Professional Documents

Culture Documents

Weld Is Adequate & Stress Ratio 0.51

Weld Is Adequate & Stress Ratio 0.51

Uploaded by

Gerardo BeckerOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Weld Is Adequate & Stress Ratio 0.51

Weld Is Adequate & Stress Ratio 0.51

Uploaded by

Gerardo BeckerCopyright:

Available Formats

This worksheet is for checking weld sizes

References: Pressure Vessel Handbook, 8th ed, Megyesy

Mechanical Engineering Design, 7th ed, Shigley

By: DJY

Date: 8/4/2008

Job: 6093

Description of weld: Vaporizer skid cross beam to main welds

WELD OUTLINE CASE

DEFINITION OF SYMBOLS

Aw = Length of weld, in

f = Allowable unit force on weld, kip per lin in of weld

M = Bending moment, kip-in

l = Bending moment arm length, in

P = Tension or Compression Load

Sw = Section Modulus of weld lines subjected to bending moment, in^2

V = Vertical load for bending and/or shear, kip

w = Fillet weld leg dimension, in

Wn = Tensive or compressive force on weld, kip per lineal inch of weld

t

i

M

o

a

n

t

e

g

rr

iL

o

e

a

o

g

l

Table 9-6 from "Mechanical Engineering vDesign", Shigley, 7th ed., 2004, pg. 479

e

S

T

Schedule A: Allowable Load foriw

h Various Sizes of Fillet Welds

zi

Strength Level of Weld

Metal (EXX)

e

ce

60*

l

kd

w

(tau)n

, =

Allowable Unit Force on e

Fillet Weld, kip/linear in

s

f =is

n

o

###

7/8f

3/4

T

5/8

h

1/2i

c

7/16

3/8k

e

5/16

r

1/4

P

3/16

a

1/8

r

1/16

t

Ws = Average vertical shear on fillet weld, kip per lineal inch of weld

Wb = Bending force on weld, kip per lineal inch of weld

Wr = Resultant load on fillet weld, kip per lineal inch of weld

FORMULAS FOR FORCES ON WELD

TENSION OR COMPRESSION

VERTICAL SHEAR

Wn =

P

Aw

Ws =

V

Aw

J

o

i

n

e

d Fillet Weld Size, h

Schedule B: Minimum

,

i

n

* To 1/4 incl.

Over 1/4

Over 1/2

BENDING

Wb =

M

Sw

RESULTANT FORCE: Wr = (Wn2 + Ws2 + Wb2)

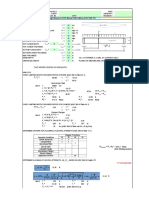

Weld is adequate & stress ratio = 0.51

INPUT

Weld Outline Case:

5

Strength Level of Weld Metal:

70*

Loading condition for bending, ieCantilever

or Mid-Span of Simply Supported Beam

Mid-Span

w = 3/8

in

P=

12.50 kip

If no tension or compression is present, P = 0

V=

12.50 kip

If only tension or compression is present, V = 0

b=

4 in

Weld dimension; refer to figure on right

d=

10 in

Weld dimension; refer to figure on right

l=

48 in

If bending is not to be considered, l = 0

Aw =

18.00 in

Sw =

56.67 in^2

M=

150 lb-in

f=

5.57 kip/lin in

Calculating Tensive or Compressive Force

Wn =

0.69 kip/lin in

Over 3/4

Over 1 1/2

Over 2 1/4

Over 6

###

Not to exceed the thickness of the thinner part.

Calculating Shear Force

Ws =

0.69 kip/lin in

=P/Aw

=V/Aw

=12.5kip/18lin in

=12.5kip/18lin in

Calculating Bending Force

Wb =

2.65 kip/lin in

=M/Sw

=150kip-in/56.67in^2

Calculating Resultant Force

Wr =

2.82 kip/lin in

=SQRT(W n^2 + W s^2 + W b^2)

=SQRT(0.69^2 + 0.69^2 + 2.65^2)

You might also like

- As Combined Stress Ratio Is Below 1 So Anchor Bolt Is OKDocument1 pageAs Combined Stress Ratio Is Below 1 So Anchor Bolt Is OKNaresh KumarNo ratings yet

- Welding Splice DesignDocument4 pagesWelding Splice DesignSana Ullah67% (3)

- General Academic School Calendar: Our Lady of Fatima UniversityDocument2 pagesGeneral Academic School Calendar: Our Lady of Fatima UniversityJanine GarciaNo ratings yet

- Weld StrengthDocument9 pagesWeld StrengthRUDHRA DHANASEKAR50% (2)

- Calculation Sheet: Padeye Calculations LoadsDocument15 pagesCalculation Sheet: Padeye Calculations Loadsshani5573No ratings yet

- R0.base Plate - (Top) )Document4 pagesR0.base Plate - (Top) )Srishti Project Consultants0% (1)

- "Bracket13" - Bracket Plate Stress Analysis ProgramDocument7 pages"Bracket13" - Bracket Plate Stress Analysis ProgramFarid TataNo ratings yet

- Capacity of Bolts in Bearing Connection Based On AISC-ASD 9th EditionDocument1 pageCapacity of Bolts in Bearing Connection Based On AISC-ASD 9th EditionThiha KyawNo ratings yet

- Moment Connection Design Hea220Document56 pagesMoment Connection Design Hea220Atul WanodeNo ratings yet

- DG Consulting EngineersDocument8 pagesDG Consulting EngineersThakshayani SellavelNo ratings yet

- Beam Shear ConnDocument26 pagesBeam Shear Connraghav abudhabiNo ratings yet

- AISC360 05 LRFD Shear Plate Bolted Connection Check 17-09-2013Document8 pagesAISC360 05 LRFD Shear Plate Bolted Connection Check 17-09-2013RUBEN BARTOLOME GARCIANo ratings yet

- UB254 To UB457Document7 pagesUB254 To UB457ihpeterNo ratings yet

- RHS & SHS Welding DesignDocument1 pageRHS & SHS Welding DesignMyat Thu Zar KhineNo ratings yet

- Anchoring Conditions: Non-Cracked Concrete 25 6 900 115 100 10 190 40 31.66667 6.666667 150 Hilti HIT-RE 500-SDDocument11 pagesAnchoring Conditions: Non-Cracked Concrete 25 6 900 115 100 10 190 40 31.66667 6.666667 150 Hilti HIT-RE 500-SDTimothy PinchinNo ratings yet

- UB Fin Plate DesignDocument8 pagesUB Fin Plate DesignWin ThanNo ratings yet

- Detail 81Document210 pagesDetail 81balaNo ratings yet

- 8Document6 pages8Mohan BhalmeNo ratings yet

- Clipconn All Bolt 13Document22 pagesClipconn All Bolt 13NEONo ratings yet

- Bracing Back To Back (Version 1)Document118 pagesBracing Back To Back (Version 1)Tameem AnsariNo ratings yet

- Design of Beam To Beam Connection Using Web CleatDocument2 pagesDesign of Beam To Beam Connection Using Web CleatAnonymous UUAriPf8KqNo ratings yet

- Base Plate Very EccentricityDocument2 pagesBase Plate Very EccentricityJetn SrisuthumNo ratings yet

- AISC Connection-2nd Edition - (2+2) Anchor Rod-FixedDocument16 pagesAISC Connection-2nd Edition - (2+2) Anchor Rod-FixedTuấnThanhNo ratings yet

- 21.65 Kips/bolt Shear Strength Controls: Section at ADocument3 pages21.65 Kips/bolt Shear Strength Controls: Section at ASuneesh PNo ratings yet

- Padeye CalDocument6 pagesPadeye Calhuangjl100% (1)

- Bolted Connection Angle Brace TensionDocument2 pagesBolted Connection Angle Brace TensionRajib MaharjanNo ratings yet

- Coector Bolt Estimation 54m SSTDocument5 pagesCoector Bolt Estimation 54m SSThenjie mirasolNo ratings yet

- Beam TabDocument19 pagesBeam Tab45k4No ratings yet

- R D H W FW: Design of Tailing LugDocument2 pagesR D H W FW: Design of Tailing LugvpjagannaathNo ratings yet

- Embedded PlateDocument2 pagesEmbedded PlateAlma M. LaraNo ratings yet

- Welded Moment Connection PDFDocument22 pagesWelded Moment Connection PDFRajasekar MeghanadhNo ratings yet

- Beam Simply SupportedDocument16 pagesBeam Simply SupportedVengatesh HariNo ratings yet

- Castellate Beam CheckDocument19 pagesCastellate Beam Checkken koemhongNo ratings yet

- 1.01D21A Post perp-TYPE - II B1 (UC152x152X37) Tob2 (UC203X46)Document49 pages1.01D21A Post perp-TYPE - II B1 (UC152x152X37) Tob2 (UC203X46)balaNo ratings yet

- Base Plate Ver Brace Connection - Column FlangeDocument27 pagesBase Plate Ver Brace Connection - Column FlangeAnıl Berk SağırNo ratings yet

- Side Girt Design-RwphDocument23 pagesSide Girt Design-Rwphasvenk309100% (1)

- Lashing Lug Round Bar Design: 1. GeneralDocument3 pagesLashing Lug Round Bar Design: 1. GeneralinnovativekarthiNo ratings yet

- Shear Connections (Steel-Steel)Document14 pagesShear Connections (Steel-Steel)Izzan SabelloNo ratings yet

- BOLTGRP13Document33 pagesBOLTGRP13NEONo ratings yet

- Design of Base Plate and Anchor BoltDocument7 pagesDesign of Base Plate and Anchor BoltsavsagarNo ratings yet

- TQ-0305-R00 - Calculo Estrutura PDFDocument4 pagesTQ-0305-R00 - Calculo Estrutura PDFPeterson MagroNo ratings yet

- Fi RE4Document259 pagesFi RE4vedranNo ratings yet

- Base Plate p1Document128 pagesBase Plate p1Pranav PrabhakarNo ratings yet

- Atasehir Gardens Podium OF: Member: LocationDocument7 pagesAtasehir Gardens Podium OF: Member: LocationAlphyl BalasabasNo ratings yet

- Bolted Web Plate ConnectionDocument20 pagesBolted Web Plate ConnectionjatinNo ratings yet

- Corbel and NibDocument17 pagesCorbel and NibCatherine Mohanji GeraNo ratings yet

- Beam Pin Connection, Bsa, BSC (Single Shear Gusset Plate Type)Document6 pagesBeam Pin Connection, Bsa, BSC (Single Shear Gusset Plate Type)vijaystructuralNo ratings yet

- Indes Enginnering: Design Code - IS800:2007Document2 pagesIndes Enginnering: Design Code - IS800:2007KARTHIK SGNo ratings yet

- 2L5x3x1/2LLBB: #N/A #N/A #N/ADocument1 page2L5x3x1/2LLBB: #N/A #N/A #N/ARaza AidanNo ratings yet

- Beam - Section Classification Is 800-2007Document6 pagesBeam - Section Classification Is 800-2007ranjitNo ratings yet

- MB 400 Base PlateDocument3 pagesMB 400 Base PlatePeace Rain100% (1)

- Baseplate Cirrcle 2018 - HUTATI LAPDocument11 pagesBaseplate Cirrcle 2018 - HUTATI LAPThinh ViproNo ratings yet

- Frame For Area 7-8Document173 pagesFrame For Area 7-8Saurabh GuptaNo ratings yet

- Column Properties:-: Due To UplitDocument2 pagesColumn Properties:-: Due To UplitRohit SinghNo ratings yet

- Four Bolts Extended Stiffened Endplate FR Moment Connection - AiscDocument49 pagesFour Bolts Extended Stiffened Endplate FR Moment Connection - AiscSAROJ BISWASNo ratings yet

- GratingDocument4 pagesGratingrammohan100% (1)

- Weld Joint DesignDocument4 pagesWeld Joint Designmiteshpatel191No ratings yet

- Saddle SupportDocument12 pagesSaddle SupportrustamriyadiNo ratings yet

- 4.2.3 Design of Eccentric Welded Connections (IIIDocument10 pages4.2.3 Design of Eccentric Welded Connections (IIIyadoleNo ratings yet

- Introduction To Shear Resistance of Plain' and Reinforced Concrete SectionsDocument11 pagesIntroduction To Shear Resistance of Plain' and Reinforced Concrete SectionsEmad KhanNo ratings yet

- Inventor Calculators NewDocument63 pagesInventor Calculators NewcostycgNo ratings yet

- Project Management Answer KeyDocument14 pagesProject Management Answer KeyMohamed Abdel-AzizNo ratings yet

- The Children Who Built Victorian BritainDocument1 pageThe Children Who Built Victorian Britain38014939No ratings yet

- Design of A Synchronous Reluctance DriveDocument9 pagesDesign of A Synchronous Reluctance DriveroyourboatNo ratings yet

- International Negotiation, IESEG, BrochureDocument1 pageInternational Negotiation, IESEG, BrochurecoxfnNo ratings yet

- Below Is The Elitmus Syllabus: Quantitative Aptitude Section Normally Contains Questions From Following TopicsDocument3 pagesBelow Is The Elitmus Syllabus: Quantitative Aptitude Section Normally Contains Questions From Following TopicsrandyzzzNo ratings yet

- Buddha's Daily RoutineDocument2 pagesBuddha's Daily Routinesu pannaNo ratings yet

- BioMEMS BooksDocument16 pagesBioMEMS BooksMadhu MidhaNo ratings yet

- Writing Argumentative EssaysDocument142 pagesWriting Argumentative EssaysEla Dragotă100% (2)

- The Main Advantage of School Uniforms Is That They Give A Common Identity To The School. Even When TheDocument3 pagesThe Main Advantage of School Uniforms Is That They Give A Common Identity To The School. Even When TheBelinha FerreiraNo ratings yet

- NSTP MODULE 1 1st SemesterDocument29 pagesNSTP MODULE 1 1st SemesterAngelica AyaganNo ratings yet

- 2 - 3472-2 MT - Marking Scheme Paper 2 2016Document12 pages2 - 3472-2 MT - Marking Scheme Paper 2 2016Siva RajahNo ratings yet

- Activity 6Document2 pagesActivity 6Juliana FormalejoNo ratings yet

- Effective Teaching Techniques: Keys To Classroom ManagementDocument31 pagesEffective Teaching Techniques: Keys To Classroom ManagementDr Dheeraj MehrotraNo ratings yet

- Narrative ReportDocument2 pagesNarrative Reportjanelorque91No ratings yet

- Chapter 1, 2 and 3Document34 pagesChapter 1, 2 and 3meriiNo ratings yet

- Vidya Bharati: Akhil Bhartiya Shiksha SansthanDocument9 pagesVidya Bharati: Akhil Bhartiya Shiksha SansthanVinayak SharmaNo ratings yet

- Admission Package 2022-2Document7 pagesAdmission Package 2022-2Marcia AddaNo ratings yet

- Cap756 - Web TechnologiesDocument18 pagesCap756 - Web TechnologiesShivanshu Kumar GuptaNo ratings yet

- Chimwemwe Ndovi - Team Leadership Case Study AssignmentDocument4 pagesChimwemwe Ndovi - Team Leadership Case Study AssignmentChimwemwe NdoviNo ratings yet

- Research On Social Work Practice: PurposeDocument10 pagesResearch On Social Work Practice: PurposeMAHESH KOUJALAGINo ratings yet

- PR 2 Quarter 02 Modules Student Copy 1Document129 pagesPR 2 Quarter 02 Modules Student Copy 1Lawrence TubiganNo ratings yet

- Chapter 1 - Developmental PsychologyDocument51 pagesChapter 1 - Developmental PsychologyJAVIER, JEREMY G.No ratings yet

- GRADE 2 - 1ST QUARTERDocument46 pagesGRADE 2 - 1ST QUARTERLoreta Ancheta Cataina AciertoNo ratings yet

- 1.5.2 Factors Affecting The Integration of ICT in Science and Mathematics Teaching in Selected Science, TDocument13 pages1.5.2 Factors Affecting The Integration of ICT in Science and Mathematics Teaching in Selected Science, Tgwayne dongalloNo ratings yet

- Taking A Course: BBC Learning English QuiznetDocument3 pagesTaking A Course: BBC Learning English Quiznets.belkaNo ratings yet

- Suggested Summer Reading 2020 - 976872800293752833SD - PDFDocument4 pagesSuggested Summer Reading 2020 - 976872800293752833SD - PDFSivaSubramanianNo ratings yet

- 1st Quarter Summative Exam Grade 9 MathematicsDocument3 pages1st Quarter Summative Exam Grade 9 MathematicsVienna MendozaNo ratings yet

- Subsets of Real Numbers: Learner's Module in Mathematics 7Document16 pagesSubsets of Real Numbers: Learner's Module in Mathematics 7Ric NapusNo ratings yet

- Directing: Dr. Rosemarie I. SoDocument36 pagesDirecting: Dr. Rosemarie I. SoChin MartinzNo ratings yet