Professional Documents

Culture Documents

Foxboro E69P (Valve Positioner)

Uploaded by

Rumpun GiggsCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Foxboro E69P (Valve Positioner)

Uploaded by

Rumpun GiggsCopyright:

Available Formats

MI 018-440

Instruction

January 1985

E69P Current-to-Pneumatic

Valve Positioner

! DANGER

This valve positioner may have agency certification for installation in hazardous

locations or for intrinsic safety. Use of the valve positioner in atmospheres for which it

has not been certified can cause an explosion resulting in death or injury. Refer to

label affixed to the valve positioner for type of certification and observe applicable

wiring practices. For conditions of certification, see Table 1, Product Safety

Specifications.

Introduction

General Description

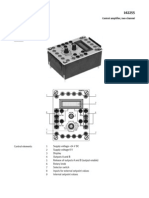

The E69P Current-to-Pneumatic Valve Positioner (Figure 1) is a yoke-mounted instrument that

converts a dc milliampere input signal to a pneumatic output. The output is calibrated for a specific valve stroke rather than for a pneumatic output signal. The positioner will deliver all the air

required, limited to its supply pressure, to reposition the valve stem to satisfy a given input.

When the positioner is shipped on a valve yoke, it is calibrated for the proper action and stroke.

When shipped separately, it is calibrated for increase-increase air-to-raise action, and for a stroke

of approximately 25 mm (1 in) when used with a P50 Actuator. Recalibration will be required if

not used in the above mode.

Principle of Operation

A milliampere dc input signal is converted to a proportional valve stem position in the following

manner (see Figure 2):

A coil, positioned in the field of a permanent magnet, exerts a tangential thrust proportional to

the direct current input signal flowing through it. This thrust moves the flapper with respect to

the nozzle thereby changing the air output pressure of a pneumatic relay. The output pressure is

applied to the pneumatic actuator which moves the valve stem. The motion of the valve stem is

fed back to the nozzle by a direct mechanical linkage, producing a throttling relationship between

the flapper and the nozzle.

A Siebe Group Company

MI 018-440 January 1985

Introduction

Figure 1.

Figure 2.

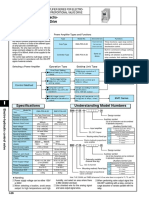

Standard Specifications

Input and Output Ranges

Input

(mA)

4 to 20(1)

or

10 to 50(2)

(1)

4 to 12 or 12 to 20 mA

to 30 or 30 to 50 mA

(2)10

NOTE

Output

kPa

psi

5 to 240

5 to 420

1 to 35

1 to 60

To get these inputs, merely recalibrate

positioner.

Ranges are listed in kPa and psi. For alternative ranges in kg/cm2 or bar, divide

applicable kPa values by 100.

Introduction

MI 018-440 January 1985

Input Resistance

4 to 20 mA input: 170

10 to 50 mA input: 27

Approximate Mass

2.3 kg (5 lb)

Air Consumption

With 140 kPa (20 psi) supply pressure:

1.3 m3/h (0.75 cfm) at standard conditions

With all other supply pressures:

1.7 m3/h (1.0 cfm) at standard conditions

Mounting

Vertical on valve yoke

Ambient Temperature Limits

Normal Operating Conditions:

-30 and +60C (-20 and +140F)

Operative Limits:

-40 and +80C (-40 and +180F)

Supply Pressure

Nominal

140 kPa (20 psi)

240 kPa (35 psi)

415 kPa (60 psi)

Limits

130 and 160 kPa

(19 and 23 psi)

225 and 260 kPa

(33 and 38 psi)

400 and 435 kPa

(58 and 63 psi)

Also, supply pressure must be a minimum of 20 kPa or 3 psi above maximum output

signal.

Product Safety

For electrical classification of valve positioner, refer to data plate. For conditions of certification,

refer to Table 1.

MI 018-440 January 1985

Introduction

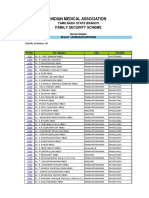

Table 1. Product Safety Specifications

Testing Laboratory, Types of Protection,

and Area Classification

Conditions of Certification

BASEEFA certified intrinsically safe (Ex) ia 4 to 20 mA input only. Power source must

for IIC, Zone 0 or IIC, Zone 1.

be intrinsically safe and must not exceed

35 V or 0.66 W. Temperature Class T6.

BASEEFA certified nonincendive Ex n for 4 to 20 mA input only. Power source must

IIC, Zone 2.

not exceed 75 V dc or 35 mA.

Temperature Class T6.

CSA certified intrinsically safe for Class I, 4 to 20 mA input only. Connect per

Groups A, B, C, and D, Division 1.

TI 005-105. Temperature Class T6.

CSA certified explosionproof for Class I, 4 to 20 and 10 to 50 mA input.

Group D, Division 1, Class II, Groups E, Temperature Class T6. E69P-T only.

F, and G, Division 1, and Class III.

CSA certified nonincendive for Class I,

Groups A, B, C, and D, Division 2.

CSA certified nonincendive for Class I,

4 to 20 and 10 to 50 mA input.

Groups A, B, C, and D, Division 2.

Temperature Class T6. E69P-B only.

FM certified intrinsically safe for Class I, 4 to 20 mA input only. Connect per

Groups A, B, C, and D, Division 1 and

TI 005-101. Temperature Class T6.

Class II, Groups E and G, Division 1.

FM certified intrinsically safe for Class I, 4 to 20 mA input only. Connect to

Groups C and D, Division 1 and Class II, Honeywell Class 38 Barrier. Refer to

Groups E and G, Division 1.

TI 005-101 for Barrier types and groups.

FM certified intrinsically safe for Class I, Temperature Class T6.

Groups A, B, C, and D, Division 1 and

Class II, Groups E and G, Division 1.

4 to 20 and 10 to 50 mA input.

FM certified explosionproof for Class I,

Groups C and D, Division 1 and Class II, Temperature Class T6. E69P-T only.

Groups E and G, Division 1.

FM certified nonincendive for Class I,

Groups A, B, C, and D, Division 2 and

Class II, Group G, Division 2.

FM certified nonincendive for Class I,

4 to 20 and 10 to 50 mA input.

Groups A, B, C, and D, Division 2 and

Temperature Class T6. E69P-B only.

Class II, Group G, Division 2.

LCIE certified flameproof EEx d for IIB, 4 to 20 mA and 10 to 50 mA input.

Zone 1 (CENELEC).

Temperature Class T6. E69P-T only.

PTB certified intrinsically safe (EEx) ib for 4 to 20 mA input only. Connect to

IIC, Zone 1 (CENELEC).

intrinsically safe circuit with a maximum

current of 90 mA. Temperature Class T6.

Elec. Class.

Code

CS-E/BA-A

CS-E/BN-A

CS-E/CB-A

CS-E/CD-A

CS-E/CN-A

CS-E/FB-A

CS-E/FB-H

CS-E/FD-A

CS-E/FN-A

CS-E/LD-E

CS-E/PB-E

Installation

MI 018-440 January 1985

Table 1. Product Safety Specifications (Continued)

Testing Laboratory, Types of Protection,

Elec. Class.

and Area Classification

Conditions of Certification

Code

SAA certified intrinsically safe (Ex) is for 4 to 20 mA input only. Connect per

CS-E/AA-A

IIC, Zone 0.

drawing 15001EZ, 15001FA, 15001FB,

15001FC, or 15001FM. Temperature

Class T6.

S-COMM (Yugoslavia) certified

4 to 20 mA input only. Connect to SCS-E/YB-A

intrinsically safe (Sib) for IIC, Zone 1.

COMMISSION certified apparatus with a

short circuit current of 90 mA maximum.

Temperature Class T6.

Installation

Dimensions

Refer to Dimensional Print DP 018-440 for positioner dimensions and installation data.

Mounting Positioner on Valve Yoke

Before mounting the positioner, check that the positioner action (specified in sales order) is compatible with the valve actuator action. If necessary, reverse the positioner output (see Reversing

Positioner Output procedure). Mounting details are shown in Figure 3.

NOTE

Positioner is shipped with all mounting hardware.

Figure 3.

! CAUTION

In normal fail-safe action, an increasing input produces an increasing output and

opens the valve. Thus the valve closes on failure of current input or air supply. Proper

action for the specific application must be determined in each case.

MI 018-440 January 1985

Installation

Connecting Positioner to Valve Stem

Depending on valve and actuator used, actuating pin and connection arrangement may vary.

Check that linkage is not obstructed during full stroke of valve. For connection details, see

Figure 4.

Figure 4.

Installation Piping and Wiring

Installation piping and wiring are shown in Figure 5. After the positioner is completely installed

on the valve, it must be calibrated to the valve stroke before being put into operation.

Figure 5.

Calibration

MI 018-440 January 1985

Calibration

For simplicity, the procedure below assumes a valve positioner with a 4 to 20 mA input and a

20 to 100 kPa or 3 to 15 psi output. For other ranges, substitute the applicable values. The specific input and output are listed on the data plate.

Equipment Set-up

Calibration set-up is shown in Figure 6.

NOTE

Accuracy is dependent on accuracy of milliammeter. For 0.5% accuracy use DVM

across a 100 precision resistor in place of milliammeter.

Visual Check

1. Determine if the positioner motor and span pivot assembly (shown in Figure 7) are in

the correct mode of operation per the table below for actuator action desired.

Actuator Action Span Pivot Assembly

Air-to-Raise

Air-to-Lower

Motor

INC-INC

INC-DEC

INC-INC

Air-to-Lower Position

INC-DEC

Air-to-Raise Position

2. If necessary, correct position of motor by referring to Reversing Positioner Output

section.

3. If necessary, correct span pivot position by turning span screw (shown in Figure 7)

clockwise for air-to-lower position and counterclockwise for air-to-raise position.

Alignment Procedure

1. Remove output line and set up equipment as shown in Figure 6.

2. Apply midrange signal input.

3. See Figure 8. Pinch nozzle tubing to drive actuator beyond mid-stroke position. Close

shutoff valve. Bleed air from actuator until stem is at 50%.

NOTE

Circuit and/or actuator may leak slightly. Occasionally check stem position to be

certain stem remains at 50%.

4. Loosen lever clamp screw.

5. Adjust stem nuts (see Figure 8) so that lever is at right angle (90) to stem (as close as

possible).

6. Slowly rotate span pivot assembly (connector shaft) until output pressure is 34 to

90 kPa or 5 to 13 psi. Tighten lever clamp screw.

MI 018-440 January 1985

Calibration

7. Open shutoff valve (stem should not move appreciably) and proceed to Calibration

Procedure .

Figure 6.

NOTE

If pivot assembly was not repositioned (air-to-lower) and this is first time

installation, positioner is now set to the factory calibration (air-to-raise, 25 mm

(1 in) stroke on a P50 Actuator). Pivot assembly should be approximately parallel to

axis of lever.

Calibration

MI 018-440 January 1985

Figure 7.

MI 018-440 January 1985

Calibration

Figure 8.

Calibration Procedure

NOTE

Due to the interaction of zero and span screw adjustments at 0 and 100%, it is

advisable to always re-zero at 50% input prior to checking results of span

adjustments.

1. Apply 50% input to positioner.

2. Adjust coarse and/or fine zero screw so that stem reading is at mid-stroke position. See

Figure 9.

10

Calibration

MI 018-440 January 1985

Figure 9.

3. Apply 0 and 100% input to positioner and note stem positions.

4. If stem positions are not 0 and 100% respectively, adjust span screw per span table.

NOTE

One revolution of span screw influences the stroke by approximately 10%.

Span Table

Actuator

Action

Span Screw

Adj.

Result

Air to Lower Stem

Inc. Stroke

Dec. Stroke

Air to Raise Stem

Dec. Stroke

Inc. Stroke

5. Apply 50% input. If stem is not at mid-stroke, turn zero screw to reposition stem to

50% of travel and check results of previous stroke adjustment. Repeat Steps 3, 4, and

5 if necessary until stroke is correct. Roller must remain in contact with nozzle

assembly arm throughout entire stroke.

Alignment Check

1. Apply approximately 10% input. Close shutoff valve.

2. Change input by 5% in direction to increase output pressure. Output pressure should

increase to within 15 kPa or 4 psi of supply pressure. If not, check that nozzle axis is at

right angle (90) to flapper at 50% input. See Figure 10.

11

MI 018-440 January 1985

Maintenance

Use coarse and fine zero adjustments to achieve right angle (90).

Figure 10.

3. Apply approximately 90% input, close shutoff valve and repeat Step 2.

Maintenance

Relay Maintenance

Relay Removal

Refer to Figure 11. Remove the two large screws and pry off relay. A gasket is supplied with each

replacement relay.

For servicing details, see Instruction MI 011-493 (Model 40G) or MI 011-491 (Model 40D).

! WARNING

If positioner is equipped with explosionproof cover, two flame arresters are present.

Arresters must remain in place for explosionproof protection.

Cleaning Restrictor

Remove relay. See Relay Removal procedure.

Clean restrictor by inserting a 0.1 mm (0.005 in) diameter wire (or Foxboro cleaning wire, Part

No. 0042527) through orifice.

12

Maintenance

MI 018-440 January 1985

Figure 11.

Positioner Modifications

NOTE

Foxboro does not consider the following modifications a field conversion. They are

considered factory modifications due to the complexity of the procedures and the

large amount of time required to perform them. If the modifications must be made

in the field, use the following procedures and contact Foxboro for additional

assistance.

Reversing Positioner Output

The existing action of the positioner is indicated by the marking on the exposed top of motor:

INC-INC (increasing input produces an increasing output), or INC-DEC (increasing input produces a decreasing output). When reinstalling the motor (Step 7), the exposed marking on the

motor must indicate the new positioner action.

This procedure is not required when changing actuator action. To reverse actuator action, refer to

Reversing Actuator Action procedure.

1. Remove positioner from valve.

a. Disconnect input wiring and air piping.

b. Loosen clamp screw at linkage.

c. Remove two bolts holding positioner to valve yoke.

2. Remove the two feedback assembly mounting screws (Figure 12). Disconnect tubing

from connection at case.

Carefully lift out feedback assembly (do not damage nozzle). Spring on bottom of case

will be exposed.

3. Unhook spring from motor bracket.

4. Remove two screws and lift off motor pivot plate (Figure 12).

13

MI 018-440 January 1985

Maintenance

Figure 12.

5. Lift out motor. Note wire routing.

Carefully lift flapper (see Figure 13) straight up from flapper arm on motor. Do not

deform flapper. Holding onto flapper arm on other end of motor while removing will

prevent internal motor flexure deformation.

Figure 13.

6. Remove two screws holding bracket to bottom of motor.

Invert motor and reinstall bracket (on side that was formerly on top).

7. Wind excess wire clockwise around motor and carefully place motor into position in

case assuring that bottom tab is in cavity provided. Make sure that wires will not

interfere with moving parts and pivot is in hole at bottom of motor.

NOTE

Marking on top of motor must indicate new positioner action.

14

Maintenance

MI 018-440 January 1985

8. Reinstall motor pivot plate. Tighten bolts uniformly. Reconnect spring on motor

bracket. Reinstall flapper on flapper arm, maintaining gap as shown. Do not apply

excessive force to arm.

! CAUTION

Flapper contains damping material as shown in Figure 14. If damping material is

removed, positioner will operate erratically.

GAP

Figure 14.

9. Turn fine zero screw fully counterclockwise. Turn span screw so that brass block is

approximately centered on screw on span assembly.

10. Reinstall feedback assembly. Do not tighten mounting screws. Make sure that tubing

is not kinked.

11. To position feedback assembly:

Place thumb on span assembly and forefinger on surface A (Figure 15) near

mounting screw. Gently squeeze fingers together to achieve 90 angle as shown.

Check to make sure span assembly is perpendicular to base of positioner casting.

Tighten feedback assembly mounting screws.

Figure 15.

12. Turn fine zero screw six turns clockwise.

13. Reinstall positioner on valve.

14. Perform Alignment, Calibration, and Alignment Check procedures.

15

MI 018-440 January 1985

Maintenance

Reversing Actuator Action

If actuator action (air-to-lower or air-to-raise) is to be changed, reverse top of actuator (see actuator Instruction MI 012-235) and then calibrate the positioner.

Before calibrating positioner, make coarse span adjustment, as shown in Figure 16. (Turn span

screw to reposition span pivot to correct side of connector shaft center line for desired actuator

action.)

Illustration shows span adjustment positioned for air-to-raise action.

Figure 16.

The Foxboro Company

33 Commercial Street

Foxboro, MA 02035-2099

United States of America

http://www.foxboro.com

Inside U.S.: 1-888-FOXBORO

(1-888-369-2676)

Outside U.S.: Contact your

local Foxboro Representative.

Facsimile: (508) 549-4492

Foxboro is a registered trademark of The Foxboro Company.

Siebe is a registered trademark of Siebe, plc.

A Siebe Group Company

MB 100

Copyright 1985 by The Foxboro Company

All rights reserved

Printed in U.S.A

0185

You might also like

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2No ratings yet

- Belgas T2000EP IOMDocument4 pagesBelgas T2000EP IOMSMcNo ratings yet

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- Manual Posicionador Power GenexDocument2 pagesManual Posicionador Power Genexrexxxx987No ratings yet

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Rating: 2.5 out of 5 stars2.5/5 (3)

- Electro-Pneumatic Positioner EPL Series: Instruction ManualDocument8 pagesElectro-Pneumatic Positioner EPL Series: Instruction ManualSimbu ArasanNo ratings yet

- PNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGFrom EverandPNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGNo ratings yet

- T 1000 ManualDocument6 pagesT 1000 ManualCeleste PrantlNo ratings yet

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- Type 1000 Transducer Product Instructions: Principle of OperationDocument6 pagesType 1000 Transducer Product Instructions: Principle of OperationEdge-TecNo ratings yet

- Influence of System Parameters Using Fuse Protection of Regenerative DC DrivesFrom EverandInfluence of System Parameters Using Fuse Protection of Regenerative DC DrivesNo ratings yet

- Electro/Pneumatic Valve Positioners (P3300)Document6 pagesElectro/Pneumatic Valve Positioners (P3300)workt1meNo ratings yet

- Analog Circuit Design Volume 2: Immersion in the Black Art of Analog DesignFrom EverandAnalog Circuit Design Volume 2: Immersion in the Black Art of Analog DesignNo ratings yet

- Transductor FLOWSERVE NT3000Document20 pagesTransductor FLOWSERVE NT3000Xavier EspinozaNo ratings yet

- 110 Waveform Generator Projects for the Home ConstructorFrom Everand110 Waveform Generator Projects for the Home ConstructorRating: 4 out of 5 stars4/5 (1)

- T83840en PDFDocument6 pagesT83840en PDFshareyhou100% (1)

- Calibration Procedure For Digital Multimeter, An - psm-45 and (Simpson, Model 467) and Simpson, Model 467e - Tb-9-6625-2353-24Document15 pagesCalibration Procedure For Digital Multimeter, An - psm-45 and (Simpson, Model 467) and Simpson, Model 467e - Tb-9-6625-2353-24luroguitaNo ratings yet

- D Ape Av1234 - FDocument24 pagesD Ape Av1234 - FAngel FortuneNo ratings yet

- Arca Valve Manual - 830 POSITIONERDocument13 pagesArca Valve Manual - 830 POSITIONERAtul bhabad0% (1)

- Ca3140, Ca3140A: 4.5Mhz, Bimos Operational Amplifier With Mosfet Input/Bipolar Output FeaturesDocument19 pagesCa3140, Ca3140A: 4.5Mhz, Bimos Operational Amplifier With Mosfet Input/Bipolar Output FeaturesRicardo Teixeira de AbreuNo ratings yet

- Masoneilan 8012 8013 FactSheet 0612Document8 pagesMasoneilan 8012 8013 FactSheet 0612Omar ChaoukiNo ratings yet

- PositionerDocument13 pagesPositionerLeonidas PetrouNo ratings yet

- CA3140Document20 pagesCA3140Brzata PticaNo ratings yet

- 315 - SVP3000 Alphaplus S HART Protokolom PDFDocument12 pages315 - SVP3000 Alphaplus S HART Protokolom PDFJuan Carlos Nodner RiosNo ratings yet

- Sor Adjustable Dead Band Pressure SwitchDocument16 pagesSor Adjustable Dead Band Pressure SwitchAdam SamyNo ratings yet

- Manual Valvula Divisora Comb LiqDocument20 pagesManual Valvula Divisora Comb Liqdaniel triana palciosNo ratings yet

- Electro Pneumatic EN40Document5 pagesElectro Pneumatic EN40Harold David VillacísNo ratings yet

- 2.5V and 4.096V Voltage References: Features DescriptionDocument20 pages2.5V and 4.096V Voltage References: Features Descriptionikaro181083No ratings yet

- SFA350 :: ROAL Living EnergyDocument6 pagesSFA350 :: ROAL Living EnergyroalscribdNo ratings yet

- Admiral TKF3400A (Manual)Document24 pagesAdmiral TKF3400A (Manual)crisarg_10No ratings yet

- Alpha 400 - 600Document6 pagesAlpha 400 - 600alain_coNo ratings yet

- Series 3730 Electropneumatic Positioner Type 3730-1: ApplicationDocument6 pagesSeries 3730 Electropneumatic Positioner Type 3730-1: ApplicationGuillermo A OMNo ratings yet

- AVR3AVR4IODocument12 pagesAVR3AVR4IOk ONo ratings yet

- MPX4115 (Sensor Presion)Document10 pagesMPX4115 (Sensor Presion)Ricardo Xavier Otazo LópezNo ratings yet

- RP10 e PDFDocument7 pagesRP10 e PDFTestronicpartsNo ratings yet

- Perkins P200Document4 pagesPerkins P200PaulusIwanNo ratings yet

- MPX5010Document16 pagesMPX5010Arsonval FleuryNo ratings yet

- LIPU - Valve PDFDocument71 pagesLIPU - Valve PDFLê Trung Kiên100% (1)

- Posicionador Neumatico Somas PDFDocument4 pagesPosicionador Neumatico Somas PDFJosé Manuel GonzálezNo ratings yet

- TV LG 21fu1rDocument16 pagesTV LG 21fu1rpurwants100% (1)

- Type 646 Electro-PneumaticDocument6 pagesType 646 Electro-PneumaticjplutodNo ratings yet

- MFA160 :: ROAL Living EnergyDocument5 pagesMFA160 :: ROAL Living EnergyroalscribdNo ratings yet

- PTN 78020 WDocument27 pagesPTN 78020 WabrrielNo ratings yet

- MPX5100Document17 pagesMPX5100Andri PaoNo ratings yet

- EJA530EDocument12 pagesEJA530ESourav Kumar GuptaNo ratings yet

- Datasheet MPX5100DPDocument16 pagesDatasheet MPX5100DPKemahyanto Exaudi SiahaanNo ratings yet

- Amplificador Proporcional FestoDocument6 pagesAmplificador Proporcional Festoal3xffNo ratings yet

- Manual Ep5 Spirax SarcoDocument2 pagesManual Ep5 Spirax SarcoWesley de Almeida75% (4)

- H1000e I Ema-Emc PDFDocument4 pagesH1000e I Ema-Emc PDFNguyen Van ChungNo ratings yet

- Atex 7700e-185977Document9 pagesAtex 7700e-185977Bright OkunkpolorNo ratings yet

- Valtek XL Series High Performance Positioner: For Control ValvesDocument8 pagesValtek XL Series High Performance Positioner: For Control ValvesRifadli GatesNo ratings yet

- D02601880 - Instruction ManualDocument2 pagesD02601880 - Instruction ManualAsyraf BadaruddinNo ratings yet

- Manual Servomex Xendos 1800Document20 pagesManual Servomex Xendos 1800Josh MoralesNo ratings yet

- 000 1 Ca3109Document20 pages000 1 Ca3109moongaboongaNo ratings yet

- 040shj60h8k5a4yex8yk4dhwa53y PDFDocument9 pages040shj60h8k5a4yex8yk4dhwa53y PDFRenivaldoNo ratings yet

- Fusing Equipment: Dual Sensing Bay-O-Net Fuse LinkDocument6 pagesFusing Equipment: Dual Sensing Bay-O-Net Fuse Linksaniya_mirza4No ratings yet

- 8Ch Darlington Sink Driver: TD62081 084AP/CP/F/AFDocument12 pages8Ch Darlington Sink Driver: TD62081 084AP/CP/F/AFFarley Vieira da SilvaNo ratings yet

- Micron TransformersDocument7 pagesMicron TransformersJedha YantiNo ratings yet

- SD 16 eDocument20 pagesSD 16 eseaqu3stNo ratings yet

- Top 221-227Document20 pagesTop 221-227Radu MălureanuNo ratings yet

- In-Service Training (Inset) : Theme: "Scan NHS Teachers' Empowerment Through RPMS!"Document8 pagesIn-Service Training (Inset) : Theme: "Scan NHS Teachers' Empowerment Through RPMS!"Bert RoseteNo ratings yet

- BS 230 ManualDocument12 pagesBS 230 ManualSm Bikash Kumar MohonNo ratings yet

- Weight Training and Fitness HandoutDocument10 pagesWeight Training and Fitness Handoutapi-234854471100% (1)

- Sol2e Int Progress Test 04bdoc 2Document6 pagesSol2e Int Progress Test 04bdoc 2Ella KnaislovaNo ratings yet

- FEARS Database-FDA Database of glp1 Disproportionate Adverse EventsDocument20 pagesFEARS Database-FDA Database of glp1 Disproportionate Adverse EventsW Antonio Rivera MartínezNo ratings yet

- Pcare Week 11 - First Aid (Handout)Document49 pagesPcare Week 11 - First Aid (Handout);'SiLeNt';No ratings yet

- Msds Flux Additve Sti Qatar GalDocument3 pagesMsds Flux Additve Sti Qatar GalRaj KumarNo ratings yet

- Mennekes EV SolutionsDocument20 pagesMennekes EV SolutionsCarlos Ozaeta González75% (4)

- TC533 SelectAutomationDocument1 pageTC533 SelectAutomationstephenhNo ratings yet

- Moscaya - P.T in R&WDocument4 pagesMoscaya - P.T in R&Wjosea marieNo ratings yet

- DC Power Supply Ps 305d ManualDocument2 pagesDC Power Supply Ps 305d ManualFebri - Rmd0% (2)

- Field Density Test by Sand Replacement MethodDocument6 pagesField Density Test by Sand Replacement MethodTharindu Hathurusinghe100% (1)

- Centrifugal Pump Final Lab ReportDocument14 pagesCentrifugal Pump Final Lab Reportcracking khalifNo ratings yet

- Us Dol Gina FaqsDocument5 pagesUs Dol Gina FaqsMolly DiBiancaNo ratings yet

- CPSC CH E1001 08Document6 pagesCPSC CH E1001 08ariane8910No ratings yet

- Play & Play TherapyDocument26 pagesPlay & Play TherapyTina Ann JohnNo ratings yet

- Testing of I C Engines VTUDocument31 pagesTesting of I C Engines VTUPolireddi Gopala KrishnaNo ratings yet

- The Mocha CakeDocument5 pagesThe Mocha CakeMariia100% (2)

- Radiation Safety: Presented by Mohammad Naeem Operation Theatre Technologist Lecturer GCUFDocument41 pagesRadiation Safety: Presented by Mohammad Naeem Operation Theatre Technologist Lecturer GCUFNaim50% (2)

- Pharmacognosy AssignmentDocument22 pagesPharmacognosy AssignmentJayed SadnanNo ratings yet

- DR List RamanathapuramDocument2 pagesDR List RamanathapuramIts My Place100% (1)

- Yomeishu Contains 14Document13 pagesYomeishu Contains 14Nguyễn ThuNo ratings yet

- Nicotin ADocument12 pagesNicotin ACristina OzarciucNo ratings yet

- Health Insurance For India's Missing Middle: Why in NewsDocument3 pagesHealth Insurance For India's Missing Middle: Why in NewsApaj SeekNo ratings yet

- Emergency Nursing Journal, 217-222Document2 pagesEmergency Nursing Journal, 217-222ChristineAlaNo ratings yet

- Pe 13: Badminton: Classification of Players Accoridng To LevelDocument3 pagesPe 13: Badminton: Classification of Players Accoridng To LevelJaztine CaoileNo ratings yet

- Ehs CSP 02, Procedureforehs (Sars) Rev.04, May151Document4 pagesEhs CSP 02, Procedureforehs (Sars) Rev.04, May151Luffy11100% (1)

- Ventilator Graphics: Scalars, Loops, & Secondary Measures: Amanda M Dexter and Kimberly ClarkDocument21 pagesVentilator Graphics: Scalars, Loops, & Secondary Measures: Amanda M Dexter and Kimberly ClarkarevNo ratings yet

- 10 CHCDIS002 Version 1 76352Document106 pages10 CHCDIS002 Version 1 76352Rajbir Kaur60% (5)

- List of All Manufacturers As On 31.8.2020Document25 pagesList of All Manufacturers As On 31.8.2020ankur mishra100% (2)

- The Ultimate Solar Power Design Guide Less Theory More PracticeFrom EverandThe Ultimate Solar Power Design Guide Less Theory More PracticeRating: 4.5 out of 5 stars4.5/5 (10)

- The Innovators: How a Group of Hackers, Geniuses, and Geeks Created the Digital RevolutionFrom EverandThe Innovators: How a Group of Hackers, Geniuses, and Geeks Created the Digital RevolutionRating: 4.5 out of 5 stars4.5/5 (543)

- The Journeyman Electrician Exam Study Guide: Proven Methods for Successfully Passing the Journeyman Electrician Exam with ConfidenceFrom EverandThe Journeyman Electrician Exam Study Guide: Proven Methods for Successfully Passing the Journeyman Electrician Exam with ConfidenceNo ratings yet

- High Performance Loudspeakers: Optimising High Fidelity Loudspeaker SystemsFrom EverandHigh Performance Loudspeakers: Optimising High Fidelity Loudspeaker SystemsRating: 4 out of 5 stars4/5 (1)

- Collection of Raspberry Pi ProjectsFrom EverandCollection of Raspberry Pi ProjectsRating: 5 out of 5 stars5/5 (1)

- 2022 Adobe® Premiere Pro Guide For Filmmakers and YouTubersFrom Everand2022 Adobe® Premiere Pro Guide For Filmmakers and YouTubersRating: 5 out of 5 stars5/5 (1)

- Long Hard Road: The Lithium-Ion Battery and the Electric CarFrom EverandLong Hard Road: The Lithium-Ion Battery and the Electric CarRating: 4.5 out of 5 stars4.5/5 (2)

- Open Radio Access Network (O-RAN) Systems Architecture and DesignFrom EverandOpen Radio Access Network (O-RAN) Systems Architecture and DesignNo ratings yet

- Upcycled Technology: Clever Projects You Can Do With Your Discarded Tech (Tech gift)From EverandUpcycled Technology: Clever Projects You Can Do With Your Discarded Tech (Tech gift)Rating: 4.5 out of 5 stars4.5/5 (2)

- Empires of Light: Edison, Tesla, Westinghouse, and the Race to Electrify the WorldFrom EverandEmpires of Light: Edison, Tesla, Westinghouse, and the Race to Electrify the WorldRating: 4 out of 5 stars4/5 (87)

- Practical Troubleshooting of Electrical Equipment and Control CircuitsFrom EverandPractical Troubleshooting of Electrical Equipment and Control CircuitsRating: 4 out of 5 stars4/5 (5)

- The Homeowner's DIY Guide to Electrical WiringFrom EverandThe Homeowner's DIY Guide to Electrical WiringRating: 5 out of 5 stars5/5 (2)

- The Fast Track to Your Technician Class Ham Radio License: For Exams July 1, 2022 - June 30, 2026From EverandThe Fast Track to Your Technician Class Ham Radio License: For Exams July 1, 2022 - June 30, 2026Rating: 5 out of 5 stars5/5 (1)

- INSTANT PLC Programming with RSLogix 5000From EverandINSTANT PLC Programming with RSLogix 5000Rating: 4.5 out of 5 stars4.5/5 (10)

- IEC 61850-Based Smart Substations: Principles, Testing, Operation and MaintenanceFrom EverandIEC 61850-Based Smart Substations: Principles, Testing, Operation and MaintenanceYubo YuanRating: 1 out of 5 stars1/5 (1)

- Practical Guide to FMEA : A Proactive Approach to Failure AnalysisFrom EverandPractical Guide to FMEA : A Proactive Approach to Failure AnalysisRating: 5 out of 5 stars5/5 (1)

- Hacking Electronics: An Illustrated DIY Guide for Makers and HobbyistsFrom EverandHacking Electronics: An Illustrated DIY Guide for Makers and HobbyistsRating: 3.5 out of 5 stars3.5/5 (2)

- Lithium-Ion Battery: The Power of Electric Vehicles with Basics, Design, Charging technology & Battery Management SystemsFrom EverandLithium-Ion Battery: The Power of Electric Vehicles with Basics, Design, Charging technology & Battery Management SystemsRating: 5 out of 5 stars5/5 (2)

- Foundations of Western Civilization II: A History of the Modern Western World (Transcript)From EverandFoundations of Western Civilization II: A History of the Modern Western World (Transcript)Rating: 4.5 out of 5 stars4.5/5 (12)