Professional Documents

Culture Documents

W5 การจัดสมดุล

Uploaded by

kitisakp99Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

W5 การจัดสมดุล

Uploaded by

kitisakp99Copyright:

Available Formats

5

04-042-728

3 . 5

5.1

60

5.2

60

5.3

60

5.1

5.1.1

5.1.2

5.2

5.2.1

5.2.2

5.2.3

5.2.4

5.2.5

5.3

5.3.1

5.3.2

5- 5

5.1-5.3 5-1 15-20

5.1

5.1.1

5.1.2

5.2

5.2.1

5.2.2

5.2.3

5.2.4

5.2.5

5.3

5.3.1

5.3.2

5- 6

5.1

(254 3)

2 (

Job-Order

Production Job Shop Production) ( Production to Stock)

( Intermittent

Manufacturing)

(Continuous Manufacturing) ( Mass

Production)

5.1.1 (Job-Order Production Job Shop

Production)

(2545)

(Intermittent Flow)

1)

2)

3)

4)

5- 7

5)

(Machine Shop)

5.1.2 (Continuous Production System)

(2545)

(Make to Production)

(Production Line)

(Conveyors)

(Product Layout)

1)

2)

3)

4)

5)

- (First In First Out - FIFO)

6) (Mass Production)

5.2

(

Motion Study) (Standard Time)

(, 2543)

5- 8

5.2.1

1)

2)

(Element)

(1)

(2) (Performance)

(3)

(4)

3

)

1

4

)

(Sampling Process)

(Variance)

5- 9

( Normal Distribution)

(Mean ; ) ( Standard Deviation ; )

n Xi i 1 n

Xi

(5.1)

i = 1, 2, 3, ..., n

i = 1, 2, 3, ..., n

(Xi-)2

(5.2)

(Confidence)

(Precision)

2

2

2

N

=

k/s nXi - (Xi)

(5.3)

Xi

n

=

N

=

(

)

s

=

( 0.05)

k

=

5.1

(%)

68.3

95.5

99.7

: , 2543

k

1

2

3

5- 10

5.2.2

100 %

100 %

100 %

100 % Westing House

Westing House

4

1) (Skill)

2) (Effort)

3) (Consistency)

4) (Conditions)

4

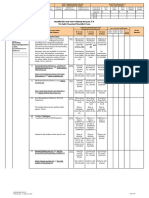

5.2

5- 11

5.2

Skill

+0.15

A1

+0.13

A2

+0.11

B1

+0.08

B2

+0.06

C1

+0.03

C2

0.00

D

-0.05

E1

-0.10

E2

-0.16

F1

-0.22

F2

Condition

+0.06

A

+0.04

B

+0.02

C

0.00

D

-0.03

E

-0.07

F

: , 2528

Super Skill

Excellent

Good

Average

Fair

Poor

Ideal

Excellent

Good

Average

Fair

Poor

+0.13

+0.12

+0.10

+0.08

+0.05

+0.02

0.00

-0.04

-0.008

-0.12

-0.17

+0.04

+0.03

+0.01

0.00

-0.02

-0.04

Effort

A1

A2

B1

B2

C1

C2

D

E1

E2

F1

F2

Consistency

A

B

C

D

E

F

Excessive

Excellent

Good

Average

Fair

Poor

Perfect

Excellent

Good

Average

Fair

Poor

5.2.3 (Determining The Normal Time)

, 2543

Normal Time

=

Selected Time x Rating Factor

(2.7)

5.2.4 (Determining Allowance Time)

1) (Delay Allowance) 2

5- 12

(1) (Unavoidable Delays)

(2) (Avoidable Delays)

,

2) (Personal Allowance)

3) (Fatigue Allowance)

5.2.5 (Determining Standards Time)

(Normal Time) (Allowance Time)

2.8

Std =

NT + A(NT)

=

NT (1+A)

(2.8)

Std

NT

A

=

=

=

(Standard Time)

(Normal Time)

(Allowance Time) %

5.3 (Flow Shop Line Balancing)

(Continuous Production)

( Elements)

5.3.1

(2545)

1

(Conveyor)

5- 13

(2534)

(Job Analysis)

1, 200

12

180

(2548) (Idle

Time)

1) (Maximum Cycle Time)

82.09 Housing 1

2) (Operating Time Per Day)

8 /

2

P

=

(2.1)

OT / CT

P

OT

CT

(Operating Time Per Day)

(Cycle Time)

)

P

( 2 16

= 16 X 3,600

82.09

= 57,600

82.09

= 701

Housing 1 16

701 Common Rail 701

CT =

OT

(2.2)

P

5- 14

1,478

CT =

57,600

1478

=

39

701

1 478

39

(2535) (Line Efficiency)

(2.3)

E

Di

1 - i=1

CxN

E

Di

C

N

=

=

=

=

x 100

(2.3)

5.3.2

1

) ( Mathematical Programming)

Dynamic Programming Jackson ..

1956 Integer Programming Bowman .. 1960

2

) Heuristic

( Zoning Constrains)

(1) Hoffman Technique

5- 15

Hoffman .. 1963

Successive Maximum Elemental Time

Technique (SMET) SMET

COMSOAL

Hoffman

1

( Precedence Matrix) 0 1

1 0

Code

Number 0

2 0 Code Number

3 Code Number 0

4

5 4 6

7

6

Code Number Code Number

7 2 0

3 2 7

9 8 0 10

11

10 Code Number 1 7

11 Code Number Code Number

9

12 2 11

Code Number

(2) COMSOAL Technique

(2545)

COMSOAL

Computer Method of Sequencing Operation for Assembly Line Heuristic

5- 16

Arcus

(1966) COMSOAL .. 1966

(Biased Sampling)

COMSOAL

Crysler

COMSOAL

1

(Immediate Following Tasks)

2 List A

(Immediate Preceding

Tasks) List A

3 List B

List A List B

4 List B

List B

4

List C

5 List C List A List B

6 List A 1

7 List B 4-7

1 2

4

A.L. Arcus

List B List C Bias Selection 9

1

5- 17

2

List B

3

4 1/x x =

5 1/ x x =

7 1 6

8

9 1 , 5 , 6

, 7 8

(3) Ranked Positional Weight Technique (RPW)

Helgeson and Birnie

.. 1961 RPW

RPW RPW

RPW

1 RPW

2 RPW

3

4 RPW

RPW

5.4

5- 18

2.5.1

Ranked Positional Weight (RPW), COMSOAL Hoffman

2.5.2

1)

2)

3)

4)

5)

6)

5- 19

5 04-042-728

1) KM-1500.3 F-24

KM-1500.3 F-24

1 ( 120 )

()

()

()

1 1.

101.25

101.25

18.75

2.

6.05

2 3.

89.54

113.29

6.71

4.

17.70

5.

25.60

6. Back joint

8.45

3

106.09

13.91

7. Back joint

9.24

8.

62.80

9.

69.46

4

106.16

13.84

10.

36.70

11.

101.64

108.55

11.45

5 12.

3.55

13.

3.36

14.

32.25

15.

8.96

6 16.

14.61

106.06

13.94

17.

28.62

18.

21.62

19.

77.52

7 20.

8.90

105.99

14.01

21.

17.57

22.

7.81

8 23.

32.61

106.17

13.83

24.

34.32

(%)

84.37

94.40

88.40

88.46

90.45

88.38

88.32

88.47

5- 20

25.

26.

9 27.

28.

10 29.

()

31.43

29.35

22.80

36.25

101.52

()

()

(%)

88.40

31.60

73.66

101.52

1,043.48

18.48

156.52

84.60

1 156.52

------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------ ------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

5- 21

( 120 )

1

2

2

()

1

101.25

2

6.05

3

89.54

4

17.70

5

25.60

6

Back joint

8.45

7

Back joint

9.24

8

62.80

9

69.46

10

36.70

11

101.64

12

3.55

13

3.36

14

32.25

15

8.96

16

14.61

17

28.62

18

21.62

19

77.52

20

8.90

21

19.57

22

7.81

23

32.61

24

34.32

25

31.43

5- 22

26

27

28

29

()

29.35

22.80

36.25

101.52

Ranked Positional Weight

(RPW) COMSOAL

5- 23

1. ( Thiniking-Based)

2. (Questioning Based)

3. (Self-Learning)

/

1. ()

2.

3.

1. :

2. : Power Point

1.

2.

3.

5- 24

. (2548) :

.

.

. (2543). . :

(-).

. (2534).

.

.

. (2535). . .

.

. (2543). .

.

. (2532). .

.

. (2545). . :

(-).

.(2545). .

.

. (2535).

.

.

. (2545). . :

.

. (2534). . :

.

. (2543).

.

:

.

. (2534). .

, .

. (2528). .

.

. (2547).

. .

5- 25

. (2539). .

,

.

Arcus,A.L. (1966). COMSOAL : A Computer Method of Sequencing Operation

for Assembly Line. International Journal of Production Research 4(4) : 259277 Hoffman, T.R. (1963). Assembly Line Balancing . With a Precedence

Matrix.

Management Science, 9(4):

You might also like

- ThaiDocument17 pagesThaikitisakp99No ratings yet

- 5S Audit Checklist TH-EN 4ADocument17 pages5S Audit Checklist TH-EN 4Akitisakp99No ratings yet

- ComplexDocument96 pagesComplexkitisakp99No ratings yet

- จัดการอารมณ์พ่อแม่ ดูแลอารมณ์ลูกDocument12 pagesจัดการอารมณ์พ่อแม่ ดูแลอารมณ์ลูกkitisakp99No ratings yet

- Lupius Library เล่ม 1Document227 pagesLupius Library เล่ม 1kitisakp99No ratings yet

- ตอนที่ 1 ดาบหิมะเลือดDocument199 pagesตอนที่ 1 ดาบหิมะเลือดkitisakp99No ratings yet

- กระบี่จอมภพ เล่ม 1Document449 pagesกระบี่จอมภพ เล่ม 1kitisakp9967% (3)