Professional Documents

Culture Documents

Methanol Manufacturing Process

Uploaded by

Ghulam Abbas0 ratings0% found this document useful (0 votes)

4 views2 pagesA Helping Docment for ethanol Production

Original Title

Methanol Manufacturing Process.docx

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentA Helping Docment for ethanol Production

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

4 views2 pagesMethanol Manufacturing Process

Uploaded by

Ghulam AbbasA Helping Docment for ethanol Production

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You are on page 1of 2

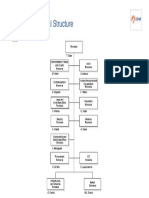

Methanol Manufacturing Process

Lurgi Methanol Process

http://www.lurgi.com/website/fileadmin/user_upload/1_PDF/1_Broshures_Flyer/englisch/0312e_MegaMethan

ol.pdf

Isothermal Reactor

Carbon Monoxide, Carbon Dioxide, and Hydrogen are converted to Methanol at

temperatures at about 500 F and pressures around 1000 psig in the presence of a copper

based catalyst according to:

Oxygen blown synthesis gas production combination with steam reforming or as

pure autothermal reforming

Autothermal reforming is used when light natural gas is used as feedstock

o Two step methanol synthesis in water and gas cooled reactors

o Hydrogen recovery

Synthesis gas production

o To generate optimum synthesis gas:

o

Vertical shell and tube heat exchanger

Catalyst is in tubes and rests on a bed of inert material

Steam pressure control permits exact control of reaction temperature

Achieves high yields at low recycle ratios and minimizes by product production

The water cooled reactor prolongs the catalyst life

Crude MeOH is purified in a distillation column

o 3 Column arrangement, 1st operates at an elevated pressure, 2nd operates at

atmospheric pressure.

End of 2009 Lurgi, received 10 contracts for the MegaMethanol plant with capacities of

0.67 to 2.3 million tons/ year.

http://books.google.com/books?id=Qdnc7uKaH8C&pg=PA15&lpg=PA15&dq=ICI+low+pressure+methanol+process&source=bl&ots=tTNAgC

knvt&sig=PW_lNWSq4IzfevoR2UDMSBfoI9A&hl=en&ei=NT5OTZvvG4n2gAfyqtFC&sa=X&oi=book

_result&ct=result&resnum=6&ved=0CEMQ6AEwBQ#v=onepage&q=ICI%20low%20pressure

%20methanol%20process&f=false Google Book: Methanol Synthesis Technology

-

Synthesis reactor operates at temperatures of 250F to 260F and pressure of 50 to 60 bar.

Shell and tube reactor where tubes are packed with a catalyst and heat of reaction is

removed by circulating water on the shell side.

The reactor is also a high pressure steam generator

Feedstock is naphtha, hydrocarbons, methane, gaseous hydrocarbons

Synthesis gas is generated by steam reforming or partial oxidation

o Steam reformer: 850-860C, where desulfurized naphtha and steam produce

Hydrogen and Carbon Oxides. The syngas is compressed at 50-80 bar and fed to

reactor

Atlas Methanol Production Plant, Point Lisa, Trinidad and Tobago

http://www.chemicals-technology.com/projects/atlas_methanol/

Project cost $400million

MegaMethanol from Lurgi, Built next to an existing plant

Methanol production process: oxygen synthesis gas reforming, 2 step Lugi methanol

synthesis and hydrogen recycle

Allows for the production of 5000 ton/day.

Stainless steel pipes, electrical installation

ICI ( Imperial Chemical Industries) Low Pressure Methanol Synthesis Process

http://books.google.com/books?id=Qdnc7uKaH8C&pg=PA15&lpg=PA15&dq=ICI+low+pressure+methanol+process&source=bl&ots=tTNAgC

knvt&sig=PW_lNWSq4IzfevoR2UDMSBfoI9A&hl=en&ei=NT5OTZvvG4n2gAfyqtFC&sa=X&oi=book

_result&ct=result&resnum=6&ved=0CEMQ6AEwBQ#v=onepage&q=ICI%20low%20pressure

%20methanol%20process&f=false Google Book: Methanol Synthesis Technology

-

Low pressure methanol was developed by ICI in the late 1960s

A widely used catalyst is a mixture of Copper, Zinc Oxide, and Alumina used by ICI in 1966

1st ICI unit produced 300 tons of refined methanol per day

o Had a syngas feed containing H2, CO, CO2, CH4

o Shaft converter adjusted the CO to CO2 ratio

o Feed compressed to 50 atm in centrifugal compressor and fed to quench type

converter at 270F

o Product was cooled and methanol was condensed out

o Purge gas stream was recycled to a reformer to convert accumulated methanol into

synthesis gas

o Low pressure operation meant lower methanol concentration therefore higher

recycle rates

o The crude methanol that was produced by the low pressure process contained

water, dimethyl ether, esters, ketones, iron carbonyls, and higher alcohols.

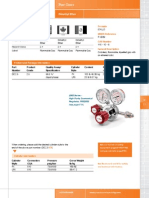

Linde Isothermal Reactor

http://www.lindeengineering.com/en/process_plants/hydrogen_and_synthesis_gas_plants/gas_products/met

hanol/index.html#

Fixed bed reactor cooled by coiled pipes and catalyst is cooled and maintained at

Optimum Temp. by steam production

Uses the ICI methanol technology

Process for the synthesis of a Methanol and DME Mixture from Synthesis Gas

http://www.freepatentsonline.com/6191175.pdf

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (589)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (842)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5806)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Alloy A286 Ams 5731 Ams 5732 Ams 5737Document2 pagesAlloy A286 Ams 5731 Ams 5732 Ams 5737gowtham raju buttiNo ratings yet

- Sterilization Disinfection OtDocument45 pagesSterilization Disinfection OtAnnie Kathreen33% (3)

- Biochemistry - An Organic Chemistry ApproachDocument399 pagesBiochemistry - An Organic Chemistry Approachmuddassar nazar100% (1)

- Syngas 2MeOHDocument10 pagesSyngas 2MeOHDaniil GhilescuNo ratings yet

- Petroleum Chemistry and Its Refineries05Document21 pagesPetroleum Chemistry and Its Refineries05Louis ThianNo ratings yet

- Inorganic Organic CoatingsDocument9 pagesInorganic Organic Coatingstocamdinhvu100% (1)

- Technical Specifications 500 LPH: Design BasisDocument8 pagesTechnical Specifications 500 LPH: Design Basishanif panja0% (1)

- Dimethyl Ether SDS E4589Document7 pagesDimethyl Ether SDS E4589Daniil GhilescuNo ratings yet

- Structura Organizatorica 2015Document1 pageStructura Organizatorica 2015Daniil GhilescuNo ratings yet

- 11-4374 AGC Webinar QA UpdatedDocument3 pages11-4374 AGC Webinar QA UpdatedDaniil GhilescuNo ratings yet

- Work OverDocument3 pagesWork OverDaniil GhilescuNo ratings yet

- AzeotropeDocument5 pagesAzeotropeDaniil GhilescuNo ratings yet

- Imagini VirusuriDocument3 pagesImagini VirusuriDaniil GhilescuNo ratings yet

- Dimethyl Ether CH32O Spec Sheet SS P4589Document1 pageDimethyl Ether CH32O Spec Sheet SS P4589Daniil GhilescuNo ratings yet

- The Effect of Sea Water On Compressive Strength of Concrete: August 2014Document10 pagesThe Effect of Sea Water On Compressive Strength of Concrete: August 2014Mohd FaizalNo ratings yet

- Monolithic Cells For Solar FuelsDocument20 pagesMonolithic Cells For Solar FuelsAmalia Rizki FauziahNo ratings yet

- 5754 Aluminum CircleDocument2 pages5754 Aluminum Circlewei huaNo ratings yet

- Introduction To Composite Materials SlidesDocument343 pagesIntroduction To Composite Materials SlideseduserenzaNo ratings yet

- GL, Materiales para Buques PDFDocument46 pagesGL, Materiales para Buques PDFCesar Quich PalNo ratings yet

- HiTEC-4313 PDSDocument2 pagesHiTEC-4313 PDSSong Hum KangNo ratings yet

- Aluminum in Water: Standard Test Method ForDocument6 pagesAluminum in Water: Standard Test Method Forastewayb_964354182No ratings yet

- The Carbon FamilyDocument26 pagesThe Carbon Familygautambadgujar30No ratings yet

- Chemistry Project Term 2 Drohan Chakraborty 12 L (A)Document13 pagesChemistry Project Term 2 Drohan Chakraborty 12 L (A)ShreyasiNo ratings yet

- CarboanionDocument23 pagesCarboanionrajendraNo ratings yet

- TDS - Total - Lubrilam S 31 L - R1W - 201412 - enDocument1 pageTDS - Total - Lubrilam S 31 L - R1W - 201412 - enVelibor Karanovic100% (1)

- The Main Postulates of Dalton's Atomic Theory AreDocument6 pagesThe Main Postulates of Dalton's Atomic Theory ArePriyanshu PalNo ratings yet

- Product Data Sheet For Sakaphen Si 14EG - 20231025Document1 pageProduct Data Sheet For Sakaphen Si 14EG - 20231025이선엽No ratings yet

- SurTec Technical Letter 4 - Service Life Extension of Trivalent Chromium Based Passivations For ZincDocument7 pagesSurTec Technical Letter 4 - Service Life Extension of Trivalent Chromium Based Passivations For ZincS P KNo ratings yet

- Solutions - AIATS JEE (Main) - 2019 (XII Studying & Passed) - Mock Test-3 - (Code-A & B) - (24-03-2019)Document22 pagesSolutions - AIATS JEE (Main) - 2019 (XII Studying & Passed) - Mock Test-3 - (Code-A & B) - (24-03-2019)Soma GhoshNo ratings yet

- IndustrialCoatings Selection GuideDocument56 pagesIndustrialCoatings Selection GuideAllen KamNo ratings yet

- Chemistry An Introduction To General Organic and Biological Chemistry 13Th Edition Timberlake Test Bank Full Chapter PDFDocument36 pagesChemistry An Introduction To General Organic and Biological Chemistry 13Th Edition Timberlake Test Bank Full Chapter PDFdolores.cook959100% (12)

- Omala s4 GXV 220Document2 pagesOmala s4 GXV 220Igreja CCMVNo ratings yet

- 2023 - Wolfersdorff Consulting Berlin - ETRA 2023Document14 pages2023 - Wolfersdorff Consulting Berlin - ETRA 2023Wolfersdorff Consulting Berlin Martin von Wolfersdorff Burchardstr. 25 12103 Berlin GermanyNo ratings yet

- Ammonia Solubility in SaltsDocument1 pageAmmonia Solubility in Saltsivan estevesNo ratings yet

- Buffer System: Danica Alyssa C. Cruz, RMTDocument27 pagesBuffer System: Danica Alyssa C. Cruz, RMTDanica Alyssa CruzNo ratings yet

- AVE General 2015Document398 pagesAVE General 2015Diego RodriguezNo ratings yet

- Chapter 1Document74 pagesChapter 1Sasmilah KandsamyNo ratings yet

- 316L Stainless Steel Technical Data SheetDocument3 pages316L Stainless Steel Technical Data Sheetchris calonzoNo ratings yet