or modified by changing the impeller speed or by

aeration flow rate which was measured with a gas mass

flow meter. The DO concentration was maintained between 60 and 80% of saturation level. The pH was not

maintained constant.

2.3

Analytical methods

Biomass concentration was determined by filtering the

P.J. Blanc, M.O. Loret, G. Goma

Departement de Genie Biochimique et Alimentaire.

mycelia through a glass fiber membrane Whatman GF/C,

UA CNRS N 544. INSA, Complexe Scientifique de Rangueil. washed with water, dried under low pressure at 60 C for

31077 Toulouse Cedex, France

24 h, and then weighed. The water soluble red pigment

were estimated by measuring the optical density at 480 nm

M. Hamdi

using a Kontron Uvikon spectrophotometer.

Ecole Superieure des Industries Alimentaires,

Ethanol concentration was determined using a Intersmat

58 Avenue Alain Savary. 1003 Tunis, Tunisia

IGC 120 DFL gas chromatograph equipped with a flame

Correspondence to: P.J. Blanc

ionization detector: column (2 m 3.2 mm) packed with a

Received: 23 September 1996

Bioprocess Engineering 17 (1997)

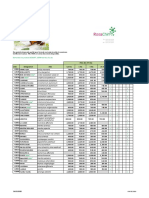

Table 1. Media used for inoculum preparation and red pigment formation

76

Nutriments or salts

Inoculum preparation

Red pigment formation

Glucose (g/l)

Ethanol (g/l)

Monosodium glutamate (g/l)

Potassium dihydrogenophosphate (g/l)

Dipotassium hydrogenophosphate (g/l)

Potassium chlorure (g/l)

Magnesium sulfate (g/l)

Iron sulfate (mg/l)

Zinc sulfate (mg/l)

Manganese sulfate (mg/l)

pH

Inoculum

25

4

2.5

2.5

0.5

1

10

10

3

5

Spores (105/ml)

2050

213*

12.4

0.125

0.125

10

10

3

5.5

Free mycelium 2%(V/V)

*Successive addition during red pigment formation: See Figs. 3 and 5

Poropack QS 80100 mesh, with nitrogen as the carrier

gas. Injector, detector, and column temperatures were 260,

260, and 195 C respectively. Quantitative data were obtained by peak integration with an Intersmat ICR 1B after

calibration with propanol (10 g/l) internal standard.

Glucose analyses of broth supernatants (centrifuged and

diluted) were by using a glucose analyzer (YSI Model 27,

SGI, France). Dissolved oxygen (DO) concentrations were

measured with an Ingold amperometric probe. Citric,

succinic, acetic and malic acids were analysed by HPLC:

Waters liquid chromatograph equipped with an ION organic acids column and a refractometer 410. Elution was

carried out with an aqueous solution of H2SO4 10 mM at a

flow rate of 0.4 ml/min.

3

Results and discussion

3.1

Optimization of media for inoculum preparation

and red pigment formation

Inocula can be crucial in fungus culture. Preliminary runs

based on the factorial design experiments showed that the

medium of Lin and Demain [4] is good for inoculum

preparation when the monosodium glutamate (MSG) was

reduced to 4 g/l, and source carbohydrates was changed to

ethanol, and the initial pH changed from 5.5 into 5. The

ethanol (23%) yields better vegetative growth than glucose. At higher concentration of ethanol, lesser biomass

was produced with formation of larger pellets (Fig. 1).

Pellets may originate from spores coalescing, freshly germinating spores aggregating, or by mycelial entanglement.

Optimum concentration of spores to inoculate the ethanol

medium is about 105 spores/ml whereas with glucose it is

higher 107 spores/ml. The ethanol is more suitable source

carbohydrate for inoculum preparation than glucose, because it gives twice mycelium concentration and it requires lesser spores for inoculation. The optimum initial

pH of 5 favors spore germination, yields a free mycelium,

higher biomass but lesser red pigment production (Fig. 1).

Indeed, Lin [1] showed that maximum cell yield was obtained at pH 5, while the maximum pigment yield was at 6.

At pH values above 5.5, cell walls of most microorganisms

are negatively charged, tending to cause separation of the

cells by electrostatic repulsion [6]. Under optimal conditions for inoculum preparation M. purpureus gave max-

Fig. 1. Influence of initial concentration of ethanol and initial pH

on the biomass ( ) and red pigment production (j) by

Monascus purpureus growth on ethanol

imum biomass in 4 days, a maximum specific growth rate

of around 0.083 h1, with biomass yield of 8.9 g/l. The

pH of the medium increased slowly from 5 up to 5.32 and

red pigment was not greater than 0.7 ODU/ml.

Optimization of red pigment production in Erlenmeyer

flasks using a vegetative inoculum showed 2% v/v as the

optimal inoculum (Table 1). Relatively low amounts of

potassium dihydrogenophosphate (50 mg/l) and dipotassium hydrogenophosphate (50 mg/l) were sufficient for

high red pigment production. An initial pH of 5.5 favored

mycelial growth, and as it rose it resulted in improved red

pigment formation. Indeed, in submerged culture, pigments normally remain in the mycelium due to low solu-

M. Hamdi et al.: Production of MonascusI red pigment

bility in usually acidic medium [7]. Yet, Mak et al. [8]

noted that high pH might facilitate the pigment removal

from mycelium and was associated with the chemical

conversion of orange to red. This optimized medium for

red pigment formation was used in further experiments.

In preliminary studies several carbon sources were

compared with regard to red pigment production (data

unreported). Glucose and ethanol appeared useful substrates. When the carbon source was a mixture of glucose

and ethanol (Fig. 2), growth was in two stages diauxie.

Glucose gave increase in biomass and ethanol, while

ethanol resulted in growth of biomass plus pigment formation (Fig. 2).

3.2

Red pigment production in fermentor

Both substrates glucose and ethanol were studied for red

pigment production in fermentor. Fermentors inoculated

with a vegetative mycelial inoculum reduced the lag phase,

and gave a higher specific growth rate than inocula of a

spore suspension or vegetative pellets (data unreported).

Culture parameters obtained with glucose are illustrated

in Figs. 3 and 4. The biomass concentration increased in

two stages corresponding to glucose consumption and

ethanol formation for 75 h, and then ethanol consumption

and red pigment formation. The specific consumption rate

of glucose (qG) increased continuously from 0.1 to 0.3 g/

g.h. The specific production rate of ethanol from glucose

(pE) ranged from 0.05 to 0.08 g/g.h, and could be increased

by decreasing the DO concentration [9]. The specific

growth rate on glucose decreases from 0.06 to 0.02 h1,

whereas on the accumulated ethanol the mean specific

growth rate was around 0.025 h1. After 80 h, the biomass

decreases probably because of pigment removal from

mycelium. The red pigment formation is initiated especially when glucose was completely exhausted and corresponding to the beginning of ethanol consumption

Fig. 2. Time courses of glucose (h), ethanol (m), biomass (), and

red pigment (j), during Monascus purpureus growth on mixed

ethanol and glucose in flask cultures

77

Fig. 3. Time courses of glucose (h), ethanol (m), biomass (),

red pigment (j) and pH () during Monascus purpureus growth

on glucose in fermentor

Fig. 4. Time courses of l (), qG (h), pE (), qE (m) and pOD (j)

during Monascus purpureus growth on glucose in fermentor

Bioprocess Engineering 17 (1997)

78

(Fig. 3). The specific consumption rate of ethanol (qE) was

0.050.08 g/g.h. The red pigment formation started after

50 h and reached 8.5 ODU/ml at the end of fermentation.

The specific production rate of red pigment (pOD) continuously increased and reached 0.1 ODU/g.h. Growth of

M. purpureus on glucose, showed that red pigment formation was not coupled to the glucose consumption but to

ethanol consumption. The pH increases continuously

during red pigment formation and reached 6.6 at the end

of culture. Red water-soluble Monascus pigment is unstable at acidic pH [10].

With ethanol as sole carbon source, ethanol consumption, biomass and red pigment formation progressed simultaneously (Figs. 5 and 6). The specific consumption

rates of ethanol (qE) were 0.2 g/g.h for the first 50 h but

only 0.1 g/g.h during red pigment production. The specific

growth rate on ethanol ranged from 0.01 to 0.06 h1 during

50 h, whereas the mean specific growth rate during red

pigment formation averaged 0.015 h1. The biomass decrease was lesser than with glucose and started after 100 h

of culture. The red pigment formation began after 50 h

and reached 7.8 ODU/ml at the end of fermentation. The Fig. 6. Time courses of l (), qE (m) and pOD (j) during Monascus

specific production rate of red pigment (pOD) continuously purpureus growth on ethanol in fermentor

increased and reached 0.05 ODU/g.h. In contrast to the

fermentations with glucose, the pH increased but gave a

decrease after each addition of ethanol. Higher citric,

malic, succinic and acetic acids concentrations were produced with ethanol fermentation than with glucose fermentation (Fig. 7).

The growth of M. purpureus on glucose and on ethanol

are summarized in Table 2. Glucose is more suitable for

red pigment production than ethanol, but ethanol can be

Fig. 7. Time courses of citric acid (j), malic acid (r), succinic acid

(h) and acetic acid (m) during Monascus purpureus growth on

glucose (above) and on ethanol (below) in fermentor

Fig. 5. Time courses of ethanol (m), biomass (), red pigment (j)

and pH () during Monascus purpureus growth on ethanol in

fermentor

supplemented after exhaustion of ethanol initially synthetized from glucose. The specific consumption rate of

glucose (qG) was higher than the specific consumption rate

of ethanol (qE) during the growth step. The biomass from

glucose was more favorable to red pigment formation than

that obtained from ethanol. In both fermentations, the

pigments were formed from the ethanol. The specific

production rate of red pigment (pOD) and the yields

(YOD/E) obtained with fermentation of glucose was twice of

M. Hamdi et al.: Production of MonascusI red pigment

Table 2. Growth characteristics of M. purpureus on glucose and on ethanol

Growth characteristics

Glucose

Ethanol

Specific consumption of glucose qG (g/g.h)

Specific consumption of ethanol qE (g/g.h)

Maximum specific growth rate l (h1)

Specific production rate of ethanol pE (g/g.h)

Maximum specific production rate of pigments pOD (ODU/g.h)

Yield of biomass on substrate Yx/s (g/g)

Yield of red pigment on ethanol YOD/s (ODU/g)

0.10.3

0.050.08

0.04

0.05 -0.08

0.1

0.15*

0.81.1

0.10.2

0.06

0.05

0.3

0.50.7

*depending of the partial oxygen pressure during fermentation

79

that obtained with ethanol fermentation, though the spe- References

cific consumption of ethanol was higher with fermentation 1. Lin, C.F. 1973.: Isolation and cultural conditions of Monascus sp.

for the production of pigment in submerged culture. J. Ferment.

using ethanol as carbohydrate source (Table 2) probably

Technol., 51: 407414

because the higher organic acids accumulated with ethanol

2. Carels, M.; Shepherd, D. 1979: The effect of changes in pH on

(Fig. 7). The modification in the metabolites formation

phosphates and potassium uptake by Monascus rubiginosus ATCC

seems to be caused by the morphological type of myce16367 in submerged shaken culture. Can. J. Microbiol. 25: 1484

lium. In fact, the fungal hyphae extended and ramified to

1488

give smooth pellets with glucose while it gave filamentous 3. Broder, C.U.; Shepherd, D. 1980: Pigment production by Monascus

purpureus with regard to quality and quantity. J. Food Science,

suspension with ethanol.

45: 567569

A new process is under design based on glucose

4. Lin, T.F.; Demain, A.L. 1991: Effect of nutrition of Monascus sp. on

(carbohydrates) as the initial carbon source, and subof red pigment. Appl. Microbiol. Biotechnol., 36: 7075

sequent controlled ethanol addition for production of red 5. formation

Fabre, C.E.; Santerre, A.L.; Loret, M.O.; Baberian, R.; Pareilleux,

pigment.

A.; Goma G.; Blanc, P.J. 1993.: Production and food applications of

the red pigment of Monascus ruber. J. Food Science, 58: 10991110

6. Braun, S.; Vecht-Lifshitz, S.E. 1991: Mycelial morphology and

metabolite production. Tibtech. 9: 6368

7. Johns, M.; Stuart, D.M. 1991: Production of pigment by Monascus

purporeus solid culture. J. Industrial Microbiol. 2328

8. Mak, N.K.; Fong, W.F.; Wong-Leung, Y.L. 1990: Improved fermentative production of Monascus pigment in roller bottle culture.

Enzyme Microbiol Technol. 12: 965968

9. Hamdi, M.; Blanc, P.J.; Goma, G.: Effect of aeration conditions on

the production of red pigments by Monascus purpureus growth on

prickly pear juice. Process Biochem 31 (6): 543547

10. Wong, H.; Koehler, P.E. 1983: Production of red water-soluble

Monascus pigment. J. Food Science, 48: 12001203

You might also like

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Carbohydrates Identification 10th GradeDocument5 pagesCarbohydrates Identification 10th GradeAndres Felipe MarroquinNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Unsaturated Polyester CuringDocument4 pagesUnsaturated Polyester Curingbehzadl98100% (1)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Cara Perhitungan PDCAASDocument5 pagesCara Perhitungan PDCAASDenny Trisetyo0% (1)

- Stock Actualizado Mayuli Al 10-09-2022Document36 pagesStock Actualizado Mayuli Al 10-09-2022Jade Rosangel SbNo ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Experiment 1: Isolation of Casein, Hydrolysis and NeutralizationDocument7 pagesExperiment 1: Isolation of Casein, Hydrolysis and NeutralizationNhess EstradaNo ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Catalogue Rosachim Ver 01.2020Document14 pagesCatalogue Rosachim Ver 01.2020mohammed amineNo ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- FR2-Isolation of Proteins and Color ReactionDocument4 pagesFR2-Isolation of Proteins and Color ReactionKriziaoumo P. OrpiaNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- TPCHWG Compositionvol2Document114 pagesTPCHWG Compositionvol2sgutierNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Enzyme HandbookDocument1,037 pagesEnzyme HandbookLe Dinh NamNo ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Thin Layer Chromatography by Merck MiliporeDocument34 pagesThin Layer Chromatography by Merck MiliporewinaNo ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Why Is Dark Chocolate HealthyDocument1 pageWhy Is Dark Chocolate HealthyAnderson HassanNo ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Resistance Guide For Kimberly Clark Nitrile GlovesDocument4 pagesResistance Guide For Kimberly Clark Nitrile GlovesandysamgarciaNo ratings yet

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Scalping of Flavors in Packaged FoodsDocument19 pagesScalping of Flavors in Packaged FoodsLuidy Alfonso RodríguezNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- News Letter of ArmarcDocument8 pagesNews Letter of Armarcprashantjha192124100% (2)

- Ami Database Price List October 2023Document4 pagesAmi Database Price List October 2023CM DubeyNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- CH 19 Aldehydes and Ketones Chemistry 2nd Year FbiseDocument17 pagesCH 19 Aldehydes and Ketones Chemistry 2nd Year FbiseSkiwordy MediaNo ratings yet

- Stereochemistry Problem Set 1) Indicate Whether The Following Structures AreDocument1 pageStereochemistry Problem Set 1) Indicate Whether The Following Structures ArekevinamyNo ratings yet

- Some of The Physical and Mechanical Properties of Composites Made From Tetra Pak™/LDPEDocument13 pagesSome of The Physical and Mechanical Properties of Composites Made From Tetra Pak™/LDPEhectoriturbeNo ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Effects of Minor Constituents On Cold Flow Properties and PerformanceDocument9 pagesEffects of Minor Constituents On Cold Flow Properties and PerformanceNestor Armando Marin SolanoNo ratings yet

- Module 1 - Clinical BacteDocument3 pagesModule 1 - Clinical BacteElyssa VergaraNo ratings yet

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Role of Microbes in Sustainable DevelopmentDocument14 pagesRole of Microbes in Sustainable DevelopmentRaj K.No ratings yet

- Steric Effects Ligands Organometallic Chemistry Homogeneous CatalysisDocument36 pagesSteric Effects Ligands Organometallic Chemistry Homogeneous CatalysisSuprotim KoleyNo ratings yet

- Economic Importance of Fungi & ParasexualityDocument11 pagesEconomic Importance of Fungi & ParasexualityMonish SaikiaNo ratings yet

- Green Synthesis of Biolubricant Base Stock From Canola OilDocument6 pagesGreen Synthesis of Biolubricant Base Stock From Canola OilkuramakurniaNo ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Chem Review 2022Document14 pagesChem Review 2022SangvenkatNo ratings yet

- Study On Manures and FertilizersDocument7 pagesStudy On Manures and Fertilizersgenerlacc21No ratings yet

- Tds-Mactex N AsiaDocument1 pageTds-Mactex N Asiasundra0100% (1)

- Green Polymer Chemistry Biobased Materials and BiocatalysisDocument471 pagesGreen Polymer Chemistry Biobased Materials and BiocatalysisGorginNo ratings yet

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- POLYMERS - ApplicationDocument54 pagesPOLYMERS - ApplicationkavineshpraneetaNo ratings yet

- Ballestra MAZZONIDocument30 pagesBallestra MAZZONIHassan HaiderNo ratings yet

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)