Professional Documents

Culture Documents

Root Cause Analysis Article Rca RCM

Root Cause Analysis Article Rca RCM

Uploaded by

reynancsOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Root Cause Analysis Article Rca RCM

Root Cause Analysis Article Rca RCM

Uploaded by

reynancsCopyright:

Available Formats

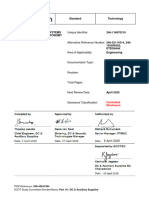

ThinkReliability

PO Box 301252

Houston, TX 77230

Phone 281.489.2904

Fax

281.489.2905

www.thinkreliability.com

Solve Problems. Prevent Problems.

Reliability-Centered Maintenance and Root Cause Analysis:

Working Together to Solve Problems

Mark Galley, Cause Mapping , ThinkReliability

Douglas J. Plucknette, RCM Blitz , Reliability Solutions, Inc.

As plants around the world strive to reduce maintenance costs and prevent incidents and accidents,

they often turn to various reliability tools to speed the road to improvement. Reliability tools first help

identify where losses are, then develop procedures to mitigate the losses and, thus, improve equipment

reliability and performance.

One tool is Reliability-Centered Maintenance, or RCM. With safety and reliability in mind, it uses the

cause-and-effect relationship to identify potential component failures and a structured decision process

to select the best maintenance strategies. Those strategies should ensure equipment and processes

function in accordance to inherent safety and reliability capabilities.

The story behind Reliability-Centered Maintenance begins during the 1970s in, among other places,

the commercial airline industryincluding two executives at United Airlines, F. Stanley Nowlan and

Howard Heap. Understanding that failures (plane crashes) could cause well over 100 deaths in a single

incident, industry members understood they could not simply stand back and wait for failures and then

adjourn to a conference room to figure out why. They needed a proactive tool that would identify

failures and develop a strategy to eliminate them, or at least reduce their probability to an acceptable

level. From this, RCM emerged as an extremely effective, proactive tool to prevent failures before they

happen. From the days of Nowlan and Heap, RCM has evolved into several methodologies used at

companies around the world to develop maintenance plans for asset care and reliability improvement.

RCM, which asks what could happen, differs from root-cause analysis (RCA), which examines what

did happen. Yet at the heart of each lie the principles of cause and effect. So though many use the two

independently, used together they can produce some extremely significant benefits.

RCA and RCM: Different but Complementary

While there are several different RCM and RCA methodologies, each with their own steps,

companiesand especially the people participating in these reliability initiativesshould understand a

simple but important distinction between them. RCM identifies all of the different ways a piece of

equipment or process could fail, while RCA identifies all of the causes answering why a piece of

equipment or process did fail.

Put another way, a Reliability-Centered effort asks the question, What could cause the problem?

A root-cause analysis asks What did cause the problem? These two questions help companies not

only differentiate between the two methods but also understand their similarities. Both require an

understanding of the function of a piece of equipment, its operating history, the most common failure

modes and why they occur, and recognizing these similarities help create a more coherent and

effective reliability effort.

Root-cause analysis asks three questions that each focus on the failure that has already occurred:

1.

2.

3.

What was the problem?

What were the causes of the problem?

What action should be taken to prevent the problem from occurring?

ThinkReliability 2008

Page 1 of 4

ThinkReliability

PO Box 301252

Houston, TX 77230

Phone 281.489.2904

Fax

281.489.2905

www.thinkreliability.com

Solve Problems. Prevent Problems.

RCM, on the other hand, asks seven questions that focus on failures that could occur in the future:

1.

2.

3.

4.

5.

6.

7.

What are the functions of the equipment or process?

How can it fail to provide the function?

What causes each functional failure?

What are the effects of each functional failure?

How does each failure impact the goals?

What action should be taken to predict and prevent each failure?

What action should be taken if a proactive task cannot be determined?

Beyond asking RCMs seven standard questions, companies should scrutinize how those questions

are utilized. After some organizations work through all of these questions, they feel the process

becomes too long and involved; it takes too many people away from their work, and, most importantly,

they did not see any benefit. Other organizations ask the same seven questions and feel the process

moved at a good pace, captured a huge amount of knowledge and, within a short time, see a reduction

in reactive maintenance and outages. Ultimately, it depends how an organization conducts RCM. Tools

are available, like RCM Blitz (discussed below), that can help speed the process and keep an

organization focused.

Considering both root cause and reliability-centered maintenance often begs the question: If RCM

is so proactive, why would you ever need root-cause analysis? While being proactive is extremely

important for any organization, problems still arise daily. Ideally, being proactive should make reactive

issues less and less significant. Aircraft regularly have problems on flights that dont result in a crash,

just maintenance at the next stop. Organizations should strive to be effective both proactively and

reactively.

RCM is not a one-time, discrete effort but part of ongoing, proactive continuous improvement.

Conversely, a root-cause analysis acts reactively, identifying the causes of a particular failure that

occurred at a specific date and time. It is a discrete event. Yet both reactive and proactive strategies

are needed. Understanding problems reactively, knowing how equipment and processes fail, is

essential for taking specific steps to prevent those failures from occurring in the first place. In other

words, organizations learn from reactive responses to become more proactive.

Failure-Mode Fundamentals

RCM identifies all the failure modes, the ways a failure could happen, for a given piece of

equipment or process. Just as a transportation mode (that is, a mode of transportation) is a way to get

from one place to another, a failure mode is a way something can fail. In essence, it is simply a cause

that produces an effect.

Some failures can have multiple failure modes, meaning there are different ways (that is, causes)

that can produce the same negative effect. Failure modes can be identified for an overall system and by

breaking the system down into parts or sub-systems.

RCM requires breaking an operating system down into its parts, and then breaking these parts

down further until failure modes/causes emerge, along with ways to prevent them from occurring.

ThinkReliability 2008

Page 2 of 4

ThinkReliability

PO Box 301252

Houston, TX 77230

Phone 281.489.2904

Fax

281.489.2905

www.thinkreliability.com

Solve Problems. Prevent Problems.

In both root cause and RCM, people with first-hand

knowledge of a system represent a valuable resource.

They know how the system operates, what works and what

doesnt, and why the failure is a big deal. Most importantly,

they can be a fountainhead of ideas for how to prevent the

failure from occurring.

Loss of

Feed System

Impact to

Production Goals

Loss of Function of

Bag Sealer System

OR

Properly seal 22

bags per minute

Loss of

Conveyor System

A front-line person that endures five system failures

during the past two years can give vital insight for RCM.

Consider that a root-cause analysis was conducted for

each of those five previous failures. Collecting cause-andeffect data from each RCA provide information and

experience used for RCM. It helps avoid duplication

between the two processes and, most importantly, makes

the overall reliability effort more effective.

OR

Loss of

Sealer System

Reliability-Centered Maintenance

Root-Cause Analysis

Done Proactively

Done Reactively

Starts with a reliability initiative

Starts when an incident occurs

Done offline

Done with the incident

OR logic for Causes

AND logic for Causes

Reliability-centered maintenance captures all of the specific tasks identified to predict, prevent or

mitigate each failure mode, and formats it all on a detailed spreadsheet. Column labels contain the

seven RCM questions, while rows detail systems, subsystems and components involved with the issue.

In this fashion, such a table can capture the failure modes, effects and causes. How detailed this

becomes depends on the issue and the associated risks. A complete RCM for a piece of equipment

may only take up five pages, while a complex system might require more than 200. This data, collected

in such a format, can be shared with other databases, such as those for work processes and

computerized maintenance management systems (CMMS).

Reliability-centered maintenance offers tremendous value but, nevertheless, has its drawbacks. For

one, it can take time and, without care, lose focus. To solve this, RCM Blitz uses the principles of

RCM by keeping the group focused on achieving timely results. Software tools also make it easy to

build the Cumulative Cause Map quickly and accurately, while the RCM itself is being conducted, or

even while individual failures actually happen in the field.

ThinkReliability 2008

Page 3 of 4

ThinkReliability

PO Box 301252

Houston, TX 77230

Phone 281.489.2904

Fax

281.489.2905

www.thinkreliability.com

Solve Problems. Prevent Problems.

The Visual Advantage

A root-cause analysis can be presented visually, organizing all causes for a

particular incident. Here, a Cause Map, with a single incident to the left connected

to boxes branching out to the right, can detail each cause and showing how they

relate. In a Cause Map, all causes relate to each other in what are called AND

relationships. Consider a cause-and-effect relationship where one effect had two

causes (Cause 1, Cause 2); both Cause 1 and Cause 2 are required to occur for the

effect to happen.

Cumulative

Cause Map - Bag Sealer

Loss of

Guide

Damage

OR

Normal Wear

Loss of

Feed Syst em

OR

Loss of

Infeed Belt

Oversized Product

OR

Overweight Bags

1

Impact to

ProductionGoal s

Los s of Function of

Bag Sealer Syst em

OR

Loss of

Mot or

Properly seal 22

bags per minute

Worn Contacts

OR

Loss of

Motor Sys tem

OR

Loss of Motor

Start er

Auxillary contact

fails open

Reliability-centered maintenance, like root cause, can also use visual tools.

Here, though, we consider multiple failure modes that could cause an error. Hence,

these modes have an OR relationship, since any one of these causes could lead to

a future incident (for example, the effect/incident could happen from Cause 1 or

Cause 2). Here, a Cumulative Cause Map can capture these relationships,

considering multiple, potential failure modes.

RCA and RCM Working Together

These visual tools reveal how root cause and RCM can truly work together. As

stated, root-cause analysis examines one issue at time. Consider a machine that

experiences three different failures over two years, and each time a root-cause

analysis failure is used to analyze them. From these RCAs come failure modes

describing how the machine broke. These failure modes can then be placed on one

larger analysis, a Cumulative Cause Map, which attempts to visually outline all

possible causes and failures for a given piece of equipment, process or system.

OR

Loss of

Disconnect

Normal Wear

OR

OR

OR

Loos e Wire

Los s of Power

System

St arter Overlo ad

Fails Clo sed

Lack of

Lubric ation

Loss of

Gearbox

OR

Excess vi e Teeth

Wear

OR

Loss of Motor

Drive Sheav es

Normal Wear

OR

Normal Wear

Loss of

Driven Sheaves

Loss of

Sheave System

(torque)

OR

Taperloc k Bushin g

fails

Normal Wear

OR

Normal wear of

Sheave Groove

Loss of Guide

Sheaves

OR

Normal wear of

Sheave Bore

OR

OR

Hanging Bags

OR

Normal Wear

Such a map gets all information on one pageand a big page at that. A large

RCM initiative displayed as a visual Cumulative Cause Map printed at a readable

size (manually on chart paper or with the computer through Microsoft Excel or other

software) could take up a three-by-five-foot space or more. Taping the map to a wall

makes it easy for people to mark it, adding what they know. It makes it easier to

digest how the specific, detailed tasks for equipment or processes fit into the overall

reliability picture.

Loss of Drive Belt

OR

OR

Misalignment

Loss of Guards

Frict ional Wear

Loss of Converyor

Belt System

Loss of Knurled

Roll

OR

BearingFailure

Contamination

Loss of Heating

Manif old Air

Hoses

Physical Damage

OR

OR

Building a Cumulative Cause Map requires both a thorough RCM (such as

RCM Blitz) and a complete understanding of a visual root-cause methodology

(such as Cause Mapping). Cause Mapping can assist RCM by identifying specific

systems, components and failure modes. Note, though, that the Cumulative Cause

Map does not combine RCM and RCA into a new methodology. Either root-cause

analysis or Reliability-Centered Maintenance can be used on its own as a sound,

proven approach to solving problems. Nevertheless, the Cumulative Cause Map

does show the complementary link between the two methods and helps create a

simpler, more coherent approach to reliability.

OR

Loss of Heater

Manif old

Heat er Cartridge

Fails Open

OR

OR

Loss of

Sealer System

OR

Heater Sealer

Relay Fails Closed

Heat er Winding

Fails

Loss of Cooling

Manifold

OR

Loss of

Thermoc ouple

Physic al Damage

OR

?

OR

Loss of

Temperature

Cont rol

OR

Loss of

Overtemperature

Reset

OR

Loss of Cooler Air

Flow Regulat or

When implemented, the Cumulative Cause Map visually captures

organizational knowledge and experience. It can be used as a troubleshooting

guide, a communication tool across shifts and sites, a teaching tool, even a way to

maintain continuity when people leave a department. Want to know what employees did at a sister

facility did to improve equipment reliability? Examine the Cumulative Cause Mapan organizations

visual record of information and experience.

Loss of

Control Syst em

ThinkReliability 2008

Nozzles Plu g

Loss of Heating

System

Disconnect Fails

Closed

OR

Loss of E-stop

Page 4 of 4

Plu gging

Physical Damage

You might also like

- Roads Magazine Issue 1 Quon 2017 PDFDocument36 pagesRoads Magazine Issue 1 Quon 2017 PDFRaing RaingNo ratings yet

- Final Session Guide Root CauseDocument11 pagesFinal Session Guide Root CauseBagamel YlananNo ratings yet

- Cat 16M Motor Grader PDFDocument28 pagesCat 16M Motor Grader PDFAzizul Kamarudin100% (1)

- 240-118870219 Standby Power Systems Topology and Autonomy For Eskom SitesDocument31 pages240-118870219 Standby Power Systems Topology and Autonomy For Eskom SitesiabhuaNo ratings yet

- Application of Fmea Method in A Manufacturing Organization Focused On QualityDocument7 pagesApplication of Fmea Method in A Manufacturing Organization Focused On QualityRudra DasNo ratings yet

- Corrosion Behavior of Steam Turbine Materials For Geothermal Power PlantsDocument6 pagesCorrosion Behavior of Steam Turbine Materials For Geothermal Power Plantsshare irgaNo ratings yet

- Project Integration ManagementDocument1 pageProject Integration ManagementFery HartantoNo ratings yet

- SATR-J-6913 Rev 0 PDFDocument6 pagesSATR-J-6913 Rev 0 PDFAdel KlkNo ratings yet

- AristocratDocument38 pagesAristocratTiến ThànhNo ratings yet

- Kaizen Event Project Charter: Project Name Agency/Division/ Location Scope Meeting Date Target Event DateDocument3 pagesKaizen Event Project Charter: Project Name Agency/Division/ Location Scope Meeting Date Target Event DateDebashishDolonNo ratings yet

- Leed Hvac Design Leed Commissioning Jorge Mbo SmriDocument39 pagesLeed Hvac Design Leed Commissioning Jorge Mbo Smrialmig200100% (1)

- Quality Control & Tests Plan: BAZ-KSA-QAC-034Document12 pagesQuality Control & Tests Plan: BAZ-KSA-QAC-034Raghad GNo ratings yet

- FMEA2002Document22 pagesFMEA2002deleep6132No ratings yet

- MeasureDocument51 pagesMeasureAshwani KumarNo ratings yet

- 3.1.WasteWater Treatment Procedure - FLOCDocument4 pages3.1.WasteWater Treatment Procedure - FLOChaseeb100% (1)

- SAIC-M-1003Location, Depth of TrenchBoreholes & Elevation For Types I - V Fences InspectionDocument3 pagesSAIC-M-1003Location, Depth of TrenchBoreholes & Elevation For Types I - V Fences InspectionAbuAhmedQuaziNo ratings yet

- 12/31/20 DESIGN NO. - SECTION 15985 Sequence of Operation Part 1 - General 1.1. Description of WorkDocument367 pages12/31/20 DESIGN NO. - SECTION 15985 Sequence of Operation Part 1 - General 1.1. Description of WorkJhoNo ratings yet

- Commentary Ec2 Def080723 PDFDocument168 pagesCommentary Ec2 Def080723 PDFManVasNo ratings yet

- Syllabus Primavera P6Document6 pagesSyllabus Primavera P6Sandeep JoshiNo ratings yet

- Session-2 & 3 Quality - Evolution of QualityDocument20 pagesSession-2 & 3 Quality - Evolution of Qualitymatten yahyaNo ratings yet

- Building Configuration Seismic Design PDFDocument310 pagesBuilding Configuration Seismic Design PDFEmanuel Agung WicaksonoNo ratings yet

- Process Control NotesDocument26 pagesProcess Control NotesVinod KumbharNo ratings yet

- Voith Safeset NEW - Tourque Limiting Coupl - LRDocument32 pagesVoith Safeset NEW - Tourque Limiting Coupl - LRHector Rivera Beltrán0% (1)

- 2014 06 23 FMEA SlidesDocument19 pages2014 06 23 FMEA SlidesMadhan RajNo ratings yet

- Poka-Yoke Team 4Document14 pagesPoka-Yoke Team 4Ratandeep PandeyNo ratings yet

- Realizing Engineering, Procurement and Construction ProjectsDocument7 pagesRealizing Engineering, Procurement and Construction ProjectsGiridhar ParabNo ratings yet

- Project Schedule Critical Path and GanttDocument21 pagesProject Schedule Critical Path and GanttJustus OtungaNo ratings yet

- Leed® Ap: Candidate HandbookDocument19 pagesLeed® Ap: Candidate Handbookvico1982100% (1)

- 15990ucd - Plumbing Hvac Final Testing, Adjusting and BalancingDocument5 pages15990ucd - Plumbing Hvac Final Testing, Adjusting and Balancingvin ssNo ratings yet

- ABB ACS 800 PM KitsDocument2 pagesABB ACS 800 PM Kitsvenkatesan0% (1)

- Demag Standard CranesDocument16 pagesDemag Standard CranesEldio KlenNo ratings yet

- Project Quality Management Part 3Document36 pagesProject Quality Management Part 3Mustafa Salah MahdiNo ratings yet

- Factory Acceptance Test Procedure For DCS - Page 1Document2 pagesFactory Acceptance Test Procedure For DCS - Page 1kapsarcNo ratings yet

- Bag Filter AHPDocument1 pageBag Filter AHPKarthi Keyan100% (1)

- SCH Rs2020 FieldofStudyandResearchPlanDocument3 pagesSCH Rs2020 FieldofStudyandResearchPlanMikhail KazarovNo ratings yet

- Water Meter SpecificationsDocument17 pagesWater Meter Specificationsbeo beoNo ratings yet

- Understanding Human Errors in Construction Industry Where, WhenDocument223 pagesUnderstanding Human Errors in Construction Industry Where, WhenMohamed SalemNo ratings yet

- Water Details 2017Document35 pagesWater Details 2017beo beo100% (1)

- BMS Defining ProjectDocument6 pagesBMS Defining ProjectSamuel Kamau Kang'etheNo ratings yet

- Operating Manual Including Operations Logbook Manual For Installation, Commissioning, and MaintenanceDocument62 pagesOperating Manual Including Operations Logbook Manual For Installation, Commissioning, and MaintenanceBob MillerNo ratings yet

- BSJ - Data CentreDocument4 pagesBSJ - Data CentrePaul KwongNo ratings yet

- MSA Presentation by M Negi 31.01.09Document76 pagesMSA Presentation by M Negi 31.01.09Mahendra100% (2)

- Data Center Power and Cooling: White PaperDocument25 pagesData Center Power and Cooling: White PaperarmasciaNo ratings yet

- Senior Project Design Engineer - Electrical Energy CIMA +Document3 pagesSenior Project Design Engineer - Electrical Energy CIMA +Sherif RafikNo ratings yet

- QA Processes, Tools and Metrics: Group 1Document18 pagesQA Processes, Tools and Metrics: Group 1Rhea AgulayNo ratings yet

- Model-Based Method For Testing, Adjusting andDocument31 pagesModel-Based Method For Testing, Adjusting andIntan Luruh LarasatiNo ratings yet

- Syabas - Pressure Test - Devmanual - 34Document1 pageSyabas - Pressure Test - Devmanual - 34Ri3zaNo ratings yet

- Modular AHU ManualDocument17 pagesModular AHU ManualwolfzemunNo ratings yet

- AHU IsolationDocument1 pageAHU IsolationNandkumar PatilNo ratings yet

- Air Supply Distribution Ventilation and Exhaust SystemsDocument64 pagesAir Supply Distribution Ventilation and Exhaust SystemsAnonymous ntE0hG2TPNo ratings yet

- What: Where (Location) : When (Date) : Who (Name) : HowDocument3 pagesWhat: Where (Location) : When (Date) : Who (Name) : HowDaniswara Krisna PrabathaNo ratings yet

- Checklist of Fcu-AhuDocument4 pagesChecklist of Fcu-AhuMoizuddin Khaja100% (1)

- 26 18 00 MV Circuit Protection Devices SicamDocument21 pages26 18 00 MV Circuit Protection Devices SicamRahul S.JagtapNo ratings yet

- A FMEA-based Approach To Prioritize Waste Reduction in Lean ImplementationDocument22 pagesA FMEA-based Approach To Prioritize Waste Reduction in Lean ImplementationLi NearNo ratings yet

- Ahu Documentantion Minimum RequirementsDocument7 pagesAhu Documentantion Minimum RequirementsdanielsilvavNo ratings yet

- PPAPDocument16 pagesPPAPRohit JanardananNo ratings yet

- Annexure - H - Safety PolicyDocument4 pagesAnnexure - H - Safety Policynim_gourav1997No ratings yet

- Red Flags SurveyDocument6 pagesRed Flags Surveyhmp90No ratings yet

- Work Breakdown StructureDocument7 pagesWork Breakdown Structurerajdeepsingh16No ratings yet

- Definition of CondenserDocument6 pagesDefinition of CondenserAllensius Karelsta HarefaNo ratings yet

- Ssfiles Tools FMEAScalesGuideDocument1 pageSsfiles Tools FMEAScalesGuideKurt FinkNo ratings yet

- Inspection Guides - Pharmaceutical Quality Control Labs (7 - 93)Document10 pagesInspection Guides - Pharmaceutical Quality Control Labs (7 - 93)MilonhgNo ratings yet

- Quiz Submissions - Quiz 3 - Chapter 6Document5 pagesQuiz Submissions - Quiz 3 - Chapter 6charlesNo ratings yet

- Root Cause AnalysisDocument19 pagesRoot Cause AnalysisMentari Putri PertiwiNo ratings yet

- Tact Time StudyDocument10 pagesTact Time StudyAtul SharmaNo ratings yet

- Obo Commissioning 9Document75 pagesObo Commissioning 998257002No ratings yet

- Physical Infrastructure Management Basics TranscriptDocument20 pagesPhysical Infrastructure Management Basics TranscriptMuntasir0% (1)

- Specification No: ELRS /SPEC/ SI /0015: Government of IndiaDocument12 pagesSpecification No: ELRS /SPEC/ SI /0015: Government of Indiavikas katiyarNo ratings yet

- 3 SEM - Software-Engineering-NotesDocument95 pages3 SEM - Software-Engineering-NotesNemo KNo ratings yet

- TC74HC4017AP Datasheet en 20140301Document9 pagesTC74HC4017AP Datasheet en 20140301Yann Van OsselaerNo ratings yet

- Banlaw Sales Brochures Company Brochure 06-08-02Document10 pagesBanlaw Sales Brochures Company Brochure 06-08-02api-3752216No ratings yet

- GeneratorModelDQBPU enDocument4 pagesGeneratorModelDQBPU enJayadevDamodaranNo ratings yet

- H011809DA AdvantageOneOffshoreCementingSystemDocument3 pagesH011809DA AdvantageOneOffshoreCementingSystemAnonymous uKoNmLxk100% (1)

- Lightweight and CrashworthinessDocument20 pagesLightweight and CrashworthinessgfdczxNo ratings yet

- Operator E-Jets News Rel 24Document12 pagesOperator E-Jets News Rel 24PDDELUCANo ratings yet

- Os Ecm L2Document50 pagesOs Ecm L2Tariku MehdiNo ratings yet

- Poster - Training in Human Factor: Angel Martinez, Francisco Acedo, Antonio Justicia & Vicente Ochoa de LamoDocument2 pagesPoster - Training in Human Factor: Angel Martinez, Francisco Acedo, Antonio Justicia & Vicente Ochoa de Lamoyahi1000No ratings yet

- Software Requirement Analysis AND Estimation Unit - 3Document40 pagesSoftware Requirement Analysis AND Estimation Unit - 3Natnael TeferaNo ratings yet

- Brochure +Fisher+Control+Valves+for+High-Cycle+ApplicationsDocument16 pagesBrochure +Fisher+Control+Valves+for+High-Cycle+ApplicationsVellandya Devi P SNo ratings yet

- Rand Rra1377-2Document46 pagesRand Rra1377-2tbj1990No ratings yet

- Chapter 21 - Morphing Devices Safety Reliability A - 2018 - Morphing Wing TecDocument36 pagesChapter 21 - Morphing Devices Safety Reliability A - 2018 - Morphing Wing TecRichardNo ratings yet

- Drift Speed in Detail PDFDocument29 pagesDrift Speed in Detail PDFMathan Selva Kumar ANo ratings yet

- Reliability Test Methods, Plans, and Environments For Engineering Development, Qualification, and ProductionDocument375 pagesReliability Test Methods, Plans, and Environments For Engineering Development, Qualification, and ProductiongiovannobgNo ratings yet

- Case Study #3 - Gigantone, JustineDocument2 pagesCase Study #3 - Gigantone, JustineJustine LinesNo ratings yet

- Multilin 889: Grid SolutionsDocument16 pagesMultilin 889: Grid SolutionsIrwanNo ratings yet

- FTA HistoryDocument9 pagesFTA HistoryPeter BrownNo ratings yet

- Lead Dev Talk (Fork) PDFDocument45 pagesLead Dev Talk (Fork) PDFyosiamanurunNo ratings yet