Professional Documents

Culture Documents

Welding Procedure Specifications (WPS) : Groove Design, Root Spacing As Per The Enclosed Sketch

Uploaded by

aOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Welding Procedure Specifications (WPS) : Groove Design, Root Spacing As Per The Enclosed Sketch

Uploaded by

aCopyright:

Available Formats

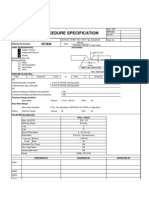

WELDING PROCEDURE SPECIFICATIONS(WPS)

W P S No: 3786-GT-SS-01

Revision No: 1

Date: 07-11-2005

Supporting PQR #: PQR-A-77-GT-03

Process(es): GTAW

Type: Manual

Welding

Code(s): ASME IX, 2004 Edn.

BASE METALS (QW-403)

P. No: 8

Group No: 1

Specification type and grade

grade:

to

OR

P No: 8

to

Group No: 1

Specification type and

SA 240 TP 316 L to SA 240 TP 316 L, SA 240 TP 316L to SA 312 TP 316L,

SA 312 TP 316L to SA 403 WP 316 LN

Thickness Range (T) :

Base Metal:

Groove: 0.0629" (1.6 mm) to 0.436" (11.08 mm)

Fillet: All

Pipe Dia. Range:

Groove: All

Fillet: All

Other:

None

JOINTS: (QW-402)

Details:

Joint Design:

(Bevel Preparation: Flame Cut, Machining/ Grinding)

Backing: No

Retainer: None

GROOVE DESIGN, ROOT SPACING AS PER THE ENCLOSED SKETCH.

FILLER METALS (QW-404):

Specification No (SFA) :

AWS No. (CLASS) :

Filler No. (F):

Analysis No (A):

Size of Filler Metals:

Type:

Weld Metal Thichness Range

(t) :

Groove

Fillet

Consumable Insert:

Other:

5.9 (GTAW)

ER 316L

6

8

2.4 mm

Solid

11.08 mm(Max)

All

None

None

1 OF 3

WPS #: 3786-GT-

SS-01 Rev.1

POSITIONS (QW-405)

Positions of Groove :

All

Welding Progression:

Vertical Up

Positions of fillet

None

POST WELD HEAT TREATMENT(QW407)

Temperature Range: 600 - 620 0 C

Time Range:

1 Hour/ Inch

Heating Rate: 2220 C / Hr Max from

4270 C

Cooling Rate: 2000 C / Hr Max from

4270 C

PREHEAT (QW-406)

Preheat Temp. Min: 21 Deg C

GAS (QW-408)

Shielding Gas(es): Argon

Interpass Temp. Max: 177 Deg C

Purging Gas

Preheat Maintenance: None

% Composition (mixtures): 99.99 %

Measurement : Thermostick

Flow Rate

Gas Trailing

TECHNIQUE(QW-410)

String or Weave Bead

Orifice or Gas Cup Size

Initial and Interpass Cleaning

required

Method of Back Gouging

Oscillation

Closed to out Chamber

: 25-30 CFH

: None

String/ Weave

0.5"

: Grinding/ Power Brushing(SS) as

: NA (See Note Below)

: None

: NA

Multiple or Single Pass (per side) : Multiple

Multiple or Single Electrodes

: Argon

Single

Travel Speed Range (In/ Mt)

: 2-4

Peening

: None

Other

: None

2 OF 3

WPS #: 3786-

GT-SS-01 Rev.1

ELECTRICAL CHARACTERISTICS (QW-409)

Tungsten Electrode Size

: 3/32" , EW Th2

Mode of Transfer

: None

Wire Speed Range (in/mt)

Pulsing Current

Weld

Layer

s

Proces

s

Root

GTAW

Hot

: None

: None

Filler Metal

Current

Type

Amp

Polar

Range

Volt

Rang

e

ER 316L

3/32"

DCSP

115

95-

1013

1.5 - 3.0

GTAW

ER 316L

3/32"

DCSP

125

105-

1114

2.0 - 3.5

Fill

GTAW

ER 316L

3/32"

DCSP

155

120-

1318

1.5 - 4.0

Cap

GTAW

ER 316L

3/32"

DCSP

150

125-

1519

2.0 - 3.5

Class

Dia

Travel

Speed

Range(in/

mt)

Other

Note: When accessible and if necessary, back welding will be done using ER

316L.

Root shall be ground to white metal before back welding using grinders

and

wire brush meant exclusivly for Stainless Steel.

THIS WPS SHALL BE USED AND APPLICABLE TO WELD THE

STAINLESS STEEL INTERNALS ON THE CLADDED AREA.

FOR GMMOS:

3 OF 3

Date:

4 OF 3

You might also like

- Revised Wps For Gtaw - Xls Dated 25.01.2017Document2 pagesRevised Wps For Gtaw - Xls Dated 25.01.2017GopinathNo ratings yet

- WPS002 312Document2 pagesWPS002 312proxywarNo ratings yet

- Pressure Test RecordDocument4 pagesPressure Test RecordhikmahNo ratings yet

- 03 WPS CS 1Document3 pages03 WPS CS 1mohammadNo ratings yet

- Saudi Aramco Inspection ChecklistDocument2 pagesSaudi Aramco Inspection Checklistkarthi51289No ratings yet

- Agoco Welding Procedure Specification: Gtaw/Smaw Manual JOINTS (QW-402)Document3 pagesAgoco Welding Procedure Specification: Gtaw/Smaw Manual JOINTS (QW-402)Anonymous 7vljJzHNo ratings yet

- Hard Facing Overlay PDF FreeDocument2 pagesHard Facing Overlay PDF Freemayav1No ratings yet

- WPS Asme Ix PDFDocument4 pagesWPS Asme Ix PDFSergiu LungNo ratings yet

- P 0200 152 LHS 01Document2 pagesP 0200 152 LHS 01Zaidi100% (1)

- WPS and PQR of GMAWDocument8 pagesWPS and PQR of GMAW魏利强No ratings yet

- New Microsoft Excel WorksheetDocument6 pagesNew Microsoft Excel Worksheetravi00098No ratings yet

- PQR Asme Template EDITABLEDocument6 pagesPQR Asme Template EDITABLErcpretoriusNo ratings yet

- Welding Traceability ReportDocument1 pageWelding Traceability ReportvinothNo ratings yet

- AUT-1023 A2 Multitrac PEKDocument1 pageAUT-1023 A2 Multitrac PEKcarlosNo ratings yet

- DOCDocument207 pagesDOCdhaktodesatyajitNo ratings yet

- MSOG-QAQC-F-19 Welder Qualification Test (WQT) SummaryDocument1 pageMSOG-QAQC-F-19 Welder Qualification Test (WQT) SummaryMohd SaffririzalNo ratings yet

- SS Pipe Welding ProcedureDocument5 pagesSS Pipe Welding Procedureamit rajputNo ratings yet

- Saudi Aramco Inspection Checklist: Vent Piping Connection SAIC-S-4041 18-May-05 PlumbDocument2 pagesSaudi Aramco Inspection Checklist: Vent Piping Connection SAIC-S-4041 18-May-05 PlumbUzair AhmadNo ratings yet

- WPS 11-23-1Document3 pagesWPS 11-23-1Anoop Raj RaoNo ratings yet

- DRAFT Sample Welding Procedure GuidebookDocument3 pagesDRAFT Sample Welding Procedure Guidebookahmad100% (1)

- SA 387 Grade 91 Class 2Document4 pagesSA 387 Grade 91 Class 2briang-2No ratings yet

- Company Name Key Information Questions Answers File Reference Test Conducted On Reviews & ApprovalsDocument11 pagesCompany Name Key Information Questions Answers File Reference Test Conducted On Reviews & ApprovalsMAT-LIONNo ratings yet

- Blasting ProcedureDocument3 pagesBlasting ProcedureFaiz ZainudinNo ratings yet

- Hydro TestDocument1 pageHydro TestMilan BanerjeeNo ratings yet

- KBR Inspection Test Plan For Anchor Bolts: Level 1 Level 2 Level 3Document4 pagesKBR Inspection Test Plan For Anchor Bolts: Level 1 Level 2 Level 3kamlNo ratings yet

- Wps Non PWHTDocument193 pagesWps Non PWHTMaxwell G SihotangNo ratings yet

- Wps Pip Gtaw - ArabianDocument1 pageWps Pip Gtaw - ArabianIshack MohammedNo ratings yet

- STD PPM 330-3000 Opl v3 ENDocument33 pagesSTD PPM 330-3000 Opl v3 ENRenata SantosNo ratings yet

- PQR Al 6xxxDocument7 pagesPQR Al 6xxxAmin ThabetNo ratings yet

- Pin Brazing - DN80 Ph.1Document14 pagesPin Brazing - DN80 Ph.1Nickath BanuNo ratings yet

- Welding Procedure Specification (WPS) : in The Outer TubeDocument1 pageWelding Procedure Specification (WPS) : in The Outer TubeMohamed AlkhawagaNo ratings yet

- Report Blasting PDFDocument22 pagesReport Blasting PDFLord MobileNo ratings yet

- AnnuallyDocument70 pagesAnnuallyFloreidNo ratings yet

- WPS PQR-05Document10 pagesWPS PQR-05Ranjan KumarNo ratings yet

- Saudi Aramco Inspection Checklist: Hangers and Supports Receiving, Handling and Storage SAIC-S-4017 18-May-05 PlumbDocument1 pageSaudi Aramco Inspection Checklist: Hangers and Supports Receiving, Handling and Storage SAIC-S-4017 18-May-05 PlumbUzair AhmadNo ratings yet

- QW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)Document1 pageQW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)rohitbhat2345No ratings yet

- Bridge & Roof Co - (I) LTD: Iocl Tankage Work (M&I) in PHBPL Paradip, OdishaDocument5 pagesBridge & Roof Co - (I) LTD: Iocl Tankage Work (M&I) in PHBPL Paradip, Odishaniraj mouryaNo ratings yet

- TopCoreBelco 101 FCDocument9 pagesTopCoreBelco 101 FCCesar ArellanoNo ratings yet

- Mainline Under Ground HydrotestingDocument12 pagesMainline Under Ground HydrotestingrexNo ratings yet

- Chem-Wps - PQR - WPQ-003 CS-CS 08-08 Gtaw-SmawDocument5 pagesChem-Wps - PQR - WPQ-003 CS-CS 08-08 Gtaw-Smawvijay padaleNo ratings yet

- Nde-1711-T393-F0005 Annular To Bottom Plate JointDocument1 pageNde-1711-T393-F0005 Annular To Bottom Plate Jointdada khalandar100% (1)

- Joints (Qw-402) DetailsDocument3 pagesJoints (Qw-402) DetailsNaqqash SajidNo ratings yet

- PQRDocument3 pagesPQRnazirulhakimNo ratings yet

- 0268 - Company Profile of Joint Filler - Jolly Board Bitumen IDocument15 pages0268 - Company Profile of Joint Filler - Jolly Board Bitumen INalaka Santhajeewa100% (1)

- Ultrasonic Test Report: Before AfterDocument7 pagesUltrasonic Test Report: Before AfterMenad SalahNo ratings yet

- WPS FGPDocument1 pageWPS FGPShabbir HussainNo ratings yet

- QW 483Document2 pagesQW 483delta lab sangliNo ratings yet

- QW-482 201.1Document2 pagesQW-482 201.1Barwin CruzNo ratings yet

- R0607-Cm-Itr-08-606 321a PDFDocument13 pagesR0607-Cm-Itr-08-606 321a PDFShelton S S SheltonNo ratings yet

- K-FLEX HVAC Applications Installation ManualDocument63 pagesK-FLEX HVAC Applications Installation ManualMohammad TaheriNo ratings yet

- 035 Procedure For Material Traceability and Markingpdf PDF FreeDocument16 pages035 Procedure For Material Traceability and Markingpdf PDF FreeabbasNo ratings yet

- Gate & Globe PDFDocument0 pagesGate & Globe PDFZoebairNo ratings yet

- Welding Procedure Qualification Records (WPQR) : (Section IX, ASME Boiler and Pressure Vessel Code)Document2 pagesWelding Procedure Qualification Records (WPQR) : (Section IX, ASME Boiler and Pressure Vessel Code)ngonphanhoangNo ratings yet

- Scope: Painting ProcedureDocument2 pagesScope: Painting Procedureคุณพ่อน้อง บิ๊กบอสNo ratings yet

- WPS - 016Document11 pagesWPS - 016MAT-LIONNo ratings yet

- WPS Resrvoire Sous Pression Smaw SawDocument6 pagesWPS Resrvoire Sous Pression Smaw SawDanem HalasNo ratings yet

- WPS GTAW Stainless SteelDocument2 pagesWPS GTAW Stainless SteelSrinivasan Muruganantham84% (31)

- WPS (AsmeDocument8 pagesWPS (AsmeMohammad Elhedaby100% (6)

- Wps For SS 304Document3 pagesWps For SS 304MuraliKrishna87% (23)