Professional Documents

Culture Documents

Mitsubishi Energy Recovery System FOR Container Vessel S

Uploaded by

Oprea IulianOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Mitsubishi Energy Recovery System FOR Container Vessel S

Uploaded by

Oprea IulianCopyright:

Available Formats

MITSUBISHI

ENERGY RECOVERY SYSTEM

FOR

CONTAINER VESSELS

MITSUBISHI HEAVY INDUSTRIES, LTD.

NAGASAKI SHIPYARD & MACHINERY WORKS

MARINE MACHINERY DESIGN DEPARTMENT

MERS (Mitsubishi Energy Recovery System) for Container Vessels

-

CONTENTS

1. HISTORY OF MERS (Mitsubishi Energy Recovery System)

2. ADVANTAGES & FEATURE OF MERS

Established STG whole system by One Design Dept

Component of each equipments for STG whole system

3. INTRODUCTION OF RESPECTIVE SYSTEM

Eco-TG (Economizer Steam Turbine Generator)

STG (Super Turbo Generating System)

PTG (Power Turbine Generator)

Hybrid Turbocharger Generating System

4. COMPARISON OF APPLICATION FOR EACH SYSTEMS

For Comparison for 8K98ME-C & 12K98ME-C

For Comparison for Generated output

For Comparison for Provision & Economic Fee

MERS (Mitsubishi Energy Recovery System) for Container Vessels

1. HISTORY OF MERS (Mitsubishi Energy Recovery System)

Transition of MERS for Motor Vessels

SETS OF STEAM TURBINE GENERATOR

50

45

Single press.

Dual press.

Dual press.

Hot water flush

40

STG

35

STG

30

25

20

15

10

5

0

1970

1975

1980

1985

1990

1995

2000

2005

Since the 1973 oil shock, various energy-saving system adoption for plants was considered and waste heat

recovery generator had been actively introduced. However, fuel-saving main diesel engine has appeared into

market, hull body and diesel engine design was improved to save energy, and low output system was developed

based on the said environment, so that an application scope of the turbo power generating system utilizing

exhaust gas energy has become limited.

As typical event, Hot water flush steam generator turbine and STG have been developed in 1983~1985 and

installed to 19 and 4 newly-built vessels, but occurred the economizer low temperature corrosion on the few

ships.

MERS (Mitsubishi Energy Recovery System) for Container Vessels

Production record of MERS

Conventional Eco-TG : Total over 300 ships

Hot Water Flush Steam Generating System : Total 19 ships

For VLCC

: 9 ships

For Container

: 8 ships

For PCC

: 2 ships

Steam Turbo Generating System (STG : whole system) : Total 4 ships

For VLCC

: 4 ships

Steam Turbo Generating System (STG : Only for Power turbine) : Total 12 ships

For Container

: 12 ships

MERS (Mitsubishi Energy Recovery System) for Container Vessels

Introduction of typical system (Hot Water Flush Steam Generator Turbine)

120

Ship service steam

LP steam

Economizer

LP steam separator

Mixed fluid of

steam and hot water

is separated to

Steam and hot water.

Flush Turbine

Heating

service

Generator

HP steam

Condenser

Aux. Boiler

Hot water flusher

Energy of the separated hot water

will be recovered by steam turbine

through the Hot water Flusher

Booster pump

36

Sea water

Condensate pump

Suction air

250

Boiler water

circulating Pump

Feed water pump

90

Main Engine

Engine Scavenging

Air cooler

40

Scavenging air cooler

Turbo charger

Exhaust gas manifold

MERS (Mitsubishi Energy Recovery System) for Container Vessels

Introduction of Eco-TG system diagram

USE

TYPE

SYSTEM NAME

DRIVING GENETATOR TURNBINE + GENETAL SERVICE

MONO PRESS.

MONO PRESS.(NOT PREHEATER)

DUAL PRESS.

DUAL PRESS.

DUAL PRESS.(NOT PREHEATER)

MARK-

MARK-A

MARK-S

170

180

145

150

158

100

95

115

120

115

1.T/G driving the generator turbine and

service steam are covered on a

voyage.

1. The tube corrosion without concern

because there is no preheating

section.

1. The tube corrosion without concern

because there is no preheating

section.

4. Drain from Low-pressure separator is

used for Feed water heating.

1. T/G driving the generator turbine

(High-pressure superheater steam)

and service steam (Low-pressure

saturated steam) are covered on a

voyage.

2. Section of superheater, Highpressure evaporation, Lowpressure evaporation and

preheating are organized.

3. The boiler water Circulating special

pump is necessary in the Lowpressure evaporation section.

4. The feed water flows directly into

the drum, the oxidation corrosion

internal tube of preheating section

can be prevented.

5. Mixed generator turbine is possible.

It is suitable for the vessel is not used

an external heat source for feed water

heating.

It is suitable for the vessel is used an

external heat source of main engine

air conditioner for feed water heating.

The same as the left.

SYSTEM

OUTLET GAS

TEMP.

ELECTRIC

POWER RATIO

FEATURE

2. Section of superheater,

evaporation and preheating are

organized.

1. T/G driving the generator turbine

(High-pressure superheater steam)

and service steam (Low-pressure

saturated steam) are covered on a

voyage..

2. Section of superheater, Highpressure evaporation, Low-pressure

evaporation and preheating are

organized.

3.Mono pressure type is simple as

Exhaust Gas Economizer system for

T/G driving the generator turbine.

3. The boiler water circulating pump is

unnecessary in the Low-pressure

evaporation section.

APPLICATION

VESSEL

For generation electric power is small,

it is suitable for the vessel with small

electric power demand inboard and

equipped intermediate velocity engine

with high-temperature of exhaust gas.

The same as the left.

MERS (Mitsubishi Energy Recovery System) for Container Vessels

2. ADVANTAGE & FEATURE OF MERS

Established STG whole system by One Design Dept

One design dep't can establish the whole system with single supplier & responsibility

Number of

designer150

Turbo charger designing section

Turbocharger, Power turbine

Marine boiler designing section

M/E

Economizer

SGM

Marine turbine designing section

Steam turbine generator

Ship service power

G

~

D/G

G

~

G

~

G

~

D/G

To economizer

Cyoryo control system

Marine control system dep

dept

Shaft generator / motor

Power management system

PMS

D/G

D/G

MERS (Mitsubishi Energy Recovery System) for Container Vessels

Component of each equipments for STG whole system

DCS or IAS

By shipyard

By MHI sub vendor

Power Management System

Mitsubishi Heavy Industries

STG system

Generator

Steam turbine Power turbine

* : MHI supply all relevant equipment by

SINGLE RESPONSIBILITY as package for STG

Exh. gas boiler

Main engine

STG

0Shaft Gen. / Motor

By shipyard

MAN B&W

Wartsila

MHI-UE

By MHI sub vendor

Diesel Generator 1

: MHIs Scope of supply

Diesel Generator 2

Diesel Generator 3

MERS (Mitsubishi Energy Recovery System) for Container Vessels

Eco-TG (Economizer Steam Turbine Generator)

(1) System diagram of Eco-TG without gas bypass

Scavenge air

cooler

Exhaust gas

4.0k x sat.

Central cooling

water

4.0k

LP

Drum

Economizer

21,700kg/h x 135

7.5k x sat. x 5,500kg/h

7.0k x 233

6.5k x 228 x 10,400kg/h

Ship service load

HP

Drum

Main

Engine

3.5k x sat. x 5,800kg/h

S/T2,150 kWe

Generator=2,150 kWe

Gland

condenser

16,200kg/h x 38

Condenser

Suction air

Main engine

jacket cooler

21,700kg/h x 41

586,800kg/h x 248.5

7.5k

41

Atoms. Drain

tank

Feed water

pump

Turbocharger

MERS (Mitsubishi Energy Recovery System) for Container Vessels

(2) System diagram of Eco-TG with gas bypass

Scavenge air

cooler

Exhaust gas

4.0k x sat.

Central cooling

water

4.0k

LP

Drum

Economizer

32,150kg/h x 135

7.5k x sat. x 5,500kg/h

7.0k x 294

6.5k x 289 x 21,500kg/h

Ship service load

HP

Drum

Main

Engine

3.5k x sat. x 5,150kg/h

S/T4,000 kWe

Generator=4,000 kWe

Gland

condenser

26,650kg/h x 38

Condenser

Suction air

Main engine

jacket cooler

32,150kg/h x 41

525,240kg/h x 309.4

7.5k

41

Atoms. Drain

tank

Feed water

pump

Turbocharger

MERS (Mitsubishi Energy Recovery System) for Container Vessels

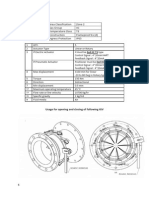

(3) Outside view of AT52 type steam turbine generator

Main oil pump

Local gauge board

Oil cooler

Turning device

Gland seal system

Lube oil temp. control valve

Oil press. control valve

Control oil strainer Aux. oil pump

Reduction gear

Steam turbine

Generator

Common bed

Oil tank

Lube oil strainer

MERS (Mitsubishi Energy Recovery System) for Container Vessels

(4) The condition of FAT (Factory Acceptance Test)

Generator

Steam turbine

Reduction

Gear

Oil Pump

Oil Strainer

Common Bed with Oil Tank

Oil Cooler

10

MERS (Mitsubishi Energy Recovery System) for Container Vessels

STG (Super Turbo Generating System)

(1) System diagram of STG

Scavenge air

cooler

Exhaust gas

4.0k x sat.

Central cooling

water

4.0k

LP

Drum

Economizer

26,700kg/h x 135

7.5k x sat. x 5,500kg/h

7.0k x 274

SSS clutch

6.5k x 269 x 16,300kg/h

497,160kg/h x 289.5

7.5k

Ship service load

HP

Drum

Main

Engine

3.5k x sat. x 4,900kg/h

S/T3,160 kWe

Suction air

Main engine

jacket cooler

P/T2,450 kWe

26,700kg/h x 41

Generator=5,610 kWe

Gland

condenser

21,200kg/h x 38

Condenser

41

Atoms. Drain

tank

11

Feed water

pump

Turbocharger

MERS (Mitsubishi Energy Recovery System) for Container Vessels

(2) Outside view of 64/53 type STG

Control oil strainer

Gland seal system

SSS Clutch

Power turbine

No.1 Reduction gear

Main oil pump

Lube oil strainer

Aux. oil pump

Turning device

Steam turbine

No.2 Reduction gear

Oil tank

Common bed

12

Lube oil cooler

Generator

MERS (Mitsubishi Energy Recovery System) for Container Vessels

(3) Function of SSS clutch

The main components of the SSS clutch are

input hub, output hub and sliding component.

The input hub, mounted upon the chain wheel

shaft, is machined and externally helically

splined to engage the recess and internal

splines of the sliding component. The sliding

component is machined externally to provide

ratchet teeth and clutch teeth.

The output hub, attached to the drive gear

shaft, is grooved internally and axial holes are

drilled to allow the mounting of spring loaded

pawls. Clutch teeth, to match with those of

the sliding component, protrude from the

output hub bore.

A: Pawl

B: Clutch teeth

C: Sliding component

D: Helical splines

E: Input shaft

F: Output clutch ring

G: Ratchet teeth

13

MERS (Mitsubishi Energy Recovery System) for Container Vessels

Disengaged condition

Engaged condition

A: Pawl

B: Clutch teeth

C: Sliding component

D: Helical splines

E: Input shaft

F: Output clutch ring

G: Ratchet teeth

As this equipment may be unfamiliar, a description of the basic operation of the SSS clutch follows:

When the rotational speed of the chain wheel shaft is greater than that of the drive gear shaft, the ratchet of the

sliding component will engage the pawl within the output hub. The sliding component travels along the helical

spline until it contacts the face of the input hub. At this point, the clutch teeth of the sliding component and the

output hub are fully engaged and torque is transmitted from the chain wheel shaft to the drive gear shaft.

If the rotational speed of the drive gear shaft speed is greater than that of the chain wheel shaft, the sliding

component travels along the helical spline until the clutch teeth of the sliding component and output hub disengage.

At this point, no torque will be transmitted between the chain wheel shaft and the drive gear shaft

14

MERS (Mitsubishi Energy Recovery System) for Container Vessels

(4) Shaft generator / motor (SGM)

System concept

Steam turbine

Generator

Power turbine

ACB

SGM

SC

Motoring

ACB

Freq. Control Panel

Power Management System (PMS)

M/E

ACB

D/G

D/G

D/G

ACB

ACB

ACB

Ship load

ACB

Ref. Container

Generating

15

MERS (Mitsubishi Energy Recovery System) for Container Vessels

Power capacity ( as an Example)

Generating

3,500 kW

2,900 kW

Motoring

2,450 kW

1,960 kW

63

84

20

50

98.5 104 rpm

(NCR) (MCR)

85

100 % M/E load

Suppliers

Following well experienced suppliers and proposed principally

Nishishiba Electric Co., Ltd.

In Japan

Taiyo Electric Co., Ltd.

In Japan

SIEMENS

In Germany

Ex. ) 3,500 kW

16

MERS (Mitsubishi Energy Recovery System) for Container Vessels

(5) Power management system

Functional concept

IAS (Machinery)

Economizer

PMS

Main switch board

Control

1) Generator control

Group starter

2) Gen. numbers control

STG

3) Load sharing

4) Large motor start blocking

SGM

D/G

D/G

5) Auto synchro starting

6) Preference trip

7) Bus- bar motoring

M/E remote control

MHI scope of supply

Please refer demonstration of generators operation

17

M/E

MERS (Mitsubishi Energy Recovery System) for Container Vessels

Demonstration of generator operation (1)

18

MERS (Mitsubishi Energy Recovery System) for Container Vessels

Demonstration of generator operation (2)

19

MERS (Mitsubishi Energy Recovery System) for Container Vessels

Generators operating condition by PMS

Operating range

Capacity

Generator

set

Start condition

Rated

Diesel generator

Steam & Exh. gas

turbine generator

Shaft generator &

motor

3

2

Condition

2,850kW

3,300kW

Min

30%

4,500kW

at M/E 85% load

ST:2,070kW

PT:1,530kW

3,500kW

at M/E 20% load

2,450kW

50% or more load

3,500kW

Stop condition

Max

90%

ST:553kW

PT:492kW

ST:2,525kW

P/T:1,975kW

-2,800kW

+3500KW

90% or more of

running

generators

70% or less of

rest running

generator

at M/E load

ST:35% or more

P/T:50% or more

2% less than left

at M/E load

25% or more

2% less than left

Supplier of PMS

1)

Terasaki electric co., ltd. is proposed principally in case of MHI supply.

2)

If PMS is supplied by the shipyard, MHI will support with necessary interfacing information.

20

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (589)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (842)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5807)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- User Munual For DENAIR Diesel Portable Air CompressorDocument25 pagesUser Munual For DENAIR Diesel Portable Air CompressorBoumediene CHIKHAOUINo ratings yet

- Fire HazardDocument26 pagesFire HazardBETHUEL P. ALQUIROZNo ratings yet

- Rising Main Design SampleDocument6 pagesRising Main Design SampleShashi Rana RawatNo ratings yet

- Metcar Physical Properties PDFDocument3 pagesMetcar Physical Properties PDFJavad AmnianNo ratings yet

- Centrifugal Blower Test Rig PDFDocument7 pagesCentrifugal Blower Test Rig PDFGurmeet Mehma100% (2)

- Sanha LPG FPSO - Presenatation - 2005Document36 pagesSanha LPG FPSO - Presenatation - 2005Ravipavan ManuriNo ratings yet

- Bomba A10vso Bosch RexrothDocument5 pagesBomba A10vso Bosch RexrothHIDRAFLUIDNo ratings yet

- Izombe Pareto Analysis Report 2016Document88 pagesIzombe Pareto Analysis Report 2016Wariebi Oghene Lawani100% (1)

- Final Multi Rifled TubesDocument8 pagesFinal Multi Rifled TubesböhmitNo ratings yet

- Cryostar Process Machinery PDFDocument0 pagesCryostar Process Machinery PDFJavad AmnianNo ratings yet

- Gasification Vs Pyrolysis Vs IncinerationDocument7 pagesGasification Vs Pyrolysis Vs IncinerationAJ Conde100% (1)

- BoilerDocument5 pagesBoilerJeremy Lim Choon KeatNo ratings yet

- Research Article Stress Analysis of Nonhomogeneous Rotating Disc With Arbitrarily Variable Thickness Using Finite Element MethodDocument12 pagesResearch Article Stress Analysis of Nonhomogeneous Rotating Disc With Arbitrarily Variable Thickness Using Finite Element MethodJavad AmnianNo ratings yet

- Axial and Radial Turbines - TMI 11-12 - P 32 PDFDocument1 pageAxial and Radial Turbines - TMI 11-12 - P 32 PDFJavad AmnianNo ratings yet

- Mechanical Properties of Pure Ni and Ni-Alloy Substrate Materials For Y-Ba-Cu-O Coated SuperconductorsDocument7 pagesMechanical Properties of Pure Ni and Ni-Alloy Substrate Materials For Y-Ba-Cu-O Coated SuperconductorsJavad AmnianNo ratings yet

- Emvin PHD Introduction1Document68 pagesEmvin PHD Introduction1Javad AmnianNo ratings yet

- Dynamical Modeling, Control and Simulation of Single Shaft Gas TurbineDocument8 pagesDynamical Modeling, Control and Simulation of Single Shaft Gas TurbineJavad AmnianNo ratings yet

- Air Pak User GuideDocument939 pagesAir Pak User GuideGowtham MechNo ratings yet

- Lars Davidson: MTF270 Turbulence Modelling 77: t j t j j t ˜ ν t j b2 ˜ ν t j t j t t 1Document5 pagesLars Davidson: MTF270 Turbulence Modelling 77: t j t j j t ˜ ν t j b2 ˜ ν t j t j t t 1Javad AmnianNo ratings yet

- Dambreak: Volume of Fluid)Document12 pagesDambreak: Volume of Fluid)Javad AmnianNo ratings yet

- GRT Steam Turbines PDFDocument2 pagesGRT Steam Turbines PDFJavad AmnianNo ratings yet

- 4 Actuator: 4.1 DatasheetDocument1 page4 Actuator: 4.1 DatasheetJavad AmnianNo ratings yet

- 30 38 Engl PDFDocument18 pages30 38 Engl PDFJavad AmnianNo ratings yet

- HTPEM Fuel Cells Versus LTPEM Fuel Cells - SerenergyDocument2 pagesHTPEM Fuel Cells Versus LTPEM Fuel Cells - SerenergyJavad AmnianNo ratings yet

- Mobile 6, EPADocument186 pagesMobile 6, EPAJavad AmnianNo ratings yet

- PemfcDocument18 pagesPemfcJavad AmnianNo ratings yet

- Hydrogen CombustionDocument6 pagesHydrogen CombustionCésarNo ratings yet

- Report Mill and Boiler FinalDocument35 pagesReport Mill and Boiler FinalMuhammad Nur ShidiqNo ratings yet

- Lab Name: Performance and Analysis of Kaplan Turbine On Multi Turbine TestDocument11 pagesLab Name: Performance and Analysis of Kaplan Turbine On Multi Turbine TestFarhan EdwinNo ratings yet

- Copeland cr34k6-pfv-875 Article 1377777672152 en SsDocument1 pageCopeland cr34k6-pfv-875 Article 1377777672152 en SsJesus GrilletNo ratings yet

- Solar® FS Series 3™ PV ModuleDocument2 pagesSolar® FS Series 3™ PV ModuleRonald MarcelleNo ratings yet

- Fabrication Solar Refrigeration System by Peltier Effect Ijariie8926Document6 pagesFabrication Solar Refrigeration System by Peltier Effect Ijariie8926Prachurjya BaruahNo ratings yet

- 12-01 Boltec S - Air and Water ComponentsDocument14 pages12-01 Boltec S - Air and Water ComponentsALVARO ANTONIO SILVA DELGADONo ratings yet

- Tugas 1 Pengendalian ProsesDocument9 pagesTugas 1 Pengendalian ProsesAldo HoseaNo ratings yet

- Tracer 1210rnDocument2 pagesTracer 1210rnimaduddien ariefaNo ratings yet

- ICE Assignment 8AMDocument5 pagesICE Assignment 8AMRushabh PatelNo ratings yet

- Thermodynamics An Interactive Approach 1St Edition Bhattacharjee Solutions Manual Full Chapter PDFDocument36 pagesThermodynamics An Interactive Approach 1St Edition Bhattacharjee Solutions Manual Full Chapter PDFgeraldine.wells536100% (11)

- Protection & InterlockDocument36 pagesProtection & Interlockarunrajmech09100% (2)

- Day 5 Pumps in Carbonate ServiceDocument10 pagesDay 5 Pumps in Carbonate ServiceJack ReacherNo ratings yet

- Method of Steam Piping: Method Statement For Mechanical WorkDocument9 pagesMethod of Steam Piping: Method Statement For Mechanical WorkVăn Công TuấnNo ratings yet

- Me 303 CH9Document72 pagesMe 303 CH9Osman KutluNo ratings yet

- Reference List Simoprime A4Document3 pagesReference List Simoprime A4Muhammad Fathoni FikriNo ratings yet

- Thermal Power PlantDocument44 pagesThermal Power PlantArun kumar rouniyarNo ratings yet

- Flow Control ValveDocument38 pagesFlow Control Valvecherif yahyaouiNo ratings yet

- Extinguishing Techniques in Confined Spaces. Shan Raffel GIFireEDocument4 pagesExtinguishing Techniques in Confined Spaces. Shan Raffel GIFireEShan RaffelNo ratings yet

- Group1 - Wyeth NutritionDocument13 pagesGroup1 - Wyeth NutritionBienNo ratings yet