Professional Documents

Culture Documents

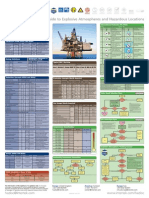

Eexd Iic T6: Hazardous Location Rating Systems For Interlock Switches

Uploaded by

eng_abourayaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Eexd Iic T6: Hazardous Location Rating Systems For Interlock Switches

Uploaded by

eng_abourayaCopyright:

Available Formats

Process Safeguarding The Safety Library

Hazardous Location Rating Systems for Interlock Switches

he Omron STI Hazardous Location Rated Safety Interlock

Switches presented in this

catalog are classified by the European

standard as Ex, ExdIIc T6. A sealed contact block makes these interlock switches

suitable for use in Zone 1 and Zone 2

environments, which are typical of those

found in the chemical and petrochemical

industries. The tables that follow explain

and compare the European method

with the U.S. method of classification of

Explosion Proof products. The European

classification of E ExdIIc T6 is explained

as follows:

E Ex indicates they meet the European

safety standards of EN 60079-0 and EN

60079-1 and BS5501 parts I-V.

d suffix indicates that the explosion

proof enclosure of the contact block is

designed to contain an internal explosion and will not ignite a surrounding

flammable atmosphere.

llc refers to the group of gases for

which the switches are suitable. Group

II gases are sub-divided into three

categories by the suffix a, b, or c. Suffix

c gases are the most flammable within

Group II and include gases such as

hydrogen. Special precautions may be

required to protect the vulnerable parts

Explanation of Marking of EX Equipment

for European Market

Ex = equipment corresponds to a type of

protection covered by British or Baseefa

Standards (e.g. BS 4683, SFA 3009)

EEx = equipment corresponds to a type of

protection covered by specific European

Standards (e.g. EN 60079-1)

example

Type of protection used

o = oil immersion

p = pressurized apparatus

q = powder filing

d = flameproof enclosure

e = increased safety

i = intrinsic safety (ia or ib)

m = encapsulation

s = special protection

Covered by Standard

EN 50015

EN 50016

EN 50017

EN 50018

EN 50019

EN 50020

EN 50021

BASEEFA SFA 3009

of the switch from corrosion, such as

PVC covered cables against attack by

certain corrosive elements and physical

damage.

The T designation represents the

surface temperature classification of the

switch and is divided into categories

with the suffix 1 to 6. T6 is the lowest temperature and thus the safest

classification with a maximum permitted

surface temperature of 85C (providing

that the electric loading of the switch

does not exceed its stated current rating). These switches have been tested

with an ambient temperature of 60C as

opposed to the normal test limit of only

40C, allowing them to be used in gases

having a low flash point.

Switches classified as E Exdllc T6 (All

Omron STI Ex switches) are not suitable

for use in atmospheres containing

Group I gases, e.g. methane (firedamp).

Please note that these switches

DO NOT meet all conditions of the US

classification of Class I, Div 1 due to the

differences between European and US

classification methods. See the table on

the following page, (Figure 7.2).

EEx d IIC T6

Subdivisions A, B & C are based on classification of

Maximum Experimental Safe Gap (MESG) and

Minimum Ignition Currents (MIC) - For more

information refer to EN 50014: 1992 Annex A.

Usage / gas group

Group Usage place

I =

Mines

IIA = Surface

IIB = Surface

IIC = Surface

Representative gas

Methane

Propane

Ethylene, Propane

Hydrogen, Ethylene,Propane

Classification of maximum surface temperature

T1 = 450C

The maximum surface temperature must

T2 = 300C

be less than the lowest ignition

T3 = 200C

temperature of the explosive atmosphere.

T4 = 135C

T5 = 100C

T6 = 85C

Fig. 7.1

Omron Scientific Technologies, Inc.

USA Tel. 1/888/510-4357 Canada Tel. 1/866/986-6766

For the Latest Information

On the Internet: www.sti.com

A81

Process Safeguarding The Safety Library

A

hazardous location Rating Systems For Interlock Switches

Classifications of

Hazardous Locations

Gas Groups

Marking Temperatures

Explosive

Continuous

Atmosphere

Presence

IEC

Zone 0 (gas)

(International)

Zone 20 (dust)

France (19.12.88)

Zone 0 (gas)

and Europe

Canada (CEC)

CI. I Div. 1 (gas)

and USA (NEC)

CI. II Div. 1 (dust)

CI. III Div. 1 (fibers)

Intermittent

Presence

(normal operating

conditions)

Zone 1 (gas)

Zone 21 (dust)

Zone 1 (gas)

Occasional

Presence

(abnormal operating

conditions)

Zone 2 (gas)

Zone 22 (dust)

Zone 2 (gas)

CI. I Div. 1 (gas)

CI. II Div. 1 (dust)

CI. III Div. 1 (fibers)

CI. I Div. 2 (gas)

CI. II Div. 2 (dust)

CI. III Div. 2 (fibers)

Place of Use

Mines with firedamp

Surface industries

Group

CENELEC/IEC

l

IIA

IIB

IIC

IIC

Class & Group

Canada & USA

Gaseous Mines

I-D

I-C

I-B

I-A

Representative

Gas

Methane

Propane

Ethylene

Hydrogen

Acetylene

T1

T6

T2

T3

T4

450C

85C

300C

200C

135C

Temperature Class

(CENELEC/IEC)

T5

Group ll

Maximum Surface

100C

Temperature

Fig. 7.2

A82

Omron Scientific Technologies, Inc.

USA Tel. 1/888/510-4357 Canada Tel. 1/866/986-6766

The maximum surface temperature of equipment must always

be lower than the ignition temperature of the gas present in the

hazardous area.

For the Latest Information

On the Internet: www.sti.com

Process Safeguarding The Safety Library

A

Hazardous (Classified) Locations NEC Article 500

Class I

Combustible material in the

form of gas or vapor.

500-5

Division 1

Division 2

(1) in which hazardous concentrations of flammable gases or vapors

(1) in which volatile flammable liquids or flammable gases are

exist continuously, intermittently, or periodically under normal operating

handled, processed, or used, but in which the hazardous liquids,

conditions.

vapors, or gases will normally be confined within closed containers or

(2) in which ignitable concentrations of such gases or vapors may exist

closed systems from which they can escape only in case of accidental

frequently because of repair or maintenance operations or because of

rupture or breakdown of such containers or systems, or in the case of

leakage.

abnormal operation of equipment.

(3) in which breakdown or faulty operation of flammable gases or

(2) in which ignitable concentrations of gases or vapors are normally

vapors, might also cause simultaneous failure of electrical equipment.

prevented by positive mechanical ventilation, but which might

500-5 (A)

become hazardous through failure or abnormal operation of the

ventilating equipment

(3) that are adjacent to Class I, Division 1 locations, and to which

ignitable concentrations of gases or vapors might occasionally be

communicated unless such communication is prevented by adequate

positive-pressure ventilation safeguards against ventilation failure are

provided.

500-5(B)

Group A Atmospheres containing acetylene

500-3 FPN #5

Group B Atmospheres containing hydrogen, gases or vapors of equivalent hazard, such as manufactured gas.

500-3 FPN #6

Group C Atmospheres containing ethyl ether vapors, ethylene, or cyclopropane.

500-3 FPN #7

Group D Atmospheres containing gasoline, hexane, naphtha, benzine, butane, propane, alcohol, acetone,

500-3 FPN #8

benzol, lacquer, solvent vapors, or natural gas.

Group E Atmospheres containing metal dust, including aluminum, magnesium, and their commercial alloys,

and other metals of similar hazardous characteristics.

500-3 FPN #17

Group F Atmospheres containing carbon black, coal, or coke dust.

500-3 FPN #14

Group G Atmospheres containing flour starch or grain dusts.

500-3 FPN #15

Fig. 7.3

Omron Scientific Technologies, Inc.

USA Tel. 1/888/510-4357 Canada Tel. 1/866/986-6766

For the Latest Information

On the Internet: www.sti.com

A83

Process Safeguarding The Safety Library

A

Hazardous (Classified) Locations european standard

Gases

Combustible material in the

form of gas or vapor.

US Class I

Zone O

Zone 1

Zone 2

An area in which ignitable concentrations

An area in which ignitable concentrations

An area in which ignitable concentrations

of flammable gases or vapors are present

of flammable gases or vapors are likely to

of flammable gases or vapors are not likely

continuously or present for long periods of

exist under normal operating conditions, or

to occur in normal operation; but if they do,

US Div. 1

time.

US Div. 1

because of leakage.

only for short periods.

US Div. 2

Group IIC Atmospheres containing acetylene

US Group A

Group IIC Atmospheres containing hydrogen, gases or vapors of equivalent hazard, such as manufactured gas.

US Group B

Group IIB Atmospheres containing ethyl ether vapors, ethylene, or cyclopropane.

US Group C

Group IIA Atmospheres containing gasoline, hexane, naphtha, benzine, butane, propane, alcohol, acetone,

US Group D

benzol, lacquer, solvent vapors, or natural gas.

In Prep

Atmospheres containing metal dust, including aluminum, magnesium, and their commercial alloys,

and other metals of similar hazardous characteristics.

US Group E

In Prep

Atmospheres containing carbon black, coal, or coke dust.

US Group F

In Prep

Atmospheres containing flour starch or grain dusts.

US Group G

Fig. 7.1

A84

Omron Scientific Technologies, Inc.

USA Tel. 1/888/510-4357 Canada Tel. 1/866/986-6766

For the Latest Information

On the Internet: www.sti.com

You might also like

- CompEx GuideDocument22 pagesCompEx GuideFederico MaggiNo ratings yet

- iUPS101: XXXX Ii 2 G Ex D (E) Iib T6 GBDocument1 pageiUPS101: XXXX Ii 2 G Ex D (E) Iib T6 GBAdemola Olajide TejumolaNo ratings yet

- Intertek Poster A1 (HazLoc - Guide) - 0Document1 pageIntertek Poster A1 (HazLoc - Guide) - 0Antonio FilipeNo ratings yet

- ZonesDocument19 pagesZonesVaidheeshwar VetrivelNo ratings yet

- Pocket ManualDocument21 pagesPocket Manualakhilesh_kabra17100% (1)

- A Guide To European (Eec) Certification For Hzardus AreasDocument5 pagesA Guide To European (Eec) Certification For Hzardus AreasDeepak DinkarNo ratings yet

- Hazardous Area ClassificationDocument63 pagesHazardous Area Classificationhtetwin100% (3)

- Hazardous Area SH CourseDocument22 pagesHazardous Area SH CourseafnakshNo ratings yet

- Hazardous AREA ClassificationDocument10 pagesHazardous AREA Classificationfarzam100% (1)

- CompEx Course SyllabusDocument14 pagesCompEx Course SyllabusJoshuaNo ratings yet

- UK ATEX IECEx Sensor CatalogueDocument26 pagesUK ATEX IECEx Sensor Cataloguedj22500No ratings yet

- Hazardous Areas Are Defined by Three Main CriteriaDocument5 pagesHazardous Areas Are Defined by Three Main Criteriaswarm62No ratings yet

- Hazardous Area TerminologyDocument7 pagesHazardous Area TerminologyDayo IdowuNo ratings yet

- ATEX StandardDocument4 pagesATEX StandardharmlesdragonNo ratings yet

- Explosion Proof TriangleDocument26 pagesExplosion Proof TriangleAndrew1221568No ratings yet

- Heat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsFrom EverandHeat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsRating: 5 out of 5 stars5/5 (1)

- Basics of Explosion Protection - IecDocument4 pagesBasics of Explosion Protection - IecbenounaomarNo ratings yet

- Hazardous Area Classification EN PDFDocument6 pagesHazardous Area Classification EN PDFUsama IqbalNo ratings yet

- AtexDocument8 pagesAtexBao Quoc Mai100% (1)

- Thermal Insulation Handbook for the Oil, Gas, and Petrochemical IndustriesFrom EverandThermal Insulation Handbook for the Oil, Gas, and Petrochemical IndustriesRating: 3.5 out of 5 stars3.5/5 (3)

- ATEX Handout PDFDocument7 pagesATEX Handout PDFEhsan RohaniNo ratings yet

- Hazardous AreasDocument4 pagesHazardous AreasChoochart ThongnarkNo ratings yet

- Exia & ExibDocument4 pagesExia & ExibShiniNo ratings yet

- 100V-Line 15 Watt Horn Speaker With Series Blocking Capacitor For Use in Hazardous areasBEXL15D-inDocument26 pages100V-Line 15 Watt Horn Speaker With Series Blocking Capacitor For Use in Hazardous areasBEXL15D-inEufemiano Noble JrNo ratings yet

- 986 07 1006 031 - ManDocument8 pages986 07 1006 031 - ManFernando Ledesma RamirezNo ratings yet

- Petrel Guide To Hazardous Areas: Atex DirectiveDocument4 pagesPetrel Guide To Hazardous Areas: Atex DirectivePrabhu SingapuraNo ratings yet

- Electrical Question BankDocument176 pagesElectrical Question BankAbdulrhman AlyafeiNo ratings yet

- Methods of Explosion Protection For Electrical EquipmentDocument6 pagesMethods of Explosion Protection For Electrical EquipmentjivajiveNo ratings yet

- Hazardous Environment JHX-EJHX PDFDocument8 pagesHazardous Environment JHX-EJHX PDFhardik033No ratings yet

- ATEX Groups and ZonesDocument11 pagesATEX Groups and ZoneskejujuranNo ratings yet

- Ex-Magazine 2005: Figure 1: Assessment of Hazardous Areas in The Russian FederationDocument1 pageEx-Magazine 2005: Figure 1: Assessment of Hazardous Areas in The Russian FederationBaoLCNo ratings yet

- Haz Area ClassificationDocument8 pagesHaz Area ClassificationBalasubramanianNo ratings yet

- Hazardous Areas Are Defined by Three Main CriteriaDocument10 pagesHazardous Areas Are Defined by Three Main CriteriaviddyadrianNo ratings yet

- Electrical Equipment in Hazardous AreasDocument8 pagesElectrical Equipment in Hazardous AreasMehulkumar PatelNo ratings yet

- Harmony Product Application Guide For Harmony Rack Block I O Used in Class I Division 2 HazardousDocument17 pagesHarmony Product Application Guide For Harmony Rack Block I O Used in Class I Division 2 HazardousYhony Gamarra VargasNo ratings yet

- Crouse HindsDocument7 pagesCrouse HindsNoman KhanNo ratings yet

- Hazardous AreasDocument118 pagesHazardous AreaskamalNo ratings yet

- Clasificacion de Enclosures Nema Ip AtexDocument5 pagesClasificacion de Enclosures Nema Ip AtexJORGE ALBERTO PEREZ RAMIREZNo ratings yet

- SirenaDocument6 pagesSirenaLuiza OcheanaNo ratings yet

- EX Og IP KlasserDocument10 pagesEX Og IP KlasserJørgen Dhia TEBNINo ratings yet

- At Ex Poster LowDocument1 pageAt Ex Poster LowBalanSelvamNo ratings yet

- Explosion-Proof KnowledgeDocument4 pagesExplosion-Proof KnowledgeEra SutrajayaNo ratings yet

- Hazardous Area Motors Low PDFDocument12 pagesHazardous Area Motors Low PDFreji_kNo ratings yet

- Pp1095 Xp95 Is Epg Issue 4Document20 pagesPp1095 Xp95 Is Epg Issue 4Aquitec SeguridadNo ratings yet

- Instruction Manual (Atex) : Bexbgl1D Flameproof Led Beacon For Use in Flammable Gas and Dust AtmospheresDocument4 pagesInstruction Manual (Atex) : Bexbgl1D Flameproof Led Beacon For Use in Flammable Gas and Dust Atmospheresgelustan2006No ratings yet

- Eye C GasDocument3 pagesEye C GasLuis ReyesNo ratings yet

- Handleiding YokogawaDocument6 pagesHandleiding YokogawaGeri Varga KalberNo ratings yet

- 1KS 34075 en PDFDocument1 page1KS 34075 en PDFbebeNo ratings yet

- ATEX Explosive AtmospheresDocument3 pagesATEX Explosive AtmospheresrakicbgNo ratings yet

- Hazardous Areas: Gases and VapoursDocument10 pagesHazardous Areas: Gases and VapoursShah JayNo ratings yet

- D199-00-601-IS Issue 2 STExC1 MANUALDocument9 pagesD199-00-601-IS Issue 2 STExC1 MANUALRoberto Martin NavarroNo ratings yet

- Svacina Larson - Understanding Hazardous Area Sensing - Intrinsic Safety - Part2Document10 pagesSvacina Larson - Understanding Hazardous Area Sensing - Intrinsic Safety - Part2AbdelRahmanNo ratings yet

- LF User ManualDocument8 pagesLF User ManualaghaiyNo ratings yet

- Understanding Hazardous Area Classification PDFDocument7 pagesUnderstanding Hazardous Area Classification PDFNaveed IrshadNo ratings yet

- Armacell LT Armaflex Industrial TDS ACE 201912 A Web 01Document5 pagesArmacell LT Armaflex Industrial TDS ACE 201912 A Web 01adrianioantomaNo ratings yet

- Area ClassificationDocument12 pagesArea ClassificationSandeep GuptaNo ratings yet

- ATEX Handout PDFDocument7 pagesATEX Handout PDFArif KhanNo ratings yet

- Your Safety - Our Reality: Class I, Zone 1, A Ex de IIC T6 Ex de Iic T6 Ex de Iic T6Document1 pageYour Safety - Our Reality: Class I, Zone 1, A Ex de IIC T6 Ex de Iic T6 Ex de Iic T6And WebNo ratings yet