Professional Documents

Culture Documents

Design of welded joints formulas

Uploaded by

miteshpatel1910 ratings0% found this document useful (0 votes)

94 views4 pagesWeld joint design

Original Title

Weld joint design

Copyright

© © All Rights Reserved

Available Formats

XLSX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentWeld joint design

Copyright:

© All Rights Reserved

Available Formats

Download as XLSX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

94 views4 pagesDesign of welded joints formulas

Uploaded by

miteshpatel191Weld joint design

Copyright:

© All Rights Reserved

Available Formats

Download as XLSX, PDF, TXT or read online from Scribd

You are on page 1of 4

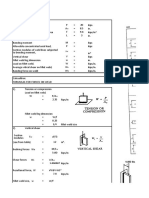

DESIGN OF WELDED JOINTS

DEFINITION OF SYMBOLS

Tension load P = 20 kips.

Length of weld Aw = 8.5 in.

Allowable load on weld per leg-area f = 9.6 kips/in²

Cleat outer distance from weld L = 3 in.

Bending moment M = kips

Allowable concentrated axial load, P = kips

Section modulus of weld lines subjected Sw =

to bending moment, in²

Vertical shear V = kips

Fillet weld leg dimension w = in.

Load on fillet weld. W = kips/in.

Average vrtical shear on fillet weld, Ws = kips/in.

Bending force on weld Wb = kips/in.

Calcualtion:

FORMULAS FOR FORCES ON WELD

1). Tension or compression

Load on fillet weld.

W = P/Aw

= 2.35 kips/in

Fillet weld leg dimension

w = W/f

= 0.25

= 1/4 fillet weld size

2). Vertical shear

Section

modulus

Sw = d²/3

(see from table) = 12 in³.

Bedning forces Wb = M/Sw

= 5.00 kips/in

Shear forces Ws = V/Aw

= 1.666667 kips/in

Resultanat force, W = √Wb²+WS²

= 7.8 kips/in

Fillet weld size, w = W/f

= 0.81

= 1/4 use fillet weld

You might also like

- RCC Footing Design As Per BS CodeDocument50 pagesRCC Footing Design As Per BS CodeREENA VINODNo ratings yet

- Behaviour of Cold-Formed Z Purlins With Sag-Rods in Pre-Engineered BuildingsDocument7 pagesBehaviour of Cold-Formed Z Purlins With Sag-Rods in Pre-Engineered BuildingsIJRASETPublicationsNo ratings yet

- Trash Rack Design of Compression Member As Per Is 800-2007Document12 pagesTrash Rack Design of Compression Member As Per Is 800-2007D SRINIVASNo ratings yet

- IS 800-2007 Provisions SummaryDocument30 pagesIS 800-2007 Provisions SummarySachin MeenaNo ratings yet

- Roof TrussDocument4 pagesRoof TrussShamie Dela Cruz CaldeaNo ratings yet

- Design Gusset Plate JointsDocument59 pagesDesign Gusset Plate JointsVaibhav SharmaNo ratings yet

- Gusset Plate Connection DesignDocument3 pagesGusset Plate Connection DesignMin Khant KyawNo ratings yet

- Wind Load AS1170 2Document15 pagesWind Load AS1170 2Divesh rahulNo ratings yet

- Corbel designDocument4 pagesCorbel designnonameNo ratings yet

- Bearing CheckDocument6 pagesBearing CheckdhanushkaNo ratings yet

- 16 Bolt Pattern Fixed Base Plate Design - For 4.6 Grade Anchor BoltsDocument30 pages16 Bolt Pattern Fixed Base Plate Design - For 4.6 Grade Anchor Boltsafzal samaNo ratings yet

- Splice DesignDocument13 pagesSplice Designtitir bagchiNo ratings yet

- Is800-2007 Appendix PDFDocument85 pagesIs800-2007 Appendix PDFDebasish MondalNo ratings yet

- Combined Footing Design2Document39 pagesCombined Footing Design2sujit naikwadi100% (1)

- Steelwork Design Guide To BS 5950 Vol 1 Part B1 Dimensions & PropertiesDocument56 pagesSteelwork Design Guide To BS 5950 Vol 1 Part B1 Dimensions & PropertiessubamanivelNo ratings yet

- Strength and Behavior of Reinforced Concrete Obtuse Corners Under Opening Bending MomentsDocument6 pagesStrength and Behavior of Reinforced Concrete Obtuse Corners Under Opening Bending MomentsValdemir ColaresNo ratings yet

- Bolt Capacities: Grade 4.6 Bolts in S355Document3 pagesBolt Capacities: Grade 4.6 Bolts in S355Ah ChiaNo ratings yet

- Web Bearing and Buck1ling To BS en 1993Document3 pagesWeb Bearing and Buck1ling To BS en 1993antoninoNo ratings yet

- FND BoltDocument1 pageFND BoltArunkumar RackanNo ratings yet

- Staircase Design 001Document18 pagesStaircase Design 001Er navneet jassiNo ratings yet

- Welded & Pinned Connection Design CalculationDocument14 pagesWelded & Pinned Connection Design CalculationPrakash Singh RawalNo ratings yet

- Design of Stirrups As Per IS456-2000Document1 pageDesign of Stirrups As Per IS456-2000Sanjay RokkaNo ratings yet

- Wind Load IS875Document30 pagesWind Load IS875Pranjal Pareek100% (2)

- Calculation of end plate beam connection designDocument1 pageCalculation of end plate beam connection designFortunata Citraningrum SukmonoNo ratings yet

- NSCP 2001 Allowable Stress Design Bending of I-Shaped MembersDocument1 pageNSCP 2001 Allowable Stress Design Bending of I-Shaped MembersDavid Nelson AngiwanNo ratings yet

- General Sheet NotesDocument1 pageGeneral Sheet NotesManoj JaiswalNo ratings yet

- Design of BracingDocument4 pagesDesign of Bracingankkeshmundra1No ratings yet

- Design of Moment connection Welded TypeDocument10 pagesDesign of Moment connection Welded TypeRajib MaharjanNo ratings yet

- Plate GirderDocument6 pagesPlate GirderOkayNo ratings yet

- COLUMN BASE PLATE DESIGN CALCULATIONS (BS5950-1:2000Document7 pagesCOLUMN BASE PLATE DESIGN CALCULATIONS (BS5950-1:2000Shakil Akhter100% (1)

- Web Flange WeldDocument1 pageWeb Flange Weldakgupta733779No ratings yet

- Crack Width Check For Water Tank BaseDocument4 pagesCrack Width Check For Water Tank BaseShamim Ahsan ZuberyNo ratings yet

- Is 13920Document183 pagesIs 13920p_ignatiusNo ratings yet

- REINFORCEMENT CALCULATION FOR 1000MM THICK CF1Document3 pagesREINFORCEMENT CALCULATION FOR 1000MM THICK CF1ARUNKUMAR KNo ratings yet

- Com ColumnDocument2 pagesCom ColumnHarjasa AdhiNo ratings yet

- CONT 3S Ofre OcantiDocument2 pagesCONT 3S Ofre OcantiRiazahemad B Jagadal100% (1)

- Plate GirderDocument15 pagesPlate GirderPriodeep ChowdhuryNo ratings yet

- DESIGN OF INTERMEDIATE SPAN SIDE GIRTDocument2 pagesDESIGN OF INTERMEDIATE SPAN SIDE GIRTSantosh BapuNo ratings yet

- Members With Combined Bending and Axial ForceDocument32 pagesMembers With Combined Bending and Axial ForceJohn RomanusNo ratings yet

- Effective LengthDocument17 pagesEffective LengthJob NantawatNo ratings yet

- Slab Design:-Out House Room: (One Long & One Short Edge Discontineous) (Two Way)Document12 pagesSlab Design:-Out House Room: (One Long & One Short Edge Discontineous) (Two Way)shiv kumarNo ratings yet

- Load Case, Load Combination, Modal Case Options. Choose The Load Case To Be DisplayedDocument5 pagesLoad Case, Load Combination, Modal Case Options. Choose The Load Case To Be DisplayedLivia15No ratings yet

- BPOSDAGDocument27 pagesBPOSDAGIndustry Standard Structural DesignNo ratings yet

- 2 Way Slab OkDocument4 pages2 Way Slab OkMikeNo ratings yet

- Mathcad - 09. Design Combined Shear & TorsionDocument5 pagesMathcad - 09. Design Combined Shear & TorsionMrAlittle FingerNo ratings yet

- As Combined Stress Ratio Is Below 1 So Anchor Bolt Is OKDocument1 pageAs Combined Stress Ratio Is Below 1 So Anchor Bolt Is OKNaresh KumarNo ratings yet

- HSS Flange Plate Moment Connection - Temporary SteelDocument9 pagesHSS Flange Plate Moment Connection - Temporary SteelrajedmaglinteNo ratings yet

- RCC31R Rigorous One-Way SlabsDocument148 pagesRCC31R Rigorous One-Way SlabsMohammad Twaha JaumbocusNo ratings yet

- Stiffner Design For Beam Column ConnectionsDocument84 pagesStiffner Design For Beam Column ConnectionsfabnameNo ratings yet

- Column Beam Seismic ConnectionDocument8 pagesColumn Beam Seismic ConnectionPrakash Singh RawalNo ratings yet

- Design of Raft SlabDocument6 pagesDesign of Raft SlabVenkatesha HebbarNo ratings yet

- Design Calculation for Bracing ConnectionDocument10 pagesDesign Calculation for Bracing ConnectionLian Jia JieNo ratings yet

- Lecture 11-1 Bases by H.J. MtyanaDocument29 pagesLecture 11-1 Bases by H.J. MtyanaHarold Jackson Mtyana100% (1)

- Opening in Slab and BeamDocument13 pagesOpening in Slab and BeamYohan LimNo ratings yet

- Column Design - As Per BS CodeDocument16 pagesColumn Design - As Per BS CodeYam BalaoingNo ratings yet

- Design of Common Structural MembersDocument16 pagesDesign of Common Structural MembersmanojmoryeNo ratings yet

- Welding Splice DesignDocument4 pagesWelding Splice DesignSana Ullah50% (2)

- WeldsDocument1 pageWeldsabeyivanNo ratings yet

- Primary Lifting LugDocument4 pagesPrimary Lifting LugAnthony GravagneNo ratings yet

- Lifting Lug CalculationDocument2 pagesLifting Lug Calculationmiteshpatel191No ratings yet

- Lifting Trunnion Calculations On Horizontal Vessel - 1Document1 pageLifting Trunnion Calculations On Horizontal Vessel - 1miteshpatel191No ratings yet

- GTAW Welding Process ParametersDocument12 pagesGTAW Welding Process Parametersmiteshpatel191No ratings yet

- Platform Cleat CalculationDocument1 pagePlatform Cleat Calculationmiteshpatel191No ratings yet

- Hydrotest Test Pressure CalculationDocument1 pageHydrotest Test Pressure Calculationmiteshpatel191No ratings yet

- Evaluation of Hydro Test PressureDocument1 pageEvaluation of Hydro Test Pressuremiteshpatel191No ratings yet

- MAWP Design Report ASME DesignDocument2 pagesMAWP Design Report ASME Designmiteshpatel191No ratings yet

- Design Pressure EstimationDocument1 pageDesign Pressure Estimationmiteshpatel191No ratings yet

- Section DataDocument5 pagesSection Datamiteshpatel191No ratings yet

- Skid lug and lifting lug stress analysisDocument8 pagesSkid lug and lifting lug stress analysismiteshpatel191No ratings yet

- Uc COLUMNSDocument4 pagesUc COLUMNSmiteshpatel191No ratings yet

- Tension in SlingDocument2 pagesTension in Slingmiteshpatel191No ratings yet

- Column W10x49 Brace 2L6x4x1/2Document10 pagesColumn W10x49 Brace 2L6x4x1/2narasimmans100% (1)

- Weight CalculationDocument17 pagesWeight Calculationmiteshpatel191No ratings yet

- I-Beam and Structural Shape CalculationsDocument5 pagesI-Beam and Structural Shape Calculationsmiteshpatel191No ratings yet

- Design of welded joints formulasDocument4 pagesDesign of welded joints formulasmiteshpatel191No ratings yet

- Skid lug and lifting lug stress analysisDocument8 pagesSkid lug and lifting lug stress analysismiteshpatel191No ratings yet

- Base Ring Fillet Size CalculationDocument4 pagesBase Ring Fillet Size Calculationmiteshpatel191No ratings yet

- SA 516 Gr. 70 Lifting Lug Material Stress AnalysisDocument2 pagesSA 516 Gr. 70 Lifting Lug Material Stress Analysismiteshpatel191100% (2)

- Figure UG-34 Forged HeadDocument8 pagesFigure UG-34 Forged Headmiteshpatel191No ratings yet

- Lug - On - FlangeDocument17 pagesLug - On - Flangeshaishav100% (1)

- Tie Rod Support For Retangular TanksDocument11 pagesTie Rod Support For Retangular Tanksmiteshpatel191No ratings yet

- Storage Tank Design Calculation - Api 650Document21 pagesStorage Tank Design Calculation - Api 650miteshpatel191100% (3)

- Vessel lifting lug design data and stress analysisDocument3 pagesVessel lifting lug design data and stress analysismiteshpatel191100% (1)

- Shell / Dished Head(s) Calculations: Description Regulation Formula Symbol Value UnitDocument2 pagesShell / Dished Head(s) Calculations: Description Regulation Formula Symbol Value Unitmiteshpatel191100% (1)

- Nozzle Reinforcement Calculations: HH1&HH2 (Hand Hole) : Description Regulation Formula Symbol Value UnitDocument1 pageNozzle Reinforcement Calculations: HH1&HH2 (Hand Hole) : Description Regulation Formula Symbol Value Unitmiteshpatel191No ratings yet

- Ellipsoidal HEAD THICKNESS CALCULATION FOR INTERNAL PRESSUREDocument3 pagesEllipsoidal HEAD THICKNESS CALCULATION FOR INTERNAL PRESSUREmiteshpatel191No ratings yet

- Top Cover Design Without StiffnersDocument2 pagesTop Cover Design Without Stiffnersmiteshpatel191No ratings yet

- Torispherical Heads THICKNESS CALCULATION FOR INTERNAL PRESSUREDocument3 pagesTorispherical Heads THICKNESS CALCULATION FOR INTERNAL PRESSUREmiteshpatel191No ratings yet