Professional Documents

Culture Documents

Manual of Garrard Model RC88 4 Record Changer

Uploaded by

dwrosa0 ratings0% found this document useful (0 votes)

915 views15 pagesmanual of Garrard Model RC88 4 Record Changer

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentmanual of Garrard Model RC88 4 Record Changer

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

915 views15 pagesManual of Garrard Model RC88 4 Record Changer

Uploaded by

dwrosamanual of Garrard Model RC88 4 Record Changer

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 15

ee,

The “Garrard” Model RC88/4 Record Changer

GARRARD" Record

Changers are simple and

feliable in operation. They

see thoroughly tested be

fore leaving ur works

nd wil give long period

of satisfactory service

Instructions for opera.

ing the, Model RCS8i¢

please follow these in

stoctons eaetally. Tn

ommon with sll echo

Teal devices, however,

minor -adjusiments are

Sometimes necessary. The

Service Instructions ite

Sluded tive been” com

Address your enquiries to:

The

Farrard Engineering. and Manufacturing

Company, Lid.

Technical Service Department,

Neweastle Steet,

‘SWINDON, Wilts

Telephone No.: Swindon 5381 (5 lines,

a

piled to. cover practically

All the information neces

Sy to" ensure. elem

1f, after carefully perus-

Sng this manual you are

Sul im doubs, our ‘Teche

leat Service: Departnent

wil gladly asi you

NOTE.

Always meation the

Model’ Number, Sehede

Number, and type of

Pickup Head ited when

‘communicating. withthe

It you wish to make enquiries concerning the return

‘of 3 Unit for repair, or to order spare pacts, address

jour etter to:

The Garrard Engineering and Manufacturing

‘Company, Ltd,

Service and Spares Department,

50-54 Radnor Strect,

SWINDON, Wilt.

‘Telephone No.: Swindon 2606,

ge One

CONTENTS

page

OPERATING INSTRUCTIONS - oS

INSTALLATION : : - 4

MAINTENANCE : : oe 8

SERVICE ADJUSTMENTS : - 8

SPARE PARTS LIST - : - 15

‘Tae GARRARD Record Changer Mode! R.C.88/4 js made under the

following patents:

Beiten Canada Holland «U.S.A.

741308 sovr —“79s4s) 2683039.

risaas

6021

‘73852

1673030

Germany Switzerland Sweden France

60677 anise 1Sasis ——a02938

230036

Other Patents Pending

Page Two

OPERATING INSTRUCTIONS

‘The “GARRARD” Model R.C.88/4 Record Changer will play automatically any number of records up to

ight, of any one of the following types at ench loadiagé-10" of 12” at 78 r-pam, 7”, 10” or 12” at 394 rpm

7 at 45 expan, 7” records with large centre hole may be played using the arge record spindle type LRS.3, available

in opilonal extra, or with centre hole clip In adaptors, available at record stores. Records may also. be

played mansally. 16] rpm. records can also be played

‘To OPERATE CHANGER PROCEED AS FOLLOWS—

2 Move speed change knob to desired speed.

e™ 2

3. Setleverat side of platform to sizeof record 4. Place upto 8 records on record spindle and

to be played. lower record clip. y

Page Three

Switeh on,

NOTE: When using large record spindle, Type LRS3, for 7” 45 rpm, (Fine Groove) records the record clip i

‘hot lowere

REJECT, To reject a record move the right hand knob to “REJECT” position.

STOP. If itis desired to stop the Chanser before it does so automatically, move the right hand knob to “STOP

position. If this is done whilst a record is playing that record will be Tejected on switching on again

MANUAL CONTROL. The purpose of the manual control is to disconnect the changing mechanism so. that

single records can be played as on a single record player. ‘To use this feature, move the Manual/ Auto Knob

to the Manual position, fit short spindle. supplied with unit, and switch on changer to allow the mechan'smy

to complete its evele. ‘The pickup will then be free on ils rest and can be handled and the unit used as &

Single record plaver. At the completion of the record the pickup will rise and return to its rest Ieav ng the

turntable evalving, fo stap moter and turntable, move rah hand control knob fo “STOP” On switching

fn again time must be allowed for unit to complete eyele once again.

To retum to Auto Working, move the Manual] Auto knod to Auto. If this is done while a record is playing,

at the end of the record the pickup will return to. the pickup rest and the auto stop will switch off the unit

If the control is moved to Auto when the pickup Js on the rest. move the right hand knob tg" REECT® thus,

the mechanism will move into Auto working position and then automatically switch off unit

NOTE, Should the Record Chanser be stopped with the pickup arm not on its rest whist the unit

the pickup should not be handled but the right hand knob. shouldbe moved to "START

‘mechanism will operate and the pickup. arm will lift and return to its rest

‘The pickup arm will not move from its rest unless ane or more records are on the record spindle. ‘This

is a safety device designed to prevent the pickup being damaged should the Changer be switched on without

being’ loaded with records,

Page Four

PICKUP. ‘To play 18 rpm. (Coarse Groove) record, the knab of the turnover pickup should show 18 or ST and

Tor 16},

34 or 43 rpm. (Fine Groove) records it should show 33/43 on LLP.

RECORDS, To obtain the best results from your records care should be taken to see that records are stored and

leaned in the manner recommended by the record manufacturers. Do not lave records on the nore ate

fot In use.

INSTALLATION

DIMENSIONS,

‘The eabinet space required for Siting is 154” long

x 134 “wide, with 3” clearance above ‘and. 31

clearance below the plate. An extra depth of 2” 18,

Fequired for the Universal and D.C. Models,

FITTING TO CABINET.

‘The motor board should be cut and drilled as

shown on template enclosed with each ‘unit. “Open

ation, remove cardboard packing around turntable

and lift out unit by means of string loops. Remove all

elastic bands and string,

The spring suspensions, which will be found

packed in a bag, should be assembled to the Unit Plate,

siagram 1, in four of the six holes, the two transit

fixing holes are shown on diagram 9. They ate designed

for motor boards +” thick. or less but should it be

necessary to use a board thicker than 4” the fixing

SUSPENSION SCREW

UNIT PLATE,

‘SPRING SUSPENSION ASSEMBLY

Dagm 1

holes should be recessed on the underside 14” diameter

and of sufficient depth to leave the board }” thick

‘A lead should be connected to the power supply

block on the tear of the motor and the links ie

block should be set to correspond with the voltage

of he" power supply, diagrams 3 to8. Connoct a

tengih of sereened pickup lead, for conection to the

Feproducer, to the tgs on the pickup connecting sip

dlagram 5, then connect a lead fron the earthing ap

fn the motor, diagram 11, 10 good earth point,

‘The changer should be placed in position and fixed

to the motor board by pressing the Spring suspension

lawn through the holes in the motor boargh the leat

Springs flexing to pass through the holes." Adjusiment

{0 level the unit is made by turning each ssepension

Serew — clockwise to" lower the’ unit and. Eounler

Clockwise 10 raise

[tis essential to use the spring suspension assem-

blies on this model” changer: to prevent extraneous

bration from reaching the nit

If the plugsin feature isto be used to change pick-

ups, the transit erew under the pickup ant at fear

oF pickup should be removed. “Ths screw should be

feplaced and tightened up Tor transit purposes onl).

See diagram 2

‘sencenina connecren

2¢0 (620) vena

N suoe 0

‘To facilitate packing, the plate selector arm exten

‘ion 4 removed and packed separately in-an onli

When the units aly in positon the extension sho

be fited on the selector arm and pressed nto porting

while supporting the arm as showePin dears &

‘TRANSIT SCREWS.

"vo copper plated wood serews are supplied for

se in clamping the changer to the motor beard for

(ransit purposes. The small presspabn washers should

be fitted under these screws to prevent marking, the

unit plate, “These screws must be removed before using

the Record Changer. The position of the transit screws

are shown on diagram 9.

VOLTAGE AND FREQUENCY.

The Garrard R.C.88/4/A.C. Record Changer is suit-

ble for use on either 100/130 volts or 200/350 vols

‘AC, 50 or 60 eveles according ta the motor pulley fitted

‘A imotor driving pulley can he supplied. for SO. ce

60 cyele power supply as required. “The links in the

power supply terminal block should be set to sorrespard

fo the voltage of the power supply ay shows: fo

Diagram 5,

The model RC. 88/4/D.C. Record Changer is

suitable for use on 100/130 and_ 200/330 Volts iret

arFem only and the lnk om the trial block seek

be et to the correct position to cartespond Wee

Yollage Of the Dower supply a8 diagiant me Mode

ako available tor low seeds,

The Model RC.'88/4/Univ, Record Changer is

Suitable for ase on 100/130 and, 200/330 vole B.c

and AC, 25/100 eycles with recter supplied, YA:

postin te male thule a coe

Position to. correspond to the voltage of the Soeeet

Sunnis A.C ie lagram 7 or Dae ghar

reget On and moan ert

controled ‘and information for adusting Uke Sock

wil loud mae Sree Ajmer

supplied, the mains dropping resistance on the

De and AC D.C, Models fied to the onder

tovarm ‘up fon the

dssipated by the resistance. Is therefore seo

mended that where convenient the renee So

be removed from the unit plate and ned by tad

sere oa aden int othe ed rom ie

motor 19 the resistance being sullenly ob fone

this to be done. od

“The motor sho

ul be earthed by connecting a lead

‘rom the carthing tag, (oeated under one of the ea

over screws) t0.2 good earth connection,

The moulded ‘cover’on the. terminal block

‘is coloured to distinguish the type of motor

‘BROWN—Motor for A.C. only.

BLUE Motor for D.C, oaly.

GREEN~Low voltage D.C. thotor only.

RED Universal motor for A.C. or DiC.

If the record changer isto be used with « radio set

giamplifer having a Universal (A.C./D.C) chassis ort

the re ft coupled to a Universal

producer i battery

ALT. battery eliminator, it's essential to make ease

that isolating components (condensers

are incorporated inthe pickup input cited mate,

otherwise the pickup circuit can “lives

Should the isolating components not be i

in the set they should be fit

the pickup leads. Consult your fasion

LINK CONNECTIONS FoR A.C.MooEL

LINK CONNECTIONS FOR A.C. MopEL

CONNECT BoTH BARS

THUS FOR

200/250 Volts Ac

LINK CONNECTION FoR D.C.Moper

CONNECT bar

THUS FoR

200/250 Votes 0.

CONNECT BARS

THUS FoR.

100/130 Votes a.c.

CONNECT BAR

THUS FoR

109/130 Volts ac.

sins Leaos

Dismae +

LINK CONNECTIONS FOR UNIVERSAL MopEeL

SER SONNECTIONS FOR UNIVERSAL MODEL

CONNECT Bars

THUS FOR

100/130 Voies ac.

CONNECT Bags.

THUS FOR.

CONNECT BOTH BARS CONNECT BOTH Bags.

200/250 Voies ac,

TOGETHER THUS FOR TOGETHER THUS roe

200/260 Volts Dc. 100/130 Volts o<,

uaiNs _LeAns

MAINS Leaps

Dieses 7 Dime #

Page Seven

MAINTENANCE

‘The motor and intermediate wheel bearings are of

the oil retaining type and rarely need lubricating; when

the need for oil is apparent, hold the intermediate

wheel out of the way and lubricate the top motor

bearing with a fine grade of machine oil. Carefully

remove all traces of surplus oil before running. The

intermediate wheel rubber tyre, motor pulley and

inside of turntable im must be kept Te of oi

‘To liftoff turmtable remove the ‘etaining. clip,

diagram 9, and the turntable can then be removed ty

carefully lifting with equal pressure on diameticaly

‘opposite sides, Turntable should be replaced wi the

hanger in switched of postion

SERVICE ADJUSTMENTS

Tueze motes are included t0 help the owner of the Record Changer make any minor adjustments that may become

meee Ne aa ERY falecment. fi the protecting eip to The pickup. arf the rnaner Ab hes a

safety mid-position, tur it to this position to protect i

SPEED.

‘The Model R.C. 88/4 motor is designed to g've the

desired turntable speed within close tolerances. ‘Should

the turntable ‘run excessively fast or sow ana the

Speed change knob js set correctly. examine the motor

pulley to see if it is the correct one to suit the free

ueney of the power supply

To assist identification the motor pulley is colour

finished as follows to distinguish the two tips,

Nickel a 50 eveles

Brast 60 eveles

The motor pulley used on the D.C. and Universal

motors is always nickel plated.

‘The speed of the R.C.88/4 D.C. Univ. and low

voltage models is governor controlled. The governor

is located at the lower end of the motor. being screwed

‘on to the armature shaft and held in position by a set

fetew through the governor collar. To adjust the speed,

loosen the screw in the governar and turn the eovernor

a very small amount clockwise to increase the speed. oF

counterclockwise to reduce it, Tighten the serew before

running the motor to check the speed

sapphire siyi from possible darage,

SPEED VARIATION.

Should the speed vary during playing, remove the

Lurptable as deserved ender “MAINTE ANCES

and examine the motor rulley intermediate nian od

inside of turntable wn fon traces of ol and ites

Wipe thoroughly vith clean loth Algo check thet

the motor pulley isin ts correct postion on tne erat

‘ali'swtth the Chavger ou and 4 that hema

wheel runs inthe centre ofthe appropiate step on ie

Pale ‘and does not fui the side of the sdsaceo ue

IW necetar, loosen the sews holding pulley shot

and move to is correct postion

See that the tumble spindle has @ small amount

of enpla,To chook thi hth te tunable mane

rip the turntable. spindle fimly. lifting ap eee

down. If no movement is fel Toosen the crews eit

hold ihe fixed norton of the turntable spindle ase

the turntable spindle very small amount sad

fiahten the screws. There should be’ approximately

1.005" end play.

Page Eight

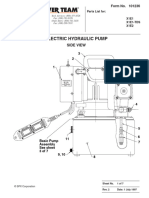

RECORD TRANSIT RECORD TURNTABLE PICKUP HEIGHT AIUUSTING STYLUS PRESSURE

CLIP SCREW SPINDLE RETAINING SCREW ON TOP OF PICKUP ARM AQWUSTING. SCREW

ae cup, AT REAR OF

PICKUP ARM:

Tan.

RECORD PLATFORM

PLASTIC EXTENSION

SETTING

ee? CaP ON RecoRD

— SIZE SELECTOR &

MITCH OFF ARM

ADLUSTING. SCREW

THRO’ HOLE FOR

PICKUP DROPPING

MODEL 2 scheoute Position

NUMBERS:

RECORD SPINOLE & ‘AUTO-MANUAL

ADAPTOR FOR PLAYING KNOB:

RECORDS MANUALLY

Page Nine

RECORD PUSHING TRANSIT TURNYABLE ADJUSTING SCREW FOR HEIGHT FRICTION.

PAM SCREW SPINDLE OF AUTO TRIP OPERATING LEER PLATE

\ Co atames) oe

wo S

econo se

SPAING cue SELECTOR &

RETAINING _ Smt OF A

wnrens weet

(ou tome) wots

wnren wate,

woron PULLEY — (CATCH LEVER

(01. 10” oeann

Ee: SPRING FOR SWITCH

oF Morar) 8 CATCH Levers

— TURNOVER

support ~~ ee

ever

—~ auto TAI

<7 OPERATING. LeveR

‘STRIKER TURNTABLE SWITCH TRANSIT FELT PAD

BRAKE ScREW

‘Top View with Testa removed

Page Ten

ADJUSTMENT FOR

INTERMEDIATE WHEEL TENSION

PICKUP CONNECTING

STRIP & MUTING

‘SwiTeH

EARTHING TAG

MoToR

ae ADJUSTMENT FOR

PrcRuP HEIGHT

sowswent ro Postion

RECORD ASH Pa

POWER SUPPLY &

VOLTAGE. CHANGE:

OVER BLOCK

‘ADJUSTMENT FOR

RECORD PLATFORM POSITION

Underde View of RCHS/4

Dacre it

Page Pleven

Morors.

ifthe motor fails to start when the Changer is

switched on, first check the power supply to see it

current is reaching the motor. Tt correct, switch off the

ower supply, and examine the blades in the switch

lock to see that they are clean and are making good

contact when. the switch is in the "ON". position,

lean and adjust if necessary. ‘Check that all/connee:

tions in the power supply eifeut are tight and secure

iyoSiathe mcg hal in fs Ct ao, ty

lubrcating with very thin oll 'and spinning the shah

THICK OIL must NOT be used.

Should the motor momentarily start and then stop

when switching on, liftoff the turntable and examine

the lever on op 9f the unl plate that are moved by

the START/STOP/REIECT knob, Ensure that they

are quite free and not sticky with congealed oil or

foreign matter and that the spring. i correctly in

Position. ‘See diagram 10,

I the motor appears to run too hot check that the

voltage changeover links’ inthe. power supply and

changeover block are set correctly to correspond to

the voltage of the power supply, diagrams 5 10 &

Ut correct check the motor windings by inserting an AC

ammeter in either motor leads

The maximum current consumption of the

R.CRB/4 AC should not execed 0.26 amp, on 100)

130 volts 50/60 cycles, oF 0.13 amp. on 200;250 volts

50/60 cycles. On. the R.CA8)4/Univ. the current

should not exceed 0.14 amp. A.C. snd 0.18 amp: D.C.

‘on 100/130 voits or 02 amp. A.C and 0.25 amp. D.C.

fn 200/280 volts, On the RC#8/4/D.C. the current

should not exceed 0.18 amp. on 100/130 volts or 025

‘amp. on 200/250 volts. On the low voltage 12 vit

‘mod! the curzent should aot execed 1 amps, or the

6 voit model 2 amps,

I readings in excess of the above figures are ob

tained, the motor should Be returned for examination,

PICKUP DROPPING POSITION.

The pickup arm dropping poston is factory se

for optimum aesuracy But should any minor adjust

ment be requited to Aesommodate abaorial recor,

Totate the serew accessible trough the hole in tne unit

Plate as shown in diagram 3, ‘This adjustment can ony

bemade withthe pickup amon its Tet

PICKUP HEIGHT.

‘The distance the pickup lifts can be adjusted by

turning the screw on top of pickup arm, diagram 13,

with a small screwdriver: Bight 12° 18 rpm, (Coarse

Groove seo shoud be placed onthe tiale and

the pickup height adjusted so that asthe piesup returns

to the rest on competion of the top record the ip of the

Pickup stylus clears the record surface by 4”

Af found necessary further adjustment may be

obtained by turning’ screw accessible underneath

changer, diagram I

Page Twelve

PICKUP STYLUS PRESSURE.

‘The recommended stylus pressure for playing

records should be 10 grammes and itis strongly recor

ended that an occasional. check be made. with a

GARRARD” Sivius Pressure Gauge obtainable from

your deater, To. adjust the stylus pressure: turn the

Sctew atthe rear of the pickup arm, diagram 13. clock

Wise to reduce pressure and” counterclockwise to

PICKUP TRACKING.

Should there be a tendency’ for the pickup to track

incorrectly. especially on the first record, check the

sislus pressure and if required adjust as explained

tunder ‘Pickup Stylus Pressure.

IF the pickup does not run ito the record groove

apr alsin te or ede ea the frend

hanger s evel by placing 2 spirit level on a reco

Gn turntable, Altomake sue tat the exible wife

Ieading fo the pickup fs not twisted or held in such a

danner as to prevent the Tree movement of Ihe pickup

J rm: arther, See that the associated overs are fee

CAUTION.

When making any adjustments to the Pickup Arm

it should NEVER on any account be foroed into post:

‘ion, If the turntable is turned by hind it should NOT.

be tamed backwards.

PICKUP HEADS,

Sipe con ae re

can be fitted. nN .

eile i eam

faneey et

Should trouble be experienced with the repraduc-

tion from 2 pickup it should e returned to the manu:

facturer whose name or trade mark appears on the

cartridge

NOTE.

‘A continuity test cannot he carried out on erystal

cariridges with an obmmeter. Pickup cartidges mi

not be opened or the manufacturer will disclaim

responsibility.

Page Thirteen

PICKUP MUTING SWITCH.

‘A Pickup Muting Switch is connceted across the

pickup to short circuit the piekup during the time that

the changing mechanism is in action. Diagram Il

AUTO-TRIP MECHANISM.

‘The auto trip mechanism is the velocity type, that

is, it operates by the quick inward movement of the

pickup’ arm when the pickup reaches the run off

froove at the end of the record. It is 07 a special

patented design to be very light and sensitive in Opera

tion and is set to commence operation when the stylus

reaches a 2” radius from the centre, It the auco trip

fails to operate the pickup will remain running in the

centre of the record and to correct this remove the

turatable and ‘aise the auto trip operating lever by

fiving the “adjusting screw for height of auto trip

‘Sperating lever," diagram 10, about half’ « turn in a

clockwise direction; ‘This will faise the auto-ttip opera:

fing lever and enable it to engage the cam on the striker

when the pickup runs into the record run-off groove,

TEMPLATE FOR R.C88/$ RECORD SPINDLE.

Should the sloping record spindle be accidentally

bent out of position through being dropped, or other

reasons, the record dropping will be. allected. If

trouble’ is experienced with eratic record. dropping,

lay’ the record spindle on the template. diagram 14

‘and check that it conforms to the shape thereot.

RECORD DROPPING.

If the changer fails to drop records other than the

45 rpm. type having a large centre hole, first make

sure that the records are not badly warped. "If they

fre reasonably flat, the record. pushing. pawl setting

should be checked and adjustments made tf necessary

To adjust the position of the record pushing av, the

eccentric pin accessible under the uait plate (see dia=

gram 11) should be tumed with a screwdriver, Also

heck the record spindle by laying it on the template

(diagram 14) 0 see that it i not bent out of postion.

Should records fail to drop correctly when using

the large ameter record spindle type LRS.3. replace

this spindle with the sloping one and see that it leans

towards the record platform and is directly in line with

it If this spindle 1s out of position, i should be set

correctly by loosening the two 4BA screws In the base

ff the turntable spindle housing and Which hold the

fixed part of the turntable spindle in position, Turn

the record spindle until itis imine withthe centre of the

record. platform and relighten the screws, After

tightening the serews, soe that the turntable spindle

has a slight amount of end play, as described under

“Speed Variation” (Page 8) snd adjust if necessary.

Should the record changer stall just bofore a record

drops on to the turntable, the equse may be due to

Jack of lubrication of the Switch Off and Selector Arm

mechanism, ‘Thin grease should be applied to the pin

fon the cam which moves the lever controlling t

mechanism, Check the tracks in the cam unit and if

they are dev, Tubricate them with a thin smear of light

‘grease alse grease the cam followers on the levers.

Page Fourteen

SPARE PARTS LIST FOR RC88/4

‘The Schedule Number printed on the name plate of the Record Changer is changed whenever

on-interchangeable variations are introduced into the mechanism. It is therefore essential when

‘ordering spare parts to quote the Schedule Number of the Record Changer as well as the Reference

Number of the part required

Name of Part Ret. No. Name of Part Ref. No,

Record Spindle (Sloping) Bs27%64 Fixing Nut Aaion

Record Spindle (Large) Type LRS3 852950 Cover for Switch Block AS1327

Record Spindle (Manual) ASI37 Fixing Serew 40383

Adaptor for 45 rp.m. records ‘50391 Switch Contaet Spring Asi686

Turntable C-52406 Rotor Spindle with Rotor A.a8319

Rubber Mat €51286 Garrard _MPM/2_ Multi Purpose Plug-in

Pickup Arm 2.52900, Piekup Case Assembly (ess cartridge)

Bee kc iclanicanetva Wheel Kesal with open front for turnover cartridges 4.52225

rave Dalley Soy aicloa, ‘53950 Garrard MPM/2 Multi Purpose Plug-in

iekup Case Assembly (less cart

Motor Pale 60 xeon AS3951Sihse froot for trvound or sage

Cover for Changeover Block (A.C. Units). B.51161 purpose cartridges A226

REPLACEMENT STYLI

For Garrard GC2 and GCE4 Turnover Pickups—

(Check make of pickup cartridge before obtaining replacement styli as other pickups are sometimes fitted to

Garrard Units.

GC2/3 Sapphire Stylus (Green) for 78 rpm. (Coarse GC2/3D Diamond Stylus (Green) for 78 rpm. (Coarse

foave) record Groove) records,

GC2{11 Sapphite Stylus (Red) for mierogroove (Fine GC2/1D Diamond Stylus (Red) for microgroove (Fine

Groove) records. Groove) revords

Page Fifteen

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- MRO Stop Industrial Fastener CatalogDocument53 pagesMRO Stop Industrial Fastener CatalogMROstop.comNo ratings yet

- Electrical Wire Harness DesignDocument12 pagesElectrical Wire Harness Designmahaprabhu78100% (4)

- 1FICO01 - Filtro LaroxDocument534 pages1FICO01 - Filtro LaroxMarcelo AlvarezNo ratings yet

- Fuel Injection Equipment (Diesel) (9166A056AFH02043)Document4 pagesFuel Injection Equipment (Diesel) (9166A056AFH02043)HanNo ratings yet

- 10Document48 pages10RB STNo ratings yet

- Ga30+ 75partlistDocument31 pagesGa30+ 75partlistjassimNo ratings yet

- Dehumidifiers DrieazDocument24 pagesDehumidifiers DrieazYahir LópezNo ratings yet

- AIR CONDITIONING SYSTEM INSTALLATIONDocument2 pagesAIR CONDITIONING SYSTEM INSTALLATIONSaharudin SaidinNo ratings yet

- 3 Phase Wiring Installation in Multi Story BuildingDocument5 pages3 Phase Wiring Installation in Multi Story BuildingRishi Kamal100% (1)

- Fit Tolerances and Applications - Mec Engineering SpreadsheetsDocument14 pagesFit Tolerances and Applications - Mec Engineering Spreadsheetstemu ShashNo ratings yet

- Catalogue Data Everest Heat Pump (10-108)Document15 pagesCatalogue Data Everest Heat Pump (10-108)rachman hardianNo ratings yet

- 2023-06-28 KEI Wires Price ListDocument1 page2023-06-28 KEI Wires Price ListCpgeorge JohnNo ratings yet

- Instruction Manual: TCR - MC TypeDocument20 pagesInstruction Manual: TCR - MC TypeKhaled RabeaNo ratings yet

- 686 Rotary Harvesting Unit (103954-) North American Edition Primary Pictorial IndexDocument106 pages686 Rotary Harvesting Unit (103954-) North American Edition Primary Pictorial Indexavant comercialNo ratings yet

- Concrete Pump Spare PartsDocument17 pagesConcrete Pump Spare PartssantoshNo ratings yet

- Manual Transaxle: AT AXDocument64 pagesManual Transaxle: AT AXTony SaborioNo ratings yet

- Tsugami America M08SY IIDocument8 pagesTsugami America M08SY IIchinhtrungvttNo ratings yet

- Power ActionDocument27 pagesPower ActionBagas PratamaNo ratings yet

- QIB LA Legend and AbbreviationsDocument1 pageQIB LA Legend and AbbreviationsNoufal OthupurayilNo ratings yet

- PC of HYDRA SPARESDocument3 pagesPC of HYDRA SPARESSiddhi SparesNo ratings yet

- Tress Volume Akram Nor EulmaDocument7 pagesTress Volume Akram Nor EulmaZine eddine LefkirNo ratings yet

- Workshop Manual: TBR SeriesDocument60 pagesWorkshop Manual: TBR Seriesfrankhil ramosNo ratings yet

- DJF Module 3Document104 pagesDJF Module 3jestin100% (1)

- Spare Parts: Circuit D'Eau Hydrabolt/Wib Assemblé - NssDocument28 pagesSpare Parts: Circuit D'Eau Hydrabolt/Wib Assemblé - Nssmarcos.esquivelNo ratings yet

- Hydraulic Calculation - Sprinkler System (V 1.2) - OKDocument5 pagesHydraulic Calculation - Sprinkler System (V 1.2) - OKPerunding LNB100% (1)

- Piezas Del Grupo (MAGNUM 180) - TRACTOR DE MARCO PEQUEÑO NIVEL 4 (NA) - ZARH06086 Y DESPUÉS (10 / 10-12 / 10)Document2 pagesPiezas Del Grupo (MAGNUM 180) - TRACTOR DE MARCO PEQUEÑO NIVEL 4 (NA) - ZARH06086 Y DESPUÉS (10 / 10-12 / 10)Ramón ManglesNo ratings yet

- PDF Caterpillar 3516 CompressDocument60 pagesPDF Caterpillar 3516 CompressPhạm Hữu PhướcNo ratings yet

- 28 - 55-PDF - 035.2 Parts Catalog PDS655S, F530S, G460S-4B1,4B2,5B1 (2) (39524 84000)Document1 page28 - 55-PDF - 035.2 Parts Catalog PDS655S, F530S, G460S-4B1,4B2,5B1 (2) (39524 84000)ArakanNo ratings yet

- BombaDocument14 pagesBombaAdix GarridoNo ratings yet

- Miter Shooting Board: Close-ShavingDocument1 pageMiter Shooting Board: Close-ShavingJeffery OsvoldNo ratings yet