100% found this document useful (2 votes)

2K views3 pagesLifting Lug Design and Calculations

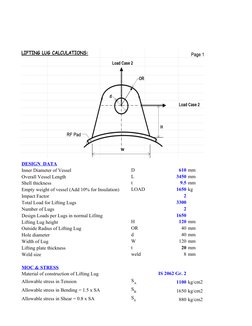

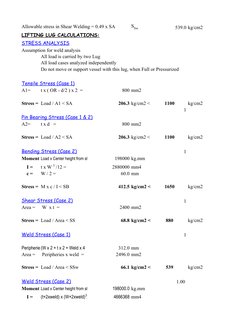

This document provides design data and calculations for lifting lugs on a vessel with an inner diameter of 610mm and overall length of 3450mm. Key specifications include a shell thickness of 9.5mm and total load of 3300kg distributed evenly over two lifting lugs. Stress analysis was performed for tensile, pin bearing, bending, shear, and weld stresses and showed stresses are less than the allowable limits for the specified material, IS 2062 Gr. 2 steel. The design of the lifting lugs is therefore acceptable.

Uploaded by

miteshpatel191Copyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as XLS, PDF, TXT or read online on Scribd

100% found this document useful (2 votes)

2K views3 pagesLifting Lug Design and Calculations

This document provides design data and calculations for lifting lugs on a vessel with an inner diameter of 610mm and overall length of 3450mm. Key specifications include a shell thickness of 9.5mm and total load of 3300kg distributed evenly over two lifting lugs. Stress analysis was performed for tensile, pin bearing, bending, shear, and weld stresses and showed stresses are less than the allowable limits for the specified material, IS 2062 Gr. 2 steel. The design of the lifting lugs is therefore acceptable.

Uploaded by

miteshpatel191Copyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as XLS, PDF, TXT or read online on Scribd